Professional Documents

Culture Documents

175 000003

Uploaded by

zhang0 ratings0% found this document useful (0 votes)

449 views1 pageinspection test list

Original Title

175-000003

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinspection test list

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

449 views1 page175 000003

Uploaded by

zhanginspection test list

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

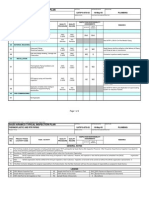

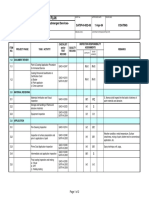

INSPECTION & TESTING REQUIREMENTS REVISION: 11/98 CODE NUMBER: PAGE:

SAUDI ARAMCO FORM-175 REPLACES: 10/97 IR000003

INSTRUCTIONS AND EXPLANATION OF REQUIREMENTS

EXPLANATION OF COLUMN ACTIVITES

An X in this column indicates a hold point for the Inspector to verify the

Visual Inspection / Manufacturers compliance in the listed line activity and shall not proceed

Witnessing by Buyer beyond any hold point until a written release is issued by the Inspector.

Representative Manufacturer shall notify Inspector a minimum of 5 working days in advance of

the hold points.

An X in this column indicates that:

a) The Inspector will verify the quality records for compliance with specifications

Certificates / Records to at the Manufacturers or sub-contractors plant prior to accepting the material.

Be Checked by Buyer b) The Manufacturer shall provide the necessary quality records to the Inspector

Representative for review.

c) When radiography is involved, the actual radiographs shall be reviewed for

compliance to the applicable requirements.

An X in this column indicates that the Inspector is to review the certificates,

data and/or test reports for compliance with the specifications prior to accepting

Certificates / Data to Be the material and forward copies with the inspection report. If visual inspection is

waived, the Manufacturer shall send the required certificates to the responsible

Provided by Vendor / Inspection Office for review and acceptance. All inspection certificates / test

Supplier / Manufacturer reports shall be in duplicate, in English, using foot-pound or SI system of

measurement, and shall reference Saudi Aramco P.O. & L/I numbers.

Manufacturer shall not ship material prior to issuance of a release note by the

responsible Inspection Office.

Specification Details / This column provides detailed inspection procedures, test methods, acceptance

Notes criteria, exceptions, verifications, and additional specific requirements.

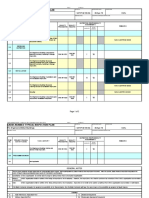

EXPLANATION OF LINE ACTIVITES

Pre-Fabrication / The Manufacturer shall ensure that incoming product is not used or processed

Pre-Production until it has been inspected or otherwise verified as conforming to specific

requirements in accordance with the quality plan and/or documented

Requirements

procedures.

The Manufacturer shall:

a) Inspect and test the product as required by the approved quality plan and/or

In-Process Inspection & documented procedures.

Testing Requirements b) Hold product until the required inspection and tests have been completed or

necessary reports have been received and verified.

The Manufacturer shall carry out all final inspection and testing in accordance

with the approved quality plan and/or documented procedures to complete the

Final Inspection & evidence of conformance of the finished product to the specified requirements.

Testing Requirements No product shall be dispatched until all the activities specified in the quality plan

and/or documented procedures have been satisfactorily completed and the

associated data and documentation are available and authorized.

Additional / Tests and/or inspection requirements which apply only when the condition is

Supplementary stated in the purchase order description, attached drawings / data sheets or

referenced specifications.

Requirements

The criterion for acceptance or rejection after completion of an inspection / test

activity is governed by the applicable purchase specifications. Deviations from

Acceptance Criteria

the purchase specification require written approval by Saudi Aramco before they

can be accepted by the inspector.

You might also like

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saes A 204Document22 pagesSaes A 204محمد العيسوى100% (2)

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Saes R 004Document8 pagesSaes R 004Shahzad HussainNo ratings yet

- Saudi Aramco piping inspection planDocument2 pagesSaudi Aramco piping inspection planMuhammad Farukh Manzoor100% (1)

- 09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsDocument4 pages09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsFiras AlbaweiNo ratings yet

- Schedule Q and Its AttachmentsDocument32 pagesSchedule Q and Its Attachmentssajeevismail50% (2)

- SAUDI ARAMCO UPGRADE WATER SYSTEMDocument3 pagesSAUDI ARAMCO UPGRADE WATER SYSTEMLeopoldo TalandatoNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Ai Hempadur 87540 EnglishDocument2 pagesAi Hempadur 87540 EnglishAmilcar BolagNo ratings yet

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pages09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Saep 1150Document50 pagesSaep 1150ishaq_khanNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument6 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Satip Q-012-01Document10 pagesSatip Q-012-01Tayyab Achakzai100% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDocument2 pagesSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanNo ratings yet

- SCH.Q - Contract No.6600044663 (IK)Document81 pagesSCH.Q - Contract No.6600044663 (IK)kamilNo ratings yet

- Saep 381 PDFDocument17 pagesSaep 381 PDFAbdul Aziz100% (1)

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- 175 320300Document1 page175 320300sridhar100% (1)

- Saes Q 001Document22 pagesSaes Q 001irfan hussainNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- AEP1152Document10 pagesAEP1152walitedisonNo ratings yet

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyNo ratings yet

- 175 043000Document1 page175 043000Fahad AhmadNo ratings yet

- SATIP Q 006 02 (Recovered)Document10 pagesSATIP Q 006 02 (Recovered)Abdul HannanNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument11 pagesSaudi Aramco Inspection ChecklistleonysNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saep 316 2016 PDFDocument25 pagesSaep 316 2016 PDFAllan LindoNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Typical Inspection Plan: RH/ H RH/ HDocument2 pagesSaudi Aramco Typical Inspection Plan: RH/ H RH/ HZuhaib KhanNo ratings yet

- Saep 352 PDFDocument15 pagesSaep 352 PDFRami ElloumiNo ratings yet

- Saic Q 1014Document2 pagesSaic Q 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- 01 Samss 051 PDFDocument13 pages01 Samss 051 PDFnadeem shaikh100% (1)

- Saudi Aramco pipe inspection requirementsDocument1 pageSaudi Aramco pipe inspection requirementsAbu Anas M.Salaheldin100% (1)

- Saic L 1002Document2 pagesSaic L 1002Hussain Nasser Al- NowiesserNo ratings yet

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Satip Q 001 02Document1 pageSatip Q 001 02Abdul HannanNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- 12 Samss 008Document4 pages12 Samss 008Moustafa BayoumiNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection Plankarthi51289No ratings yet

- Saes B 006Document21 pagesSaes B 006Anonymous a4Jwz14W100% (2)

- Instructions and Explanation of RequirementsDocument1 pageInstructions and Explanation of RequirementsAbu Anas M.SalaheldinNo ratings yet

- 175 000003 PDFDocument1 page175 000003 PDFSohail TisekarNo ratings yet

- V 000003Document1 pageV 000003zamil2008No ratings yet

- ISO 9001 Quality and Inspection RequirementsDocument7 pagesISO 9001 Quality and Inspection RequirementsarissaNo ratings yet

- Inspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208ADocument18 pagesInspection Level IV Is Invoked, This System Meets The Requirements of Former MIL-I-45208AAdrian Copa JNo ratings yet

- General Technical Specification: © 2007 MECON Limited All Rights ReservedDocument5 pagesGeneral Technical Specification: © 2007 MECON Limited All Rights ReservedAK TRIPATHINo ratings yet

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralDocument3 pagesSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Satip Co 3001Document3 pagesSatip Co 3001zhangNo ratings yet

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocument4 pagesSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangNo ratings yet

- Attachment - #5 Valve Inspection ListDocument4 pagesAttachment - #5 Valve Inspection ListzhangNo ratings yet

- Saudi Aramco Test Report: Commissioning of HRSG System MechDocument2 pagesSaudi Aramco Test Report: Commissioning of HRSG System MechzhangNo ratings yet

- Attachment#9 Auxiliary SystemDocument3 pagesAttachment#9 Auxiliary SystemzhangNo ratings yet

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Saic Co 3014Document8 pagesSaic Co 3014zhangNo ratings yet

- Attachment#5 Blowdown SystemDocument3 pagesAttachment#5 Blowdown SystemzhangNo ratings yet

- Saic Co 3014Document18 pagesSaic Co 3014zhangNo ratings yet

- Attachment#6 Burner SystemDocument3 pagesAttachment#6 Burner SystemzhangNo ratings yet

- Commissioning Completion Certificate: Attachment#4Document3 pagesCommissioning Completion Certificate: Attachment#4zhangNo ratings yet

- Review of Pressure Testing ProceduresDocument24 pagesReview of Pressure Testing ProcedureszhangNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Attachmnet#8 Rotor Air SystemDocument3 pagesAttachmnet#8 Rotor Air SystemzhangNo ratings yet

- Saudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003Document2 pagesSaudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003zhangNo ratings yet

- Satip Co 3014Document3 pagesSatip Co 3014zhangNo ratings yet

- Saudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamDocument1 pageSaudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamzhangNo ratings yet

- Satip Co 3014Document3 pagesSatip Co 3014zhangNo ratings yet

- Satr Co 3008Document1 pageSatr Co 3008zhangNo ratings yet

- Saudi Aramco Hot Reheat Steam ChecklistDocument12 pagesSaudi Aramco Hot Reheat Steam ChecklistzhangNo ratings yet

- Satr Co 3008Document1 pageSatr Co 3008zhangNo ratings yet

- Steam Line SummaryDocument9 pagesSteam Line SummaryzhangNo ratings yet

- Saudi Aramco Hot Reheat Steam ChecklistDocument12 pagesSaudi Aramco Hot Reheat Steam ChecklistzhangNo ratings yet

- A10 L Iso VB 433961 105 - 01BDocument1 pageA10 L Iso VB 433961 105 - 01BzhangNo ratings yet

- VHP Steam LineDocument9 pagesVHP Steam LinezhangNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- A10 A Pid Va 449162 001 - 01aDocument1 pageA10 A Pid Va 449162 001 - 01azhangNo ratings yet

- Satr-P-3219 Rev 7 FinalDocument7 pagesSatr-P-3219 Rev 7 FinalzhangNo ratings yet

- SATR-P-3413 Rev 7 FinalDocument4 pagesSATR-P-3413 Rev 7 FinalzhangNo ratings yet

- Plate 2Document9 pagesPlate 2MichaelViloria0% (1)

- Chapter Iv Research PaperDocument6 pagesChapter Iv Research PaperMae DeloriaNo ratings yet

- Finance 5Document3 pagesFinance 5Jheannie Jenly Mia SabulberoNo ratings yet

- ASEAN India RelationsDocument13 pagesASEAN India RelationsVihaan KushwahaNo ratings yet

- Institutional Correction ModuleDocument21 pagesInstitutional Correction ModuleShan Fukasan100% (2)

- Hul ProjectDocument69 pagesHul ProjectgauravNo ratings yet

- Project Management - Harvard Management orDocument68 pagesProject Management - Harvard Management ortusharnbNo ratings yet

- Warhammer Quest (Adventure) Priests of PleasureDocument8 pagesWarhammer Quest (Adventure) Priests of Pleasurefrankelee100% (1)

- LiquidityDocument26 pagesLiquidityPallavi RanjanNo ratings yet

- Echendu Joseph ChukwuemekaDocument162 pagesEchendu Joseph ChukwuemekaAries SatriaNo ratings yet

- Benjamin Dent Arrest Press ReleaseDocument2 pagesBenjamin Dent Arrest Press ReleaseRyan GraffiusNo ratings yet

- Misconduct Policy: UrposeDocument4 pagesMisconduct Policy: Urposeali rezaNo ratings yet

- How to exploit insecure direct object references (IDOR) on Vimeo.comDocument4 pagesHow to exploit insecure direct object references (IDOR) on Vimeo.comSohel AhmedNo ratings yet

- ITC: Building World-Class Brands For IndiaDocument24 pagesITC: Building World-Class Brands For IndiaVinay GhuwalewalaNo ratings yet

- NDMC vs Prominent Hotels Limited Delhi High Court Judgement on Licence Fee DisputeDocument84 pagesNDMC vs Prominent Hotels Limited Delhi High Court Judgement on Licence Fee DisputeDeepak SharmaNo ratings yet

- Muh351 ProjeDocument2 pagesMuh351 Projesudanlı kara hakıNo ratings yet

- Jurisdiction definedDocument30 pagesJurisdiction definedJeong100% (1)

- Book Bhagavat Online - 2 PDFDocument406 pagesBook Bhagavat Online - 2 PDFShukla RoyNo ratings yet

- Ficobbpfinalone10022011 120815114154 Phpapp02Document146 pagesFicobbpfinalone10022011 120815114154 Phpapp02prashantaiwaleNo ratings yet

- CH 1 - TemplatesDocument7 pagesCH 1 - TemplatesadibbahNo ratings yet

- Milltown Biomass-To-Energy Power StationDocument2 pagesMilltown Biomass-To-Energy Power StationmisanthropoNo ratings yet

- FCC Checker TP09Document3 pagesFCC Checker TP09Alex Valdez MoralesNo ratings yet

- Process Flowchart in Firearms License ApplicationDocument15 pagesProcess Flowchart in Firearms License ApplicationPatrick RamosNo ratings yet

- Student portfolio highlights work immersion experiencesDocument28 pagesStudent portfolio highlights work immersion experiencesJohn Michael Luzaran ManilaNo ratings yet

- Gmis CalendarDocument4 pagesGmis CalendarAnonymous Yw2XhfXvNo ratings yet

- 04 Hark I Hear The Harps EternalDocument10 pages04 Hark I Hear The Harps EternalVitor Italiani RoveriNo ratings yet

- Annexure M - Bank Guarantee FormatDocument2 pagesAnnexure M - Bank Guarantee FormatRafikul RahemanNo ratings yet

- Airport Arrival and Hotel Check-In ConversationDocument4 pagesAirport Arrival and Hotel Check-In Conversationfeira fajar100% (1)

- Mendoza V CADocument2 pagesMendoza V CAranNo ratings yet

- Eng PDFDocument14 pagesEng PDFbrm1shubhaNo ratings yet