Professional Documents

Culture Documents

Td02607011e PDF

Uploaded by

apic20Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Td02607011e PDF

Uploaded by

apic20Copyright:

Available Formats

Effective June 2011

Technical Data TD02607011E Supersedes November 2008

Metal-enclosed medium voltage

power factor correction system

Contents

Description Page

Medium voltage power factor correction . . . . . . . 1

Product description . . . . . . . . . . . . . . . . . . . . . . 1

Application description. . . . . . . . . . . . . . . . . . . . 2

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Univar XV (5 kV class). . . . . . . . . . . . . . . . . . . . . . 3

Product description . . . . . . . . . . . . . . . . . . . . . . 3

Application description. . . . . . . . . . . . . . . . . . . . 3

Features, benefits, and functions. . . . . . . . . . . . 3

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Univar (15 kV class). . . . . . . . . . . . . . . . . . . . . . . . 7

Product description . . . . . . . . . . . . . . . . . . . . . . 7

Application description. . . . . . . . . . . . . . . . . . . . 7

Features, benefits, and functions. . . . . . . . . . . . 7

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Autovar MV (2.414.4 kV) . . . . . . . . . . . . . . . . . . . 9

Product description . . . . . . . . . . . . . . . . . . . . . . 9

Features, benefits, and functions. . . . . . . . . . . . 9

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Medium voltage power

factor correction

Product description

Eatons metal-enclosed medium voltage capacitor

systems and harmonic filters are designed for

indoor or outdoor applications in commercial,

industrial, and utility power systems requiring

power factor correction, motor start support,

harmonic filtering, and IEEET 519 compliance, and

can increase system capacity. Fixed motor start

capacitors are available to assist in motor starting

applications. Designs are available with a host

of options and accessories to fit the require-

ments and desired configurations of virtually

any installation. Single-stage and multi-stage,

tuned or de-tuned filter banks can be supplied.

Metal-enclosed medium voltage capacitor banks

are designed for industrial, commercial, and utility

power systems involving motors, feeder circuits,

and transmission and distribution lines where

power factor improvement is required.

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Application description Advantages

Utility customers Eatons purchase of the Commonwealth Sprague capacitor systems

business, with its over 70 years of market experience, provides

Metal-enclosed power factor correction systems are fully assem- a combination that allows the end user to obtain a world-class

bled, tested, and ready for installation. Very little field assembly solution to fill their power factor needs. Quality and reliability are

is required. Installation and maintenance costs for metal-enclosed of paramount importance to not only the Eaton engineering team,

systems are low compared to pole and rack mounted capacitor but are also the backbone of all Eaton products and services. This

banks. Metal-enclosed systems and harmonic filters are less commitment to quality means the customer can have a great deal

vulnerable to wildlife and airborne contaminants that can cause of confidence with the medium voltage capacitor or harmonic filter

tracking and faults. In addition, metal-enclosed systems significantly solution from Eaton.

reduce the risks and the associated liability involving untrained

personnel. All live parts are contained in a grounded, key interlocked Benefits

enclosure, and no internal hardware is accessible. Metal-enclosed

systems are aesthetically pleasing due to their low profile, and Ease of installation

can be painted to match the surrounding architecture. These are Eaton makes installation easy. All systems are completely assem-

just some of the reasons more and more customers are using bled in the factory, with all equipment pre-wired and pre-tested

metal-enclosed capacitor and harmonic filter systems. for easy on-site installation. Only shipping splits must be connected

in the field. Splice kits connect bus systems, and control wiring

Industrial customers

is easily connected at each enclosure. Current limiting fuses,

Many industrial power users can take advantage of the benefits contactor assemblies, and the incoming switch assembly can

associated with medium voltage power factor correction and be removed from the enclosure if needed. Line terminals are

harmonic filtering. Medium voltage solutions usually support the completely accessible from the front of the system.

scale and scope of larger services. Medium voltage applications

can be found in the following types of industries: automotive, Personnel safety

pulp and paper, plastics, petrochemical, and heavy manufacturing. A positive mechanical isolating switch with visible disconnect

Individual fixed capacitors provide power factor correction directly completely grounds and isolates the unit from the line connectors.

at the cause of the problem, such as large horsepower MV motors. A screened barrier protects personnel from live parts. All medium

Medium voltage systems allow large industrials to correct power voltage doors are mechanically interlocked with the disconnect

factor at or close to the point of common coupling (PCC), where switch. Key interlocks are provided standard on all enclosure doors,

the utility electrical system meets theirs. This allows correction for and can be coordinated with upstream disconnect devices. The low

an entire facility, instead of having to correct at multiple locations. voltage control section has a separate door-in-door design, and is

The NEMAT 3R design also allows the system to be placed out- segregated from the medium voltage sections so that an operator

doors, saving valuable manufacturing floor space. The savings can work in that section safely.

can be significant in materials, installation costs, and floor space.

In short, medium voltage solutions provide a cost-effective alterna- Ease of maintenance

tive to many local low voltage power factor correction units, while

protecting the customers entire electrical distribution system. All components are front-accessible, facilitating routine inspection

or parts replacement. A viewing window is standard on all

Commercial customers compartment doors.

Many commercial customers are purchasing power from their Flexibility

utility at higher voltages today (2.415 kV), and can also take

advantage of medium voltage power factor correction systems. Systems are expandable. The customer can add stages in the future

These solutions can meet the needs of large office complexes, by connecting the phase bus in the field via splice kits. Structures

hospitals, and universities, among others. The benefits of safety can be bolted together in the field.

(key interlocking, no exposed live parts, etc.) and aesthetics

(low profile, can be painted to match the environment) both meet

the needs of these applications where there are large numbers

of untrained personnel in proximity of electrical equipment.

Safety and aesthetics are just two compelling Insulated splice kits allow for simple interconnection in the field.

reasons to use metal-enclosed PFC systems.

2 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Univar XV (5 kV class) Application description

Large motors

Motor control centers

Branch circuits

Service entrances

Features, benefits, and functions

Standard features

Enclosure terminal box

Fourteen-gauge steel finished with durable baked-on enamel. The

wiring enclosure is gasketed to create a weatherproof, dustproof

seal. Universal mounting flanges are provided for floor installation.

The elimination of knockouts permits indoor/outdoor use. Unit

meets NEMA 1, 3R, and 12 requirements. Enclosure is painted

ANSI 61 gray.

Features

Viewing window

Top and side entry

Removable front cover

Fusing

Univar XV fixed medium voltage PFC unit Fuses are rated 50,000A symmetrical interrupting capacity. Ratings

are 165% to 250% of rated current. Fuses have visual pop-up blown

fuse indication standard.

Product description

Capacitors for medium voltage, heavy-duty applications: Discharge resistors

Univar capacitors are designed for power factor correction in appli- These reduce the residual voltage to less than 50V residual within

cations where a fixed amount of capacitance (kVAR) is required five minutes of de-energization.

Available in voltage ratings of 2400V, 4160V, and 4800V Grounding stud

Fast economical payback Standard

Individual units or multiple assemblies can be designed

Power line terminals

Indoor dustproof/outdoor waterproof enclosures

(NEMA 12, NEMA 3R) Large size for easy connection

Floor mounting Plated copper one-hole termination pad

Two- or three-phase fused options for 24004800V

Operating temperature

NEMA 3R terminal box

40F to 115F (40C to 46C)

NNote: NECT Article 460.8 (b)(1) requires capacitors to have overcurrent

protection in all ungrounded conductors (except when connected on the load

Optional features

side of a motor overload protection device). Three-phase capacitors fused CSAT testing and labels

only on two phases will not provide adequate protection if a line-to-ground

fault should occur in the unfused phase. Technical data

Table 1. Univar Three-Phase Ratings

Volts Hz kVAR

2400 60 25825

4160 60 25900

4800 60 25900

eaton corporation www.eaton.com 3

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Table 2. Two-Phase Fused

Dimension (A) Approximate

kVAR 2400V 4160V 4800V Inches (mm) Weight Lbs (kg) Figure Number

25 25243MVF 25413MVF 25483MVF 34.44 (875) 70 (32) 1

50 50243MVF 50413MVF 50483MVF 34.44 (875) 70 (32) 1

75 75243MVF 75413MVF 75483MVF 34.44 (875) 70 (32) 1

100 100243MVF 100413MVF 100483MVF 36.19 (919) 75 (34) 1

125 125243MVF 125413MVF 125483MVF 36.19 (919) 83 (38) 1

150 150243MVF 150413MVF 150483MVF 36.19 (919) 88 (40) 1

175 175243MVF 175413MVF 175483MVF 36.19 (919) 93 (42) 1

200 200243MVF 200413MVF 200483MVF 36.19 (919) 99 (45) 1

225 225243MVF 225413MVF 225483MVF 41.94 (1065) 109 (49) 1

250 250243MVF 250413MVF 250483MVF 41.94 (1065) 109 (49) 1

275 275243MVF 275413MVF 275483MVF 41.94 (1065) 121 (55) 1

300 300413MVF 300483MVF 41.94 (1065) 121 (55) 1

300 300243MVF 36.19 (919) 172 (78) 2

325 325243MVF 325413MVF 325483MVF 36.19 (919) 177 (80) 2

350 350243MVF 350413MVF 350483MVF 36.19 (919) 182 (83) 2

375 375243MVF 375413MVF 375483MVF 36.19 (919) 188 (85) 2

400 400243MVF 400413MVF 400483MVF 36.19 (919) 194 (88) 2

425 425243MVF 425413MVF 425483MVF 41.94 (1065) 206 (93) 2

450 450243MVF 450413MVF 450483MVF 41.94 (1065) 214 (97) 2

475 475243MVF 475413MVF 475483MVF 41.94 (1065) 214 (97) 2

500 500243MVF 500413MVF 500483MVF 41.94 (1065) 214 (97) 2

525 525243MVF 525413MVF 525483MVF 41.94 (1065) 226 (103) 2

550 550243MVF 550413MVF 550483MVF 41.94 (1065) 238 (108) 2

575 575413MVF 575483MVF 41.94 (1065) 238 (108) 2

575 575243MVF 36.19 (919) 259 (118) 3

600 600413MVF 600483MVF 41.94 (1065) 238 (108) 2

600 600243MVF 36.19 (919) 265 (121) 3

625 625243MVF 625413MVF 625483MVF 41.94 (1065) 279 (127) 3

650 650243MVF 650413MVF 650483MVF 41.94 (1065) 287 (131) 3

675 675243MVF 675413MVF 675483MVF 41.94 (1065) 295 (134) 3

700 700243MVF 700413MVF 700483MVF 41.94 (1065) 295 (134) 3

725 725243MVF 725413MVF 725483MVF 41.94 (1065) 295 (134) 3

750 750243MVF 750413MVF 750483MVF 41.94 (1065) 295 (134) 3

775 775243MVF 775413MVF 775483MVF 41.94 (1065) 307 (140) 3

800 800243MVF 800413MVF 800483MVF 41.94 (1065) 319 (145) 3

825 825243MVF 825413MVF 825483MVF 41.94 (1065) 331 (151) 3

850 850413MVF 850483MVF 41.94 (1065) 331 (151) 3

875 875413MVF 875483MVF 41.94 (1065) 331 (151) 3

900 900413MVF 900483MVF 41.94 (1065) 331 (151) 3

NNote: To be used on ungrounded delta systems or high resistance grounding systems only.

NNote: Add suffix C for CSA label.

4 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Table 3. Three-Phase Fused

Dimension (A) Approximate

kVAR 2400V 4160V 4800V Inches (mm) Weight Lbs (kg) Figure Number

25 25243MVF3 25413MVF3 25483MVF3 34.44 (875) 70 (32) 1

50 50243MVF3 50413MVF3 50483MVF3 34.44 (875) 70 (32) 1

75 75243MVF3 75413MVF3 75483MVF3 34.44 (875) 70 (32) 1

100 100243MVF3 100413MVF3 100483MVF3 36.19 (919) 75 (34) 1

125 125243MVF3 125413MVF3 125483MVF3 36.19 (919) 83 (38) 1

150 150243MVF3 150413MVF3 150483MVF3 36.19 (919) 88 (40) 1

175 175243MVF3 175413MVF3 175483MVF3 36.19 (919) 93 (42) 1

200 200243MVF3 200413MVF3 200483MVF3 36.19 (919) 99 (45) 1

225 225243MVF3 225413MVF3 225483MVF3 41.94 (1065) 109 (49) 1

250 250243MVF3 250413MVF3 250483MVF3 41.94 (1065) 109 (49) 1

275 275243MVF3 275413MVF3 275483MVF3 41.94 (1065) 121 (55) 1

300 300413MVF3 300483MVF3 41.94 (1065) 121 (55) 1

300 300243MVF3 36.19 (919) 172 (78) 2

325 325243MVF3 325413MVF3 325483MVF3 36.19 (919) 177 (80) 2

350 350243MVF3 350413MVF3 350483MVF3 36.19 (919) 182 (83) 2

375 375243MVF3 375413MVF3 375483MVF3 36.19 (919) 188 (85) 2

400 400243MVF3 400413MVF3 400483MVF3 36.19 (919) 194 (88) 2

425 425243MVF3 425413MVF3 425483MVF3 41.94 (1065) 206 (93) 2

450 450243MVF3 450413MVF3 450483MVF3 41.94 (1065) 214 (97) 2

475 475243MVF3 475413MVF3 475483MVF3 41.94 (1065) 214 (97) 2

500 500243MVF3 500413MVF3 500483MVF3 41.94 (1065) 214 (97) 2

525 525243MVF3 525413MVF3 525483MVF3 41.94 (1065) 226 (103) 2

550 550243MVF3 550413MVF3 550483MVF3 41.94 (1065) 238 (108) 2

575 575413MVF3 575483MVF3 41.94 (1065) 238 (108) 2

575 575243MVF3 36.19 (919) 259 (118) 3

600 600413MVF3 600483MVF3 41.94 (1065) 238 (108) 2

600 600243MVF3 36.19 (919) 265 (121) 3

625 625243MVF3 625413MVF3 625483MVF3 41.94 (1065) 279 (127) 3

650 650243MVF3 650413MVF3 650483MVF3 41.94 (1065) 287 (131) 3

675 675243MVF3 675413MVF3 675483MVF3 41.94 (1065) 295 (134) 3

700 700243MVF3 700413MVF3 700483MVF3 41.94 (1065) 295 (134) 3

725 725243MVF3 725413MVF3 725483MVF3 41.94 (1065) 295 (134) 3

750 750243MVF3 750413MVF3 750483MVF3 41.94 (1065) 295 (134) 3

775 775243MVF3 775413MVF3 775483MVF3 41.94 (1065) 307 (140) 3

800 800243MVF3 800413MVF3 800483MVF3 41.94 (1065) 319 (145) 3

825 825243MVF3 825413MVF3 825483MVF3 41.94 (1065) 331 (151) 3

850 850413MVF3 850483MVF3 41.94 (1065) 331 (151) 3

875 875413MVF3 875483MVF3 41.94 (1065) 331 (151) 3

900 900413MVF3 900483MVF3 41.94 (1065) 331 (151) 3

NNote: Add suffix C for CSA label.

eaton corporation www.eaton.com 5

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Dimensions

Figure 1. Univar XV Outline Drawing Figure 3. Univar XV Outline Drawing

Figure 2. Univar XV Outline Drawing

6 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Univar (15 kV class) Features, benefits, and functions

Standard features

Enclosure

Sixteen-gauge steel finished with durable baked-on enamel. The

wiring enclosure is gasketed to create a weatherproof, dustproof

seal. Universal mounting flanges are provided for floor installation.

The elimination of knockouts permits indoor/outdoor use. Unit

meets NEMA 1, 3R, and 12 requirements. Enclosure is painted

ANSI 70 gray.

Fusing

Fuses are rated 50,000A symmetrical interrupting capacity.

Ratings are 165% to 250% of rated current. Fuses have visual

pop-up blown fuse indication standard.

Discharge resistors

These reduce the residual voltage to less than 50V residual

within 5 minutes of de-energization.

Univar fixed medium voltage PFC unit

Grounding stud

Product description Standard

Capacitors for medium voltage, heavy-duty applications: Power line terminals

Univar capacitors are designed for power factor correction Large size for easy connection

in applications where a fixed amount of capacitance (kVAR)

is required Operating temperature

Available in voltage ratings of 6.6 kV, 7.2 kV, 12.47 kV and 13.8 kV 40F to 115F (40C to 46C)

Fast economical payback

Optional features

Individual units or multiple assemblies can be designed

CSA testing and labels

Indoor dustproof/outdoor waterproof enclosures

(NEMA 12, NEMA 3R) Technical data

Floor mounting

Table 4. Univar Three-Phase Ratings

Fuses supplied on all three phases

Volts Hz kVAR

NEMA 3R terminal box

6600 60 50400

Application description 7200 60 50400

Large motors 12,470 60 50500

13,800 60 50500

Motor control centers

Branch circuits

Service entrances

eaton corporation www.eaton.com 7

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Table 5. Standard Three Fuses (660013,800V)

Standard Three Fuses Dimensions in Inches (mm)

Approx. Standard

Weight Figure DWG

kVAR 6600V 7200V 12,470V 13,800V (A) (B) (C) (D) Lbs (kg) Number Number

50 50663FKED3 50723FKED3 50123FKED3 50133FKED3 4.25 (108) 45.50 (1156) 14.46 (367) 0.25 (6) 198 (90) 4 5D10243

100 100663FKED3 100723FKED3 100123FKED3 100133FKED3 4.25 (108) 45.50 (1156) 14.46 (367) 0.25 (6) 198 (90) 4 5D10243

150 150663FKED3 150723FKED3 150123FKED3 150133FKED3 4.25 (108) 45.50 (1156) 14.46 (367) 0.25 (6) 198 (90) 4 5D10243

200 200663FKED3 200723FKED3 200123FKED3 200133FKED3 5.62 (143) 45.50 (1156) 14.46 (367) 0.25 (6) 220 (100) 4 5D10243

250 250FKY66323 250FKY72323 250FKY12323 250FKY13323 5.62 (143) 48.50 (1232) 17.46 (443) 0.25 (6) 246 (112) 4 5D10243

300 300FKY66323 300FKY72323 300FKY12323 300FKY13323 5.62 (143) 53.50 (1359) 17.46 (443) 0.25 (6) 246 (112) 4 5D10243

350 350FKY66323 350FKY72323 350FKY12323 350FKY13323 5.62 (143) 53.50 (1359) 17.46 (443) 0.25 (6) 246 (112) 4 5D10243

400 400FKY66323 400FKY72323 400FKY12323 400FKY13323 5.62 (143) 57.25 (1454) 22.46 (570) 0.25 (6) 281 (128) 4 5D10243

450 450FKY12323 450FKY13323 5.62 (143) 57.25 (1454) 22.46 (570) 0.25 (6) 281 (128) 4 5D10243

500 500FKY12323 500FKY13323 5.62 (143) 57.25 (1454) 26.21 (666) 0.25 (6) 336 (153) 4 5D10243

Dimensions

Removable

Top Cover 0.250-20

Ground Screw

16.42 34.00

Barriers When

Necessary

Solderless Conn.

for A #10 Solid

to A #4 Str'd. Conn.

B

(2) 0.500 x 0.625

Slots [13 x 16]

C

D

24.12

A 25.08

Figure 4. Drawing Number 5D10243

8 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Autovar MV (2.414.4 kV) Standard features

Enclosure

Free-standing, 11-gauge steel construction with three-point

padlockable latching handles and stainless steel hinges. The

enclosure is painted with a corrosion-resistant ANSI 61 light

gray powder-coated paint as standard. Other colors are available

as an option. NEMA 3R construction is standard; NEMA 3R

stainless steel is available as an option.

Enclosure type is ULT/CSA approved. Enclosure design is modular,

and future sections can be added on the left or the right.

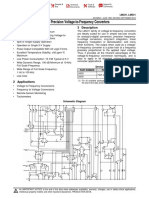

See Figure 5 for typical dimensions and elevations.

See Figure 6 for a typical single-line drawing.

Medium voltage metal-enclosed PFC system

Product description

Autovar medium voltage automatic power factor capacitor systems

are designed for power factor correction in applications where

plant power factor can be constant or changing and a custom

solution is required. These systems can be a fixed amount of

capacitance with a disconnect, a number of switched capacitance

stages, or a combination of both. The Autovar medium voltage Medium voltage PFC enclosure

capacitor system can switch stages of capacitance in and out

automatically based on information collected by the power factor

controller on the door-in-door control panel.

Features, benefits, and functions

Voltages from 2400 to 14,400V

Reactive power ratings through 15 MVAR

Harmonic tuned, de-tuned, or multi-tuned filter designs available

Externally fused capacitor units standard

Blown fuse indication standard

Integral load interrupter switch with NEMA two- or four-hole Bottom plate incoming cutout provided standard

termination pad for incoming cables

Factory tested and ready for interconnection Load interrupter air disconnect switch

Integral protection and control system Integral disconnect switch, externally operated, mechanically chain

Top or bottom cable entry driven with visible blades is available as per NEC requirements.

Grounding switch Disconnect switch is mechanically interlocked with the ground

switch, and with the customers upstream device (if applicable).

60 kV BIL up to 4.8 kV For safety, the incoming section is front-accessible only, and

95 kV BIL from 7.2 kV to 14.4 kV a barrier isolates live components from the user.

Up to 12 automatic switched capacitor stages

Warning labels

Removable air filters without opening enclosure doors

Adjustable blocking timers to prevent re-closing of a capacitor

stage in less than 200 seconds

Meets the following requirements:

ANSI

IEEE

NEC

NESC

CSA (when specified)

Main incoming fuses are rated 50 kAIC to provide main bus pro-

tection, as well as backup protection for the capacitor systems

4.00-inch base channel is standard Incoming section

eaton corporation www.eaton.com 9

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Ground switch Individual capacitor fusing

A ground switch is provided to ground the load-side terminals Each capacitor is externally fused with current limiting fuses.

of the incoming switch (or MLO) for safety during maintenance. Fuses are equipped with blown fuse indication. Internally fused

Optional controls are available to permit closing contactors after capacitors are also available as an option. Fuses are rated for

the grounding switch has been closed to ground capacitors capacitor protection. All fuses are rated 50 kAIC.

immediately (rather than waiting 5 minutes for full discharge).

Environmental controls

Vacuum switches and contactors rated for capacitor switching Exhaust fans are provided for forced air ventilation of all

On 2.4 to 4.8 kV multi-stage capacitor systems, each stage is enclosures as standard

controlled by low maintenance Eaton SL AMPGARDT three- Thermostats are included as standard to help maintain an

pole vacuum contactors. On 6.6 to 14.4 kV multi-stage capacitor acceptable internal environment for all components

systems, each stage is controlled by low maintenance single-pole

vacuum switches. Space heaters are provided to control moisture and humidity

inside all enclosures

Each compartment has individual thermostats for fan and space

heater controls

Capacitors

Low loss, double-bushing capacitors that meet or exceed IEC 871,

IEEE Std. 18, and CSA standards are supplied. Capacitors are

available in delta, ungrounded wye, or solidly grounded wye.

The dielectric fluid is environmentally friendly and biodegradable,

and contains no PCBs. Capacitor units are equipped with internal

discharge resistors that reduce the residual voltage to less than

50 volts within 5 minutes of de-energization.

Harmonic filtering

Eatons medium voltage harmonic filter systems are designed

for industrial, utility, and commercial power systems to improve

power factor, to reduce harmonic distortion, and to increase system

capacity. The reactors are typically tuned to either the 4.2nd or the

4.7th harmonic, to filter the 5th level harmonic. Other tuning orders

15 kV switched capacitor stage enclosure are available. This is the most common harmonic produced by six-

pulse variable speed drives. These filters are designed to the unique

The type SL power contactors are self-supporting, compact, specifications of each electrical distribution system. Medium voltage

three-pole vacuum contactors, rated for capacitor switching. capacitor banks can also be configured with de-tuned anti-resonant

The SL contactor uses a solid-state control board, allowing the harmonic filters, typically set to the 4.2nd harmonic. Capacitor banks

user maximum flexibility to change control voltages and dropout tuned to the 4.2nd or 4.7th harmonic prevent parallel resonance

times in the field simply by adjusting DIP switch settings. The conditions, reduce transients, and provide harmonic filtering.

SL contactor is available in voltage ratings from 2.4 to 4.8 kV

with current ratings of 200A and 800A (the highest rated capacitor

switching contactor available), and the SL contactor has interruption

ratings of 8500A, allowing for better coordination with power fuses.

Harmonic filter capacitor stage enclosure

5 kV switched capacitor stage enclosure

10 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Key interlock system Microprocessor-based controller

The key interlock system controls the sequential operation of All switched metal-enclosed capacitors and harmonic filter systems

the load break switch (or circuit breaker) and the ground switch come equipped with an automatic controller that switches each

to permit safe entry into the capacitor system. All capacitor capacitor stage based upon power factor. The customer simply

stage enclosures are also interlocked with the ground switch. programs in the target power factor desired. The controller analyzes

If applicable, the customers upstream disconnect device can the present power factor, the size of each stage, and turns on and

be interlocked as well. See Figure 6 for key interlock operation off stages to meet the customers programmed target. The power

on a typical single-line drawing. factor controller comes with the following alarms as standard:

over/under compensation, no current input, step fault, step warning,

Blown fuse detection system target PF not reached, total voltage harmonic distortion, total current

A visual pop-up blown fuse detection system is provided harmonic distortion, and over/under voltage.

as standard. Up to 12 steps of capacitance can be designed into any system.

Customers can exploit this feature when designing systems for

Control power transformer future plant expansion.

A fused control power transformer rated for 1.5 kVA is provided

Communication options

for protection, control, and operation of the capacitor or harmonic

filter system. Communications of power factor data via RS-485. ModbusT is avail-

able as an option. Communicated information from the controllers:

Surge protective device (SPD) Voltage

An SPD unit is always supplied for protection of all low voltage Current

controls in the system, increasing the reliability of the system.

Target power factor

Control panel Current power factor

A door-in-door NEMA 3R swing-out control panel is provided on the Active power

main incoming structure as standard. This unit includes a viewing

window so that all controls and information can be viewed without Apparent power

opening the panel. All low voltage controls and logic are accessible Reactive power

from the front of the system, and are isolated from the medium Number of steps in the circuit

voltage section.

All alarm status

Included: All counters

PFC power factor controller Time and date

Multifunction digital meter/relay

Inrush reactors

Full voltage LED lights for status, alarm, and trip indication

Series air core inrush reactors are provided as standard on all

Manual stage operation switches switched (non-harmonic filtered) capacitor systems for protection

Any special controls requested by the customer against transients from back-to-back switching. Reactors in harmonic

filtered applications provide this same protection.

Bus

Standard main bus is continuous 1/4 x 2-inch silver-plated copper

bus rated 600A and is provided throughout the lineup for easy

interconnection, field installation, and future expansion.

Ground bus is continuous 1/4 x 1-inch silver-plated copper rated

300A and is provided throughout the lineup for easy intercon-

nection, field installation, and future expansion. Ground studs

are available in all structures for customer connection.

Control panel

eaton corporation www.eaton.com 11

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Additional standard controls and features Lightning arresters

Three-phase current monitoring of capacitor bank Optional heavy-duty distribution intermediate or station class

Unbalance alarm and unit shutdown on all lightning arresters protect the capacitor system from lightning

wye-connected systems and switching transients.

Unit alarm and isolated fail-safe contacts for customer use on all 15 kV capacitor vacuum switch

systems. Controls allow sufficient time (5 minutes) to allow the

capacitors time to discharge before re-energization can occur 15 kV capacitor vacuum switch is available in vacuum contactor in oil

dielectric or vacuum contactor in solid dielectric. Vacuum switches

Temperature alarms on all harmonic filter units are certified to ANSI C37.66 standard.

Manual stage controls (H-O-A selector switches)

Harmonic manager multifunction digital meter/relay

Optional features Multifunction harmonic manager meter/relay with current and

Harmonic filter reactors voltage harmonic monitoring and various alarm/trip set points.

Iron core reactors provide the necessary reactance to tune the Enclosure options

capacitor system to a desired frequency. Standard filters can be

tuned to 4.2, 4.4, 4.6, or 4.7, with other tuning frequencies available NEMA 3R stainless steel construction for highly caustic

if needed. Iron core reactors are 100% copper windings, 115C environments.

rise with 220C insulation VPI varnish.

Alarm strobe

Strobe light can be provided for visual indication of faults and alarms.

Unbalance protection

Neutral PT or CT-based unbalance protection for wye ungrounded

capacitor configuration.

Power cable termination

Incoming power cable lugs are available when specified.

Time delayed enclosure entry interlock

Electrically controlled solenoid time delay to allow adjustable

time delay between opening of main switch and entry into

capacitor section.

Reactors for harmonic filter Heavy-duty capacitor units

Capacitor units suited to the rigors of industrial power systems for

power factor, harmonic filter, and excessive switching applications.

Heavy-duty capacitor units have 125% continuous rms overvoltage

capability, 15,000A fault handling capability, 100 kA transient current

withstand capability, 131F (55C) ambient temperature operation,

and 135% peak overvoltage capability.

Other options

Second PT for voltage sensing of all three phases

Special CSA label for assembly

Individual harmonic filter current monitoring

Overload protection

12 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Technical data

Top Power

Cable Entry

Lifting Eyes

Shipping Split

Incoming Main Section

Main Switch

92.56 24.00

K1 (2351.0) (609.6)

Control

Panel 18.00

CAUTION CAUTION CAUTION

Customer (457.2)

DANGER DANGER DANGER

NAMEPLATE

Cable

Ground Switch

Termination

Danger Danger Danger Danger

CAUTION

K1 (Approximate

Location, See

High Voltage High Voltage High Voltage High Voltage DANGER

Keep Out Keep Out Keep Out Keep Out

Actual Unit

D1

for Exact

D2

D3

Dimensions)

D2 D3 D2 D1

90.33 Ground Bus

Door Interlocks

(2294.4) 1/4-inch x 1-inch

Base Channel

180.80 Bottom Power

(4592.3) Cable Entry

8 Tie-Down Points 45.00 49.00

per Enclosure Front Elevation 1.50

(1143.0) (1244.6)

Front and Rear (38.1)

13.50 15.00 13.50

for 1/2 Inch Hardware Rear Access Doors Optional (Typ) (342.9) (381.0) (342.9) Right Side Elevation

Each Section is

Base Channel 45.00 (1143.0) W x 49.00 (1244.6) D

18.00 21.79

40-Inches High

(457.2) (553.5)

49.00

Bottom Entry 18.00 (1244.6)

Cover Plate

(457.2)

5.09 9.07

(129.3) (230.4)

Front Access 5 Foot Clearane 1.00

(25.4)

Floor Plan

Top Entry MV Conduit Area

19.00

(482.6)

Top Entry 16.00

Control (406.4)

Conduit

4.00 x 4.00 15.00 13.00

(381.0) (330.2)

Top View 4.00 38.00

(101.6) (965.2)

Figure 5. Typical Engineered Metal-Enclosed Power Factor Correction System Dimensional Data

eaton corporation www.eaton.com 13

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Utility Line

Utility

Transformer

Main Breaker

CT

A-Phase 1

Feeder Breaker K0

Plant Loads

K-K Interlock

K-K Interlock (Optional)

C1

K-K Interlock K0 Power Factor

K1

Main Controller

CPT BLR-CM

Switch

1-Phase

Tap On

B&C

S1 S2 S3 Control

K1 Ground

Switch CT1 46 AS AM 59 Relays

S1

3

Alarm or Trip

Fuse

S1

Enclosure

Door

C1

Vacuum

Contactor

Reactor

Capacitor Capacitor Capacitor

Delta/Wye Delta/Wye Delta/Wye

Figure 6. Typical Medium Voltage Automatic Power Factor Correction Single-Line Drawing

14 eaton corporation www.eaton.com

Metal-enclosed medium voltage Technical Data TD02607011E

power factor correction system Effective June 2011

Figure 7. Automatic Capacitor Banks Medium Voltage Main-Tie-Main

eaton corporation www.eaton.com 15

Technical Data TD02607011E Metal-enclosed medium voltage

Effective June 2011 power factor correction system

Eaton Corporation

Electrical Sector

1111 Superior Ave.

Cleveland, OH 44114

United States

877-ETN-CARE (877-386-2273)

Eaton.com

2011 Eaton Corporation Eaton is a registered trademark

All Rights Reserved of Eaton Corporation.

Printed in USA

Publication No. TD02607011E / Z11009 All other trademarks are property

June 2011 of their respective owners.

You might also like

- Metal-Enclosed Medium Voltage Power Factor Correction SystemDocument16 pagesMetal-Enclosed Medium Voltage Power Factor Correction SystemYigit SarıkayaNo ratings yet

- MV PFC - Metal Enclosed - EatonDocument24 pagesMV PFC - Metal Enclosed - EatonlassasaNo ratings yet

- AN-1849 An Audio Amplifier Power Supply Design: Application ReportDocument17 pagesAN-1849 An Audio Amplifier Power Supply Design: Application ReportJuzt AdhitNo ratings yet

- TD02300001EDocument8 pagesTD02300001EDavid J LopezNo ratings yet

- UCC27324-Q1 Dual 4-A Peak High-Speed Low-Side Power MOSFET DriverDocument25 pagesUCC27324-Q1 Dual 4-A Peak High-Speed Low-Side Power MOSFET DriverMarcel SavioloNo ratings yet

- Bonitron Model 3452Document60 pagesBonitron Model 3452Jesus SanchezNo ratings yet

- Catalogue - S811 Soft Starters PDFDocument28 pagesCatalogue - S811 Soft Starters PDFAnonymous HsNodUwzNo ratings yet

- LM2594MXDocument44 pagesLM2594MXtecnicogato27No ratings yet

- Softstarters: Type PSR, PSS, Pse, PST and PSTBDocument64 pagesSoftstarters: Type PSR, PSS, Pse, PST and PSTBmoulin sitifisNo ratings yet

- Utran: Radio Subsystem Node B CC Redundancy FD012226A - UMR3.5Document20 pagesUtran: Radio Subsystem Node B CC Redundancy FD012226A - UMR3.5Anonymous g8YR8b9No ratings yet

- 8000 ANTHEM U RevF 161010Document184 pages8000 ANTHEM U RevF 161010Mario Raul Gonzalez TerrazaNo ratings yet

- Transformer Protection Relay: Technical Data TD02600003EDocument20 pagesTransformer Protection Relay: Technical Data TD02600003EJahidul IslamNo ratings yet

- Reduced Voltage Motor Starters 1: Description ITDocument32 pagesReduced Voltage Motor Starters 1: Description ITANDRE LUIZ RAMOS DE FREITASNo ratings yet

- LM431 Adjustable Precision Zener Shunt Regulator: 1 Features 3 DescriptionDocument40 pagesLM431 Adjustable Precision Zener Shunt Regulator: 1 Features 3 DescriptionGregory MuriaNo ratings yet

- LM 431Document41 pagesLM 431Iftikhar RamayNo ratings yet

- LM431 Adjustable Precision Zener Shunt Regulator: 1 Features 3 DescriptionDocument38 pagesLM431 Adjustable Precision Zener Shunt Regulator: 1 Features 3 DescriptionPERLUESNo ratings yet

- TS5A3159 1 - SPDT Analog Switch: 1 Features 3 DescriptionDocument29 pagesTS5A3159 1 - SPDT Analog Switch: 1 Features 3 DescriptionDaniel VargasNo ratings yet

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument24 pagesLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionShruthi reddyNo ratings yet

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument23 pagesLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionJayant KirpekarNo ratings yet

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument23 pagesLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionJavierPariNo ratings yet

- Lm331 Voltaje A FrecuenciaDocument24 pagesLm331 Voltaje A FrecuenciaLeguel LNo ratings yet

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument23 pagesLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionAndres Felipe Perez BustamanteNo ratings yet

- SVX9000 ManualDocument84 pagesSVX9000 ManualGuillermo Alexis Mella CordovaNo ratings yet

- Eaton Tb09500001e PDFDocument62 pagesEaton Tb09500001e PDFJuan E Torres MNo ratings yet

- AN6001-G16 Optical Line Terminal Equipment Product Overview Version ADocument74 pagesAN6001-G16 Optical Line Terminal Equipment Product Overview Version AAdriano CostaNo ratings yet

- A78xx Fixed Positive Voltage Regulators: 1 Features 3 DescriptionDocument27 pagesA78xx Fixed Positive Voltage Regulators: 1 Features 3 DescriptionGeraldo Aparecido SantosNo ratings yet

- TS3A5018RSVRDocument37 pagesTS3A5018RSVRThomas GuoNo ratings yet

- Commander SK - Control TechniquesDocument81 pagesCommander SK - Control TechniquesLeo Dos RamosNo ratings yet

- ACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Document48 pagesACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Jose MellaNo ratings yet

- Infineon-Motor Control Shield With IFX007T For Arduino-UserManual-V02 00-EnDocument15 pagesInfineon-Motor Control Shield With IFX007T For Arduino-UserManual-V02 00-EnMR. VAIBHAVSINGH VARMANo ratings yet

- Seven Service ManualDocument84 pagesSeven Service ManualDavid EguezNo ratings yet

- Data Sheet Variador de Frec. Eton PDFDocument20 pagesData Sheet Variador de Frec. Eton PDFLeo SalgadoNo ratings yet

- K-Line Mini - Contactors, Overload Relays and Accessories: Class 8502Document48 pagesK-Line Mini - Contactors, Overload Relays and Accessories: Class 8502hassan karimiNo ratings yet

- Catalog ATS48 USADocument36 pagesCatalog ATS48 USAFrancisco PerezNo ratings yet

- Adc 0804 Data SheetDocument58 pagesAdc 0804 Data SheetOmar Chavez MontesNo ratings yet

- DRV8821 Dual Stepper Motor Controller and Driver: 1 Features 3 DescriptionDocument32 pagesDRV8821 Dual Stepper Motor Controller and Driver: 1 Features 3 DescriptionVictor CuevasNo ratings yet

- Snx5Lbc184 Differential Transceiver With Transient Voltage SuppressionDocument29 pagesSnx5Lbc184 Differential Transceiver With Transient Voltage SuppressionGabriel EscamillaNo ratings yet

- Apx 525Document243 pagesApx 525AR ElectromedicaNo ratings yet

- Z8 MicrocontrollersDocument84 pagesZ8 MicrocontrollersMarco Antonio DamacenoNo ratings yet

- Catalogo Final de Carreras EATONDocument102 pagesCatalogo Final de Carreras EATONAriel Alexis Pinto PintoNo ratings yet

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocument246 pagesADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- tps40210 q1 PDFDocument47 pagestps40210 q1 PDFLuong Anh TuanNo ratings yet

- Utran: Radio Subsystem Remote Modem Access FD012222A - UMR3.5Document19 pagesUtran: Radio Subsystem Remote Modem Access FD012222A - UMR3.5Anonymous g8YR8b9No ratings yet

- Altistart™ 48: Panel-Mount Soft StartsDocument40 pagesAltistart™ 48: Panel-Mount Soft StartsYasser SayedNo ratings yet

- Application Note: Replaces AN5947-1 With AN5947-2 November 2014 LN32141Document23 pagesApplication Note: Replaces AN5947-1 With AN5947-2 November 2014 LN32141Rifdian AntoNo ratings yet

- IZMX Catalog ENG 20160419Document104 pagesIZMX Catalog ENG 20160419Mahesh BabuNo ratings yet

- Power Xpert FMX - Application Guide 6054036 02 ENGDocument52 pagesPower Xpert FMX - Application Guide 6054036 02 ENGcepchileNo ratings yet

- Infineon IMC100 DataSheet v01 06 enDocument54 pagesInfineon IMC100 DataSheet v01 06 enHATEM68No ratings yet

- StatcomDocument16 pagesStatcomksg9731100% (1)

- SN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RDocument32 pagesSN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RAmir Reza BeheshtianNo ratings yet

- Lm2596 Simple Switcher Power Converter 150-Khz 3-A Step-Down Voltage RegulatorDocument45 pagesLm2596 Simple Switcher Power Converter 150-Khz 3-A Step-Down Voltage RegulatorDaniel TaftăNo ratings yet

- Abb CCMDocument60 pagesAbb CCMdaperroNo ratings yet

- Eaton Xgis MV Switchgear Design Guide Dg022020enDocument22 pagesEaton Xgis MV Switchgear Design Guide Dg022020enMatias Soto BilbaoNo ratings yet

- Softstarter Sepc GuideDocument16 pagesSoftstarter Sepc GuideclauNo ratings yet

- ML0001 MultiComm RTHDocument48 pagesML0001 MultiComm RTHUrsula JohnsonNo ratings yet

- Collision of Two Washington Metropolitan Area TransitDocument156 pagesCollision of Two Washington Metropolitan Area Transitapic20No ratings yet

- 1 PDFDocument46 pages1 PDFThisum DissanayakeNo ratings yet

- Transortation in Canada 2021-Greenhouse Gas EmissionsDocument3 pagesTransortation in Canada 2021-Greenhouse Gas Emissionsapic20No ratings yet

- 6947 SwitchOnto RM 20200513 Web4Document12 pages6947 SwitchOnto RM 20200513 Web4alkilanyNo ratings yet

- Supercapacitors vs. BatteriesDocument3 pagesSupercapacitors vs. Batteriesapic20No ratings yet

- Collision of Two Washington Metropolitan Area TransitDocument156 pagesCollision of Two Washington Metropolitan Area Transitapic20No ratings yet

- GMTT0111 Iss 1Document12 pagesGMTT0111 Iss 1apic20No ratings yet

- Electric and Hybrid Rail Technology - Railway Association of Canada Report Outlines Path Forward For Rail Decarbonization in CanadaDocument2 pagesElectric and Hybrid Rail Technology - Railway Association of Canada Report Outlines Path Forward For Rail Decarbonization in Canadaapic20No ratings yet

- GERT8016 Iss 1Document9 pagesGERT8016 Iss 1apic20No ratings yet

- Railway GuideDocument22 pagesRailway Guideapic20No ratings yet

- Safetymessage 2011 08 01 Dcmetrorailwaycollision VitsDocument6 pagesSafetymessage 2011 08 01 Dcmetrorailwaycollision Vitsapic20No ratings yet

- Docker CheatsheetDocument1 pageDocker Cheatsheetliang liuNo ratings yet

- Python Cheat Sheet April 2021Document26 pagesPython Cheat Sheet April 2021Rajesh Shinde100% (1)

- SR808ac User Manual 1.1Document42 pagesSR808ac User Manual 1.1apic20No ratings yet

- TV 20 2013 3 505 509 PDFDocument5 pagesTV 20 2013 3 505 509 PDFKunal SharmaNo ratings yet

- SECTION 34 21 18 Ac SwitchgearDocument15 pagesSECTION 34 21 18 Ac Switchgearapic20No ratings yet

- Implementation of Emtp Atp Software in The Study of Electromagnetic Transient PhenomenonDocument14 pagesImplementation of Emtp Atp Software in The Study of Electromagnetic Transient PhenomenonsoumyaNo ratings yet

- Modeling Short-Circuit Strength and System ReliabilityDocument24 pagesModeling Short-Circuit Strength and System Reliabilityapic20No ratings yet

- ESA Guideline - Approval - of - Equipment - v1.2Document37 pagesESA Guideline - Approval - of - Equipment - v1.2apic20No ratings yet

- Digital I/O For Raspberry Pi Selection Guide: Form 2208Document62 pagesDigital I/O For Raspberry Pi Selection Guide: Form 2208apic20No ratings yet

- Digital I/O For Raspberry Pi Starter Kit: FeaturesDocument6 pagesDigital I/O For Raspberry Pi Starter Kit: Featuresapic20No ratings yet

- Electrical GuideDocument36 pagesElectrical GuidecrazyshivaNo ratings yet

- Electrical GuideDocument36 pagesElectrical GuidecrazyshivaNo ratings yet

- SNAP D-Series Racks: FeaturesDocument9 pagesSNAP D-Series Racks: Featuresapic20No ratings yet

- Multilin F60: Grid SolutionsDocument9 pagesMultilin F60: Grid Solutionsapic20No ratings yet

- Modeling Short-Circuit Strength and System ReliabilityDocument24 pagesModeling Short-Circuit Strength and System Reliabilityapic20No ratings yet

- Molded Case Circuit BreakersDocument13 pagesMolded Case Circuit Breakersapic20No ratings yet

- Modeling Short-Circuit Strength and System ReliabilityDocument24 pagesModeling Short-Circuit Strength and System Reliabilityapic20No ratings yet

- TB6600 Stepper Motor Driver User Guide SEODocument11 pagesTB6600 Stepper Motor Driver User Guide SEOAnonymous gdJiDHNo ratings yet

- TB6600 User Guide V1.2Document11 pagesTB6600 User Guide V1.2apic20No ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Recent Advances in Electrical Engineering: Applications OrientedFrom EverandRecent Advances in Electrical Engineering: Applications OrientedNo ratings yet