Professional Documents

Culture Documents

Me6005 Process Planning and Cost Estimation L T P C

Uploaded by

Murugesan Jeeva0 ratings0% found this document useful (0 votes)

70 views1 pageprocess planning and cost estimation

Original Title

Me6005 Process Planning and Cost Estimation l t p c

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentprocess planning and cost estimation

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

70 views1 pageMe6005 Process Planning and Cost Estimation L T P C

Uploaded by

Murugesan Jeevaprocess planning and cost estimation

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

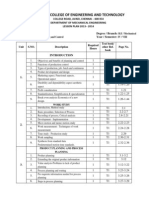

ME6005 PROCESS PLANNING AND COST ESTIMATION LTPC

3003

OBJECTIVES:

To introduce the process planning concepts to make cost estimation for various products after

process planning.

UNIT I INTRODUCTION TO PROCESS PLANNING 10

Introduction- methods of process planning-Drawing interpretation-Material evaluation steps in

process selection-.Production equipment and tooling selection

UNIT II PROCESS PLANNING ACTIVITIES 10

Process parameters calculation for various production processes-Selection jigs and fixtures election

of quality assurance methods - Set of documents for process planning-Economics of process

planning- case studies

UNIT III INTRODUCTION TO COST ESTIMATION 8

Importance of costing and estimation methods of costing-elements of cost estimation Types of

estimates Estimating procedure- Estimation labor cost, material cost- allocation of over head

charges- Calculation of depreciation cost

UNIT IV PRODUCTION COST ESTIMATION 8

Estimation of Different Types of Jobs - Estimation of Forging Shop, Estimation of Welding Shop,

Estimation of Foundry Shop

UNIT V MACHINING TIME CALCULATION 9

Estimation of Machining Time - Importance of Machine Time Calculation- Calculation of Machining

Time for Different Lathe Operations ,Drilling and Boring - Machining Time Calculation for Milling,

Shaping and Planning -Machining Time Calculation for Grinding

TOTAL: 45 PERIODS

OUTCOMES:

Upon completion of this course, the students can able to use the concepts of process planning

and cost estimation for various products.

TEXT BOOKS:

1. Peter scalon, Process planning, Design/Manufacture Interface, Elsevier science technology

Books, Dec 2002.

REFERENCES:

1. Ostwalal P.F. and Munez J., Manufacturing Processes and systems, 9th Edition, John Wiley,

1998.

2. Russell R.S and Tailor B.W, Operations Management, 4th Edition, PHI, 2003.

3. Chitale A.V. and Gupta R.C., Product Design and Manufacturing, 2nd Edition, PHI, 2002.

You might also like

- ME6005 Process Planning and Cost EstimationDocument1 pageME6005 Process Planning and Cost EstimationT.V.B.BabuNo ratings yet

- Ppce Me8793Document1 pagePpce Me8793chandrasekarcncetNo ratings yet

- ME8793 Process Planning and Cost Estimation: Faculty Verified by HODDocument3 pagesME8793 Process Planning and Cost Estimation: Faculty Verified by HODBuckshu PhdNo ratings yet

- 08aa603 Process Planning and Cost EstimationDocument1 page08aa603 Process Planning and Cost EstimationMari Muthu100% (1)

- ME2027 PPCE SyllabusDocument1 pageME2027 PPCE SyllabusbsamantonyNo ratings yet

- Me8793 Process Planning and Cost Estimation: Diploma, Anna Univ UG & PG CoursesDocument1 pageMe8793 Process Planning and Cost Estimation: Diploma, Anna Univ UG & PG CoursesVijayakumar TNo ratings yet

- 08AA603-Process Planning and Cost Estimation-Lesson PlanDocument3 pages08AA603-Process Planning and Cost Estimation-Lesson PlanMari MuthuNo ratings yet

- ME 2027 PPCE Important QuestionsDocument2 pagesME 2027 PPCE Important QuestionsKarthick NNo ratings yet

- ME8793 Process Planning and Cost Estimation - by WWW - Learnengineering.inDocument92 pagesME8793 Process Planning and Cost Estimation - by WWW - Learnengineering.inPrakashNo ratings yet

- Course Title: Course Code: 5022 Course Category: A Periods/ Week: 5 Periods/ Semester: 75 Credit: 4Document6 pagesCourse Title: Course Code: 5022 Course Category: A Periods/ Week: 5 Periods/ Semester: 75 Credit: 4Kannan SreenivasanNo ratings yet

- Industrial Engineering SyllabusDocument2 pagesIndustrial Engineering SyllabusMech DeptNo ratings yet

- Compressed PDF ME 6005 PPCE Revised PDFDocument313 pagesCompressed PDF ME 6005 PPCE Revised PDFManojKumar MNo ratings yet

- PPC Lesson PlanDocument2 pagesPPC Lesson PlanSathiya MoorthyNo ratings yet

- Unit - 3Document61 pagesUnit - 3028MECH KESAVA KRISHNAN D SNo ratings yet

- Pom IeDocument5 pagesPom IepmagrawalNo ratings yet

- Economic Documentation. Bill of Quantities: Capitolu 10Document6 pagesEconomic Documentation. Bill of Quantities: Capitolu 10Dutcă GeorgeNo ratings yet

- Estimating Costing VDocument4 pagesEstimating Costing VTanveer PathanNo ratings yet

- Topic Periods: I 18 II 18 III 18 IV 18Document4 pagesTopic Periods: I 18 II 18 III 18 IV 18SoorajKRajeevNo ratings yet

- Production Planning and ControlDocument2 pagesProduction Planning and Controlmontu chahurpagarNo ratings yet

- Ppce 2 MarksDocument6 pagesPpce 2 MarksMohammedRafficNo ratings yet

- Producation Planning Estimating & CostingDocument351 pagesProducation Planning Estimating & CostingNavajyoti PandaNo ratings yet

- ME8793 Notes - by WWW - Easyengineering.net 2Document93 pagesME8793 Notes - by WWW - Easyengineering.net 2CAD With RaoNo ratings yet

- PT 2 SyllabusDocument1 pagePT 2 SyllabusMangesh JoshiNo ratings yet

- Unit - 1Document64 pagesUnit - 1028MECH KESAVA KRISHNAN D SNo ratings yet

- Ie6605 Production Planning and Control L T P C 3 0 0 3Document1 pageIe6605 Production Planning and Control L T P C 3 0 0 3kumar km0% (1)

- Process Planning and Cost EstimationDocument7 pagesProcess Planning and Cost EstimationMariappan ArumugamNo ratings yet

- Ie6605 Production Planning and Control L T P C 3 0 0 3Document2 pagesIe6605 Production Planning and Control L T P C 3 0 0 3Sathrudhan ChoudharyNo ratings yet

- CRP 7th 8th Syllabus..Document34 pagesCRP 7th 8th Syllabus..Archana MaskeNo ratings yet

- Date:: Cia Test-IDocument2 pagesDate:: Cia Test-IRamar MadasamyNo ratings yet

- CE404 Civil Engineering Project ManagementDocument2 pagesCE404 Civil Engineering Project Managementshalu R F100% (1)

- PPC SYLLABUSDocument2 pagesPPC SYLLABUSddeepak123No ratings yet

- Function of Production DepartmentDocument15 pagesFunction of Production DepartmentSiddharth Patel0% (1)

- Process PlanningDocument14 pagesProcess PlanningBabu AsokanNo ratings yet

- Ie 6605 - PPC - SyllabusDocument2 pagesIe 6605 - PPC - SyllabusmuthusNo ratings yet

- 5264 Exjobb Sandvik 12 JES PDFDocument63 pages5264 Exjobb Sandvik 12 JES PDFCristhian Portocarrero CastroNo ratings yet

- Operations Management 1Document30 pagesOperations Management 1BalujagadishNo ratings yet

- Unit 3 PPCDocument49 pagesUnit 3 PPCRama Narasimha ReddyNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial EngineeringRam RenNo ratings yet

- Scope, Tasks and Proposed QuotationDocument5 pagesScope, Tasks and Proposed QuotationRichard OchNo ratings yet

- The Production CycleDocument15 pagesThe Production CycleVelia MonicaNo ratings yet

- Industrial and System EngineeringDocument213 pagesIndustrial and System EngineeringAjaikrishnaNo ratings yet

- Clas01, Fund DiseñoDocument19 pagesClas01, Fund DiseñoKIKE_25No ratings yet

- Product Design 1Document10 pagesProduct Design 1elango_mm3307No ratings yet

- Assignment Nicmar / Code OfficeDocument8 pagesAssignment Nicmar / Code OfficeRevanth KumarNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial Engineeringnandan144No ratings yet

- Me8793 - Process Planning and Cost EstimationDocument35 pagesMe8793 - Process Planning and Cost EstimationJayasimmanNo ratings yet

- Production Planning and Control SyllabusDocument2 pagesProduction Planning and Control SyllabusdsathiyaNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial EngineeringHusni mubsshirNo ratings yet

- CIM-2 MarksDocument18 pagesCIM-2 MarksHod MechNo ratings yet

- Design of Hydraulic and Pneumatic SystemsDocument2 pagesDesign of Hydraulic and Pneumatic SystemsGokul raj SNo ratings yet

- OPERATIONS MANAGEMENT - Model Questions and AnswersDocument34 pagesOPERATIONS MANAGEMENT - Model Questions and AnswersAkshay KsNo ratings yet

- Michael NeesDocument18 pagesMichael Neesavca65No ratings yet

- Cftri RDDocument30 pagesCftri RDAheesha J VadaviNo ratings yet

- M.E. Industrial Engineering SyllabusDocument46 pagesM.E. Industrial Engineering SyllabusJoswa CaxtonNo ratings yet

- Tt6602 Financial Management For Textile and Apparel L T P CDocument5 pagesTt6602 Financial Management For Textile and Apparel L T P CAnonymous GohKUCxhDNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Ce3311 Set4Document2 pagesCe3311 Set4maniNo ratings yet

- sOM NotesDocument48 pagessOM NotesmaniNo ratings yet

- Ce3311 Set1 PDFDocument2 pagesCe3311 Set1 PDFmaniNo ratings yet

- Ngineering: EchanicsDocument800 pagesNgineering: EchanicsmaniNo ratings yet

- EE2252 PPE Lecture Notes - NPRDocument91 pagesEE2252 PPE Lecture Notes - NPRmaniNo ratings yet

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- Nuclear PowersemDocument22 pagesNuclear PowersemPradeep Kumar MehtaNo ratings yet

- EE2252 PPENotesDocument44 pagesEE2252 PPENotesmaniNo ratings yet

- Unit-I Introduction To Power Plants and Boilers: Layout of Steam Power PlantDocument30 pagesUnit-I Introduction To Power Plants and Boilers: Layout of Steam Power PlantmaniNo ratings yet

- English Poems For KidsDocument1 pageEnglish Poems For KidsmaniNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)