Professional Documents

Culture Documents

Aluminum 5052 PDF

Aluminum 5052 PDF

Uploaded by

Manjunath GowdaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum 5052 PDF

Aluminum 5052 PDF

Uploaded by

Manjunath GowdaCopyright:

Available Formats

Aluminium 5052

PRODUCT DATA

SHEET

Aluminium

Alloys

UNS A95052

Aluminium alloy 5052 contains nominally 2.5% magnesium & 0.25% chromium. It has good

workability, medium static strength, high fatigue strength, good weldability, and very good corrosion

resistance, especially in marine atmospheres. It also has the low density and excellent thermal

conductivity common to all aluminium alloys. It is commonly used in sheet, plate and tube form.

Typical Applications Architecture, general sheet metal work, heat exchangers.

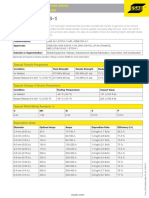

Chemical Composition

Element

Aluminium

Magnesium

Chromium

Silicon

Iron

Aluminium Development Council

of Australia

Temper

O (annealed)

H32

H34

H36

H38

0.2% Proof

Stress, MPa

min

65

160

180

200

220

Tensile

Strength, MPa

170 215

215 265

235 285

255 305

270 min

Elongation

%

min

14 20

4 10

38

24

24

%

Balance

2.2 2.8

0.15 0.35

0.25 max

0.40 max

Element

Copper

Manganese

Zinc

Others, each

Others, total

%

0.10 max

0.10 max

0.10 max

0.05 max

0.15 max

Specified Mechanical

Properties

Aluminium Development Council

of Australia

For information only, proof stress is not specified or measured

except by prior agreement

Minimum elongation, actual value depends on thickness

thicker gauges have higher elongation

Key to tempers:

Temper

O

H1x

H3x

Condition

Annealed (soft)

Strain hardened only

Strain hardened and then stabilised (i.e. low temperature heat treated to pre-empt

natural ageing, by reducing strength and increasing ductility)

Second digit: (x)

8

full hard

4

hard

6

hard

2

hard

Description Aluminium 5052 is an aluminium magnesium alloy which can be hardened by cold

work: it is not heat treatable to higher strength. It is about mid way through the series of

aluminium magnesium alloys for alloying content and strength. It has excellent fatigue properties,

with an endurance limit of 115 MPa in the H32 temper and 125 MPa in the H34 temper.

Austral Wright Metals can supply this alloy as plate, sheet and strip. See Austral Wright Metals

Catalogue for normal stock sizes and tempers.

Corrosion Resistance 5052 has the same high resistance to general corrosion as other non heat

treatable aluminium alloys. It also has the higher resistance to slightly alkaline conditions common

to the 5000 series alloys. The resistance of 5052 to corrosion in marine atmospheres is excellent,

exceeding that of 5005, hence the frequent use of 5052 in marine applications.

The corrosion resistance of aluminium alloys relies on a protective surface oxide film, which when

damaged is readily repaired by the rapid reaction between aluminium and oxygen. However, the

high reactivity of the base metal can give rapid corrosion if the film cannot be repaired, so

aluminium alloys are not suitable for use with reducing media. 5052 can be anodised to improve

the corrosion resistance by thickening the protective surface film.

Aluminium Grade 5052

A95052

Since aluminium is a reactive metal, it may corrode more quickly when in electrical contact with

most other metals. The prediction of galvanic corrosion is complex; please consult Austral Wright

Metals for specific advice.

Pressure Vessels AS1210 Pressure Vessels and AS4041 Pressure Piping prequalify the alloy for

pressure service for temperatures up to 200oC.

Physical Properties

Property

Density

At

20oC

Melting Range

Modulus of Elasticity

Tension

Torsion

Compression

value

2,680

unit

kg/m3

607 650

20oC

20oC

20oC

Property

Mean Coefficient

of Expansion

Thermal Conductivity

Electrical Resistivity

Electrical conductivity

equal volume

equal weight

oC

69.3

25.9

70.7

GPa

GPa

GPa

at

20oC

Value

23.75

unit

x 10-6 / oC

25oC

20oC

138

0.050

W / m . oC

micro-ohm . m

20oC

20oC

35

116

% IACS

% IACS

Fabrication Aluminium 5052 is not generally hot worked. It is very readily cold formable in the

annealed condition, as it is ductile. Forming loads and tool & press wear are generally less than

with carbon steel. For piercing and blanking the punch to die clearance should be about 7% of the

thickness per side for the H32 & H34 tempers. Sharp tools are required.

Indicative minimum bend radii for 90o cold forming for various thickness, t mm

Temper

H32

H34

0.4

0t

0t

0.8

0t

1t

1.6

1t

1 t

3.2

1 t

2t

4.8

1 t

2t

6.4

1 t

2 t

9.5

1 t

2 t

13

2t

3t

Machinability 5052 is readily machinable by conventional methods. It should be machined at

high speed with copious lubrication to avoid thermal distortion of the workpiece. Sharp tools are

essential. High speed steel or tungsten carbide may be used. Cuts should be deep and continuous,

with high cutting speeds. Woodworking machinery may be suitable for short runs.

Welding 5052 is readily weldable by standard techniques. It is frequently welded with GTAW

(TIG) or GMAW (MIG). Aluminium must be very dry & clean to avoid contamination & porosity of

the weld. Filler metals 1100, 4043 or 4047 are used. 4043 is the most crack tolerant. Best colour

match is obtained with 1188 filler metal. Shielding gas must be dry & free of hydrogen.

Heat Treatment Aluminium 5052 is annealed at 345oC, time at temperature and cooling rate are

unimportant. Stress relief is rarely required, but can be carried out at about 220oC. If loss of

strength is of concern, stress relief tests should be conducted.

ASTM

Product

Specifications

Specification

B209

B316

B210

B483

Title

Aluminium and Aluminium Alloy Sheet and Plate

Aluminium and Aluminium Alloy Rivet & Cold Heading Wire & Rods

Aluminium and Aluminium Alloy Drawn Seamless Tubes

Aluminium and Aluminium Alloy Drawn Tubes for General Purpose Applications

300

15

H34

250

200

H32

5005

150

100

100

H32

Elongation, %

Tensile Strength, MPa

Typical strength and ductility of alloys 5005 & 5052 in the H32 & H34 tempers

5052

H34

150

200

250

0.2% Proof Stress, MPa

300

5052

H32

H32

10

5005

H34

H34

0

100

150

200

250

0.2% Proof Stress, MPa

300

You might also like

- Introduction To Aluminum Alloys and TempersDocument237 pagesIntroduction To Aluminum Alloys and Temperselvis hidalgo100% (4)

- Aluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Document8 pagesAluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Hussain MahmudNo ratings yet

- NAS1169Document2 pagesNAS1169Yong-il Kim0% (1)

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- BS2L99 Alloy DetailDocument2 pagesBS2L99 Alloy Detailcharles_boyle_3No ratings yet

- 6061 Aluminum Sheet SuppliersDocument7 pages6061 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- Aluminium Alloy Sheet / Plate - Aa: (H32) Astm B209 / Ams 4016Document25 pagesAluminium Alloy Sheet / Plate - Aa: (H32) Astm B209 / Ams 4016Rahmat AnpsNo ratings yet

- Scope Aluminum 6061 Catalogue enDocument4 pagesScope Aluminum 6061 Catalogue ensav33No ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Bearing Steel Material Specification Sheet SAE52100Document1 pageBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNo ratings yet

- Special Blind Rivet NutsDocument8 pagesSpecial Blind Rivet NutsVishal BangarNo ratings yet

- Rra Heat Treatment of Al 7075-T6Document12 pagesRra Heat Treatment of Al 7075-T6Arissa Lidia Eva AdventiaNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Arcelomittal - SA - Hot-Dip Galvanised Cold Rolled and Hot Rolled Steel SubstrateDocument10 pagesArcelomittal - SA - Hot-Dip Galvanised Cold Rolled and Hot Rolled Steel SubstrateHen8No ratings yet

- Geomet 500 PDFDocument2 pagesGeomet 500 PDFKaran Chadha100% (1)

- Astm A827-14Document3 pagesAstm A827-14Артем Титов100% (1)

- Alluminio Inglese Binder PDFDocument28 pagesAlluminio Inglese Binder PDFrudi 01No ratings yet

- Aerospace Material Specification: Plating, Nickel General PurposeDocument8 pagesAerospace Material Specification: Plating, Nickel General PurposeSURYAS63No ratings yet

- Aluminized Steel Sheet PropertiesDocument8 pagesAluminized Steel Sheet PropertiesAhmadreza AminianNo ratings yet

- Letter of Intent (Loi) : Kindly Contact For More Details. Contact - Syed Ahmed Ali Mobile - 966 560 700 103Document1 pageLetter of Intent (Loi) : Kindly Contact For More Details. Contact - Syed Ahmed Ali Mobile - 966 560 700 103Luis HernandezNo ratings yet

- Die Design ParametersDocument3 pagesDie Design ParameterspunkhunkNo ratings yet

- AluminizedDocument4 pagesAluminizedmarkengineerNo ratings yet

- Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocument4 pagesWelded, Unannealed Austenitic Stainless Steel Tubular ProductsDarwin DarmawanNo ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- High Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsDocument18 pagesHigh Strength Sheet Steel, 180 Mpa Through 700 Mpa Yield StrengthsRicardo UriasNo ratings yet

- Magnesium & Its AlloysDocument24 pagesMagnesium & Its AlloysNataliyaNo ratings yet

- WSS-M1A346-A - Calidad de ChapaDocument12 pagesWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNo ratings yet

- 20160323110112-Sae 1215Document1 page20160323110112-Sae 1215awesome_600No ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- Comaparação A572 G50-A992Document4 pagesComaparação A572 G50-A992Tiago CastelaniNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Cold Shut DefectsDocument3 pagesCold Shut Defectsvivek1312No ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Hydroclear Spec SheetDocument4 pagesHydroclear Spec Sheetamitleck100% (1)

- Corrosion Resistance in FastenersDocument26 pagesCorrosion Resistance in FastenersShreyas IyengarNo ratings yet

- Surface Preparation Metallizing ProcedureDocument6 pagesSurface Preparation Metallizing ProcedureCorrosion FactoryNo ratings yet

- Ams 4965 HDocument11 pagesAms 4965 HOTK Micro-FixNo ratings yet

- Tool Steel Grade and Standard DesignationDocument7 pagesTool Steel Grade and Standard DesignationMustafa SevimliNo ratings yet

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- Electrodo Aws 7018-1 EsabDocument1 pageElectrodo Aws 7018-1 EsabHORACIONo ratings yet

- Filter NotesDocument46 pagesFilter Notestanzil10100% (1)

- Stainless Steel - Grade 321 (UNS S32100)Document4 pagesStainless Steel - Grade 321 (UNS S32100)mp87_ingNo ratings yet

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDocument1 page024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaNo ratings yet

- Aluzinc Corrosion Resistance en 2012Document17 pagesAluzinc Corrosion Resistance en 2012electronicmail2ughf6525No ratings yet

- Design and Fabrication of Pneumatic Sheet Metal CuDocument3 pagesDesign and Fabrication of Pneumatic Sheet Metal CuMohammed Abdul KaleemNo ratings yet

- Henkel PDFDocument20 pagesHenkel PDFmangal deo pathakNo ratings yet

- JIS C 3406 (1971) - Auto CablesDocument1 pageJIS C 3406 (1971) - Auto CablesBrandon BroNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8Document9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8muraliNo ratings yet

- Interpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Document10 pagesInterpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Nick pilipenkoNo ratings yet

- Aluminum 5083Document2 pagesAluminum 5083razormebackNo ratings yet

- Die Casting AlloysDocument75 pagesDie Casting AlloysYuvaraj YuvarajNo ratings yet

- .Au-Aluminium Alloy 3003Document5 pages.Au-Aluminium Alloy 3003ali alhamilNo ratings yet

- Aluminium 1100Document2 pagesAluminium 1100Anup DalalNo ratings yet

- Atlas Aluminium Datasheet 5052 Rev Oct 2013Document3 pagesAtlas Aluminium Datasheet 5052 Rev Oct 2013Jason-chungNo ratings yet

- LM4 Alloy DetailDocument5 pagesLM4 Alloy Detailcharles_boyle_3No ratings yet

- LM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical Compositiondaniel_sasikumarNo ratings yet

- Aluminum SolderingDocument14 pagesAluminum SolderingChris De La TorreNo ratings yet

- Jamesbury Polymer and Elastomer Selection GuideDocument20 pagesJamesbury Polymer and Elastomer Selection Guidesheldon1jay100% (1)

- Aerogrammi Technical Catalogue enDocument208 pagesAerogrammi Technical Catalogue enErica MorrisonNo ratings yet

- Aluminum and Magnesium Metal Matrix Nanocomposites by M GuptaDocument171 pagesAluminum and Magnesium Metal Matrix Nanocomposites by M GuptaMd Mehbub SamratNo ratings yet

- Inorganic Adhesives & Animal GluesDocument14 pagesInorganic Adhesives & Animal GluesSachidananda MohapatraNo ratings yet

- Aluminum Extrusion ThesisDocument4 pagesAluminum Extrusion Thesisvictorialeonlittlerock100% (2)

- Gta Analytical Methods 0848Document226 pagesGta Analytical Methods 0848milossmile100% (1)

- S1-1 Ken Seddon ADocument28 pagesS1-1 Ken Seddon AHugo FerrãoNo ratings yet

- SOP Testing Water Wastewater Treatment ChemicalsDocument56 pagesSOP Testing Water Wastewater Treatment ChemicalslaurianNo ratings yet

- Strong Ceramic Foams From Polyurethane TemplatesDocument5 pagesStrong Ceramic Foams From Polyurethane TemplatesAnonymous TcHXxaVNo ratings yet

- Enzymes Used in Detergents: Lipases: ReviewDocument9 pagesEnzymes Used in Detergents: Lipases: ReviewKatrina MillerNo ratings yet

- M08CDocument16 pagesM08CMiriam LópezNo ratings yet

- Adewole Et Al 2013Document20 pagesAdewole Et Al 2013Norafiqah IsmailNo ratings yet

- Optimization of Heat Treatment Parameters of Al-Si AlloysDocument86 pagesOptimization of Heat Treatment Parameters of Al-Si Alloysanil kumarNo ratings yet

- Working Capital Management and Stores Inventory AnalysisDocument76 pagesWorking Capital Management and Stores Inventory Analysisagr_belaNo ratings yet

- Preparing of Alumina From Aluminum WasteDocument6 pagesPreparing of Alumina From Aluminum WasteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Metals and Non-MetalsDocument37 pagesMetals and Non-MetalsNeeraj Ilal100% (1)

- Synthesis of Zeolites in The Absence of Organic Structure-Directing AgentsDocument49 pagesSynthesis of Zeolites in The Absence of Organic Structure-Directing AgentsHenrique SouzaNo ratings yet

- Processing and Characterization of Aluminum Metal Matrix Composites: An OverviewDocument12 pagesProcessing and Characterization of Aluminum Metal Matrix Composites: An OverviewTraian TiberiuNo ratings yet

- Introduction To Properties of Materials: Badi 1 John Errington MSCDocument42 pagesIntroduction To Properties of Materials: Badi 1 John Errington MSCgereNo ratings yet

- Chapter 3 Metals and NonmetalsDocument37 pagesChapter 3 Metals and NonmetalsVibi VibesNo ratings yet

- Aluminum and Its AlloyDocument18 pagesAluminum and Its AlloyJackylyn SagadalNo ratings yet

- Cased ChargesDocument10 pagesCased ChargeshezigrisaroNo ratings yet

- Mod2 PDFDocument254 pagesMod2 PDFjeas grejoyNo ratings yet

- GEOENVIRONMENTAL Introduction PDFDocument151 pagesGEOENVIRONMENTAL Introduction PDFHari RamNo ratings yet

- Heavy Metal Detox ProtocolDocument1 pageHeavy Metal Detox Protocolgracie4288No ratings yet

- 12 Chemistry Exemplar Chapter 1Document403 pages12 Chemistry Exemplar Chapter 1chiragNo ratings yet

- Thermodynamic Study of The Galvanizing Process in A Zn-0.1%Ni Bath G.Document10 pagesThermodynamic Study of The Galvanizing Process in A Zn-0.1%Ni Bath G.Akash PatelNo ratings yet

- Period 3 ElementsDocument51 pagesPeriod 3 ElementsHaram TanveerNo ratings yet

- BurndyDocument43 pagesBurndyJose Antonio Guadiana SánchezNo ratings yet