Professional Documents

Culture Documents

LCS0024 AEPPhaseShift ENG 20080317 PDF

Uploaded by

Luis Angel Huaratazo HuallpaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LCS0024 AEPPhaseShift ENG 20080317 PDF

Uploaded by

Luis Angel Huaratazo HuallpaCopyright:

Available Formats

CASE STUDY

American Electric Power (AEP)South Texas, United States

Innovative Phase-Angle Control Helps AEP

Optimize Power Flow on Transmission Grid

AEP (American Electric Power) has desired one-pushbutton-in-service and

installed 138 kV, 150 MVA phase-shifting one-pushbutton-out-of-service capabilities.

transformers (PSTs) on the ERCOT (Electric AEP commissioned SEL to engineer, con-

Reliability Council of Texas) transmission figure, and program this control system.

grid. Three units went into service in 2006,

one in 2007, and at least one installation is

planned for 2008. These transformers were

selected to help optimize power flow from

existing transmission system assets until fu-

ture 345 kV line construction projects can be

completed. The delta/hex PSTs deployed in

South Texas are a new, single-tank design

that promises to be much more economical

than previous designs.

These specialized transformers require a

protection system that is redundant, sensi-

tive, and secure for all types of faults,

including turn-to-turn faults in the trans-

former and its surrounding buswork. In

addition, a flexible, automated PST control Figure 1First of several PSTs under assembly

is required. AEP selected a combination of

conventional protection concepts and a com- While SEL is perhaps best known for their

pletely new differential protection system prowess on the protection side of power

that compensates for the variable phase- systems, the company also provides innova-

angle shift introduced by operation of the tive products and services for the control

PST. Traditional percentage-restrained trans- side, including engineering, programming,

former differential protection could not be installation, and training. SEL developed the

used because of the continuously variable power flow regulating tap-changer control to

phase shift across a PST. The protection meet the AEP project requirements.

system incorporates a series of relays from

Schweitzer Engineering Laboratories (SEL), PSTs, also called phase shifters or PAR

Pullman, Washington. (phase-angle regulating) transformers, are

becoming more popular, says SELs

Initially, the original transformer manufac- Michael Thompson, because they are

turer was to provide the PST controls per considered FACTS devices, or flexible ac

AEP specifications. However, because auto- transmission system devices. There is a lot

mated controls were required, the customer of interest in getting more power down ex-

decided that a device with extensive pro- isting lines, which requires advanced power-

grammability was needed to provide the flow regulation.

Case StudyAEP South Texas Transmission Grid Page 1

Thompson adds that while PSTs are becom- and overload conditions. Included are alarms

ing a more common tool to optimize trans- and remedial action schemes that will alert

mission assets, until now the controls have key personnel and take proper actions if a

often been operated manually. SEL has problem occurs.

been able to automate the control technology

to enable the system operator to simply S1 L1

input a megawatt set point, allowing the tap-

changer control to automatically regulate

according to the operators requirements, Regulating

Ex

on

he says.

ati

cita

cit

tio

Ex

n

Regulating the Angle and Flow

Re

ing

Because power flow through a transmission

gu

lat

L3

S2

lati

gu

line is largely a function of the angle be-

Re

ng

tween two voltages, if the angle across the Excitation

line can be regulated, the power flow can

S3

L2

also be regulated. Power can be increased by

Figure 2Delta/hex configuration has two tap-changers

introducing a phase angle that is additive

(advance). Conversely, by introducing an

angle that is subtractive (retard), the power An Automated Control System

can be reduced. SEL engineers designed and installed the

first of the PST control systems within a few

PSTs typically inject a quadature voltage weeks of AEPs request. After testing the

into each phase between the source and the system with the AEP Protection and Control

load bushings to induce phase shifting. group, engineers from their Operations group

Traditional PST designs require two trans- added new specifications to take advantage

former cores to accomplish this task. How- of the PST overload capabilities without

ever, a new type of single-tank PST has undue risk of thermal damage.

emerged. This new design promises to

improve the economic viability of deploying In addition to the automated control system,

such devices on the transmission grid. Thompson explained, The design documen-

tation was an important deliverable in this

On the delta/hex PST, the three excitation project. We wrote a comprehensive instruc-

windings and three regulating windings are tion manual so others can understand how

connected in a delta/hex configuration. Two the tap-changer control works.

three-phase tap-changers are installed: one

for the source terminals and one for the load The primary PST control device is an

terminals. Each tap-changer mechanism SEL-451 connected to an SEL-2100 Logic

moves its terminals up and down the regu- Processor. The SEL-451 receives informa-

lating winding to create the phase shift tion on the open/close status of the bypass,

across the transformer. When the two tap- load, and source breakers via the communi-

changers pass each other, the transformer cations links through the logic processor.

shifts from advance to retard operation. The programming prevents invalid switch-

ing sequences that can result in a trip or

AEPs PST control system is based on the damage to the PST.

SEL-451 Protection, Automation, and Con-

trol System as the core for a transformer tap- For example, there are three different ways

changer control, Thompson explains. In for the control to check to see if the PST is

addition to controlling power flow, the tap- on neutral or not, Thompson explains. If

changer control provides automatic detec- you try to bypass a transformer that is not on

tion of improper tap operation sequences neutral, you are going to get some tremen-

Page 2 Case StudyAEP South Texas Transmission Grid

dously high circulating currents, so high it poor regulation around the desired set point.

would look like a fault. It is necessary to be The tap-changer control installed on the

absolutely sure that it is on neutral before AEP transformers includes a method for

you start any automatic procedures to put adapting bandwidth based on measured

the transformer in or out of service. power changes.

The control provides information through Source Side

AEPs SCADA system to the operations

center. Electronic information is available

inside the local area network at each of the

substations, so the control can automatically

make appropriate decisions as to when to

provide a bypass and when to place the unit MOD

in service. If the operator (dispatcher) starts

Tap Changer Position

to place the unit in service and it fails, a S1 S2 S3

Tap Change in Process PFR Tap-

routine check will send a warning, for exam- PST Lower Tap Changer

ple, if the dispatcher starts to put the unit in L1 L2 L3 Raise Tap

Control

service and it fails, the control returns a mes- IA

sage incomplete automatic sequence and

IB

aborts the process.

IC

Through the SEL-451, the control provides

automatic or manual control of tap-changer Load-Side

Circuit Breaker

Bypass

Circuit Breaker

position and gives operators complete

command of all tap-changer functions with

automatic safeguards to prevent overload

conditions, Thompson says. Programming VA

automatic sequences to run the tap-changer VB

position to neutral and open and close break- VC

ers and motor operated disconnect (MOD)

switches in the correct order enhances Load Side

safety.

Figure 3The tap-changer control measures real power flow

from source to load and controls the tap-changer to regulate

The tap-changer control maintains precise power flow when the bypass is open

regulation of system power flow. Automatic

control functions within the tap-changer The adaptive bandwidth function is one of

control include a power-flow dead-band the powerful innovations incorporated into

control with adaptive bandwidth. the SEL tap-changer control, Thompson

says. It stores the most recent eight tap

Adaptive Bandwidth Control changes in memory registers. So, in effect, it

learns with each step. From the operator

Thompson notes that one of the problems set point and bandwidth, the control calcu-

with automatic control of a discrete step de- lates the upper and lower band limits. To

vice such as the PST is hunting. Hunting prevent operation above the user-settable

occurs when a tap step results in a change in maximum automatic regulation set point, the

power that is near or greater than the total control also calculates band limits from the

bandwidth. For each tap step, the power MVA rating and the measured power factor

change can overshoot the band, and the of the load through the PST and uses the

regulator will soon attempt to step in the more restrictive of the two limits. Without

opposite direction. Selecting a high band- the adaptive bandwidth capability, the AEP

width will reduce the possibility of exces- controls would not have worked.

sive operations and hunting but result in

Case StudyAEP South Texas Transmission Grid Page 3

ENABLED ADJUST MW RAISE

TARGET SET POINT TAP/

RESET

TRIP SET POINT

INCOMPLETE

NEUTRAL

AUTOMATIC SEQ MANUAL LOWER

OK TO PUT OK TO REMOVE ENABLED TAP/

IN SERVICE FROM SERVICE

SET POINT

FLOW HIGH FLOW LOW

-OUT-OF-BAND -OUT-OF-BAND

-TIMING -TIMING AUTOMATIC PUT

ENABLED PST IN

-TIMED OUT -TIMED OUT SERVICE

-RESET -RESET

AUTO-TIMING MAN. CONTROL

REMOTE REMOVE

SUSPENDED CUTOUT ENABLED PST FROM

ADDITIONAL MAINT. L/R SW. SERVICE

ALARMS IN LOCAL

Figure 4In addition to remote control via SCADA, the local user interface allows complete control and indication of PST functions

About AEP About SEL

Headquartered in Columbus, Ohio, AEP is SEL has been making electric power safer,

one of the largest electric utilities in the more reliable, and more economical since

United States, delivering electricity to more 1984. This ISO 9001:2000-certified compa-

than 5 million customers in 11 states. AEP ny serves the electric power industry

ranks among the nations largest generators worldwide through the design, manufacture,

of electricity, owning nearly 38,000 mega- supply, and support of products and services

watts of generating capacity in the United for power system protection, control, and

States. AEP also owns the nations largest monitoring. For more information, visit

electricity transmission system, a nearly www.selinc.com, or contact SEL by phone:

39,000-mile network that includes more +1 (509) 332-1890; fax: +1 (509) 332-7990;

765 kilovolt extra-high voltage transmission or mail: 2350 NE Hopkins Court, Pullman,

lines than all other U.S. transmission sys- WA 99163, USA.

tems combined.

2008 by Schweitzer Engineering Laboratories, Inc. All rights

reserved.

All brand or product names appearing in this document are

the trademark or registered trademark of their respective

holders. No SEL trademarks may be used without written

permission.

SEL products appearing in this document may be covered by

US and Foreign patents. Date Code 20080317 *LCS0024*

Page 4 Case StudyAEP South Texas Transmission Grid

You might also like

- 6868 NewAdvancements MT 20180426 WebDocument21 pages6868 NewAdvancements MT 20180426 Webkessir taouilNo ratings yet

- 2020-Applications For Phase-Shifting Transformers in Rural Power SystemsDocument6 pages2020-Applications For Phase-Shifting Transformers in Rural Power SystemsSMS AbdullahNo ratings yet

- Remote Control System For Transformers With On-Load Tap ChangerDocument6 pagesRemote Control System For Transformers With On-Load Tap Changerигорь сидоренкоNo ratings yet

- Digital Technology Revives ..Document6 pagesDigital Technology Revives ..Chien C TschangNo ratings yet

- Power system protection termsDocument10 pagesPower system protection termsMRIGANKA RANANo ratings yet

- Improve Voltage Stability Using TCSCDocument66 pagesImprove Voltage Stability Using TCSCsenthil_k23No ratings yet

- Application of FACTS Technology in Modern AGC Connected Power SystemDocument16 pagesApplication of FACTS Technology in Modern AGC Connected Power SystemzahidNo ratings yet

- 6578 ProtectionSystem MT 20121022Document12 pages6578 ProtectionSystem MT 20121022thyago_hcNo ratings yet

- EMTP, Transient Stability and Power Flow Models and Controls of VSC Based FACTS Controllers - E. Uzunovic - 2001Document231 pagesEMTP, Transient Stability and Power Flow Models and Controls of VSC Based FACTS Controllers - E. Uzunovic - 2001M8ow6f100% (1)

- PLL-Based Seamless Transfer Control Between Grid-Connected and Islanding Modes in Grid-Connected InvertersDocument11 pagesPLL-Based Seamless Transfer Control Between Grid-Connected and Islanding Modes in Grid-Connected Inverterspradeep kumar sahuNo ratings yet

- Phase Shifting Transformers: A Novel Approach To Comprehensive Tests OnDocument4 pagesPhase Shifting Transformers: A Novel Approach To Comprehensive Tests OnBhanu ThestarNo ratings yet

- Power System Protection: Shoaib Ahmed Shaikh Lecturer (EE) Sukkur IBA UniversityDocument67 pagesPower System Protection: Shoaib Ahmed Shaikh Lecturer (EE) Sukkur IBA Universityfaizan100% (1)

- Transformer Tap Setting in Optimal Load FlowDocument7 pagesTransformer Tap Setting in Optimal Load FlowjhongeralpeNo ratings yet

- Pole-Placement Designs of Power System StabilizersDocument7 pagesPole-Placement Designs of Power System StabilizersabelcatayNo ratings yet

- Location of Tap-Changer SwitchDocument8 pagesLocation of Tap-Changer SwitchAbdulyunus AmirNo ratings yet

- Application of FACTS Technology in Modern AGC Connected Power SystemDocument14 pagesApplication of FACTS Technology in Modern AGC Connected Power SystemzahidNo ratings yet

- DC Load FlowDocument5 pagesDC Load Flowstrange_kid82100% (1)

- Control of A Single-Stage Three-Phase Boost Power Factor Correction RectifierDocument6 pagesControl of A Single-Stage Three-Phase Boost Power Factor Correction RectifierGoriparthi SambasievaraavNo ratings yet

- Bistable MultivibratorDocument6 pagesBistable MultivibratorblaagicaNo ratings yet

- Chen 2013Document8 pagesChen 2013Anonymous TLMC0uNo ratings yet

- Optimal Tap Setting of Voltage Regulation Transformers Using Batch Reinforcement LearningDocument8 pagesOptimal Tap Setting of Voltage Regulation Transformers Using Batch Reinforcement LearningJone JonathanNo ratings yet

- Power Factor Correction AC-DC ConverterDocument5 pagesPower Factor Correction AC-DC Convertermatadamahesh1No ratings yet

- Wang2021 Article Z-domainModelingOfPeakCurrentMDocument11 pagesWang2021 Article Z-domainModelingOfPeakCurrentMSinyxNo ratings yet

- Transition Modes For Automatic Transfer Switches Part 1Document6 pagesTransition Modes For Automatic Transfer Switches Part 1Jason29No ratings yet

- 48 Pulse PWMDocument6 pages48 Pulse PWMWilliam JavierNo ratings yet

- IET Power Electronics Volume 4 Issue 9 2011 [Doi 10.1049_iet-Pel.2010.0363] Jung, J.-h.; Ahmed, S. -- Flyback Converter With Novel Active Clamp Control and Secondary Side Post Regulator for Low Standby Power Consumption Under HighDocument10 pagesIET Power Electronics Volume 4 Issue 9 2011 [Doi 10.1049_iet-Pel.2010.0363] Jung, J.-h.; Ahmed, S. -- Flyback Converter With Novel Active Clamp Control and Secondary Side Post Regulator for Low Standby Power Consumption Under HighTuấn Anh PhạmNo ratings yet

- Mathematical Model of Flexible Alternating Current Link Based On Phase-Shifting Transformer With Circular Rotation of The Phase AngleDocument6 pagesMathematical Model of Flexible Alternating Current Link Based On Phase-Shifting Transformer With Circular Rotation of The Phase AngleCosmic GateNo ratings yet

- STATICCHECK SYNCHRONISERS: ELECTRONIC CIRCUITS OVERCOME LIMITATIONSDocument6 pagesSTATICCHECK SYNCHRONISERS: ELECTRONIC CIRCUITS OVERCOME LIMITATIONSsravankotlasNo ratings yet

- Application of Supervisory Adaptive Predictive Control Scheme in Electrical Power SystemsDocument70 pagesApplication of Supervisory Adaptive Predictive Control Scheme in Electrical Power SystemszahidNo ratings yet

- Phase-Shifting Transformer Control and Protection Settings VerificationDocument15 pagesPhase-Shifting Transformer Control and Protection Settings Verificationsno-koneNo ratings yet

- Simulation of D-Q Control System For A Unified Power Flow ControllerDocument10 pagesSimulation of D-Q Control System For A Unified Power Flow ControllerSyed Faizan AliNo ratings yet

- 3.autoselection of Any Available PhaseDocument39 pages3.autoselection of Any Available PhaseRamalingam Shanmugam100% (16)

- PS Lab ManualDocument49 pagesPS Lab Manual18-206 Ajay KumarNo ratings yet

- Alexander 1966Document9 pagesAlexander 1966Robert David Guedez SierraNo ratings yet

- Dynamic Modeling and Analysis of The Bidirectional DCDC Boost-Buck ConverterDocument40 pagesDynamic Modeling and Analysis of The Bidirectional DCDC Boost-Buck ConverterAndresSs NineNo ratings yet

- 2008 23 6 IEEE PELS Dual PhaseshiftDocument10 pages2008 23 6 IEEE PELS Dual PhaseshiftDEBARATI DAMNo ratings yet

- A Novel Approach To Comprehensive Tests On Phase Shifting TransformersDocument12 pagesA Novel Approach To Comprehensive Tests On Phase Shifting Transformerssemih1443No ratings yet

- Voltage Control in Deregulated Power SystemsDocument15 pagesVoltage Control in Deregulated Power SystemsAshok PalakondaNo ratings yet

- Quality: Power Implications Associated A Series FACTS ControllerDocument6 pagesQuality: Power Implications Associated A Series FACTS ControllerH C Aasif LoneNo ratings yet

- Analysis and Parameter Optimization of Start-Up Process For LLC ResonantConverterDocument10 pagesAnalysis and Parameter Optimization of Start-Up Process For LLC ResonantConverterBook4AllNo ratings yet

- Current Mode Slope CompensationDocument11 pagesCurrent Mode Slope CompensationDaniel BiasiNo ratings yet

- Zero-Voltage Switching For Three-Level Capacitor Clamping InverterDocument11 pagesZero-Voltage Switching For Three-Level Capacitor Clamping InverterTiền Hoàng VănNo ratings yet

- Automatic Phase Connection ReportDocument38 pagesAutomatic Phase Connection Reportnovio333No ratings yet

- Phase Shifting TransformersDocument6 pagesPhase Shifting TransformersWaldemar ZiomekNo ratings yet

- Piezo Power Drive EPEDocument7 pagesPiezo Power Drive EPEShubhamJainNo ratings yet

- AGC of A Hydrothermal System With Thyristor Controlled Phase Shifter in The Tie-LineDocument7 pagesAGC of A Hydrothermal System With Thyristor Controlled Phase Shifter in The Tie-LineRajeshJosephAbrahamEdasseriathuNo ratings yet

- Analysis and Design of Three-Phase AC-to-DC Converters With High Power Factor and Near-Optimum FeedforwardDocument10 pagesAnalysis and Design of Three-Phase AC-to-DC Converters With High Power Factor and Near-Optimum FeedforwardTalha SadiqNo ratings yet

- UPEC2010 Review Voltage Control Techniques Networks Distributed Generations OLTC TransformersDocument6 pagesUPEC2010 Review Voltage Control Techniques Networks Distributed Generations OLTC Transformersstrange_kid82No ratings yet

- Power System AnalysisDocument22 pagesPower System AnalysisBhavesh KaushalNo ratings yet

- Connections and Operating Characteristics of Different Types of Relays ObjectiveDocument5 pagesConnections and Operating Characteristics of Different Types of Relays ObjectivePili HamisNo ratings yet

- Voltage Stability Constrained Available Transfer Capability Calculation Using MatlabDocument11 pagesVoltage Stability Constrained Available Transfer Capability Calculation Using Matlabpralay royNo ratings yet

- Optimal Placement of SVC and Statcom For Voltage Stability Enhancement Under Contingency Using Cat Swarm OptimizationDocument16 pagesOptimal Placement of SVC and Statcom For Voltage Stability Enhancement Under Contingency Using Cat Swarm Optimizationsabarullah haliNo ratings yet

- A Fast-Response Pseudo-PWM Buck Converter WithDocument8 pagesA Fast-Response Pseudo-PWM Buck Converter WithSethu GeorgeNo ratings yet

- Advanced Transformer Control Modeling in An Optimal Power Flow Using Newton's MethodDocument9 pagesAdvanced Transformer Control Modeling in An Optimal Power Flow Using Newton's MethodHoracio Manuel Ayala DazaNo ratings yet

- Cascade Controller For DCDC Buck ConvertorDocument6 pagesCascade Controller For DCDC Buck ConvertorCristóbal Eduardo Carreño MosqueiraNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- VIZIMAX SynchroTeq - The Ultimate Inrush Current LimiterDocument4 pagesVIZIMAX SynchroTeq - The Ultimate Inrush Current LimiterLuis Angel Huaratazo HuallpaNo ratings yet

- VIZIMAX - VIZIMAX Unified Communication ServicesDocument2 pagesVIZIMAX - VIZIMAX Unified Communication ServicesLuis Angel Huaratazo HuallpaNo ratings yet

- VIZIMAX - SynchroTeq MVX Brochure 20180904Document2 pagesVIZIMAX - SynchroTeq MVX Brochure 20180904Luis Angel Huaratazo HuallpaNo ratings yet

- VIZIMAX - SynchroTeq MVR Brochure - EN - 20160225Document2 pagesVIZIMAX - SynchroTeq MVR Brochure - EN - 20160225Luis Angel Huaratazo HuallpaNo ratings yet

- VIZIMAX - SynchroTeq - Customer Product Catalog EN - 2019 - 20181019Document11 pagesVIZIMAX - SynchroTeq - Customer Product Catalog EN - 2019 - 20181019Luis Angel Huaratazo HuallpaNo ratings yet

- SYS600 - Java Programming InterfacDocument94 pagesSYS600 - Java Programming InterfacLuis Angel Huaratazo HuallpaNo ratings yet

- OHB Manual PDFDocument68 pagesOHB Manual PDFLuis Angel Huaratazo HuallpaNo ratings yet

- ATP ManualDocument270 pagesATP ManualJose Jorge Fontalvo100% (1)

- Cisco ASR 5000 System Administration GuideDocument380 pagesCisco ASR 5000 System Administration Guiderohitkamahi100% (1)

- Opentext Imaging Enterprise Scan 1050 Installation Guide English Cles100500 Igd en PDFDocument46 pagesOpentext Imaging Enterprise Scan 1050 Installation Guide English Cles100500 Igd en PDFMihai PaunescuNo ratings yet

- DIY Paper Airplane Instructions DownloadDocument2 pagesDIY Paper Airplane Instructions DownloadPauloHendrix100% (1)

- River View Luxury Homes Clover By The RiverDocument24 pagesRiver View Luxury Homes Clover By The RiverE. PoornimaNo ratings yet

- CCNA Lab M4 5.5.1Document6 pagesCCNA Lab M4 5.5.1vadancorneliuNo ratings yet

- Daftar Spare Parts Alternatif Suzuki EveryDocument1 pageDaftar Spare Parts Alternatif Suzuki EveryNacz92100% (1)

- TechRef StationController PDFDocument28 pagesTechRef StationController PDFAlexNo ratings yet

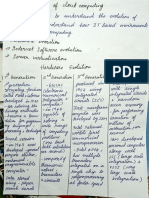

- Evolution of Cloud ComputingDocument3 pagesEvolution of Cloud ComputingVaishnavi ChockalingamNo ratings yet

- RibbonDocument33 pagesRibbonjavluqNo ratings yet

- Axial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationDocument10 pagesAxial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationAditya SawantNo ratings yet

- Technical ReportDocument2 pagesTechnical ReportsihamNo ratings yet

- Evermotion Archmodels 79 PDFDocument2 pagesEvermotion Archmodels 79 PDFKimNo ratings yet

- Vehicle owner's manual essential safety guideDocument232 pagesVehicle owner's manual essential safety guideHamzah Hussain100% (2)

- PG To Metric Conversion TableDocument1 pagePG To Metric Conversion TableKyaw La Pyi WunnNo ratings yet

- Matlab ExeDocument39 pagesMatlab Exekashif_115No ratings yet

- Low Voltage Switchgear and Control Gear Application GuideDocument152 pagesLow Voltage Switchgear and Control Gear Application GuideAntonio MejiaNo ratings yet

- Kia Industrial SectorDocument1 pageKia Industrial SectorvgvpplNo ratings yet

- Scheduling in SAS 9.4Document78 pagesScheduling in SAS 9.4danielhidalgopNo ratings yet

- OSI vs TCP/IP Communication Protocols ExplainedDocument33 pagesOSI vs TCP/IP Communication Protocols ExplainedKiran ZahraNo ratings yet

- DH Ipc Hdbw5541e Z5e Datasheet 20190620Document3 pagesDH Ipc Hdbw5541e Z5e Datasheet 20190620Ali KılıçkayaNo ratings yet

- AcademicBulletin2015 16Document140 pagesAcademicBulletin2015 16Sreekumar KsNo ratings yet

- 5a4b0 Compal LA-6072PDocument61 pages5a4b0 Compal LA-6072Pابراهيم السعيديNo ratings yet

- Smart-L MM/F: Long Range Multi Mission RadarDocument2 pagesSmart-L MM/F: Long Range Multi Mission RadarCarakaNo ratings yet

- Lesson 10 Data and Hardware Protection: Computer Literacy Basics: A Comprehensive Guide To IC, 5 EditionDocument39 pagesLesson 10 Data and Hardware Protection: Computer Literacy Basics: A Comprehensive Guide To IC, 5 EditionJeriz Marie GamboaNo ratings yet

- 709 Cab CO2 Weld ReductionDocument68 pages709 Cab CO2 Weld ReductionVishwarath TaduruNo ratings yet

- Asme B31.3Document2 pagesAsme B31.3Gilmar MarquesNo ratings yet

- X RayDocument3 pagesX RayjacksonNo ratings yet

- Workshop IDocument6 pagesWorkshop IValentina GonzálezNo ratings yet

- WT-805M Modbus Protocol V2.3Document16 pagesWT-805M Modbus Protocol V2.3Krishnakumar GanesanNo ratings yet

- RemList EPSS Generator 2010Document3 pagesRemList EPSS Generator 2010Hugo Ramon Saravia CampelliNo ratings yet

![IET Power Electronics Volume 4 Issue 9 2011 [Doi 10.1049_iet-Pel.2010.0363] Jung, J.-h.; Ahmed, S. -- Flyback Converter With Novel Active Clamp Control and Secondary Side Post Regulator for Low Standby Power Consumption Under High](https://imgv2-1-f.scribdassets.com/img/document/220209509/149x198/8baf096670/1429428106?v=1)