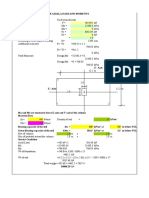

Quick Intake Design Calculator v1.

8

Independent Throttle Body Tuning

By Stefan Vince

For use with ITB induction or plenum type induction with very large plenum sizes ( > 1 x engine capacity).

Base Engine Data

Bore:

Stroke:

Rod length:

Port C/L length:

Peak HP RPM:

Intake cam

duration (0.050"):

Intake air

temperature:

103.25

90.932

155.52

0

mm

mm

mm

mm

6900

280

deg

37

98.6

deg C

deg F

Calculation Results

Suggested Runner Diameters.

Minimum:

45.3

mm

1.78

in

Best:

46.2

mm

1.82

in

Maximum:

47.1

mm

1.85

in

Suggested Runner Areas.

Minimum:

1610.9

mm^2

2.497

in^2

Best:

1674.4

mm^2

2.595

in^2

Maximum:

1743.3

mm^2

2.702

in^2

Suggested Runner Mach Numbers at Peak HP RPM.

Minimum:

0.502

At Peak Piston Speed - Mach number should be 0.500

or less for the runner diameter being used or choke in

Best:

0.483

the port will occur.

Maximum:

0.463

Suggested Runner Entry Diameter/Area For Tapered Runners.

Best:

61.4

mm

Best:

2961.9

mm^2

2.42

in

4.591

in^2

Suggested Runner CFM at 28"H2O For Peak HP RPM.

246.0

(At 100% VE)

270.6

(At 110% VE)

295.2

(At 120% VE)

319.8

(At 130% VE)

Suggested Runner Lengths.

1st Harmonic:

895

mm

35.25

in

2nd Harmonic:

501

mm

19.71

in

3rd Harmonic:

358

mm

14.10

in

4th Harmonic:

287

mm

11.28

in

5th Harmonic:

239

mm

9.40

in

(Total:

(Total:

(Total:

(Total:

(Total:

(Total:

(Total:

(Total:

(Total:

(Total:

895

35.25

501

19.71

358

14.10

287

11.28

239

9.40

mm)

in)

mm)

in)

mm)

in)

mm)

in)

mm)

in)

Suggested Peak Torque RPM Using 2nd Harmonic.

5245

TO

5745

Notes.

Peak torque rpm is based on 2nd Harmonic intake length only and will be affected by other factors

than the intake length alone and so actual values could be lower or higher than calculated values.

Intake length calculations are based on NACA-TN-935 by Boden et al and the work of Prof. G. P.

Blair. Diameters based on mean runner speed of 73-79m/sec (240-260ft/sec). Suggested runner

CFM from David Vizard's "How to Build & Modify Cheverolet Small-block V-8 Cylinder Heads".

��Quick Intake Design Calculator v1.8

Resonance Tuning

By Stefan Vince

For use with OEM style plenum manifolds for EFI and Turbo.

Inputs

Results

Intake air temp:

Runner average dia D1:

Total runner length L1:

No. of runners:

40

37.2

245

4

deg C

mm

mm

Runner bellmouth?

1

Plenum volume V:

Zip tube dia D2:

Zip tube length L2:

Runner Spacing

Less than port spacing

Port spacing or greater

1.8

63

1000

Litres

mm

mm

Zip tube bellmouth?

0

Natural frequency of

total intake system:

Natural frequency of

runner only:

Runner tuned rpm

(2nd harmonic):

Runner tuned rpm

(3rd harmonic):

Runner tuned rpm

(4th harmonic):

Total system upper

tuned rpm:

Total system lower

tuned rpm:

57.7

Hz

347.0

Hz

9713

to

10113

6515

to

6915

4877

to

5277

6720

to

7120

3260

to

3660

Notes.

Tuned RPM values are derived from SAE 820407 by Ohata et al, SAE 2006-01-3653 and SAE 2007-01-1399 by Brennan et al.

Calculating the natural frequency of a total manifold system is not entirely accurate. Higher accuracy is obtained with simple plenum

designs. The more complex a manifold system is the more chance it's actual natural frequency will be higher or lower than the calculated

values. The only accurate way of finding the natural frequency of a total manifold system is by performing a frequency sweep using CFD

or by using the actual manifold and using acoustical methods (loudspeaker and microphone) to determine at what frequency it will go into

resonance.

Tuning values for the total manifold are dependent on the runner spacing and internal geometry of the plenum. Close runner spacings will

dampen or cancel frequencies excited by single cylinder frequency and be excited by multiple cylinder frequencies and their harmonics.

Large runner spacings will dampen or cancel some multiple cylinder frequencies whilst allowing excitation by single cylinder frequencies.

The user is referred to the above SAE papers for more details.

*Use the I.T.B Tuning worksheet to determine initial runner lengths and diameters*

�Quick Intake Design Calculator v1.8

Throttle Body Sizing.

By Stefan Vince

Inputs

Results

Maximum RPM:

Engine Displacement:

cc's

ci's

Number of Cylinders:

6500

1998

122

4

Volumetric efficiency:

100

Intake air temp:

104

40.0

21.5

1.48

Degrees F

Degrees C

Psi

Bar

Intake air pressure:

Compressor or

intercooler flowrate:

Throttle CD value:

Pressure drop:

40

lb/min

0.836

0.5

Intake air density:

Intake air velocity:

0.173

163.4

lb/ft^3

ft/sec

Average CFM demand:

Peak CFM demand:

230.6

230.6

CFM

CFM

Throttle body size:

58

2.3

0.140

mm

inches

Throttle body mach no:

Notes.

This spreadsheet uses simplified calculations and that greater

accuracy would be obtained by using formulas for

compressible flow through orifices and accurately determined

CD maps.

Psi

Coefficient of Discharge Calculator.

Area Method

Throttle body size:

Throttle shaft dia:

57

2.24

6

0.24

CD: 0.836

mm

inches

mm

inches

Measurement Method

Throttle body size:

Flow bench CFM@20.4" H2O:

65

2.56

509

CD: 0.788

mm

inches

CFM

��Quick Intake Design Calculator v1.8

Bellmouth Design.

By Stefan Vince

Inputs

Runner diameter:

37.2

mm

If the runner is non-circular its hydraulic diameter

needs to be calculated and used to determine the

major and minor axis of the bellmouth.

Runner area:

Runner circumference:

Hydraulic diameter:

Runner diameter

Results

Type A

0

0

#DIV/0!

mm^2

mm

mm

Notes.

This worksheet is used to design bellmouths for

runner entries. They are both based on ASME

nozzle/bellmouth design principles and both have

Cd values of over 0.95. Type A works well up to

~Mach 0.65 and is quite compact. Type B is

more efficient and works up to ~Mach 0.95 but is

limited to larger runner spacings. Bellmouth

profiles are elliptical and can be easily drawn

using CAD or traditional drafting methods.

Always make a template to check the internal

profile.

Hydraulic diameter

Major axis:

37.2

mm

Minor axis:

18.6

Radius R:

Type B

Major axis:

37.2

mm

mm

Minor axis:

24.8

mm

7.4

mm

Radius R:

7.4

mm

Inlet diameter:

74.4

mm

Inlet diameter:

86.8

mm

Area ratio:

4.0

:1

Area ratio:

5.4

:1

Minimum centres:

92.3

mm

Minimum centres:

104.7

mm