Professional Documents

Culture Documents

CrosbyShackleLoadCapacityTable PDF

Uploaded by

ASKOKOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CrosbyShackleLoadCapacityTable PDF

Uploaded by

ASKOKOCopyright:

Available Formats

EngineeringSpreadsheets.co.

uk

The Website for Civil, Structural and Mechanical Engineers

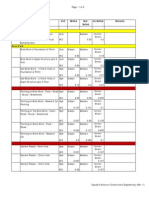

Technical Data Sheet :- Crosby Shackle Load Capacity Table Date :- 06.07.2004

CROSBY SHACKLE LOAD CAPACITY TABLE

Crosby Shackle, Bolt Type (US Fed Spec Type IVA, Class 3), G-2130 & S2130

G-2130 S-2130

Working Load Limit permanently shown on every shackle. Capacities 1/3 thro 150 metric tons.

Forged-Quenched and Tempered, with alloy pins.

Look for the Red Pinthe mark of genuine Crosby quality.

Shackles 55 metric tons and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV,

Lloyds or other certification

Shackles 85 metric tons and larger can be provided as follows

Non Destructive Tested

Serialised Pin and Bow

Material Certification (Chemical) certification must be requested at time of order.

Hot Dip Galvanised or Self Coloured

Fatigue rated

Nominal Working Stock No Weight Dimensions (mm)

Tolerance

Size Load Each +/-

(in.) Limit (kg)

(t)* G-2130 S-2130 A B C D E F H L N C A

3/16 1/3 1019464 --- 0.03 9.65 6.35 22.4 4.85 15.2 14.2 37.3 24.9 4.85 1.50 1.50

1/4 1/2 1019466 --- 0.05 11.9 7.85 28.7 6.35 19.8 15.5 46.7 32.5 6.35 1.50 1.50

5/16 3/4 1019468 --- 0.10 13.5 9.65 31.0 7.85 21.3 19.1 53.0 37.3 7.85 3.30 1.50

3/8 1 1019470 --- 0.15 16.8 11.2 36.6 9.65 26.2 23.1 63.0 45.2 9.65 3.30 1.50

7/16 1-1/2 1019471 --- 0.22 19.1 12.7 42.9 11.2 29.5 26.9 74.0 51.5 11.2 3.30 1.50

1/2 2 1019472 1019481 0.36 20.6 16.0 47.8 12.7 33.3 30.2 83.5 58.5 12.7 3.30 1.50

5/8 3-1/4 1019490 1019506 0.76 26.9 19.1 60.5 16.0 42.9 38.1 106 74.5 17.5 6.35 1.50

3/4 4-3/4 1019515 1019524 1.23 31.8 22.4 71.5 19.1 51.0 46.0 126 89.0 20.6 6.35 1.50

7/8 6-1/2 1019533 1019542 1.79 36.6 25.4 84.0 22.4 58.0 53.0 148 102 24.6 6.35 1.50

1 8-1/2 1019551 1019560 2.57 42.9 28.7 95.5 25.4 68.5 60.5 167 119 26.9 6.35 1.50

1-1/8 9-1/2 1019579 1019588 3.75 46.0 31.8 108 28.7 74.0 68.5 190 131 31.8 6.35 1.50

1-1/4 12 1019597 1019604 5.31 51.5 35.1 119 31.8 82.5 76.0 210 146 35.1 6.35 1.50

1-3/8 13-1/2 1019613 1019622 7.18 57.0 38.1 133 35.1 92.0 84.0 233 162 38.1 6.35 3.30

1-1/2 17 1019631 1019640 9.43 60.5 41.4 146 38.1 98.5 92.0 254 175 41.1 6.35 3.30

1-3/4 25 1019659 1019668 15.4 73.0 51.0 178 44.5 127 106 313 225 57.0 6.35 3.30

2 35 1019677 1019686 23.7 82.5 57.0 197 51.0 146 122 348 253 61.0 6.35 3.30

2-1/2 55 1019695 1019702 44.6 105 70.0 267 66.5 184 145 453 327 79.5 6.35 6.35

3 85 1019711 --- 70 127 82.5 330 76.0 200 165 546 365 92.0 6.35 6.35

3-1/2 120 1019739 --- 120 133 95.5 372 92.0 229 203 626 419 105 6.35 6.35

4 150 1019757 --- 153 140 108 368 104 254 229 653 468 116 6.35 6.35

Note : Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit.

Individually Proof Tested with certification

Furnished in Anchor style only and furnished with Round Head Bolts with welded handles.

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- IHGStandards-IHG Technical SpecificationsDocument36 pagesIHGStandards-IHG Technical Specificationsatlcomputech100% (2)

- Labour Productivity NormsDocument3 pagesLabour Productivity NormsSharad Kumar71% (7)

- Safe Working Load Calculation For Round BarDocument1 pageSafe Working Load Calculation For Round BarAdura OgunnuNo ratings yet

- N042049-0001 BoltTorque HDocument2 pagesN042049-0001 BoltTorque HP Sandana NaraNo ratings yet

- Fingerstyle Guitar - Fingerpicking Patterns and ExercisesDocument42 pagesFingerstyle Guitar - Fingerpicking Patterns and ExercisesSeminario Lipa100% (6)

- Period Based Accounting Versus Cost of Sales AccountingDocument13 pagesPeriod Based Accounting Versus Cost of Sales AccountingAnil Kumar100% (1)

- Electrical Design Checklist v1.2Document39 pagesElectrical Design Checklist v1.2huangjlNo ratings yet

- World Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.Document11 pagesWorld Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.:Lawiy-Zodok:Shamu:-El50% (2)

- Manilhas Crosby G2130Document1 pageManilhas Crosby G2130Álamo NatividadeNo ratings yet

- Crosby ShacklesDocument12 pagesCrosby Shacklesj_herndzNo ratings yet

- 4 EyeBolts-HoistRings-LiftingSlings - US PricingDocument5 pages4 EyeBolts-HoistRings-LiftingSlings - US PricingJohn MuellerNo ratings yet

- Padeye Calculation For Anchor Block R0 20140722Document3 pagesPadeye Calculation For Anchor Block R0 20140722subucwiNo ratings yet

- Tank Lifting Design PDFDocument47 pagesTank Lifting Design PDFDavid PuenNo ratings yet

- 1.3 - Tubular Member Design ConsiderationsDocument27 pages1.3 - Tubular Member Design ConsiderationsDanNo ratings yet

- Bolts,: Threaded Parts TensionDocument2 pagesBolts,: Threaded Parts TensionMary MarasiganNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Lifting A Pressure Vessel With Two Main Lift Cranes and One Tail CraneDocument12 pagesLifting A Pressure Vessel With Two Main Lift Cranes and One Tail Cranezeusvares100% (1)

- Jib Cranes 20875644 Colour CatalogueDocument30 pagesJib Cranes 20875644 Colour Cataloguepsingh1996No ratings yet

- Tail Lifting Lug Calculation MS WordDocument11 pagesTail Lifting Lug Calculation MS WordWijayanto BekasiNo ratings yet

- Lifting Eye DesignDocument1 pageLifting Eye DesignFabio Okamoto0% (1)

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Lug Design R4, ASME BTH-1Document4 pagesLug Design R4, ASME BTH-1chuckhsu1248No ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Pad Eye Design CalculationDocument7 pagesPad Eye Design CalculationLưu Xuân0% (1)

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocument3 pages8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNo ratings yet

- Lifting Lug Calculation Rev - 1Document2 pagesLifting Lug Calculation Rev - 1WijayantoNo ratings yet

- Lifting Lug Calculation-1Document1 pageLifting Lug Calculation-1dtgpand100% (4)

- 1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Document25 pages1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Aditya Jain100% (2)

- Lift & Tail CalcsDocument3 pagesLift & Tail Calcsnazeer_mohdNo ratings yet

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Document7 pagesLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonNo ratings yet

- Clamped Cover Plate DesignDocument7 pagesClamped Cover Plate DesignChiedu OkonduNo ratings yet

- Lifting Lug DesignDocument4 pagesLifting Lug DesignRohith V VNo ratings yet

- Hydraulic Torque WrenchDocument16 pagesHydraulic Torque WrenchMr. S.L. AdvaniNo ratings yet

- Spreader Bar With LugsDocument15 pagesSpreader Bar With LugsvamsiNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Lifting Trunnion Calculations SampleDocument10 pagesLifting Trunnion Calculations SampleshazanNo ratings yet

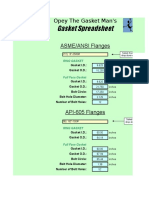

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)ama100% (1)

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- 750mm X-Beam CalculationDocument13 pages750mm X-Beam CalculationapollocradlesNo ratings yet

- Gunnebo Lifting Shackle Catalogue 2010Document16 pagesGunnebo Lifting Shackle Catalogue 2010ofitec787No ratings yet

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahNo ratings yet

- Design Lifting Beam (80 MT)Document10 pagesDesign Lifting Beam (80 MT)hardeep SinghNo ratings yet

- Calculation Rigging PlanDocument1 pageCalculation Rigging PlancahyaNo ratings yet

- Blind Flange CalculationDocument12 pagesBlind Flange CalculationrajarajanNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationhuangjlNo ratings yet

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Calculation Lifting LugDocument4 pagesCalculation Lifting Lugelang purbayaNo ratings yet

- Trunnion & Tailing Lug DesignDocument25 pagesTrunnion & Tailing Lug Designvpjagannaath100% (2)

- Calculation For Sight Glass FlangeDocument4 pagesCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- Weld Stress CalculationsDocument8 pagesWeld Stress CalculationsMoezet AungNo ratings yet

- Design Procedure of A Wire RopeDocument1 pageDesign Procedure of A Wire RopeKutty Aravind100% (3)

- FEA Check List For Expansion BellowDocument3 pagesFEA Check List For Expansion BellowRyan FisherNo ratings yet

- Is-5372-Taper Washer For ChannelDocument2 pagesIs-5372-Taper Washer For ChannelSurendra Kumar ChordiaNo ratings yet

- Fe Report of Base SkidDocument16 pagesFe Report of Base SkidpawanNo ratings yet

- MonorailDocument6 pagesMonorailrosemaryhere8649100% (1)

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsAwais Hameed100% (1)

- Pad Eye FailureDocument1 pagePad Eye FailuremalawanyNo ratings yet

- Shackles: 5150 - Nut & Bolt Bow ShackleDocument1 pageShackles: 5150 - Nut & Bolt Bow ShackleAlthaf R100% (1)

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionNicoleta cristianNo ratings yet

- Crosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150Document2 pagesCrosby Bolt-Type Shackles: Bolt Type Anchor Shackle G-2130 S-2130 Bolt Type Chain Shackle G-2150 S-2150gdgfdNo ratings yet

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1No ratings yet

- Crosby G-2140 Alloy Shackle Product SheetDocument1 pageCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13No ratings yet

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain Shacklesfcesar1986No ratings yet

- Crosby Hoist RingsDocument12 pagesCrosby Hoist Ringssany12No ratings yet

- G-209 / S-209 Screw Pin Anchor ShacklesDocument1 pageG-209 / S-209 Screw Pin Anchor Shacklesaizzi1989No ratings yet

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- Proposal and Questionnaire For Contractor'sDocument6 pagesProposal and Questionnaire For Contractor'sVisas SivaNo ratings yet

- 7 - SBI BC ManualDocument24 pages7 - SBI BC ManualVisas SivaNo ratings yet

- PliDocument2 pagesPliVisas SivaNo ratings yet

- Proposal For Standard Fire & Special Perils PolicyDocument6 pagesProposal For Standard Fire & Special Perils PolicyVisas SivaNo ratings yet

- 5-Project Summary and Description TemplateDocument23 pages5-Project Summary and Description TemplateVisas SivaNo ratings yet

- Proposal and Questionnaire For Erection All Risks/Marine-Cum-Erection InsuranceDocument5 pagesProposal and Questionnaire For Erection All Risks/Marine-Cum-Erection InsuranceVisas SivaNo ratings yet

- Carbon Steel Storage TanksDocument1 pageCarbon Steel Storage TanksVisas SivaNo ratings yet

- Proposal For Contractor'S Plant & Machinery InsuranceDocument5 pagesProposal For Contractor'S Plant & Machinery InsuranceVisas SivaNo ratings yet

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Level of Schedule in PlanningDocument5 pagesLevel of Schedule in PlanningVisas SivaNo ratings yet

- S.no Emplyoee Name Dept. Bank Name Bank A/c No. Working Days BasicDocument7 pagesS.no Emplyoee Name Dept. Bank Name Bank A/c No. Working Days BasicVisas SivaNo ratings yet

- Lift PlanDocument1 pageLift PlanVisas SivaNo ratings yet

- CP MM Project ScheduleDocument1 pageCP MM Project ScheduleVisas SivaNo ratings yet

- The Project Summary Is Limited To 250 WordsDocument1 pageThe Project Summary Is Limited To 250 WordsVisas SivaNo ratings yet

- IMCA9Document3 pagesIMCA9Visas SivaNo ratings yet

- Asset Register FormDocument8 pagesAsset Register FormVisas SivaNo ratings yet

- Project Schedule / Activity / Task List - Progress Tracking: Place Project Name HereDocument2 pagesProject Schedule / Activity / Task List - Progress Tracking: Place Project Name Heresurender78No ratings yet

- Spherical Pillow Block Manual (MN3085, 2018)Document13 pagesSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeNo ratings yet

- Kota StationDocument5 pagesKota StationshashankjeeNo ratings yet

- Series: 25 TON (222 KN)Document2 pagesSeries: 25 TON (222 KN)Marius IlcaNo ratings yet

- MBR Presentation LatestDocument12 pagesMBR Presentation LatestRuchi GuptaNo ratings yet

- Sangfor NGAF Introduction 8.0.5 FinalDocument24 pagesSangfor NGAF Introduction 8.0.5 FinalAlbarn Paul AlicanteNo ratings yet

- Database Testing: Prepared by Sujaritha MDocument21 pagesDatabase Testing: Prepared by Sujaritha Mavumaa22No ratings yet

- CE ThesisDocument210 pagesCE ThesisKristin ArgosinoNo ratings yet

- IRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakesDocument4 pagesIRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakessaidNo ratings yet

- Sony NX Series PDFDocument62 pagesSony NX Series PDFMaya Tes0% (1)

- How02 - Z11 - Mec503 - C01 - Oss Piping Matr Class SpecDocument31 pagesHow02 - Z11 - Mec503 - C01 - Oss Piping Matr Class Speckristian100% (1)

- DIN 3900 1984 04 Compression CouplingsDocument3 pagesDIN 3900 1984 04 Compression Couplingsjangaswathi0% (1)

- Gardenia RedddDocument44 pagesGardenia RedddYasmin Yvonne De Chavez100% (1)

- Digital Booklet - Oh My My (Deluxe) PDFDocument8 pagesDigital Booklet - Oh My My (Deluxe) PDFMehmet Akif DelibaşNo ratings yet

- RFCC KBR FeaturesDocument24 pagesRFCC KBR FeaturesKannanGK100% (1)

- SMAC CA12 BrochureDocument2 pagesSMAC CA12 BrochureElectromateNo ratings yet

- Building Information Modeling BIM Systems and TheiDocument13 pagesBuilding Information Modeling BIM Systems and Theipurvakul10No ratings yet

- Using Spreadsheets For Steel DesignDocument4 pagesUsing Spreadsheets For Steel DesignAmro Ahmad AliNo ratings yet

- Life-Saving Rules: Tool Box Talk SeriesDocument86 pagesLife-Saving Rules: Tool Box Talk SeriesSalahBouzianeNo ratings yet

- GCCDocument265 pagesGCCzhenguoliNo ratings yet

- Arni AdvertisementDocument2 pagesArni AdvertisementHemanthNo ratings yet

- OC Thin Shell Panels SCREENDocument19 pagesOC Thin Shell Panels SCREENKushaal VirdiNo ratings yet

- kp-57-65wv600 SONYDocument33 pageskp-57-65wv600 SONYdjcamdtvNo ratings yet

- 9A01304 Fluid MechanicsDocument4 pages9A01304 Fluid MechanicssivabharathamurthyNo ratings yet

- CNC Grinding Notching and Marking Machine: AT 710 ENDocument2 pagesCNC Grinding Notching and Marking Machine: AT 710 ENsmarjanNo ratings yet

- Xpulse200t Manual de PartesDocument92 pagesXpulse200t Manual de PartesAthiq Nehman100% (2)