ENGINEERING SPECIFICATION ES-YF12-1294-AA

The following information is intended as a general interpretation of the ES-YF12-1294-AA Engineering

Specification. It is intended to help the user understand the intent of the 1294 specification and is for

explanatory purposes only.

This document was prepared with the following guidelines:

The text from the 1294 specification appears inside a double line box.

Informational notes and graphics have been included to help the user understand the intent of the 1294

specification and is for explanatory purposes only.

Datum letters have been assigned (Primary Datum A, Secondary Datum B and Tertiary Datum C) to help

the user understand the intent of the 1294 specification. They will not necessarily be the datum letters selected

for any actual application.

In some situations additional GD&T callouts and symbology, not included in the 1294 specification, have been

added to help the user envision the concepts and intent of the 1294 specification.

The principles described in this document may relate to several sections in the 1294 and they may not be

repeated in each section. The user should become familiar with this entire document to obtain a complete

understanding of the material.

This document is not intended to mandate a particular gaging method. Any reference to gaging is included for

explanatory purposes only.

Originated by:

Date Issued

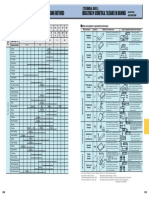

�OVERVIEW OF THE DATUM REFERENCE FRAME

The example illustrated is a typical Datum Reference Frame, however other combinations may be appropriate i.e. using the edges

of a part when the component contains on holes. The datums should be defined appropriately to constrain all 6 degrees of freedom.

Generally, a full Datum Reference Frame is achieved by combining a set of Primary net pads, a Secondary hole and a Tertiary slot

as described in the 1294 Spec. The part is immobilized using datum features similar to those described below.

XX +/- 0.05

0.2 M A

TERTIARY (2 WAY LOCATOR)

The tertiary datum feature is generally

simulated by a fixed (virtual condition) pin in

the manufacturing and gaging equipment,

and is used to stop rotation. Because of the

tight size and location tolerance of this

datum feature, the datum displacement

(shift) is minimal.

XX 0.05

25

A2

B

25

A1

PRIMARY (UP DOWN)

Although not covered in the 1294 Spec. the

primary datum feature(s) is typically simulated

by a set (usually 3 minimum) of net pads in the

manufacturing and gaging equipment. A typical

set of datum targets would consist of datum

targets A1, A2 and A3.

Originated by:

SECONDARY (4 WAY LOCATOR)

The secondary datum feature is simulated

by a fixed (virtual condition) pin in the

manufacturing and gaging equipment.

Because of the tight size tolerance of this

datum feature, the datum displacement

(shift) is minimal.

25

A3

Date Issued

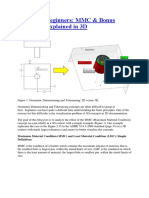

�The use of the 1294 eliminates repetitive

information that would typically be repeated on

sheet metal detail or assembly drawings.

The tolerances shown in

the 1294 are generic and

generally considered

standard tolerances.

I.

SCOPE:

This specification is issued to provide generic General Notes for detail drawings and data

files of sheet metal parts and assemblies.

II.

APPLICATION:

Notes: are to be used for sheet metal details and for assemblies when specified.

Tolerances that are unique from those below are to be shown on the face of the drawing or

on the Format #2 of the data files.

III.

PRIORITY RANKING ORDER:

First Level Math Surface Data

Second Level Wireframe Data

Third Level 5 mil Mylar Reproduction

Fourth Level Die Model

The Math Surface Data is the most

common method used and is considered

basic (theoretically exact) for GD&T

tolerancing purposes.

Originated by:

Date Issued

�SECONDARY DATUM

The fourth box contains the

secondary datum and is generally

a 4 way locating hole modified at

MMC taken from section V, B)

The ASME Y14.5M 1994 Standard, as amended by the Ford

(USCAR) addendum, is the GDT tolerancing Standard use by Ford

Motor Co. world wide. It can be can be accessed using the WISE

collection of standards (http://www.ese.ford.com/aso/wise/)

I V.

IN ACCORDANCE WITH THE A.S.M.E. Y14.5M - 1994 STANDARD, THE FOLLOWING

APPLIES:

Secondary Datum

Tolerance

GEOMETRIC CONTROL

The first box contains one of

the following geometric

controls

0.5

Tertiary Datum

Control

Primary Datum

Perpendicularity

Position

Profile of a Surface

Profile of a Line

TERTIARY DATUM

The fifth box contains the tertiary

datum and is generally a 2 way

locating slot modified at MMC taken

from section V, C)

TOLERANCE ZONE

The second box contains the

tolerance zone shape, size

and any applicable material

modifier (usually MMC)

Originated by:

PRIMARY DATUM

The third box contains the

primary datum which is

generally a planer datum

simulated by three or more

datum targets

Date Issued

�Maximum Material Condition (MMC). The condition in which a

feature of size contains the maximum amount of material within

the stated limits of size for example, minimum hole diameter.

IV. CONTINUED

The material modifier used will be M (maximum material condition), when features of size

are used as secondary and tertiary features.

Secondary Datum

A B

Tertiary Datum

Primary Datum

There are several advantages of applying the MMC to the secondary and tertiary datum features of size (hole / slot).

It allows the use of fixed (virtual condition) pins in the manufacturing and gaging equipment. Because of the tight size tolerance (+/- 0.05) of

these datum features, the datum displacement (shift) is minimal.

The other material modifiers available are regardless of feature size RFS and least material condition LMC. These modifiers are not

recommended for the following reasons:

RFS (regardless of feature size ) requires a moveable fixture i.e. a spring loaded tapered pin (for holes) and a spring loaded diamond pin (for

slots). It is expensive to verify, and rarely reflects the relevant feature function, and therefore should not be used in a Body application without

the agreement of the entire core team.

LMC (least material condition) is expensive to verify. To date no application in the Feature Control Frame for this symbol has been identified in

Body Engineering.

Originated by:

Date Issued

�V.

The most restrictive

tolerance is the default

GENERAL NOTES UNLESS OTHERWISE SPECIFIED:

If two or more general note tolerances can be applied to one part condition, the most

restrictive will apply.

HOLES:

A)

The secondary datum

feature hole (4 way

locating hole), and

tertiary datum feature (2

way locating slot width)

size is to be +/- 0.05

Size tolerance for any shape hole used as a secondary or tertiary (locator)

feature be +/- 0.05.

Size tolerance for any shape hole used as a transferred locator be +/0.05.

All other size tolerances to be +/- 0.4 with the exception: All lightening,

access, and drainage holes are to be:

The general size for all

other holes is to be +/0.4. This is typically

applied to round holes and

the width and length of

slotted holes

Originated by:

Profile of a line control (covered

in the profile section)

Transfer locating holes

were previously use in

the manufacturing

equipment to transfer

the stampings during

the manufacturing

process. They are

considered non

functional and will not

be used for interrelating

functional features.

When used for

manufacturing purposes

they will use the same

size tolerance as the

secondary and tertiary

(hole / slot) datum

features.

The exception is generally applied to all

other non critical holes, including round,

slotted and irregular shaped. These types

of holes are controlled using profile of a

line applied all around.

Date Issued

�SECONDARY DATUM

Generally a hole is used as a Secondary Datum and

functions as a 4 way locator

V. HOLES: CONTINUED.

B)

The positional tolerance of the secondary datum feature in relation to the primary datum to

be:

XX 0.05

This should read The

orientation tolerance

Note: If the secondary Datum hole is not

perpendicular (90) to the primary plane,

ANGULARITY

shall be used.

The asterisk

refers to the

description of 0

@ MMC

tolerancing

addressed at the

end of the 1294

section VII.

The secondary Datum feature is Generally a

Feature of Size, i.e. Single circular Hole, oriented

(90) on a surface (ideally that is parallel) to the

Primary datum Plane, and is ultimately used as a

four way locator. It is generally controlled relative to

the Primary Datum Plane using the Geometric

control of PERPENDICULARITY

. Note: use

ANGULARITY

If the secondary Datum hole is

not perpendicular (90) to the primary plane.

Size tolerance

taken from

section V.

HOLES: A)

If applied on the face of

the drawing a Datum

Feature symbol would be

used

Only a Primary Datum

callout is required

The intersection of the derived axis of the feature

is generally perpendicular to the Primary Datum

Plane, and the design side of the component and

is the local origin of all basic dimensions; 0,0,0

Reference: Simulated Primary Datum Plane

(up down). Although not covered in the 1294

Spec. the primary datum feature(s) is

typically simulated by a set of net pads in the

manufacturing and gaging equipment. A

typical set of Datum Targets would be

identified using datum targets.

Originated by:

Date Issued

�TERTIARY DATUM

Generally the width of a Slotted Feature of Size is used as a

Tertiary Datum and functions as a 2 way locator to stop rotation

V. HOLES: CONTINUED.

C)

The positional tolerance of the tertiary datum feature in relation to the primary and

secondary datums is to be:

Total width zone for

size (no diameter

symbol shown)

XX +/- 0.05

0.2 M A

0.2 total width zone (no

diameter symbol shown)

Size tolerance taken from

section V. HOLES: A )

XX +/- 0.05

0.2 M A B M C

Size tolerance taken

from section V.

HOLES: A )

Primary and

secondary

Datum required

If applied on the face of

the drawing a Datum

Feature symbol would be

used

The length of the slot is controlled

back to datum features A, B and C

Using the same tolerance as the

Tertiary datum slot width location.

Originated by:

If applied on the face of the drawing, the

arrows would be perpendicular to the

edges of the slot to indicate the desired

direction of the total width zone.

Date Issued

�EFFECTS OF SLOT TOLERANCE

10 +/- 0.05

0.2

A B

9.95

0.20

9.75

The 1294 Tertiary Datum slot tolerancing allows

this virtual condition datum feature simulator

gage pin (9.75 X 13.75), to be used to verify the

location and orientation of the slot

13.95

0.20

13.75

MMC width of slot

Positional tolerance

Wide boundary

MMC length of slot

Positional tolerance

Wide boundary

90

14 +/- 0.05

0.2

A B

Datum plane A

XX

THIS CONTROL

MEANS THIS

POSSIBLE LMC SLOT ORIENTATION

9.95

0.20

9.75

MMC width of slot

Positional tolerance

Wide boundary

virtual condition datum feature

simulator gage pin (9.75 X 13.75),

As a result the actual slot produced at

its least material condition (largest

slot size) can rotate about the virtual

condition gage pin

13.95

0.20

13.75

MMC length of slot

Positional tolerance

Wide boundary

VIRTUAL GAGE PIN AND SLOT

Originated by:

Date Issued

�EFFECTS OF SLOT TOLERANCE

Secondary Datum

Virtual Condition "Pin For Datum

Feature B" is equal to the holes MMC

Size. (since the hole is toleranced at 0

at MMC its virtual condition size is the

MMC limit)

Tertiary Datum

Virtual Condition "Race Track Pin For Datum

Feature "C" is equal to the slots MMC Size

Minus the Positional Tolerance.

Gage to Verify Secondary and Tertiary Datums

Verification of the interrelationship of the Secondary and Tertiary datums is

required. The gage shown here represents a virtual condition go / no go gage,

however different gaging methods could be used i.e. Coordinate Measuring

Machine, Non Contact Optical etc.

Originated by:

10

Date Issued

�EFFECTS OF SLOT TOLERANCE CONTINUED

Nominal (basic) location of pin.

Nominal (basic) location of slot.

NOMINAL CONDITION SHOWN

Possible part / assembly shift due to the

location and orientation of the slot and pin.

This will contribute to the variation in the

location and orientation of the mating part

with respect to intended design location.

Nominal location of center plane of

hole / slot and pins in the mating part

Note: although shown to nominally

intersect, the slot centerplane may be

offset (does not intersect hole axis) by

design.

The Datum C slot has rotated within the

maximum tolerance range specified on the 1294.

XXX

Nominal location of center plane of

hole / slot and pins in the mating part

Possible location of center plane of

mating part pin due to part variation.

Possible location of mating part

pin due to part variation.

POSSIBLE PART / ASSEMBLY SHIFT SHOWN

Originated by:

11

Date Issued

�????????? FABRICATION HOLES

In the past Fabrication Holes were synonymous with Transferred Locator Holes. They were non functional and were previously use in

the manufacturing equipment during the manufacturing process. Both terms are no longer used and since they were non functional, the

terms will not be used for holes controlling interrelating functional features.

Similar functional holes now referred to as ?????????? Holes are used to assemble mating parts and will use the positional tolerances

previously described as Fabrication holes in section V D)

NEED A NEW NAME TO

REPLACE FABRICATION

?????????? Holes are typically used to:

locate components assembled in a fixture , i.e. locate individual components to create an assembly to be welded together (see

fig. 1)

locate mating parts in the assembly. i.e. locate a trim panel for proper assembly (see fig. 2)

They typically consist of a combination hole / slot, a pair of holes or a pair of slots.

They are generally toleranced in relation to the global datum reference frame (master control holes).

2-WAY

LOCATOR PIN

4-WAY

LOCATOR PIN

2-WAY LOCATOR HOLEHINGE REINFORCEMENT

2-WAY

FABRICATION

HOLE

4-WAY

FABRICATION HOLE

4-WAY LOCATOR HOLE HINGE REINFORCEMENT

PINS IN DOOR INNER

PANEL LOCATOR HOLES

PIN IN CORRESPONDING FABRICATION

HOLES IN DOOR INNER PANEL

fig. 2

fig. 1

Originated by:

12

Date Issued

�NEED A NEW NAME TO

REPLACE FABRICATION

V. HOLES: CONTINUED.

D)

Round holes

are generally

used as a 4

way locator.

Now referred to as ?????????? Holes

Round hole location

tolerance controls location

and orientation

The positional tolerance for fabrication holes to be:

0.5

For round holes:

For slots:

Slots are generally used as a

2 way locator to stop rotation

and require a tolerance for

width and length.

Slot width size tolerance taken

from section V. HOLES: A)

transfer locator

Slot width location tolerance

controls orientation

A B

Width

1.6

A B

Length

Round hole size tolerance

taken from section V.

HOLES: A) transfer locator

10 +/- 0.05

0.5 M A B M C M

Slot length location tolerance

is generally not as critical as

width

Round holes are generally

positioned back to the

global datum reference

frame (master control

holes)

Subsequent use of holes to

locate related features

could require additional

datum identification

14 +/- 0.4

1.6 M A B M

Originated by:

0.5 M A B M C M

Slot size length tolerance

taken from section V.

HOLES: A) all other size

A B

0.5

10 +/- 0.05

NEED A NEW NAME TO

REPLACE TRANSFER

LOCATOR

C M

XX

13

Date Issued

�V. HOLES: CONTINUED.

POSITIONAL TOLERANCE OTHER HOLES

Holes other than secondary, tertiary and

locator are considered non critical and have a

general tolerance of 1.6 for location. All other

non critical holes such as lighting, access and

drainage are toleranced using profile of a line

and will be covered under the profile section.

E)

The positional tolerance for other holes to be:

For round holes:

1.6

A B

A B

A B

For slots:

1.6

1.6

Slot width size tolerance taken

from section V. HOLES: A) all

other sizes

Width

Length

Round hole size tolerance taken

from section V. HOLES: A) all

other sizes

10 +/- 0.4

1.6

A B

10 +/- 0.4

1.6 M A B

Slot size length tolerance taken

from section V. HOLES: A) all

other size

14 +/- 0.4

1.6

Originated by:

14

A B

Date Issued

�V. HOLES: CONTINUED

The positional tolerance of group of holes and tolerance between all holes that are

labeled or dimensioned as a group to be:

1.6

0.5

M

M

A B

A

A group of holes defined as those which have the same function.

Only one symbol shown

indicates a composite

tolerance application

A typical group of holes could be those used to attach a

door handle assembly

The upper segment is

referred to as the Pattern

Locating Tolerance Zone

Framework (PLTZF)

The lower segment is

referred to as the

Feature Relating

Tolerance Zone

Framework (FRTZF)

COMPOSITE POSITIONAL TOLERANCE

Where design requirements permit a FeatureRelating Tolerance Zone Framework (FRTZF) to be located and oriented within limits imposed

upon it by a PatternLocating Tolerance Zone Framework (PLTZF), composite positional tolerancing is used. (The acronyms are pronounced

``Fritz'' and ``Plahtz.'')

Composite Positional Tolerancing provides a composite application of positional tolerancing for the location of feature patterns as well as the

interrelation (position and orientation) of features within these patterns. Requirements are annotated by the use of a composite feature control

frame. The position symbol is entered once and is applicable to both horizontal segments. Each complete horizontal segment in the feature

control frames may be verified separately, but the lower segment is always a subset of the upper segment.

Originated by:

15

Date Issued

�GROUP OF HOLES FRAME V. F) CONTINUED

3X 20 +/- 0.4

1.6

0.5

M

M

A B

A

THIS CONTROL

M

A typical drawing callout

applied to three holes

The Pattern Locating Tolerance Zone is

the larger tolerance located in the upper

FCF (1.6). It is related to datums A, B

and C for location and orientation

Actual Hole

The Feature Relating tolerance Zone

is the smaller tolerance zone (0.5)

located in the lower segment of the

FCF. It is not related to datums B and

C and is allowed to rotate within the

larger (1.6) zone.

Basic dimension

Basic dimension

25.0

Originated by:

MEANS THIS

The control requires that

each actual feature axis

must lie within the specified

tolerance zones of both the

upper and lower segments

simultaneously

25.0

16

Date Issued

�PROFILE V. SURFACES: GENERAL

PROFILE CONTROLS

Profile tolerance specifies a uniform boundary along the true profile within which the elements of the surface must lie. The Math Surface Data

is the most common method used to describe the true profile and is considered basic (theoretically exact). Profile is used to control form or

combinations of size, form, orientation, and location.

Profile of a surface is typically applied to the sheet metal surface (design / dimension side) and profile of a line is applied to edges (trim and

margin lines).

The tolerance value represents the distance between two boundaries equally disposed about the true profile. (Although the ASME Y14.5

Standard allows the zone to be unilaterally in one direction, or bilaterally unequally disposed, the 1294 only recognizes the equally disposed

application).

Profile tolerances apply normal (perpendicular) to the true profile at all points along the profile. The boundaries of the tolerance zone follow the

geometric shape of the true profile.

1.4

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

Profile tolerances apply

normal (perpendicular) to

the true profile

Basic contour shown

Tolerance zone 0.7 above

Basic contour shown

Tolerance zone 0.7 below

Originated by:

17

1.4

Zone is equally disposed

about basic contour +/- 0.7

Date Issued

�PROFILE FRAME V. APPLIED TO SURFACES LINES AND HOLES: GENERAL

A B

On a GDT drawing, leader is

directed to basic contour

True basic contour shown

The actual line element must lie

within the Specified Tolerance

Zone.

The Tolerance is applied

Normal/Perpendicular to the

true profile at all points along

the profile.

10

5

0 5

10

5

0 5

10

10

90

The Tolerance establishes a

uniform two-dimensional zone

limited by two parallel zone lines

extending along the length of

the considered feature.

Originated by:

3 (Bilateral)

18

Date Issued

�This control is used on surfaces shown in general views,

that mate against other surfaces or features. All other

general surfaces receive a larger tolerance (3) taken from

V SURFACES: E)

V. SURFACES:

A)

Lines and surfaces defining mating conditions are to be:

1.4

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

This is the same control as described in V SURFACES:

A) and is used to control Lines and surfaces defining

mating conditions shown in sections

B)

Lines and surfaces defining mating conditions shown in sections are to be:

1.4

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

Profile is only applied on one side of metal. On a standard dimensioned drawing the dimensions are

applied to the design / dimensioned side (the punch side). The opposite side of metal is controlled by the

sheet metal stock size tolerance.

Originated by:

19

Date Issued

�THIS CONTROL

True Basic Profile

located on the design /

dimension side

PROFILE FRAME V. APPLIED TO SURFACES LINES AND HOLES: GENERAL

If displayed on a drawing

the arrow points to the

design / dimension side

of the surface

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

Metal thickness

Opposite side of metal

controlled by metal thickness

XX +/- XX

MEANS THIS

True Basic Profile

located on the design /

dimension side

Actual Surface must lie within

Tolerance Boundary

Opposite side of metal

controlled by metal thickness

Tolerance zone boundary

Originated by:

3

Tolerance zone boundary

1.5

Zone is equally disposed about

basic contour +/- 1.5

20

Date Issued

�Depending on application,

the all around may be

applied. The All around

symbol (a circle located at

the junction of the leader)

indicates that the profile

tolerance applies all around

the feature.

V.

SURFACES:

C)

All margin line tolerances for components to be:

Total width margin line tolerance

A B

0.5 / 250

Unit length refinement

Entire margin line must lie between a

profile boundary of 1 all around the feature

1 A B

0.5 / 250

250

0

25

As a refinement within the larger 1

zone, all elements of the margin line

surface must lie between any 0.5

boundary for a distance of 250

0

25

Basic contour shown

Any unit random

length of 250

Originated by:

21

Date Issued

�THIS CONTROL

PROFILE FRAME V. APPLIED TO SURFACES LINES AND HOLES: GENERAL

If displayed on a drawing

the arrow points to

margin line edge of the

surface

1 A B

0.5 / 250

True Basic Profile of

component edge

MEANS THIS

True Basic Profile of

component edge

Actual Element Line of the

edge must lie within both

tolerance boundaries

Any random unit

length of 250

0.5

250

250

250

250

1

Entire surface must lie between a profile boundary of 1

(Zone is equally disposed about basic contour +/- 0.5)

Originated by:

As a refinement within the

larger 1 zone, all elements

of the margin line surface

must lie between any 0.5

boundary for a distance of

250

ENLARGED TRUE VIEW OF A

PORTION OF THE TRIM EDGE

22

Date Issued

�Fender, body side etc.

V. SURFACES: CONTINUED

D)

Surface profile relating to flushness characteristics on class #1 Surface components to be:

A B

0.5 / 250

ALL OVER

Depending on the application the

surface profile can be applied either

ALL AROUND (using all around

symbol) or ALL OVER

Originated by:

23

Date Issued

�XXX FROM EDGE

Typically measured from edge

A B M C

0.5 / 250

SURFACE FLUSHNESS

Surface flushness

of controlled

surface

THIS CONTROL

Typical section cut through

controlled area see next page

MEANS THIS

Contour of the surface adjacent

to the edge must lie between a

profile boundary of 1

0

25

25

0

A B M C

0.5 / 250

As a refinement within the larger 1 zone, all elements of

the surface, adjacent to the edge, must lie between a

boundary of 0.5 within any unit length of 250

Originated by:

0

25

Any random unit

length of 250

Basic contour shown

24

Date Issued

�THIS CONTROL

PROFILE FRAME V. APPLIED TO SURFACES LINES AND HOLES: GENERAL

If displayed on a drawing

the arrow points to the

design / dimension side

of the surface

True Basic Profile

located on the design /

dimension side

A B M C

0.5 / 250

ALL OVER

Opposite side of

metal controlled by

metal thickness

MEANS THIS

TYPICAL SECTION CUT

ALONG CONTROLLED AREA

Metal thickness

XX +/- XX

Any random unit

length of 250

250

As a refinement within

the larger 1 zone, all

elements of the surface,

adjacent to the edge

must lie between a

boundary of 0.5 within

any unit area 250 X 250

Actual Element Line of the

Surface must lie within both

tolerance boundaries

250

As a refinement within the larger

1 zone, adjacent to the edge, all

elements of the surface must lie

between a boundary of 0.5

within any unit area 250 X 250

Opposite side of

metal controlled by

metal thickness

Originated by:

Entire surface, adjacent to the edge

must lie between a profile boundary

of 1 (Zone is equally disposed about

basic contour +/- 0.7)

25

0.5

Date Issued

�V. SURFACES: CONTINUED

E)

All other component surfaces to be:

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

See V. SURFACES: A) for profile of a surface interpretation

Originated by:

26

Date Issued

�Trim lines are generally non critical by nature and unless

otherwise specified receive a bilateral profile tolerance of 3.

V.

LINES:

A)

All trim line tolerance to be:

3

B)

A B

Part shape and flanges to be free of fractures.

General quality requirement

C)

Datum lines, work lines and body grid lines are +/- 0. Tolerance between the above lines not

permissible.

Datum lines, work lines and body grid lines are often shown as

reference information and are treated as theoretically exact.

Entire trim line must lie between a profile

boundary of 3 all around the feature

A B

Depending on application,

the all around may be or

may not apply.

Basic contour shown

Originated by:

27

Date Issued

�THIS CONTROL

PROFILE FRAME V. APPLIED TO SURFACES LINES AND HOLES: GENERAL

If displayed on a drawing the

arrow points to the trim line

edge of the surface

A B

True Basic Profile of

component edge

MEANS THIS

ENLARGED TRUE VIEW OF

A PORTION OF THE TRIM

EDGE

Originated by:

True Basic Profile of

component edge

3

Actual Surface edge must lie

within Tolerance Boundary

28

Entire surface must lie between a profile

boundary of 3 (Zone is equally disposed about

basic contour +/- 1.5)

Date Issued

�SHEET METAL COMPONENT DRAWING EXAMPLE

V. HOLES: A)

Secondary Datum

V. HOLES: B)

V. SURFACES: A)

XX 0.05

0

A B

1.4

A B

ALL OVER ON THE DESIGN / DIMENSION SIDE.

V. LINES: A)

V. HOLES: A)

Tertiary Datum

XX +/- 0.05

5

A B

0.2

25

A1

V. HOLES: A) OTHER

V. HOLES: A)

Tertiary Datum

V. HOLES: C)

XX +/- 0.05

0.2

XX +/- 0.4

1.6

A B

V. HOLES: C)

2X XX +/- 0.4

V. HOLES: E)

25

A2

1.6

0.5

25

A3

Originated by:

29

M

M

A B

A

V. HOLES: F)

Date Issued

�VI.

NOTES AND TOLERANCE INFORMATION FOR SHEET METAL ASSEMBLY DRAWINGS:

A)

The positional tolerance of the secondary datum in relation to the primary datum to be:

XX 0.05

0

See section V. HOLES: B) for the assembly

drawing secondary datum feature requirements.

Originated by:

30

Date Issued

�VI.

NOTES AND TOLERANCE INFORMATION FOR SHEET METAL ASSEMBLY DRAWINGS:

B)

The positional tolerance of the tertiary datum feature in relation to the primary and

secondary datums is to be:

XX +/- 0.05

0.2 M A

See section V. HOLES: C) for the assembly

drawing tertiary datum feature requirements.

Originated by:

31

Date Issued

�VI.

NOTES AND TOLERANCE INFORMATION FOR SHEET METAL ASSEMBLY DRAWINGS:

C)

Tolerances between component datum features in an assembly to be:

2.0

2.0

A B

A B

Cylindrical zone, diameter

symbol must precede the

tolerance zone value.

Positional

between

datum / locator

holes.

Positional between

datum / locator

holes and slots

Total width zone, no

diameter symbol

preceding the tolerance

zone value.

After assembly, the various components

will be interrelated using these tolerances.

Originated by:

32

Date Issued

�VI. C) Position between

datum / locator holes

VI. C) Position between

datum / locator slots

0.21

XX 0.05

2.0 M

VI. C) Position between

datum / locator holes

XX 0.05

2.0

XX 0.05

M

2.0 M

VI. C) Position between

datum / locator slots

XX 0.05

DETAIL 3

2.0

DETAIL 2

G

DETAIL 1

ASSEMBLY

XX 0.05

0.29

0.2 M

XX 0.05

0.0 M

A

C

VI. A) Secondary Datum

assemblies

DETAIL 3

VI. B) Tertiary Datum

assemblies

DETAIL 2

DETAIL 1

ASSEMBLY

A

Detail 1 Assembly drawing

(made up of details 2 and 3)

Originated by:

33

Date Issued

�VI.

NOTES AND TOLERANCE INFORMATION FOR SHEET METAL ASSEMBLY DRAWINGS:

D)

All margin line tolerances for assemblies to be:

1.4 A B

0.5 / 250

Margin line in assemblies generally

implies hemmed panels

Originated by:

See section V. SURFACES: C) for the assembly

drawing feature requirements.

34

Date Issued

�VI.

NOTES AND TOLERANCE INFORMATION FOR SHEET METAL ASSEMBLY DRAWINGS:

E)

Surface profile relating to flushness characteristics on class #1 Surface to be:

A B

0.5 / 250

ALL OVER

See section V. SURFACES: D) for the assembly

drawing feature requirements.

Originated by:

35

Flushness characteristics on class #1 Surface

generally applies to doors, hood deck etc.

Date Issued

�Size tolerance taken from

section V. HOLES: A )

SHEET METAL ASSEMBLY DRAWING EXAMPLE

XX 0.05

0

XX +/- 0.05

0.2 M A

Secondary Datum

orientation tolerance

taken from section VI. A)

A B

0.5 / 250

Tertiary Datum

Position tolerance

taken from

section VI. B)

Size tolerance taken

from section V.

HOLES: A)

25

A3

25

A1

XX +/- 0.05

0.2 M

1.4 A B

0.5 / 250

25

A2

Originated by:

Position tolerance

taken from

section VI. B)

Margin line profile tolerance for

assemblies taken from section VI. D)

36

Size tolerance

taken from section

V. HOLES: A)

Surface profile tolerance

to control for assemblies

Flushness characteristics

on class #1 taken from

section VI. E).

Date Issued

�VII.

NOTES FOR ZERO POSITION OR ORIENTATION TOLERANCE AT MMC:

When the * follows the feature control frame, the position or orientation tolerance is stated as

zero at MMC. The feature of size at its MMC size must be located or oriented at its perfect

location or perfect orientation. As the feature of size departs from its MMC size towards its

LMC size, the position and orientation tolerance is allowed to grow to an amount equal to the

departure from the MMC size of the feature.

Additional information and examples regarding this subject may be found in the A.S.M.E.

Y14.5 1994 Standard on Geometric Dimensioning and Tolerancing, Section 2.8.3.

See section 5.3.3, 5.3.3.1, and 6.6.1.2 in the

A.S.M.E. Y14.5 1994 Standard

Application of Zero Tolerance at MMC.

The purpose of applying zero at MMC for the orientation of the secondary datum hole, is to allow the

component or assemble part to be produced and gaged using a fixed size virtual condition pin.

The pin size in the gage / fixture is equal to the MMC (smallest) hole size. The datum displacement (shift) is

minimal due to the tight hole size tolerance of the secondary datum hole +/- 0.05.

If the secondary datum hole is produced at its MMC limit of size, it must be perfect in orientation with respect to

the datum. A tolerance can exist only as the feature departs from MMC. The allowable orientation tolerance is

equal to the amount of such departure.

Note: Although the 1294 only applies this concept to orientation of the secondary datum hole, it is often used with

position when relating holes to a datum of reference.

Originated by:

37

Date Issued

�END

Originated by:

38

Date Issued