Professional Documents

Culture Documents

Technical Details - 63 37 Common Brass

Technical Details - 63 37 Common Brass

Uploaded by

Anas Memon0 ratings0% found this document useful (0 votes)

4 views1 pageOriginal Title

Technical Details - 63 37 Common Brass.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageTechnical Details - 63 37 Common Brass

Technical Details - 63 37 Common Brass

Uploaded by

Anas MemonCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

63/37 Brass which is also known as Common Brass and Yellow Brass.

63/37 Brasses are copper zinc alloys with a

wide range of engineering uses. The addition of zinc to copper raises the strength and gives a range of properties,

and the brasses are a very versatile range of materials. They are used for their strength, corrosion resistance,

appearance and colour, and ease of working and joining. The single phase alpha brasses, containing up to about

37% zinc, are very ductile and easy to cold work, weld and braze. The dual phase alpha-beta brasses are usually

hot worked.

Brasses are resistant to corrosion in many media.

63/37 Brass is widely used in Radiator Tanks and Cores, Flashlight Shells, Lamp Fixtures, Fastenerslocks, Hinges,

Pins, Rivets, Buttons, Plumbing Accessories.

Chemical Composition Of Brass :

Material Normal Composition Nearest Relevant Composition Specification

Cu Zn 37 H 3100

63/37 Yellow Brass 63% Cu, 37% Zn CZ108

426/1 C 3560

MECHANICAL PROPERTIES AS PER : B.S. : 2870 :

Tensile Elongation Vickers

Material Temper Strength % on 50 Hardness ISO

JIS

N/mm2 mm G.L. VPN

AnnealedCondition(

'O') 280 Min 40 Min 80 Max

63/37 Cu Zn

Quarter Hard 340 Min 30 Min 75 Min JIS 3100

Yellow 37ISO:426/

(1/4H) 385 Min 15 Min 110 Min C 3560

Brass 1

Half Hard (1/2H) 460 Min 5 Min 135 Min

Hard (H)

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Corten A Steel Weather Resistant Steel PDFDocument8 pagesCorten A Steel Weather Resistant Steel PDFadihindNo ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- BS 4360 50eeDocument1 pageBS 4360 50eeTimNo ratings yet

- Standards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostDocument3 pagesStandards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostKhaled GamalNo ratings yet

- Magmaweld - E7018 Data SheetDocument3 pagesMagmaweld - E7018 Data Sheetnenozx.zedanNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- En GJS 500 7CDocument1 pageEn GJS 500 7CMatias OnateNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Sae J 403-Aisi 1042 1045 - ForminDocument2 pagesSae J 403-Aisi 1042 1045 - ForminKenvi AlarconNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- BS 970 070 M46Document2 pagesBS 970 070 M46Dinesh GaikwadNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_917790% (10)

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- UTP 306 PaDocument1 pageUTP 306 PaVIRPOPNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- 02112015000000B - Boehler FOX CM 5 KB - CeDocument1 page02112015000000B - Boehler FOX CM 5 KB - CejaroNo ratings yet

- Development of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsDocument6 pagesDevelopment of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsKK SinghNo ratings yet

- TIG Bohler S EMK 6 ER70S 6Document1 pageTIG Bohler S EMK 6 ER70S 6mohamedNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocument3 pagesStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Electrical Properties of Lead Solder AlloyDocument9 pagesElectrical Properties of Lead Solder AlloyVedant PrustyNo ratings yet

- Global Marketing For Tube & PipeDocument4 pagesGlobal Marketing For Tube & PipedsyashankaNo ratings yet

- Technical Data Sheet: Additional Solder Alloys Manufactured by Nathan Trotter Chemical Specifications Physical PropertiesDocument2 pagesTechnical Data Sheet: Additional Solder Alloys Manufactured by Nathan Trotter Chemical Specifications Physical PropertiesGossai HanafiNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Stainless Steel Grade AISI 430/430FDocument2 pagesStainless Steel Grade AISI 430/430Fabhijit.ghotane100% (1)

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- Bolts and Nuts Stainless SteelDocument2 pagesBolts and Nuts Stainless SteelfedemochileroNo ratings yet

- Chemical Composition of Solid Wire, WT.%:: C: AWS SFA 5.18 W P ER70S-2 H, F, Vu, Oh CDocument1 pageChemical Composition of Solid Wire, WT.%:: C: AWS SFA 5.18 W P ER70S-2 H, F, Vu, Oh CAshok RajNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- KST 316LDocument1 pageKST 316LtrueavatharNo ratings yet

- AISI Alloy 4130 Steel Supply Range& 4140Document6 pagesAISI Alloy 4130 Steel Supply Range& 4140ap taNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- Böhler Fox Skwa: Classifi CationsDocument1 pageBöhler Fox Skwa: Classifi CationsBranko FerenčakNo ratings yet

- Gould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Document2 pagesGould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Gourav SharmaNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Citoflux r82 SR (T 46 6 Ni1 P M 1 h5)Document1 pageCitoflux r82 SR (T 46 6 Ni1 P M 1 h5)brunizzaNo ratings yet

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocument1 page03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNo ratings yet

- Avesta 316L-SKRDocument1 pageAvesta 316L-SKRIuliu HurducaciNo ratings yet

- Certificado Tee sch40Document1 pageCertificado Tee sch40benedicto soto mestanzaNo ratings yet

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocument1 pageAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocument1 pageBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977No ratings yet

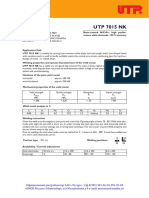

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- Carpenter Stainless Type 430: IdentificationDocument4 pagesCarpenter Stainless Type 430: Identificationumesh sengarNo ratings yet

- High Speed Steel Round BarDocument4 pagesHigh Speed Steel Round BarMANJEET KUMARNo ratings yet

- Tenax 88s HR (E 50 6 Mn1ni B 32 h5)Document1 pageTenax 88s HR (E 50 6 Mn1ni B 32 h5)brunizzaNo ratings yet

- Op 87 (Sa Cs 2 99 CR Ac)Document2 pagesOp 87 (Sa Cs 2 99 CR Ac)brunizzaNo ratings yet

- Garde CorpsDocument2 pagesGarde Corpsattiori fabriceNo ratings yet

- Böhler Fox Dcms KB: Classifi CationsDocument1 pageBöhler Fox Dcms KB: Classifi CationsBranko FerenčakNo ratings yet

- Specification For Battery and Battery Charger (Tripping Unit) For 11Kv Indoor Switchgear OfferedDocument1 pageSpecification For Battery and Battery Charger (Tripping Unit) For 11Kv Indoor Switchgear OfferedAnas MemonNo ratings yet

- Maintenance: Battery Test Cleaning Storage Battery Maintenance and Disposal/ Recycling of BatteriesDocument2 pagesMaintenance: Battery Test Cleaning Storage Battery Maintenance and Disposal/ Recycling of BatteriesAnas MemonNo ratings yet

- Bussman BS Type Fuse HoldersDocument2 pagesBussman BS Type Fuse HoldersAnas MemonNo ratings yet

- Qasida Burdha Sharif قصيدة البُردةDocument37 pagesQasida Burdha Sharif قصيدة البُردةQaisar93% (28)

- Central Lighting InverterDocument1 pageCentral Lighting InverterAnas MemonNo ratings yet

- Standard Voltage As Per IECDocument2 pagesStandard Voltage As Per IECAnas MemonNo ratings yet

- Siemens Pricelist 1 ST Nov 10 IndiaDocument144 pagesSiemens Pricelist 1 ST Nov 10 IndiaAnas MemonNo ratings yet

- Short Circuit CalculationDocument42 pagesShort Circuit Calculationgraduadoesime100% (17)

- 3 Phase Short Circuit CalculationDocument7 pages3 Phase Short Circuit Calculationcherif yahyaouiNo ratings yet