Professional Documents

Culture Documents

DH3 Buckstay

Uploaded by

ariya0 ratings0% found this document useful (0 votes)

23 views1 pagebvhvhvh

Original Title

DH3_Buckstay

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbvhvhvh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageDH3 Buckstay

Uploaded by

ariyabvhvhvh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

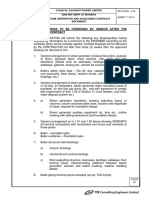

Project: Duyen Hai 3 Extension, Thermal Power Plant Project

TBWES Project Number: SJ0041 / B&W PROJECT NO: 0635-307K

WBS: P93/Buckstay

Scope of supply:

The buckstay system provides the lateral support for the furnace and convention pass enclosure wall

tubes against gas pressure, wind & earthquake. Thermally, buckstay must be able to adjust to the

changing temperatures of the wall tubes while containing pressure loads acting on the buckstay.

Because the components of a buckstay operate at different temperatures, the arrangement must be

capable of allowing various parts to expand and move relative to one another during the various

thermal differential conditions that they will encounter.

The vendors scope is buckstay system for (1) 600 MW coal fired boiler. It consists of buckstay beam

& truss, end connections , wall paddles , overturning post , ties bars , pins & clips, vertical strap &

stand offs.

Basic design:

The buckstay system (~500 tonnes) design includes for furnace enclosure (15559.1 X 20639.0mm) &

convention pass enclosure (12954 X 20639.0mm).

The various components of a buckstay system are sized for gas pressure, wind & earthquake.

Buckstay beam or trusss are typically sized to accommodate bending stresses that correspond to

specified gas side pressure loading conditions. Bending stress include tensile bending stress in the

outer flange if the gas side pressure loading is outward (or positive) and compressive bending

stresses in the inner flange for the same positive pressure condition.

Buckstay system is not designed to accommodate implosions or explosions. Buckstay system is

designed per the requirements of NFPA (National Fire Protection Association) - typically +/- 35 H2O

transient gas side pressure loading.

You might also like

- BoilerDocument48 pagesBoilerSubramanian Ravishankar100% (1)

- Horizontal Boilers Make 700C Steam EconomicDocument5 pagesHorizontal Boilers Make 700C Steam EconomicKrishnan Santhanaraj100% (1)

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdNo ratings yet

- High Intensity Slag Resistance Furnace DesignDocument10 pagesHigh Intensity Slag Resistance Furnace DesignBrian Andres Madariaga MuñozNo ratings yet

- Progress of The Weston Unit 4 Supercritical Project in Wisconsin PDFDocument6 pagesProgress of The Weston Unit 4 Supercritical Project in Wisconsin PDFktsnlNo ratings yet

- Spiral Wall System PDFDocument22 pagesSpiral Wall System PDFSomdeb Banerjee100% (1)

- Katalog CijeviDocument73 pagesKatalog CijeviTheLizardKingNo ratings yet

- Use of Vacuum Furnaces in Heat Treatment: J. OleinikDocument5 pagesUse of Vacuum Furnaces in Heat Treatment: J. OleinikhasanNo ratings yet

- Vertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersDocument7 pagesVertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersSamNo ratings yet

- Benson BoilerDocument20 pagesBenson BoilerjigsprajapatiNo ratings yet

- Boiler Pressure PartsDocument3 pagesBoiler Pressure PartsBedabyas DehuryNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- SuperCritical Boiler 1Document45 pagesSuperCritical Boiler 1swatantar17100% (1)

- Steam BoilerDocument9 pagesSteam BoilerzaidinNo ratings yet

- New Natural Draft Cooling Tower of 200 M of Height: Dieter Busch, Reinhard Harte, Wilfried B. Kra Tzig, Ulrich MontagDocument13 pagesNew Natural Draft Cooling Tower of 200 M of Height: Dieter Busch, Reinhard Harte, Wilfried B. Kra Tzig, Ulrich MontagmasteriragaNo ratings yet

- Tap HoleDocument16 pagesTap HoleRAKESH RANJANNo ratings yet

- Refractories For Electric Arc Furnace: B.N. GhoshDocument15 pagesRefractories For Electric Arc Furnace: B.N. GhoshTsubasa OozoraNo ratings yet

- 112.09 Heat Exchangers BrochureDocument4 pages112.09 Heat Exchangers BrochureAlexandru DinaNo ratings yet

- Mag Jun08 p32 ProjectArcelorMittalDocument3 pagesMag Jun08 p32 ProjectArcelorMittalkselvan_1No ratings yet

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- Funke Shell Tube He eDocument24 pagesFunke Shell Tube He eSubrata DasNo ratings yet

- Posiflow Technology of Doosan Babcock For Supercritical BoilersDocument12 pagesPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamNo ratings yet

- 0 C 960529710 F 7 F 0 Fa 5000000Document14 pages0 C 960529710 F 7 F 0 Fa 5000000parth daxiniNo ratings yet

- Design and Operation of A Gimbal Top Charging System: Peter Whitfield - Siemens VAI Metals Technologies LTDDocument4 pagesDesign and Operation of A Gimbal Top Charging System: Peter Whitfield - Siemens VAI Metals Technologies LTDklaus4321No ratings yet

- E101 3240 Industrial Water Tube Package Boilers Babcock WilcoxDocument12 pagesE101 3240 Industrial Water Tube Package Boilers Babcock Wilcoxa_parratNo ratings yet

- MHI Technical Review - Supercritical BoilerDocument10 pagesMHI Technical Review - Supercritical BoilerYou Wei WongNo ratings yet

- Technology For Electromagnetic Stirring of Aluminum Reverberatory FurnacesDocument6 pagesTechnology For Electromagnetic Stirring of Aluminum Reverberatory FurnacesghndslNo ratings yet

- Dr. Valery Rudnev: Director, Science and Technology, Inductoheat GroupDocument4 pagesDr. Valery Rudnev: Director, Science and Technology, Inductoheat GroupdhruvNo ratings yet

- Posiflow Benson BoilerDocument8 pagesPosiflow Benson BoilerKarthick VelayuthamNo ratings yet

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNo ratings yet

- BoilerDocument48 pagesBoilerhorascanman100% (1)

- Alstom Process Gas CoolerDocument12 pagesAlstom Process Gas Coolerrajaramc100% (1)

- Central Collector Solar Energy Receiverst: (Received 16july 1974 in Revised Form 3 September 1975)Document10 pagesCentral Collector Solar Energy Receiverst: (Received 16july 1974 in Revised Form 3 September 1975)xbeastxxNo ratings yet

- Inune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Document30 pagesInune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Process EngineerNo ratings yet

- Product - Info CG 3 101 TS Split Tube Furnace Range ENDocument18 pagesProduct - Info CG 3 101 TS Split Tube Furnace Range ENCarlos Alberto Salazar DuqueNo ratings yet

- Expansion Joints For Power GenerationDocument12 pagesExpansion Joints For Power GenerationNguyễn Hoàng PhúcNo ratings yet

- Importance of Proper Commisioning of Steam Pipe Spring Hanger & SupportsDocument10 pagesImportance of Proper Commisioning of Steam Pipe Spring Hanger & Supportsmohamed faragNo ratings yet

- Publication: Billet Homogenizing - Batch or Continuous?Document11 pagesPublication: Billet Homogenizing - Batch or Continuous?조기현No ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger Designcoldness_13No ratings yet

- BR 1938 PDFDocument4 pagesBR 1938 PDFashok KumarNo ratings yet

- Removable Fire Walls: Modular Concept DescriptionDocument6 pagesRemovable Fire Walls: Modular Concept DescriptionJose Valdez NeyraNo ratings yet

- Cap23 PDFDocument10 pagesCap23 PDFCamila Ramos100% (1)

- Pvp1996-Vol336 3Document4 pagesPvp1996-Vol336 3dogusNo ratings yet

- Understanding Blast Furnace Hearth Wall Temperatures To Support Operational/Maintenance DecisionsDocument8 pagesUnderstanding Blast Furnace Hearth Wall Temperatures To Support Operational/Maintenance DecisionsJJNo ratings yet

- SST-300 enDocument4 pagesSST-300 enchronometryNo ratings yet

- Benson BoilersDocument20 pagesBenson BoilersPrasanna Kumar100% (1)

- SW BrochureDocument16 pagesSW BrochurePhong Hoang LeNo ratings yet

- Special Support in PipingDocument6 pagesSpecial Support in PipingAKHIL JOSEPHNo ratings yet

- Chap 31 PDFDocument14 pagesChap 31 PDFnelson escuderoNo ratings yet

- Steam Turbine SST 300 DetailsDocument2 pagesSteam Turbine SST 300 DetailsYousuf AliNo ratings yet

- Fabrication of Hot Induction Bends - MannesmannDocument15 pagesFabrication of Hot Induction Bends - MannesmannZeljko RisticNo ratings yet

- Alternator GEDocument4 pagesAlternator GEELYOU89100% (1)

- Types Vgof Reheating FurnacesDocument5 pagesTypes Vgof Reheating FurnacesNiladri BhattacharyyaNo ratings yet

- BFDocument56 pagesBFvikrantsingh2908No ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Induction BendingDocument20 pagesInduction BendingAnoop N Kutty100% (4)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- New ParcelDocument2 pagesNew ParcelariyaNo ratings yet

- Job List Installtion ProcedureDocument4 pagesJob List Installtion ProcedureariyaNo ratings yet

- Dqa 00001Document2 pagesDqa 00001ariyaNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- OD428357735139452100Document2 pagesOD428357735139452100ariyaNo ratings yet

- Form 901.7Document2 pagesForm 901.7ariyaNo ratings yet

- Smayan Tamil WordsDocument3 pagesSmayan Tamil WordsariyaNo ratings yet

- Pongal Kondattam FirelesscookingDocument2 pagesPongal Kondattam FirelesscookingariyaNo ratings yet

- Stress - Strain CurveDocument17 pagesStress - Strain CurveariyaNo ratings yet

- Exxonmobil Refinery: Item Description: Work Request Number: NotesDocument32 pagesExxonmobil Refinery: Item Description: Work Request Number: NotesariyaNo ratings yet

- Design Package Cover Sheet: Customer: METHANEXDocument53 pagesDesign Package Cover Sheet: Customer: METHANEXariyaNo ratings yet

- Buckstay Beam Splice DetailDocument1 pageBuckstay Beam Splice Detailariya100% (1)

- Design Package Cover Sheet: Customer: Phillips 66, Wood RiverDocument22 pagesDesign Package Cover Sheet: Customer: Phillips 66, Wood RiverariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66 Wood RiverDocument24 pagesDesign Package Cover Sheet: Customer: Phillips 66 Wood RiverariyaNo ratings yet

- Cold PA Duct-TransportDocument3 pagesCold PA Duct-TransportariyaNo ratings yet

- Design Package Cover Sheet: Customer: CHEMOURSDocument1 pageDesign Package Cover Sheet: Customer: CHEMOURSariyaNo ratings yet

- Design Package Cover Sheet: Customer: HILCORPDocument15 pagesDesign Package Cover Sheet: Customer: HILCORPariyaNo ratings yet

- Consolidated Bom-G15 - Esp Outlet FlueDocument1 pageConsolidated Bom-G15 - Esp Outlet FlueariyaNo ratings yet

- Hou List-G15-Esp Outlet FlueDocument2 pagesHou List-G15-Esp Outlet FlueariyaNo ratings yet

- SCR PresentationDocument85 pagesSCR PresentationariyaNo ratings yet

- Boiler TiesDocument255 pagesBoiler TiesariyaNo ratings yet

- Ladder With Slide Expansion ConnectionDocument2 pagesLadder With Slide Expansion ConnectionariyaNo ratings yet

- SCR Velocity Profile SketchDocument1 pageSCR Velocity Profile SketchariyaNo ratings yet

- Project Drawing B0021493-0Document1 pageProject Drawing B0021493-0ariyaNo ratings yet

- TPC Mundra PIM Profile-R0Document5 pagesTPC Mundra PIM Profile-R0ariyaNo ratings yet

- Mundra SG C15 After AwardDocument6 pagesMundra SG C15 After AwardariyaNo ratings yet

- Mundra SG C16 CONTRACTOR DISTRIBUTION SHEDULE PDFDocument1 pageMundra SG C16 CONTRACTOR DISTRIBUTION SHEDULE PDFariyaNo ratings yet

- Technical Cover SheetDocument1 pageTechnical Cover SheetariyaNo ratings yet