50% found this document useful (2 votes)

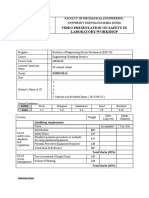

840 views7 pagesBrinell Hardness Test

The document describes a Brinell hardness test experiment that was conducted to compare the hardness of aluminum and steel samples. Steel balls were pressed into the samples using different loads. Measurements of the indentations were then used to calculate the Brinell hardness numbers (BHN) according to a standard formula. The results found that steel has a higher BHN of 140 compared to aluminum's 175, indicating that steel has greater resistance to deformation. However, the aluminum value differed significantly from the theoretical value likely due to surface roughness errors. The test demonstrated the usefulness of Brinell hardness testing for evaluating the strength of different materials.

Uploaded by

abdulazizCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

50% found this document useful (2 votes)

840 views7 pagesBrinell Hardness Test

The document describes a Brinell hardness test experiment that was conducted to compare the hardness of aluminum and steel samples. Steel balls were pressed into the samples using different loads. Measurements of the indentations were then used to calculate the Brinell hardness numbers (BHN) according to a standard formula. The results found that steel has a higher BHN of 140 compared to aluminum's 175, indicating that steel has greater resistance to deformation. However, the aluminum value differed significantly from the theoretical value likely due to surface roughness errors. The test demonstrated the usefulness of Brinell hardness testing for evaluating the strength of different materials.

Uploaded by

abdulazizCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd