Professional Documents

Culture Documents

35p PDF

Uploaded by

Raunak Timilsina0 ratings0% found this document useful (0 votes)

19 views2 pagesOriginal Title

35p (1).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pages35p PDF

Uploaded by

Raunak TimilsinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

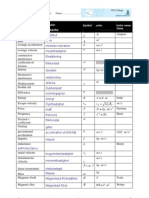

CIP 35 - Testing Compressive Strength of Concrete

WHAT is the Compressive Strength of Concrete?

Concrete mixtures can be designed to provide a wide range

of mechanical and durability properties to meet the design

requirements of a structure. The compressive strength of

concrete is the most common performance measure used by

the engineer in designing buildings and other structures.

The compressive strength is measured by breaking cylin-

drical concrete specimens in a compression-testing machine.

The compressive strength is calculated from the failure load

divided by the cross-sectional area resisting the load and

reported in units of pound-force per square inch (psi) in US

Customary units or megapascals (MPa) in SI units. Con-

crete compressive strength requirements can vary from 2500

psi (17 MPa) for residential concrete to 4000 psi (28 MPa)

and higher in commercial structures. Higher strengths up to

and exceeding 10,000 psi (70 MPa) are specified for certain

applications.

WHY is Compressive Strength Determined?

Compressive strength test results are primarily used to Fractured Test Specimen at Failure

determine that the concrete mixture as delivered meets the

requirements of the specified strength, c, in the job with the strength specification is minimized. To comply with

specification. the strength requirements of a job specification both the

Strength test results from cast cylinders may be used for following acceptance criteria apply:

quality control, acceptance of concrete, or for estimating The average of 3 consecutive tests should equal or

the concrete strength in a structure for the purpose of exceed the specified strength, c

scheduling construction operations such as form removal No single strength test should fall below c by more

or for evaluating the adequacy of curing and protection than 500 psi (3.45 MPa); or by more than 0.10 c when

afforded to the structure. Cylinders tested for acceptance c is more than 5000 psi (35 MPa)

and quality control are made and cured in accordance with It is important to understand that an individual test falling

procedures described for standard-cured specimens in below c does not necessarily constitute a failure to meet

ASTM C 31 Standard Practice for Making and Curing specification requirements. When the average of strength

Concrete Test Specimens in the Field. For estimating the in- tests on a job are at the required average strength, cr, the

place concrete strength, ASTM C 31 provides procedures probability that individual strength tests will be less than

for field-cured specimens. Cylindrical specimens are tested the specified strength is about 10% and this is accounted

in accordance with ASTM C 39, Standard Test Method for for in the acceptance criteria.

Compressive Strength of Cylindrical Concrete Specimens. When strength test results indicate that the concrete

A test result is the average of at least two standard-cured delivered fails to meet the requirements of the specification,

strength specimens made from the same concrete sample it is important to recognize that the failure may be in the

and tested at the same age. In most cases strength testing, not the concrete. This is especially true if the

requirements for concrete are at an age of 28 days. fabrication, handling, curing and testing of the cylinders are

Design engineers us the specified strength c to design not conducted in accordance with standard procedures. See

structural elements. This specified strength is incorporated CIP 9, Low Concrete Cylinder Strength.

in the job contract documents. The concrete mixture is Historical strength test records are used by the concrete

designed to produce an average strength, cr, higher than producer to establish the target average strength of concrete

the specified strength such that the risk of not complying mixtures for future work.

Most deviations from standard procedures for making,

HOW to Test the Strength of Concrete? curing and testing concrete test specimens will result in a

Cylindrical specimens for acceptance testing should be 6 lower measured strength.

x 12 inch (150 x 300 mm) size or 4 x 8 inch (100 x 200 mm) The range between companion cylinders from the same

when specified. The smaller specimens tend to be easier set and tested at the same age should be, on average,

to make and handle in the field and the laboratory. The about 2 to 3% of the average strength. If the difference

diameter of the cylinder used should be at least 3 times between two companion cylinders exceeds 8% too often,

the nominal maximum size of the coarse aggregate used or 9.5% for three companion cylinders, the testing

in the concrete. procedures at the laboratory should be evaluated and

Recording the mass of the specimen before capping rectified.

provides useful information in case of disputes. Results of tests made by different labs on the same

To provide for a uniform load distribution when testing, concrete sample should not differ by more than about

cylinders are capped generally with sulfur mortar (ASTM 13% of the average of the two test results.

C 617) or neoprene pad caps (ASTM C 1231). Sulfur caps If one or both of a set of cylinders break at strength below

should be applied at least two hours and preferably one c, evaluate the cylinders for obvious problems and hold

day before testing. Neoprene pad caps can be used to the tested cylinders for later examination. Frequently the

measure concrete strengths between 1500 and 7000 psi cause of a failed test can be readily seen in the cylinder,

(10 to 50 MPa). For higher strengths upto 12,000 psi, either immediately or by petrographic examination. If it is

neoprene pad caps are permitted to be used if they are thrown away an easy opportunity to correct the problem

qualified by companion testing with sulfur caps. may be lost. In some cases additional reserve cylinders

Durometer hardness requirements for neoprene pads vary are made and can be tested if one cylinder of a set broke

from 50 to 70 depending on the strength level tested. at a lower strength.

Pads should be replaced if there is excessive wear. A 3 or 7-day test may help detect potential problems

Cylinders should not be allowed to dry out prior to with concrete quality or testing procedures at the lab but

testing. is not a basis for rejecting concrete, with a requirement

The cylinder diameter should be measured in two for 28-day or other age strength.

locations at right angles to each other at mid-height of ASTM C 1077 requires that laboratory technicians

the specimen and averaged to calculate the cross- involved in testing concrete must be certified.

sectional area. If the two measured diameters differ by Reports of compressive strength tests provide valuable

more than 2%, the cylinder should not be tested. information to the project team for the current and future

The ends of the specimens should not depart from projects. The reports should be forwarded to the concrete

perpendicularity with the cylinder axis by more than 0.5 producer, contractor and the owners representative as

and the ends should be plane to within 0.002 inches (0.05 expeditiously as possible.

mm).

Cylinders should be centered in the compression-testing

References

1. ASTM C 31, C 39, C 617, C 1077, C 1231, Annual Book of

machine and loaded to complete failure. The loading rate ASTM Standards, Volume 04.02, ASTM, West Conshohocken,

on a hydraulic machine should be maintained in a range PA, www.astm.org

of 20 to 50 psi/s (0.15 to 0.35 MPa/s) during the latter half 2. Concrete in Practice Series, NRMCA, Silver Spring, MD,

of the loading phase. The type of break should be www.nrmca.org

recorded. A common break pattern is a conical fracture 3. In-Place Strength Evaluation - A Recommended Practice,

(see figure). NRMCA Publication 133, NRMCA RES Committee,

The concrete strength is calculated by dividing the NRMCA, Silver Spring, MD

maximum load at failure by the average cross-sectional 4. How producers can correct improper test-cylinder curing, Ward

area. C 39 has correction factors if the length-to-diameter R. Malisch, Concrete Producer Magazine, November 1997,

ratio of the cylinder is between 1.75 and 1.00, which is www.worldofconcrete.com

rare. At least two cylinders are tested at the same age and 5. NRMCA/ASCC Checklist for Concrete Pre-Construction

the average strength is reported as the test result to the Conference, NRMCA, Silver Spring, MD

nearest 10 psi (0.1 MPa) 6. Review of Variables That Influence Measured Concrete

Compressive Strength, David N. Richardson, NRMCA

The technician carrying out the test should record the

Publication 179, NRMCA, Silver Spring, MD

date they were received at the lab, the test date, specimen

7. Tips on Control Tests for Quality Concrete, PA015, Portland

identification, cylinder diameter, test age, maximum load Cement Association, Skokie, IL, www.cement.org

applied, compressive strength, type of fracture, and any

8. ACI 214, Recommended Practice for Evaluation of Strength

defects in the cylinders or caps. If measured, the mass of Tests Results of Concrete, American Concrete Institute,

the cylinders should also be noted. Farmington Hills, MI, www.concrete.org

2003

You might also like

- Flexural Strength of ConcreteDocument3 pagesFlexural Strength of ConcretevikasNo ratings yet

- CIP9 - Low Concrete Cylinder StrengthDocument2 pagesCIP9 - Low Concrete Cylinder StrengthVodanh TieutotNo ratings yet

- Concrete TestingDocument32 pagesConcrete TestingAveesh singh100% (1)

- Flexural Strength of ConcreteDocument2 pagesFlexural Strength of ConcreteVenkataLakshmiKorrapatiNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Astm C-42Document8 pagesAstm C-42thescubatater100% (3)

- Rebound Number of Hardened Concrete: Standard Test Method ForDocument3 pagesRebound Number of Hardened Concrete: Standard Test Method ForSNOWTOOSNo ratings yet

- Proper Use of The Rebound HammerDocument5 pagesProper Use of The Rebound HammerJan BooysenNo ratings yet

- Scanning Electron MicrosDocument140 pagesScanning Electron Microsmuffindidi50% (2)

- CIP16 - Flexural Strength of ConcreteDocument2 pagesCIP16 - Flexural Strength of ConcretePECMURUGANNo ratings yet

- Boiler Operation & ControlDocument56 pagesBoiler Operation & ControlMohammad Rawoof100% (2)

- Testing Concrete CoresDocument7 pagesTesting Concrete CoresvigneshwarimahamuniNo ratings yet

- How To Apply Boundary Condition For Supports and BearingsDocument10 pagesHow To Apply Boundary Condition For Supports and Bearingsamritha1790No ratings yet

- Concrete CubesDocument5 pagesConcrete CubesDipti Ranjan Swain100% (1)

- Physics A and B Formula SheetDocument14 pagesPhysics A and B Formula SheetEpic WinNo ratings yet

- Geometric Aspects of Mapping Reference SurfacesDocument17 pagesGeometric Aspects of Mapping Reference SurfacesparagjduttaNo ratings yet

- Concrete Core TestDocument5 pagesConcrete Core Testtaruc jose royNo ratings yet

- Hoist - Lifting Screw JackDocument10 pagesHoist - Lifting Screw JackAh Leng LauNo ratings yet

- Proper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Document6 pagesProper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Niroshan PereraNo ratings yet

- Rebound Hammer TestDocument12 pagesRebound Hammer Testmahmood hunar100% (4)

- Is Iso 8655 7 2005Document30 pagesIs Iso 8655 7 2005Rômulo LeãoNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument2 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixPritha DasNo ratings yet

- Astm C-1231Document5 pagesAstm C-1231Sebastian TobonNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument7 pagesCIP 35 - Testing Compressive Strength of ConcretesudhakarmnNo ratings yet

- Core Testing - Site MixDocument13 pagesCore Testing - Site MixvempadareddyNo ratings yet

- TN 39 - Testing For Engineered Brick Masonry-Brick and Mortar - 2001 PDFDocument8 pagesTN 39 - Testing For Engineered Brick Masonry-Brick and Mortar - 2001 PDFAnonymous PjmE9RJcghNo ratings yet

- Split Tensile Strength of ConcreteDocument9 pagesSplit Tensile Strength of Concreteabhineet srivastavaNo ratings yet

- Testing Compressive Strength of Concrete PDFDocument2 pagesTesting Compressive Strength of Concrete PDFaaNo ratings yet

- Symbols Note TakingDocument13 pagesSymbols Note TakingNatasha MillsNo ratings yet

- Astm C 805 - C 805m enDocument3 pagesAstm C 805 - C 805m enBayron Medina OspinaNo ratings yet

- Mic125 Laboratory Report Lab 2Document14 pagesMic125 Laboratory Report Lab 2aisyah fauzi100% (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument4 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready Mixdhan singhNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- CIP 16 - Flexural Strength of ConcreteDocument2 pagesCIP 16 - Flexural Strength of ConcreteEkinawa AwanikeNo ratings yet

- Flexural StrengthDocument2 pagesFlexural StrengthMrcoke SeieNo ratings yet

- Compressive Strength of Concrete & Concrete Cubes - What - How - CivilDigitalDocument13 pagesCompressive Strength of Concrete & Concrete Cubes - What - How - CivilDigitalArdhi TaNo ratings yet

- Breaks Evaluation CIP09pDocument2 pagesBreaks Evaluation CIP09pgemotorresNo ratings yet

- What Is The Biggest Problem With Concrete Core TestingDocument2 pagesWhat Is The Biggest Problem With Concrete Core TestingLim Lip BoonNo ratings yet

- Proper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0Document3 pagesProper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0abebechNo ratings yet

- 3.Sdcs Materials 2Document57 pages3.Sdcs Materials 2NH PNo ratings yet

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- What To Do When Cylinder Breaks Are LowDocument3 pagesWhat To Do When Cylinder Breaks Are LowRommel Villaroman EstevesNo ratings yet

- CIP16-Flexural Strenght of ConcreteDocument2 pagesCIP16-Flexural Strenght of Concrete7774R105No ratings yet

- Shrinkage TestDocument4 pagesShrinkage TestJustin SeanNo ratings yet

- Strength Od In-Place ConcreteDocument2 pagesStrength Od In-Place ConcreteaaNo ratings yet

- CI4508 Concrete QADocument2 pagesCI4508 Concrete QAEng.Ahmad AbuFaraNo ratings yet

- Rebound Hammer Test PDFDocument6 pagesRebound Hammer Test PDFjayaram miryalaNo ratings yet

- PARTIALLY DESTRUCTIVE TESTS and NON DESTRUCTIVE TESTINGDocument4 pagesPARTIALLY DESTRUCTIVE TESTS and NON DESTRUCTIVE TESTINGAfzal Waseem100% (1)

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDocument0 pagesSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNo ratings yet

- Unconfined Compressive Strength Index of Chemical-Grouted SoilsDocument3 pagesUnconfined Compressive Strength Index of Chemical-Grouted SoilsninaNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerPradeep PokhrelNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerRajesh KumarNo ratings yet

- 5.4) Job Procedure - Concrete Core CuttingDocument6 pages5.4) Job Procedure - Concrete Core CuttingDeepak Kumar MallickNo ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument6 pagesNon-Destructive Testing of Concrete by Rebound HammerPoirei ZildjianNo ratings yet

- Atm Concrete Mix RgiesselDocument34 pagesAtm Concrete Mix RgiesselMaroof imadNo ratings yet

- Attachment - 1 - SOP On Core Sample TestingDocument7 pagesAttachment - 1 - SOP On Core Sample TestingNVLNNAGENo ratings yet

- Rebound Hammer TestDocument7 pagesRebound Hammer TestHaider AliNo ratings yet

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument4 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersYENCEINo ratings yet

- Astm C39 C39M-16Document7 pagesAstm C39 C39M-16Yao Leslie Armande MélissaNo ratings yet

- Cmat Unit 1 4Document6 pagesCmat Unit 1 4Merle MañgaliNo ratings yet

- Non-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Document11 pagesNon-Destructive Testing of Concrete-Methodology of Test (Rebound Hammer)Pradeep PokhrelNo ratings yet

- ASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Document3 pagesASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Pablo Antonio Valcárcel VargasNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Mechanical Analysis of Extracted Aggregate: Standard Method of Test ForDocument2 pagesMechanical Analysis of Extracted Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- Vceasy Visual Chemistry 34 Student Booklet v1 PDFDocument39 pagesVceasy Visual Chemistry 34 Student Booklet v1 PDFJames WongNo ratings yet

- Torsion: Torsion - Introduction To Problems in Which The Stress Is Not Uniform, or Assumed To BeDocument6 pagesTorsion: Torsion - Introduction To Problems in Which The Stress Is Not Uniform, or Assumed To BeChristine Mae TinapayNo ratings yet

- BR1601 0405 RevDocument12 pagesBR1601 0405 Revmohdazlan hassanNo ratings yet

- MeanderDocument10 pagesMeanderDavid MattNo ratings yet

- 1SPACEDocument13 pages1SPACERamy Abd Elkhalek ShahinNo ratings yet

- Practice Sheet INTEGRATION SolutionDocument12 pagesPractice Sheet INTEGRATION SolutionDR. CARIBOUNo ratings yet

- FoamDocument23 pagesFoamSam JoseNo ratings yet

- Aesthetics of Building MaterialsDocument2 pagesAesthetics of Building MaterialsShubham Dua0% (1)

- Perrustol Mmu New: Rudolf Atul Chemicals LimitedDocument2 pagesPerrustol Mmu New: Rudolf Atul Chemicals LimitedShripadNo ratings yet

- Microbial Fuel Cell: Genrating Electricity From BacteriaDocument20 pagesMicrobial Fuel Cell: Genrating Electricity From BacteriaPranavChendur100% (1)

- Sample Lesson Plans in ScienceDocument66 pagesSample Lesson Plans in ScienceMitchel BibarNo ratings yet

- Module 1.0 The Nature of MathematicsDocument44 pagesModule 1.0 The Nature of MathematicsRYAN ALEXANDER HUGONo ratings yet

- EG1020 Gear Drive HelpDocument4 pagesEG1020 Gear Drive Helptimbs2004No ratings yet

- Quiz 1 SolutionDocument4 pagesQuiz 1 Solutionrahul84803No ratings yet

- International Journal of Heat and Mass Transfer: V. Dharma Rao, V. Murali Krishna, K.V. Sharma, P.V.J. Mohana RaoDocument12 pagesInternational Journal of Heat and Mass Transfer: V. Dharma Rao, V. Murali Krishna, K.V. Sharma, P.V.J. Mohana Raoait hssainNo ratings yet

- New Resampling Algorithm For Particle Filter Localization For Mobile Robot With 3 Ultrasonic Sonar SensorDocument6 pagesNew Resampling Algorithm For Particle Filter Localization For Mobile Robot With 3 Ultrasonic Sonar SensorWidyawardana AdiprawitaNo ratings yet

- Chemical Composition of CementDocument17 pagesChemical Composition of Cement929 John MathewNo ratings yet

- Ralf Mouthaan - Holographic Control of Light Propagation in Optical WaveguidesDocument230 pagesRalf Mouthaan - Holographic Control of Light Propagation in Optical WaveguidesdgNo ratings yet

- Escaner de TunelesDocument2 pagesEscaner de TunelesDiana CristinaNo ratings yet