Professional Documents

Culture Documents

BOPP Adhesive

Uploaded by

Puneet AgarwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BOPP Adhesive

Uploaded by

Puneet AgarwalCopyright:

Available Formats

BOPP SELF ADHESIVE TAPES

A. INTRODUCTION:

Packaging in India is a Rs.11,500 crores industry and growing at the rate of

18 per cent annually. The global market for packaging is US $900 billion

and Indias share is only US $3 billion, but while the per capita expenditure

on packaging in the US is a whopping US $125, it is only $6.5 in India.

Therefore, there is a huge potential for growth in the Indian packaging

industry.

The packaging industry in India, which started on a low ebb in the 1950s

has grown slowly and steadily in both quality and quantity. The 70s and

80s witnessed a remarkable change in materials as well as machinery. This

has not only given a face-lift to the industry but also opened it up

for innovations. In this period, the industry by and large, depended on

domestic resources for materials as well as machinery. This was due to

various restrictions on imports. Around the mid 90s, liberalisation opened

the industry further and it began to reflect in the changes in consumers

consumption pattern.

B. PRODUCT USES & SPECIFICATIONS:

These tapes are used in electrical insulation purpose, in packaging, sealing

and a various other general uses. These tapes are also used for general

labelling with printing.

SPECIFICATIONS:

I.S.3434 - 1965 - Glossary of terms for adhesives and pressure sensitive

tapes.

I.S.7809(Part I) 1975 - General requirement for pressure sensitive tape.

I.S.7809(Part II) 1977 - Test Methods.

I.S.7809(Part III) 1977 - Requirement for individual materials. Plasticised

Polyvinyl adhesive tapes with non-thermo setting adhesives.

The BOPP tape must have smooth surface characteristics, good elongation,

soft and flexible to give good conformability, transparency of pigmentation

and temperature resistance.

C. MARKET POTENTIAL:

The BOPP Adhesive Tapes are used for packaging. It is consumed daily in

large quantities by all industrial and commercial organisations. From

packing courier covers and bags to packing of pharmaceutical cartons, every

where, the self adhesive tapes are consumed. The consumption increases

in line with the improved standard of living and business activity in the

society. Therefore the consumption of this product is bound to increase

further.

D. TECHNICAL ASPECTS:

Installed Capacity:

50 mm width x 65 metres from 1000 mm width BOPP film the production

will be 5310000 rolls per annum per shift of 8 hours.

10mm width x 50 metres from 1000 mm width BOPP film, the production

will be 34560000 rolls.

The product mix will be 90% of 50 mm width tape and 10% of 10 mm tape

per annum of 300 days in one shift. (i.e.,)

a) 5310000 x 90% = 4779000 rolls of 50mm tape.

b) 34560000 x 10% = 3456000 rolls of 10 mm tape.

The plant will work one shift for 300 days.

Plant & Machinery

The plant and machinery required for manufacturing BOPP Self adhesive

tapes are the following.

1. Coating machine 40 (1000 mm) 1 No.

2. 1000 mm slitter turret machine with accessories 1 No.

3. Automatic core cutting machine 1 No.

4. Baby slitter 6 (150 mm)

5. Salvage rewinding machine (Doctor Winder) 1 No.

Manufacturing Process :

The BOPP roll is loaded in the coating machine and adhesive applied on one

side. The coated roll is loaded in the slitting machine and the slit tapes

wound in the paper core of required width automatically. The paper core of

required width is obtained from the automatic core cutting machine by

cutting from the long paper core.

Raw Materials

The materials required for manufacturing self adhesive tapes are the

following:

12 mm BOPP film in 1000 mm wide rolls.

Weight of BOPP film 17 gm/m2

Total length required 17280000 meters

Width 1 metre

Total 17280000 sq.metres

i.e., weight of BOPP film 293.76 metres.

[(17280000/1000)X(17/1000)]

Price of BOPP film 12 micron Rs.1.15 lakhs per ton.

Cost of Raw materials Rs.1.15 x 293.76 MT. = Rs.337.82 lakhs.

Other consumables Adhesives & paper spool

Rs.5.00 per 50mm roll.

Rs.1.00 per 10mm roll

Land & Building:

Land acre

Building area required 5000 sq. ft.

Utilities

Electricity: Power requirement is 20 HP.

Water: Water required for human consumption.

Man Power Requirement:

Production Rs./Month Rs./Month

1. Manager 1 7000 7000

2. Skilled 2 4000 8000

3. Semi-skilled 4 3000 12000

4. Unskilled 4 2500 10000

5. Accountant 1 4000 4000

6. Supervisors 1 5000 5000

46000

Add: Benefits 20% 9200

55200

Say Rs.6.62 lakhs.

7. IMPLEMENTATION SCHEDULE:

The machines are available indigenously. The entire project can be

implemented within 2 months.

8. ASSUMPTIONS

1. Installed Capacity-50 MM rolls-4779000 Rolls per annum and 10MM

rolls- 3456000 Rolls per annum.

2. Capacity utilization-Year 1-30%,Year 2-40% and Year 3-50%

3. Selling Price 50 MM roll Rs.20.00 per Roll and 10MM roll Rs.10.00 per

roll.

4. Raw material cost at 100% Rs.337.82 Lakhs.

5. Consumables Rs.5.00 per 50 mm Roll and Rs1.00 per 10mm roll

6. Power charges at Rs.1.79 lakhs per annum at 100%

7. Wages & salaries at Rs.6.62 lakhs at 100%.

8. Repairs & maintenance at Rs.10000 per month

9. Depreciatin on written down value method.

10. Administration and General expenses atRs.40000 per month.

11. Selling Expenses at 5% on sales.

12. Interest on Term Loan 12% p.a

13. Interest on working capital12%p.a

14. Income tax at 33.99% on profits

LIST OF MACHINERY SUPPLIER

1. M/s.Sainath Engineering Works, 114, 2nd floor Bhandup Industrial

Estate, Panalal Silk Mill Compound, LBS Marg Bhandup West,

Mumbai - 400 078.

2. Jangir Company, Plot No.33, Gali No.t, Raliway Lineside., Anand

Prabat Industrial Area., New Delhi.

RAW MATERIAL SUPPLIERS

1. Jampex Trading Private Limited, 160 Linghi Chetty Street

Chennai-600001

2. Kankaria Enterprises, 44/2 New No:113/1 Dr Alagppa Road

Purasawalakm, Chennai-600 084

3. Reliance Industries Ltd., No.501, JVL Plaza, Anna Salai, Chennai -18.

4. Haldia Petrochemicals, No.41, V.N.Road, T.Nagar, Chennai 600 017.

FINANCIAL ASPECTS

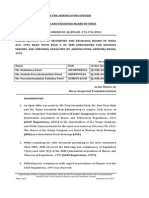

1. COST OF PROJECT [Rs.lakhs

Land 5.00

Building 30.00

Plant & Machinery 35.00

Contingencies 3.00

Other Misc. assets 1.00

Pre-Operative expenses 3.00

Margin for WC 13.49

Total 90.49

2. MEANS OF FINANCE

Capital 52.99

Term Loan 37.50

Total 90.49

3. COST OF PRODUCTION & PROFITABILITY STATEMENTS

Years 1 2 3

Installed Capacity - BOPP Self Adhesive Tapes

a) 50 mm rolls Nos. 4779000 4779000 4779000

b) 10 mm rolls Nos. 3456000 3456000 3456000

Utilisation 30% 40% 50%

Production/Sales

a) 50 mm rolls Nos. 1433700 1911600 2389500

b) 10 mm rolls Nos. 1036800 1382400 1728000

Selling Rate

a) 50 mm rolls Nos. Rs.20.00 per roll

b) 10 mm rolls Nos. Rs.10.00 per roll

Sales Value (Rs.alkhs)

a) 50 mm rolls Nos. 286.74 382.32 477.90

b) 10 mm rolls Nos. 103.68 138.24 172.80

Total Value (Rs.lakhs) 390.42 520.56 650.70

Raw Materials 101.35 135.13 168.91

Consumables 82.06 109.40 136.76

Power 0.54 0.72 0.90

Wages & Salaries 6.62 6.95 7.30

Repairs & Maintenance 1.20 1.32 1.45

Depreciation 9.93 7.50 5.68

Cost of Production 201.70 261.02 321.00

Admin. & General expenses 4.80 5.04 5.29

Selling expenses 19.52 26.03 32.54

Interest on Term Loan 4.50 3.94 2.81

Interest on Working Capital 7.02 7.02 7.02

Total 237.54 303.05 368.66

Profit Before Tax 152.88 217.51 282.04

Provision for tax 51.96 73.93 95.87

Profit After Tax 100.92 143.58 186.17

Add: Depreciation 9.93 7.50 5.68

Cash Accruals 110.85 151.08 191.85

4. WORKING CAPITAL:

Months Values % Margin Bank

Consumptions Amount Finance

Raw Materials 2.00 16.89 25% 4.22 12.67

Consumables 2.00 13.68 25% 3.42 10.26

Finished goods 0.50 8.40 25% 2.10 6.30

Debtors 1.00 32.54 10% 3.25 29.29

Expenses 1.00 0.50 100% 0.50 0.00

72.01 13.49 58.52

6. PROFITABILITY RATIOS BASED ON 50% UTILISATION

Profit after Tax 186.17

= 29%

Sales 650.70

Profit before Interest and Tax 291.87

= 196%

Total Investment 149.01

Profit after Tax 186.17

= 351%

Promoters Capital 52.99

7. BREAK EVEN LEVEL

Fixed Cost (FC): Rs.lakhs

Wages & Salaries 7.30

Repairs & Maintenance 1.45

Depreciation 5.68

Admin. & General expenses 5.29

Interest on TL 2.81

22.53

Profit Before Tax (P) 282.04

FC x 100 22.53 50

BEL = = x x 100

FC +P 304.57 100

4% of installed capacity

You might also like

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- BOPP Self Adhesive TapeDocument7 pagesBOPP Self Adhesive TapeGopi ManogaranNo ratings yet

- Plastic Bottles (Pet) : Profile No.: 48 NIC Code: 22203Document8 pagesPlastic Bottles (Pet) : Profile No.: 48 NIC Code: 22203Monica SainiNo ratings yet

- Woven Sacks For Fertilizers: Profile No.: 49 NIC Code: 22209Document8 pagesWoven Sacks For Fertilizers: Profile No.: 49 NIC Code: 22209Aparesh GantaitNo ratings yet

- InkDocument23 pagesInkSaurabh SinghNo ratings yet

- Adhesive Bopp Tape PDFDocument8 pagesAdhesive Bopp Tape PDFjitendrajain161050% (2)

- Project Report On PVC Solvent Cements Manufacture With Process and Formula (Upvc & CPVC) (Cables Cable Industry Aluminium Copper Cable)Document11 pagesProject Report On PVC Solvent Cements Manufacture With Process and Formula (Upvc & CPVC) (Cables Cable Industry Aluminium Copper Cable)Sachin Sharma33% (3)

- Adhesive Tape Manufacturing Industry in India CombineDocument21 pagesAdhesive Tape Manufacturing Industry in India Combinemayur473No ratings yet

- Tesa Tape Technology Reference GuideDocument10 pagesTesa Tape Technology Reference GuideGhost_suolNo ratings yet

- Project Report On PVC Pipe Manufacturing Plant PDFDocument11 pagesProject Report On PVC Pipe Manufacturing Plant PDFjayson100% (1)

- Sample Project ReportMohan BagDocument38 pagesSample Project ReportMohan Bagteja100% (1)

- Project Profiles For MUDRADocument183 pagesProject Profiles For MUDRAManishGuptaNo ratings yet

- Industrial Project Report On Anti Foaming Agent (Silicone Based) For Distillery, Sugar Industry, Paper PlantDocument2 pagesIndustrial Project Report On Anti Foaming Agent (Silicone Based) For Distillery, Sugar Industry, Paper PlanteiribooksNo ratings yet

- PVC Project ReportDocument21 pagesPVC Project Reportsaurabh640No ratings yet

- Epoxy Resins PDFDocument24 pagesEpoxy Resins PDFAditya ShrivastavaNo ratings yet

- Report On Packaging Industry in IndiaDocument8 pagesReport On Packaging Industry in IndiaAjey BhangaleNo ratings yet

- Paperboard Grades Cheat Sheet GuideDocument1 pagePaperboard Grades Cheat Sheet GuideEva Kovač Brčić100% (2)

- Flexible Packaging in IndiaDocument24 pagesFlexible Packaging in IndiaRavi VishnuNo ratings yet

- Project Report On Potassium SilicateDocument10 pagesProject Report On Potassium SilicateSachin SharmaNo ratings yet

- How The Triple Shaft Mixer WorksDocument8 pagesHow The Triple Shaft Mixer Worksrahul khamkarNo ratings yet

- Starch For CorrugatingDocument20 pagesStarch For Corrugatingsyifa latifa zahidaNo ratings yet

- Project Report On Corrugated Boxes (Automatic Plant)Document8 pagesProject Report On Corrugated Boxes (Automatic Plant)EIRI Board of Consultants and PublishersNo ratings yet

- Cellop Tape ProjectDocument13 pagesCellop Tape ProjectHarpy happyNo ratings yet

- Cellotape Project ReportDocument48 pagesCellotape Project ReportMohan P88% (16)

- Dic India Oldest Ink Manufacturing CompanyDocument10 pagesDic India Oldest Ink Manufacturing Companydigital dicNo ratings yet

- Starch Industry in IndiaDocument3 pagesStarch Industry in Indiabanapte59No ratings yet

- Project Profile On Fly Ash Bricks Srs EnterprisesDocument17 pagesProject Profile On Fly Ash Bricks Srs EnterprisesRAHUL SHARMANo ratings yet

- Project of Wall PuttyDocument4 pagesProject of Wall PuttyVineet MishraNo ratings yet

- India's Growing Packaging IndustryDocument10 pagesIndia's Growing Packaging IndustryAdhip Pal ChaudhuriNo ratings yet

- Neha Anand Final Report (SIP)Document35 pagesNeha Anand Final Report (SIP)Saurabh KhareNo ratings yet

- PlasticizersDocument19 pagesPlasticizersPathik ShahNo ratings yet

- PDF Project 260Document149 pagesPDF Project 260ukamaluddinmba100% (1)

- Food Packaging PresentationDocument52 pagesFood Packaging PresentationXaverius Quentin AntonNo ratings yet

- Project Report On Corrugated Boxes FactoryDocument8 pagesProject Report On Corrugated Boxes FactoryEIRI Board of Consultants and Publishers0% (1)

- Biodegradble Plastic BagDocument29 pagesBiodegradble Plastic BagRajesh KumarNo ratings yet

- Pu Dispersion Formulation 2Document1 pagePu Dispersion Formulation 2mrafigNo ratings yet

- White MasterbatchDocument9 pagesWhite MasterbatchGoldmine MultitradeNo ratings yet

- India Packaging Industry 2010Document6 pagesIndia Packaging Industry 2010anshul510No ratings yet

- Cashew Nut Shell Liquid (CNSL) .EngDocument10 pagesCashew Nut Shell Liquid (CNSL) .EngGülnur Dönmez100% (2)

- Aj Plast PDFDocument24 pagesAj Plast PDFSanjay Kumar ShahiNo ratings yet

- Elite in Packaging BusinessDocument19 pagesElite in Packaging BusinessSachin Kothari100% (1)

- Industrial Project Report MagazineDocument17 pagesIndustrial Project Report MagazineeiribooksNo ratings yet

- PVC PLasticisersDocument2 pagesPVC PLasticisersKrishna PrasadNo ratings yet

- Project Profile On Paper Cups-10lDocument14 pagesProject Profile On Paper Cups-10lRamakrishnan RajappanNo ratings yet

- Assignment#3 Group #2: Manufacturing Process Ultrasonic MachiningDocument16 pagesAssignment#3 Group #2: Manufacturing Process Ultrasonic MachiningThe Noob100% (1)

- Masterbatch Producrers in IndiaDocument39 pagesMasterbatch Producrers in IndiaFuture Innovations100% (1)

- Detergent Industry in IndiaDocument37 pagesDetergent Industry in IndiaAjjay Kumar Gupta20% (5)

- Adisive Tape MFG Flow Chart PDFDocument19 pagesAdisive Tape MFG Flow Chart PDFRedicle ConsultantsNo ratings yet

- Project ReportDocument61 pagesProject Reportjeetto75% (4)

- Paper ConesDocument8 pagesPaper ConesEng.Abdalla Qassem50% (2)

- CORRUGATED BOX GUIDEDocument8 pagesCORRUGATED BOX GUIDEabhi050191No ratings yet

- Profile For Coir Fiber or Dust Moulding UnitDocument7 pagesProfile For Coir Fiber or Dust Moulding UnitAnandh SharavanNo ratings yet

- Air Bubble PackingDocument9 pagesAir Bubble PackingSneha Sagar SharmaNo ratings yet

- Coco Log Making Unit Project ProfileDocument6 pagesCoco Log Making Unit Project ProfileRamanjaneyulu PoludasuNo ratings yet

- ED ASSIGNMENT-pages-deletedDocument6 pagesED ASSIGNMENT-pages-deletedNihal TitusNo ratings yet

- Pilfer Proof Caps - Project ReportDocument10 pagesPilfer Proof Caps - Project Reportbaddy2inNo ratings yet

- Project Profile For Coir Geo Textiles Automatic Loom UnitDocument5 pagesProject Profile For Coir Geo Textiles Automatic Loom UnitathulkmmanikyanNo ratings yet

- Leather Waist Belt Project ReportDocument6 pagesLeather Waist Belt Project ReportVinoth KumarNo ratings yet

- Bopp Self Adhesive Tape: 4. Industry Outlook and TrendsDocument7 pagesBopp Self Adhesive Tape: 4. Industry Outlook and TrendsRaees IttooNo ratings yet

- Nomination Form: Form To A Service CentreDocument2 pagesNomination Form: Form To A Service Centrejha.sofcon5941No ratings yet

- Khushiyon Ka Pataa Mil Gaya: CivitechDocument8 pagesKhushiyon Ka Pataa Mil Gaya: CivitechAbhinav VermaNo ratings yet

- Parameter of Process SubmissionDocument1 pageParameter of Process SubmissionPuneet AgarwalNo ratings yet

- Getting the Oracle Fusion session cookie in Firefox or ChromeDocument7 pagesGetting the Oracle Fusion session cookie in Firefox or ChromePuneet AgarwalNo ratings yet

- Nomination Form: Form To A Service CentreDocument2 pagesNomination Form: Form To A Service Centrejha.sofcon5941No ratings yet

- Nomination Form Feb 2013Document1 pageNomination Form Feb 2013Puneet AgarwalNo ratings yet

- CGTMSE Information Booklet 2015Document56 pagesCGTMSE Information Booklet 2015Puneet AgarwalNo ratings yet

- Raj Tour & Travels Reciept FormatDocument2 pagesRaj Tour & Travels Reciept Formatnamanagrawal259053% (159)

- Nomination Form: Form To A Service CentreDocument2 pagesNomination Form: Form To A Service Centrejha.sofcon5941No ratings yet

- AdcfDocument1 pageAdcfPuneet AgarwalNo ratings yet

- Blown Film ProblemsDocument33 pagesBlown Film Problemsjroyal69297467% (3)

- S MILE123Document1 pageS MILE123Puneet AgarwalNo ratings yet

- Creative Writing For Government IndiaDocument2 pagesCreative Writing For Government IndiaPuneet AgarwalNo ratings yet

- HDPE/PP Sacks Popular for PackagingDocument1 pageHDPE/PP Sacks Popular for PackagingPuneet Agarwal100% (1)

- Project Profile On LLDPE Printed Shopping, Stretch, Tipper BagDocument30 pagesProject Profile On LLDPE Printed Shopping, Stretch, Tipper BagPuneet AgarwalNo ratings yet

- Creative Writing For Government IndiaDocument1 pageCreative Writing For Government IndiaPuneet AgarwalNo ratings yet

- Add Multiple Products To Cart MagentoDocument5 pagesAdd Multiple Products To Cart MagentoPuneet AgarwalNo ratings yet

- HDPE/PP Sacks Popular for PackagingDocument1 pageHDPE/PP Sacks Popular for PackagingPuneet Agarwal100% (1)

- Strange document with random words and charactersDocument1 pageStrange document with random words and charactersPuneet AgarwalNo ratings yet

- Strange document with random words and lettersDocument1 pageStrange document with random words and lettersPuneet AgarwalNo ratings yet

- Creative Writing For Government IndiaDocument1 pageCreative Writing For Government IndiaPuneet AgarwalNo ratings yet

- 1 DsDocument1 page1 DsPuneet AgarwalNo ratings yet

- Creative Writing For Government IndiaDocument1 pageCreative Writing For Government IndiaPuneet AgarwalNo ratings yet

- DFSDFSDF Sdfsdfa There Erae DJDJKFLGFLGLDocument1 pageDFSDFSDF Sdfsdfa There Erae DJDJKFLGFLGLPuneet AgarwalNo ratings yet

- Hull White Prepay OASDocument24 pagesHull White Prepay OASwoodstick98No ratings yet

- Sales Journal (Sales Day Book) - Double Entry BookkeepingDocument4 pagesSales Journal (Sales Day Book) - Double Entry BookkeepingShaina Santiago AlejoNo ratings yet

- SwapsDocument38 pagesSwapsNavleen KaurNo ratings yet

- Foreign Direct Investment Market Entry ModesDocument71 pagesForeign Direct Investment Market Entry ModesAkshay Dewlekar100% (1)

- Multiple Choice QuestionsDocument25 pagesMultiple Choice QuestionsJohn Remar Lavina70% (20)

- Accounting Basics: Accounts, Debits, Credits and the Recording ProcessDocument21 pagesAccounting Basics: Accounts, Debits, Credits and the Recording ProcessfebrythiodorNo ratings yet

- Title-Information On Shares of The ComapnyDocument11 pagesTitle-Information On Shares of The ComapnySHUBHAM singhNo ratings yet

- 14 Lopez, Locsin, Ledesma & Co Vs CADocument4 pages14 Lopez, Locsin, Ledesma & Co Vs CADavid Antonio A. EscuetaNo ratings yet

- A. Vocabulary: Financial Terms: Unit 6: Money (Hp3)Document4 pagesA. Vocabulary: Financial Terms: Unit 6: Money (Hp3)Phu TaNo ratings yet

- Financiero Glosario BilingueDocument110 pagesFinanciero Glosario BilingueLudoxNo ratings yet

- Objectives of Financial Statements Analysis: Happened During A Particular Period of Time, Most Users Are Concerned AboutDocument20 pagesObjectives of Financial Statements Analysis: Happened During A Particular Period of Time, Most Users Are Concerned AboutKarla OñasNo ratings yet

- Balaji Telefilms bets big on digital with Alt Digital launchDocument4 pagesBalaji Telefilms bets big on digital with Alt Digital launchMudit KediaNo ratings yet

- Summative Assessment-1 Class 9 Mathematics Guess Paper 2016Document4 pagesSummative Assessment-1 Class 9 Mathematics Guess Paper 2016Apex Institute0% (1)

- ABC, The Balanced Scorecard and EVADocument8 pagesABC, The Balanced Scorecard and EVAEduardo CastrillónNo ratings yet

- Analyzing Your ClientDocument2 pagesAnalyzing Your ClientAnaaya SinghaniaNo ratings yet

- Circular No 14Document4 pagesCircular No 14Muhammad Ali JinnahNo ratings yet

- Phishing For Phools and The Financial Crisis: (Spears, 2016)Document6 pagesPhishing For Phools and The Financial Crisis: (Spears, 2016)Abiodun Ayo-baliNo ratings yet

- Tally and GSTDocument41 pagesTally and GSTPalani Sun InforNo ratings yet

- Bakery Business Plan Planul de Afaceri de PanificatieDocument34 pagesBakery Business Plan Planul de Afaceri de PanificatieCioloca AdrianaNo ratings yet

- Pakistan Stock Exchange - Wikipedia PDFDocument4 pagesPakistan Stock Exchange - Wikipedia PDFanon_154643438No ratings yet

- Risk Management Solution Manual Chapter 04Document5 pagesRisk Management Solution Manual Chapter 04DanielLam75% (4)

- Profitability Ratios: (Opening Inventory + Closing Inventory) ÷ 2Document1 pageProfitability Ratios: (Opening Inventory + Closing Inventory) ÷ 2AnNo ratings yet

- Getting Started with Bankscope DatasetDocument43 pagesGetting Started with Bankscope DatasetAliNo ratings yet

- How Does Insertion in Global Value Chains Affect Upgrading in Industrial Clusters? John Humphrey and Hubert SchmitzDocument17 pagesHow Does Insertion in Global Value Chains Affect Upgrading in Industrial Clusters? John Humphrey and Hubert Schmitzfederico_nacif300No ratings yet

- Corporate Finance ExercisesDocument14 pagesCorporate Finance ExercisesMatteoNebiolo100% (1)

- Hermenegildo Z. Narvaez Francisco Javier P. Bonoan Reginaldo Anthony B. CariasoDocument19 pagesHermenegildo Z. Narvaez Francisco Javier P. Bonoan Reginaldo Anthony B. CariasoCarlo NicolasNo ratings yet

- Brought To You by Http://Stockviz - BizDocument8 pagesBrought To You by Http://Stockviz - BizShyam SunderNo ratings yet

- Start, Manage and Grow Your Business: Help You SolveDocument36 pagesStart, Manage and Grow Your Business: Help You Solvemuringayi4942No ratings yet

- FWD+Funds+Performance+as+of+31+Jul+2022 FinexisDocument1 pageFWD+Funds+Performance+as+of+31+Jul+2022 FinexisSrinivasa Rao KanaparthiNo ratings yet

- Weekly Commentary BlackRockDocument6 pagesWeekly Commentary BlackRockelvisgonzalesarceNo ratings yet