Professional Documents

Culture Documents

Free GD T Wall Chart

Free GD T Wall Chart

Uploaded by

Yuan GaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Free GD T Wall Chart

Free GD T Wall Chart

Uploaded by

Yuan GaoCopyright:

Available Formats

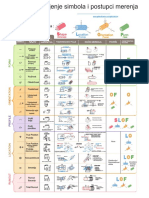

GD&T Symbols and Guidelines Cheat Sheet

Provided by GD&T Basics - www.gdandtbasics.com

For the Premium version of this chart, sign up for our GD&T Basics Fundamentals course at www.gdandtbasics.com/gdt-training

Y

V

Y

The 4 Fundamental X

Elements of GD&T: X

W U

Z X

Size Location Orientation Form

Z X

All drawings made in

first angle projection

SYMBOL NAME ON DRAWING TOLERANCE ZONE GAUGING SURFACES FEATURES OF SIZE

Two parallel lines

0.03 apart

Straightness

0.03

(Surface)

100.050 Cylindrical Tolerance Zone

Cylinder Gauge ID = M +

Straightness

0.03 M 0.03 when Part = 10.05

0.13 when Part = 9.95

M Gauge ID = 10.08

F

(Derived Median Line w/ M )

Flatness

(Surface)

0.03

Two parallel planes

0.03 apart

F (Derived Median

FORM

Line and Plane)

Planar Tolerance Zone

Flatness

Gauge spacing

100.05 Two parallel planes at Virtual Condition

0.03 M 0.03 apart

M + = 10.08

M (Derived Median

Plane w/ M )

Two concentric circles

0.03 0.03 apart

Circularity

Two concentric cylinders

0.03 0.03 apart

Cylindricity

Two parallel planes

0.03 apart

0.03 A

Parallelism

parallel to datum

Flat datum block

A (Datum A)

Datum A

Gauge kept parallel to datum

Perpendicularity

0.03 A

A

Two parallel planes

0.03 apart Flat datum block

(Datum A) OF O

ORIENTATION

(Feature) 90

Datum A Gauge kept perpendicular to datum

100.05 Gauge pin Pin Gauge OD = M Y

V

Y

V

Axis inserted

Perpendicularity

0.03 M A perpendicular Pin Gauge = 9.92

Tolerance Zone

at M to datum (9.95 - 0.03)

M 90

Multiple datums

(Feature of Size w/ M ) may be used

to specify W U W U

Perpendicularity Z X Z X

A Datum A

Two parallel planes

0.03 apart

0.03 A

Angularity 60 A Gauge

Block

60 60

60

Datum A

0.03 A B Uniform Linear Boundary About True Profile Datum B

SLOF

Profile

0.03 apart Gauge must

B A follow true profile.

of a line Profile is usually

measured with a CMM.

PROFILE

Basic dimensions (not shown) are required to

define the True Profile when datums are used. Datum A

Y Y

V

0.03 A B Uniform Surface Boundary About True Profile Datum B

Profile B A

0.03 apart Gauge must

follow true profile.

X

of a surface Basic dimensions (not shown) are required to Datum A

Profile is usually

measured with a CMM.

X

Z X Z

W U

X

define the True Profile when datums are used.

100.05

LO

Part (actual) position Measure X and Y location and compare to the true position.

0.03 A B C

2X (Actual X - True X)2 + (Actual Y - True Y)2

B Y

True Position Actual

This formula must be less than

20.0 True

the True Position tolerance

Actual Y

0.03 True Y

30.0

True

center

C A X Y

True X Actual X

None

Actual

100.05 Pin Position Part FUNCTIONAL Part Tolerance Zone

0.03 M A B C GAUGING of Pin Gauge

True Position

Z X

True

B position True Y

V

position

M For an For an

(Maximum Material 25.0 Tolerance Zone

of Hole Gauge

External

Feature

Internal

Feature Actual

Condition) Hole Position

LOCATION

W U

Z X

25.0 C A Gauge Hole = Virtual Condition Gauge Pin = Virtual Condition

Gauge Gauge (Smallest Hole Size [MMC] - Position Tol.)

(Largest Pin Size [MMC] + Position Tol.)

LOF

1

0.03 A

The following is usually

Measured axis done with a CMM:

Datum axis

Concentricity 0.03

1. Determine

Datum axis

2. Measure referenced

surface

A

Datum A

3. Determine if central

A Tolerance Zone axis falls in TZ Distribution/ Y

Diameter Symbol is required

Evenness of (Derived

0.03 A

A A

The following is Form Only Median

A

Datum A

usually done

with a CMM:

Z Y

V

X

Points)

Symmetry Plane

1

1. Determine

Datum plane

2. Measure both

surfaces of features

3. Determine if W

Two parallel planes midpoints fall in TZ Z U

X

0.03 apart

0.03 A Datum A

Fixed + Rotated

LOF

Datum A

A

Runout

A Fixed axially

+ Rotated Can also be used

on flat surfaces

perpendicular

RUNOUT

A

to the datum axis

A

Y Y

V

0.03 A Datum A

Datum A Fixed + Rotated

A

Fixed axially

A

Total Runout

+ Rotated Can also be used W U

on flat surfaces Z X Z X

A perpendicular

to the datum axis

A

Copyright Pareto Learning LLC - All Rights Reserved - Chart designed by Andrea Barbieri <www.andreabarbieri.net>

You might also like

- GD&T Basics Wall ChartDocument1 pageGD&T Basics Wall ChartAmandeep SinghNo ratings yet

- GD&T: Theory To Reality: Mission StatementDocument67 pagesGD&T: Theory To Reality: Mission StatementCharlie Tej100% (1)

- True Position TheoryDocument28 pagesTrue Position TheoryOrville Sutari100% (1)

- GD&T Symbols, Definitions ASME Y14Document8 pagesGD&T Symbols, Definitions ASME Y14deepak0% (1)

- Landscape of Planning Activity Ver. 04: Core PhaseDocument1 pageLandscape of Planning Activity Ver. 04: Core PhasetrungNo ratings yet

- Previews 2233333 PreDocument10 pagesPreviews 2233333 PreTHI MEN PHAMNo ratings yet

- Bearinx - Online Shaft CalculationDocument6 pagesBearinx - Online Shaft CalculationMarian DunareanuNo ratings yet

- Tolerance Stackup Analysis 2.0Document6 pagesTolerance Stackup Analysis 2.0Leon WangNo ratings yet

- GD&TDocument5 pagesGD&Travindra_2011No ratings yet

- GC CatalogDocument30 pagesGC CatalogMiguel QueirosNo ratings yet

- GD&TDocument10 pagesGD&TShahed FacebookNo ratings yet

- Form and PositionDocument54 pagesForm and PositionThangadurai Senthil Ram PrabhuNo ratings yet

- GD&T Symbols and Guidelines Cheat Sheet: Provided byDocument1 pageGD&T Symbols and Guidelines Cheat Sheet: Provided byLuis Angel Martinez Soto100% (1)

- Welding HandbookDocument197 pagesWelding Handbookali652272583% (6)

- GDT Training PyramidDocument1 pageGDT Training PyramidkhalidcosmosNo ratings yet

- Geometric Dimensioning and TolerancingDocument6 pagesGeometric Dimensioning and TolerancingPedro LeosNo ratings yet

- BOOK77Document5 pagesBOOK77Vaibhav GuptaNo ratings yet

- Datum ShiftDocument11 pagesDatum ShiftHarshottam DhakadNo ratings yet

- DATUMSDocument84 pagesDATUMSmaddy_scribd100% (2)

- GD&T Wall Chart SrpskiDocument1 pageGD&T Wall Chart SrpskizlatkoNo ratings yet

- Your Source For GD&T Training and MaterialsDocument6 pagesYour Source For GD&T Training and Materialskharsh23No ratings yet

- Tesa Micro-Hite: The Quick and Accurate MeasurementDocument32 pagesTesa Micro-Hite: The Quick and Accurate MeasurementEnggCoordNo ratings yet

- BasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014Document166 pagesBasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014raseen pNo ratings yet

- Chapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Document12 pagesChapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Jackie HwangNo ratings yet

- GD&T Symbols and Guidelines Cheat SheetDocument1 pageGD&T Symbols and Guidelines Cheat SheetViraj Shirole100% (1)

- GD&T BasicsDocument33 pagesGD&T Basicsjanaaidaas1996No ratings yet

- GD&TDocument33 pagesGD&TShasank PramodeNo ratings yet

- Coordinate Measuring MachineDocument13 pagesCoordinate Measuring MachineAjay G RNo ratings yet

- GDTDocument38 pagesGDTAntonio CervantesNo ratings yet

- 04 - ALL - Feature FittingDocument33 pages04 - ALL - Feature FittingBeNjaz NorthcuttNo ratings yet

- GOM Software en RevADocument16 pagesGOM Software en RevAddd100% (1)

- GD&TDocument14 pagesGD&TsrajubasavaNo ratings yet

- GD&T 1Document41 pagesGD&T 1Sai CharanNo ratings yet

- GD&T Glossary and Resource - GD&T Symbols and TermsDocument4 pagesGD&T Glossary and Resource - GD&T Symbols and TermsMohammed Adil100% (1)

- Bollhoff HeliCoil Aerospace Blue BookDocument35 pagesBollhoff HeliCoil Aerospace Blue BookAce Industrial SuppliesNo ratings yet

- GD&T Inspection in Spatialanalyzer: Jeremy Winn Philip WilsonDocument53 pagesGD&T Inspection in Spatialanalyzer: Jeremy Winn Philip WilsonAnthuan SenoirbNo ratings yet

- Dr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackDocument38 pagesDr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackpdmnbraoNo ratings yet

- Calypso Maquina de CoordenadasDocument16 pagesCalypso Maquina de CoordenadasIvonne LunaNo ratings yet

- GD&T Symbols Reference GuideDocument2 pagesGD&T Symbols Reference Guidecreating_24No ratings yet

- WWW Tec Ease Com GDT Terms PHPDocument14 pagesWWW Tec Ease Com GDT Terms PHPlaboratorioNo ratings yet

- GD&TDocument19 pagesGD&Tpavan_joshi_5No ratings yet

- Mechanical Drawing PDFDocument50 pagesMechanical Drawing PDFSagar KapadeNo ratings yet

- Notes On Geometric Dimensioning and TolerancingDocument68 pagesNotes On Geometric Dimensioning and TolerancingVinod KumarNo ratings yet

- IIGDT - Tolerancing Optimization Examples With $ SignsDocument9 pagesIIGDT - Tolerancing Optimization Examples With $ Signsநளின் கான்No ratings yet

- Geometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total RunoutDocument3 pagesGeometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total Runoutmick.pride81No ratings yet

- Metrology Public PDFDocument9 pagesMetrology Public PDFLeopoldo TescumNo ratings yet

- Flat Ness: Our Comprehensive List of GD&T SymbolsDocument29 pagesFlat Ness: Our Comprehensive List of GD&T SymbolsMidhilesh RavikindiNo ratings yet

- Simultaneous Requirements: Defines in The Following WayDocument7 pagesSimultaneous Requirements: Defines in The Following WayNishant PatilNo ratings yet

- Positional Tolerancing (GD&T)Document15 pagesPositional Tolerancing (GD&T)Kishor kumar Bhatia100% (1)

- Model Contura G2 Manufactured by Carl Zeiss Same YearDocument4 pagesModel Contura G2 Manufactured by Carl Zeiss Same YearB VarunNo ratings yet

- What Is The Tolerance Analysis - QRDocument15 pagesWhat Is The Tolerance Analysis - QRAnonymous tQhtrPbNo ratings yet

- BookGD T PDFDocument14 pagesBookGD T PDFAbsolute ElectronicsNo ratings yet

- Gaining Confidence With GD T Part 1Document24 pagesGaining Confidence With GD T Part 1pdmnbraoNo ratings yet

- Magna Supplier Quality Requirements Manual Rev2Document26 pagesMagna Supplier Quality Requirements Manual Rev2gflores65No ratings yet

- Calypso - The Easy Way To Create Part Programs: We Make It VisibleDocument16 pagesCalypso - The Easy Way To Create Part Programs: We Make It VisibleArnut PhilaNo ratings yet

- GD&T Chart - 231011 - 202857Document2 pagesGD&T Chart - 231011 - 202857SanjoGsingh RajPutNo ratings yet

- GD&T Basics Wall ChartDocument1 pageGD&T Basics Wall ChartShahzad KhanNo ratings yet

- GDT Basics Wall Chart HHDDDDDDDDDDDocument2 pagesGDT Basics Wall Chart HHDDDDDDDDDDjames.millsNo ratings yet

- L212 E GAD 001 (Rev1)Document7 pagesL212 E GAD 001 (Rev1)Md. Mahmudur RahmanNo ratings yet

- It's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentFrom EverandIt's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentNo ratings yet

- Seafastening PDFDocument1 pageSeafastening PDFAnonymous tGFxtqNNo ratings yet

- SaxsaDocument1 pageSaxsaAnonymous tGFxtqNNo ratings yet

- Welcome To ANSI/HI Pump Standards Version 2.2: Centrifugal PumpsDocument1 pageWelcome To ANSI/HI Pump Standards Version 2.2: Centrifugal PumpsAnonymous tGFxtqNNo ratings yet

- SaxsaDocument1 pageSaxsaAnonymous tGFxtqNNo ratings yet

- Passivating Pickling en 2007Document16 pagesPassivating Pickling en 2007Anonymous tGFxtqNNo ratings yet

- NWHA Tech Weld Procedure Process 2014 PDFDocument60 pagesNWHA Tech Weld Procedure Process 2014 PDFAnonymous tGFxtqNNo ratings yet

- Lamination TheoryDocument147 pagesLamination TheoryAnonymous tGFxtqNNo ratings yet

- How ToDocument1 pageHow ToAnonymous tGFxtqNNo ratings yet

- Membrane BendingDocument12 pagesMembrane BendingAnonymous tGFxtqNNo ratings yet