Professional Documents

Culture Documents

Poster GPS EN

Uploaded by

andrei-bobOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster GPS EN

Uploaded by

andrei-bobCopyright:

Available Formats

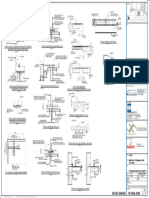

Sizes and modifiers Form and location tolerances Additional drawing entries Tolerance indications for

associations and filters

M

Maximum material requirement: M permits the addition of unused di- Ø 0.5 M

Sizes are dimensions of enclosed geometric features, e.g. diameter of Form tolerances limit the deviations of an individual feature from its geometrically ideal form. Orientati- mension tolerance portions to the toleranced form or location error. 0

Ø 6 - 1.0

cylinders and circles or distances of parallel surfaces. The type of tolerance on, location and runout tolerances limit the errors of the mutual location of two or more features. One Example (simple case): cylinder diameter 6 mm and the axis straightness

specification can be stipulated here by indicating modifiers. or more features can be specified as datum features. tolerance t = 0.5 mm (see image to the right). If the actual diameter is M In addition, indications can be made in the tolerance indicator for the associ-

5.0 mm, the straightness of the axis can deviate up to 1.5 mm. Ø6.0 Ø6.5

ation (calculated best fit) of the features and for filtering, e.g. 0.1 X G50– A

M or 0.1 N S150–50 or 0.1 F3 . The following applies:

Ø 15 ±0.1 GN ACS 0.05 SR Leader line Tolerance symbol Tolerance value

Ø5.0 Ø6.5

Leader Datum is the Toleranced fea-

arrow axis or mid- ture is the axis

0.1 A plane or mid-plane

3

L X

Ø 15 ±0.1 GN SCS Toleranced Tolerance indicator Minimum material requirement: L enables the addition of unused di- Ø 0.5 L

Inscribed feature: the toleranced feature is de-

feature

Datum Datum A mension tolerance portions (away from the material side) to the toleran- 0

Ø 6 - 1.0 fined as an inscribed circle / inscribed cylinder

feature Datum feature Toleranced

is the surface feature is the ced form or location error. (MICI / MICY).

line or surface surface line or

surface Example (simple case): cylinder diameter 6 mm and axis straightness to- L

LP

Local Point: specification of tolerance as a

N

Ø5.0

lerance t = 0.5 mm (see image to the right). If the actual diameter is 6.0 Ø4.5

Circumscribed feature: the toleranced feature is

two-point dimension (based on the midpoint mm, the straightness of the axis can deviate up to 1.5 mm. L

defined as a circumscribed circle / circumscribed

of a Gaussian circle) Roundness (form tolerance): the tolerance zone is limited in the t 0.02

Ø6.0 Ø4.5

cylinder (MCCI/ MCCY).

section plane perpendicular to the measuring axis by two concen-

GX

Global Maximum: specification of tolerance

R

tric circles a distance t apart.

G

Reciprocity requirement: the R-requirement enables the "reversal" of M Ø 0.5 M R

Gaussian feature: the toleranced feature is defi-

zone as a maximum inscribed circle / maxi- or L , i.e. the addition of unused form and location tolerances to the 0

ned as a Gaussian best fit (Gauss circle / Gauss

Ø 6 - 1.0 Ø 6.5 Ø 6.5

mum inscribed cylinder (MICI/ MICY). dimension tolerance. cylinder) (LPCI/LPCY).

Straightness (form tolerance): the tolerance zone is limited by

t 0.03

GN

Global Minimum: specification of tolerance

E

- a cylinder of diameter t ( of an axis or derived median line) Envelope requirement: as per ISO 8015, dimension tolerances and Ø 0.5

Minimum feature: the toleranced feature is defi-

zone as a minimum circumscribed circle / - two parallel planes a distance t apart ( of an edge) form and location tolerances must always be viewed independently of

C

0

Ø 6 - 1.0 E ned in accordance with the Chebyshev minimum

cylinder (MCCI/ MCCY). - two parallel lines a distance t apart ( of a surface line). each other. By inputing E on the dimension tolerance, the entire to- method (MZCI/MZCY).

E

lerance width, including form deviations, are limited to the dimensio- Ø 6.0 Ø 6.0

GC

Global Chebyshev: specification of tolerance Cylindricity (form tolerance): the tolerance zone is limited by two nal tolerance. Thus, in the example to the right, the external envelope

T

t 0.05 E Tangential feature: the toleranced feature is defined as an exter-

zone as per the Chebyshev minimum zone coaxial cylinders a distance t apart. (dimension+form) may not exceed the diameter of 6.0 mm. If this is Ø 5.5 Ø 6.0

nal tangential feature (as per the Chebyshev minimum method)

method (MZCI/ MZCY). already utilized, e.g. by the dimensional tolerance, no more form devia- (OTPL).

limits implicitly: and axis and surface and surface tions may occur.

GG

Global Gauss: specification of tolerance zone Gaussian filtering: the standard Gaussian filter must be used as

A

Ø 0.01 A

G

as a Gauss best fit (LSCI/LSCY). Flatness (form tolerance): the tolerance zone is limited by two Axis as a toleranced feature: to illustrate that not the surface but rather

t 0.05

the axis or center plane (center line) should be toleranced, a A can be a digital filter. The indication "G15–" means a low-pass filter

parallel planes a distance t apart. with 15 waves per revolution. "G150–50" would be a band-pass

input in the drawing (in 3D drawings necessary).

limits implicitly: surface or derived median line Spline filtering: the spline filter must be used as a digital

F S

Free state: the tolerance of the (elastic or plastic, non-rigid) workpiece

So-called rank-order sizes can be indicated as a supplement to the modifiers: filter. The indication "S50–" means a low-pass filter, "S150–50"

is defined in the unfixtured state (only formed by gravity), as per ISO

10579. means a band-pass filter with 50-150 waves per revolution.

Unlike form tolerances, location tolerances almost always require one or multiple datums:

SX

Statistical Maximum: largest value

UZ

Fourier analysis: the evaluation is performed using Fourier analy-

F

of the measured values Asymmetric tolerance zone (with profile form tolerances): the tolerance A

Parallelism (orientation tolerance): the tolerance zone is limited by t zone is shifted by the value t from the material center outwards (in the sis. Here "F3" limits the analysis to the third harmonic vibration

0.08 A

two parallel lines or planes a distance t apart, which are parallel example to the right, the zone is entirely outside of the material). (orbiform curve form).

SN

Statistical Minimum: smallest va-

lue of the measured values to the datum.

OZ

limits implicitly: surface or derived median line/ axis

Asymmetric tolerance zone (with profile form tolerances): the tolerance A

A

zone is shifted by a non specified value away from the material center. So

SA

Statistical Average: mean value of

the measured values Perpendicularity (orientation tolerance): the tolerance zone is limi-

ted by two parallel planes a distance t apart (or a cylinder with Ø

t

0.05 A

OZ (offset zone) only tolerances form, location and orientation, not size.

Important ISO standards for

P

6x

t) which are perpendicular to the datum. Projected tolerance zone: the tolerance zone has been moved by t entire-

the GPS

0.1 P A B

SM

A 30

ZEISS endeavors to ensure that all information is correct. However, the accuracy of the information cannot be guaranteed and ZEISS assumes no liability regarding the accuracy or completeness of the information.

Statistical Median: median of the B

limits implicitly: surface or

ly outside of the workpiece in order to inspect the locations relevant for

20

measured values derived median line/axis A

later assembly.

P

Angularity (orientation tolerance): the tolerance zone is limited

SR

Statistical Range: range of the t ISO 1101 GPS – tolerances of form, orientation, location and run-out

measured values by two parallel planes a distance t apart (or a cylinder with Ø t) 60°

A

0.1 A B

ISO 1160 GPS – Profile tolerancing

which are at the defined angle to the primary datum. B

ISO 2692 Form and position tolerancing, maximum material requirement

SD

Statistical Mid-Range: mean value

of SX and SN

limits implicitly: surface or derived median line/axis

60°

Datum and tolerance direction limitations ISO 5458 GPS – Position tolerancing

Ø 0.2 A ISO 5459 GPS – Datum and datum systems

Position (location tolerance): the tolerance zone is limited by a Ø 0.2

ISO 8015 GPS – Geometric tolerancing – Fundamentals –

><

cylinder in nominal position (for position with Ø sign). For additi- Datum feature only acts as an orientation feature. The position coordi-

Ø 0.2 A >< Concepts, principles, rules

100

onal tolerancing, see ISO 5458. nates are not considered.

Additional information give rules for specification. Corresponding measuring ISO 10579 GPS – Dimensioning and tolerancing – non-rigid parts

limits implicitly: , if applicable also and plane

PL

strategies can be derived from these: 50

Plane: datum feature only functions as a plane. Other parameters of the 0.6 A[SL] ... ISO 12180 GPS – Cylindricity

datum feature (e.g. origin coordinates) are not considered. ISO 12181 GPS – Roundness

Symmetry (location tolerance): the tolerance zone is limited by A

A

ACS

0.08 A

Any Cross Section: specification in any (possible) circular sec- ISO 12780 GPS – Straightness

SL

tion. two planes symmetrical to the datum axis or datum plane at a t Straight Line: datum feature functions only as a straight line. Other para-

distance t apart. meters of the datum feature (e.g. origin coordinates) are not considered. ISO 12781 GPS – Flatness

limits implicitly: center plane center plane if applicable center plane ISO 14405-1 GPS – Dimensional tolerancing – part 1: linear dimensions

SCS Specific Cross Section: specification only in the circular sec- 12°

PT

Point: datum feature functions only as a point. Other parameters of the ISO 14405-2 GPS – Dimensional tolerancing – part 2: dimensions other

tion (usually indicated by a theoretical dimension). datum feature (e.g. orientation information) are not considered. than linear sizes

Coaxiality or concentricity (location tolerances): the tolerance zone

øt

Ø 0.03 A

is limited by a cylinder or circle of diameter t which is coaxial or

ALS

A

Any Longitudinal Section: specification in each (possible) lon- Orientation Plane indicator: Indicates an additional orientation of the

gitudinal section. concentric to the datum. B tolerance zone. In the example to the right, the parallelism is only tole- 0.03 A B

Coaxiality limits implicitly: axis axis concentricity ranced parallel to the datum B.

AD

Altered Default: If a different standard or work standard beco-

CZ

EN_60_050_0012VI Printed in Germany. CZ-VIII/2023 © Carl Zeiss Industrielle Messtechnik GmbH

Combined Zone: joint specification of the characteristics in a mes applicable for a technical drawing in addition to the GPS

Line profile (profile tolerance with and without datum): the to- Intersection plane indicator: Specifies the section plane in which the tole-

common tolerance zone. B

0.08 A

0.03 A B standards (or if these are replaced), this can be performed in the

rance is defined In the example, parallelism is only toleranced perpendi-

t

lerance zone is limited by two curves which envelop circles of

ø

cular to B. tolerance box by adding the " AD Name of the particular stan-

diameter t whose mid-points are on a line of geometrically ideal

SZ

Seperate Zone: specification of the characteristics indepen- dard."

dently of each other (in separate tolerance zones). form. If applicable: a datum limits the position

K L

A

Tolerance zone limitation: the tolerance must be observed only in the K L

area between K and L. 0.5

TED Theoretically Exact Dimension: theoretical dimension without Surface profile (profile tolerance with and without datum): the 0.03 A

K L

K L

tolerance to indicate the ideal location, e.g. 25 or 60° . tolerance zone is limited by two surfaces which envelop spheres Continuously variable tolerance zone: the tolerance width changes from

of diameter t whose mid-points are on a surface of geometrically 0.3 mm (with K) linear up to 0.5 mm (with L). 0.3 - 0.5

ideal form. If applicable: a datum limits the location. A

t/...

øt Tolerance zone limitation: the tolerance must contain the value 0.5 in

0.5 / 100

t every section of the length 100 (in the example to the right).

Circular radial or axial run-out (run-out tolerances): the tolerance 0.1 A-B

zone is limited by two concentric circles or parallel planes a dis- All Around: the profile tolerance applies to all line and surface features

0.03

tance t apart, which are located by datum A-B. surrounding the entire workpiece in the viewing plane.

Circular radial run-out limits:

Carl Zeiss Industrielle Messtechnik GmbH

A B

Circular axial run-out limits: measuring line Collection Plane: the collection plane defines, in connection with the „All 73446 Oberkochen/Germany

B around“ symbol, a set of individual geometry elements that are toleran-

0.3 A B

Total radial or axial run-out (run-out tolerances): the tolerance t

0.1 A-B

ced together. Phone: +49 (0) 7364/ 20-6336

zone is limited by two coaxial cylinders or parallel planes a dis- Fax: +49 (0) 7364/ 20-3870

tance t apart, which are located by datum A-B. All Over: the profile tolerance applies to all (marked) line and surface Email: info.metrology.de@zeiss.com

0.03

Total radial runout limits: . Total axial run-out limits: A B features surrounding the entire workpiece. Internet: www.zeiss.com/imt

GPS – Geometric Product Specifications

There is additional information on geometric pro-

duct specifications (and the differences to the ASME

standardization) in the seminars and books of the

ZEISS Metrology Academy. Books can be ordered

here: shop.metrology.zeiss.com

You might also like

- Works standard tolerancesDocument3 pagesWorks standard tolerancesAkmal Nizametdinov100% (1)

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Pof Ili 2016 VersionDocument4 pagesPof Ili 2016 VersionAngelTinocoNo ratings yet

- Technical data on dimension tolerances for fittingsDocument1 pageTechnical data on dimension tolerances for fittingsHien Bui XuanNo ratings yet

- Fitting & ToleranceDocument2 pagesFitting & Tolerancenama sayaNo ratings yet

- Dimensional tolerance chart for machine elementsDocument1 pageDimensional tolerance chart for machine elementstrisakti.agusNo ratings yet

- ToleranceDocument33 pagesTolerancerahulrmoorthyNo ratings yet

- Passingen PDFDocument1 pagePassingen PDFAnonymous Z4Jo4fXVNo ratings yet

- New IMportant StandardsDocument1 pageNew IMportant StandardsfacadeNo ratings yet

- R08 He1d07 Bar 15 GF DWG SP 12001Document1 pageR08 He1d07 Bar 15 GF DWG SP 12001syedtalhamehmoodNo ratings yet

- Detail - B1: Section - A Elevations Elevations Section - ADocument1 pageDetail - B1: Section - A Elevations Elevations Section - AKumudu PereraNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80513Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80513Kumudu PereraNo ratings yet

- FFL - 0.15 FFL - 0.15: 1000 DoorDocument1 pageFFL - 0.15 FFL - 0.15: 1000 DoorAvanish SinghNo ratings yet

- FFL - 0.15 FFL - 0.15: 1000 DoorDocument1 pageFFL - 0.15 FFL - 0.15: 1000 DoorAvanish SinghNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-002 (P3) - Proposed Levels Plan (Sheet 2 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-002 (P3) - Proposed Levels Plan (Sheet 2 of 2)jmdavies.isNo ratings yet

- Rebar schedule and commentsDocument1 pageRebar schedule and commentstedi sopguiNo ratings yet

- Bearing Elements: Series LEL, With Ground RacewaysDocument12 pagesBearing Elements: Series LEL, With Ground RacewaysJezB1234No ratings yet

- Elevations and SchedulesDocument1 pageElevations and SchedulesMackson NkhomaNo ratings yet

- Tensile Fabric Details 3Document1 pageTensile Fabric Details 3FRANKLYN SPENCERNo ratings yet

- WEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHDocument12 pagesWEG CFW500 Installation Guide Parameter Reference 10007479673 en Es PT ZHRicardo LeiteNo ratings yet

- 3M Quick Reference Guide Jun17Document10 pages3M Quick Reference Guide Jun17Faith_No_MoreNo ratings yet

- Arb US Metro Map 10Document1 pageArb US Metro Map 10daynineNo ratings yet

- 1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelDocument1 page1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelmannshiNo ratings yet

- Empirical Support For Resilience As More Than The Counterpart and Absence of Vulnerability and Symptoms of Mental DisorderDocument14 pagesEmpirical Support For Resilience As More Than The Counterpart and Absence of Vulnerability and Symptoms of Mental DisorderFaten NajarNo ratings yet

- Conventional RepresentationDocument17 pagesConventional RepresentationZaky MuzaffarNo ratings yet

- 0030-0039 - Hou To Use The CatalogDocument5 pages0030-0039 - Hou To Use The Cataloglian silalahiNo ratings yet

- LBS-1100-10 Footings For Edge RestraintsDocument1 pageLBS-1100-10 Footings For Edge Restraintsissam.qamhiaNo ratings yet

- MPSHD Hi Ar DWG A 0213Document1 pageMPSHD Hi Ar DWG A 0213Emon RayNo ratings yet

- Bofinet-Gabs-Arch-Guard-141 Rev 5Document1 pageBofinet-Gabs-Arch-Guard-141 Rev 5zhong ganNo ratings yet

- STD1 Crimping Chart March 2020 Final 2Document1 pageSTD1 Crimping Chart March 2020 Final 2Luciano RodriguesNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNo ratings yet

- Toepc71061748 FDocument4 pagesToepc71061748 FGUILHERMENo ratings yet

- SSEB - I PLU VASO Rev02 20.09.2023 Layout2Document1 pageSSEB - I PLU VASO Rev02 20.09.2023 Layout2Aguigol MartensNo ratings yet

- L02-R02D01-FOS-00-XX-DWG-AR-62001Document1 pageL02-R02D01-FOS-00-XX-DWG-AR-62001Osama KheadryNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31155-Pdf (T00) - GRC Fins-Retail Frontage-TypesDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31155-Pdf (T00) - GRC Fins-Retail Frontage-TypesZaido Al HalabiNo ratings yet

- Residential building dimensions and notesDocument1 pageResidential building dimensions and notesIANNo ratings yet

- 02 19/06/18 100% Detailed Design Addendum 1 JB 03 31/08/18 100% Detailed Design Addendum 2 JBDocument1 page02 19/06/18 100% Detailed Design Addendum 1 JB 03 31/08/18 100% Detailed Design Addendum 2 JBPadam LimbuNo ratings yet

- Insurance BillDocument13 pagesInsurance BillSureshKarnanNo ratings yet

- StarHealthAssureInsurancePolicy BrochureDocument13 pagesStarHealthAssureInsurancePolicy Brochurepradosh002No ratings yet

- Pipe fitting assembly diagram Ø110mmDocument1 pagePipe fitting assembly diagram Ø110mmJohann Nick Flores AparicioNo ratings yet

- FafnirDocument3 pagesFafnirGustavo NielNo ratings yet

- G-126 - Lighting Control System Schematic Diagram PDFDocument1 pageG-126 - Lighting Control System Schematic Diagram PDFsyed ghufran HASSANNo ratings yet

- Faith Chogo Two BedroomDocument1 pageFaith Chogo Two BedroomBrian KibetNo ratings yet

- Faith Chogo Two BedroomDocument1 pageFaith Chogo Two BedroomBrian KibetNo ratings yet

- Strength of Adhesive Joints - Lectures 18+19Document11 pagesStrength of Adhesive Joints - Lectures 18+19Roger FeltmanNo ratings yet

- L02-R02D01-FOS-00-XX-DWG-AR-00601Document1 pageL02-R02D01-FOS-00-XX-DWG-AR-00601Osama KheadryNo ratings yet

- Word Problem Mnemonics GuideDocument3 pagesWord Problem Mnemonics GuideJamuna Pandiyan MuthatiyarNo ratings yet

- Key Reinforcement PlanDocument1 pageKey Reinforcement PlanMazen IsmailNo ratings yet

- Scale: 1:5 (1:2) : R TYP 5Document1 pageScale: 1:5 (1:2) : R TYP 5Prateek AnandNo ratings yet

- CVTec Consulting Engineers General NotesDocument1 pageCVTec Consulting Engineers General NotesAbu Baker DajahNo ratings yet

- L02-R02D01-FOS-00-XX-DWG-AR-70114Document1 pageL02-R02D01-FOS-00-XX-DWG-AR-70114Osama KheadryNo ratings yet

- IS 4241-1990 (R.A. 2020)Document6 pagesIS 4241-1990 (R.A. 2020)HARIOM INSTRU-LABSNo ratings yet

- N P FinalDocument1 pageN P FinalmlenientgtNo ratings yet

- BTGM - 1Document6 pagesBTGM - 1Eng Clive KabelengaNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31701-Pdf (T00) - Aluminium Louver Door Screen Typical DetailsZaido Al HalabiNo ratings yet

- BF150-75 Palace Sketch Plan ADocument3 pagesBF150-75 Palace Sketch Plan AJon-Pierre BooysenNo ratings yet

- Intend Alighment of GAS Pipe Under Landside Haul Road SeawallDocument6 pagesIntend Alighment of GAS Pipe Under Landside Haul Road SeawallJacky TamNo ratings yet

- General Structural Notes:: Typ. Det. For Beam or Slab Change Soffit Typ. Det. For Sleeves Thru RC BeamDocument1 pageGeneral Structural Notes:: Typ. Det. For Beam or Slab Change Soffit Typ. Det. For Sleeves Thru RC BeamJan Lawrence AlbertoNo ratings yet

- Maxillary Orthognatic SurgeryDocument1 pageMaxillary Orthognatic Surgerynapat kidsanakaraketNo ratings yet

- Works) : SABS 1200Document10 pagesWorks) : SABS 1200Palesa TshetlanyaneNo ratings yet

- Probability As A General Concept Can Be Defined As The Chance of An Event OccurDocument14 pagesProbability As A General Concept Can Be Defined As The Chance of An Event OccurMuhammad Adnan KhalidNo ratings yet

- Tooth Eruption and Movement MechanismsDocument8 pagesTooth Eruption and Movement MechanismsDrMohmed Mostafa100% (1)

- Aronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Document230 pagesAronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Matija LozicNo ratings yet

- U1L9 Student Guide (1) - 1Document4 pagesU1L9 Student Guide (1) - 1jonahNo ratings yet

- Cbse & Ntse: MathematicsDocument397 pagesCbse & Ntse: MathematicsAbhinav BNo ratings yet

- Nile and Tigris v2Document554 pagesNile and Tigris v2shuwaarabNo ratings yet

- Ce6101 Problem Sheet 3Document4 pagesCe6101 Problem Sheet 3HT BinhNo ratings yet

- Iberchem - French: Code Item Name Code Item Name 35000 7600Document2 pagesIberchem - French: Code Item Name Code Item Name 35000 7600Noor AshrafiNo ratings yet

- Postdoctoral Research Associate in Functional Organic MaterialsDocument6 pagesPostdoctoral Research Associate in Functional Organic MaterialsTheo GazisNo ratings yet

- Tubo Optiflux 2000 - Manual PDFDocument48 pagesTubo Optiflux 2000 - Manual PDFRonaldo Damasceno EmerichNo ratings yet

- Tips On Fatigue - NAVWEPS 00-25-559Document123 pagesTips On Fatigue - NAVWEPS 00-25-559Mark Evan SalutinNo ratings yet

- Chapter 7 STRDocument10 pagesChapter 7 STRmedrekNo ratings yet

- Recrystallization Mechanisms and Microstructure Development inDocument15 pagesRecrystallization Mechanisms and Microstructure Development invibeunguNo ratings yet

- BS SMP 7-8-9 Bab B. Inggris Sec. Text (Reading) (SB - Descriptive Text)Document5 pagesBS SMP 7-8-9 Bab B. Inggris Sec. Text (Reading) (SB - Descriptive Text)TeresaAvilla Ayuning BudiCayestuNo ratings yet

- Energy Security IndexDocument13 pagesEnergy Security IndexCarlos AlvarezNo ratings yet

- Northridge E250pDocument23 pagesNorthridge E250pVion VionNo ratings yet

- Liquid Gold Petroleum's Performance and SuccessesDocument2 pagesLiquid Gold Petroleum's Performance and SuccessesShubham DawleNo ratings yet

- MEK 10103 ELECTRIC DRIVES AND APPLICATIONSDocument23 pagesMEK 10103 ELECTRIC DRIVES AND APPLICATIONSNazrul KocyNo ratings yet

- The Wall Street Journal - 24-11-2021Document30 pagesThe Wall Street Journal - 24-11-2021Samuel GiovanelliNo ratings yet

- Rajalakshmi Engineering CollegeDocument2 pagesRajalakshmi Engineering CollegebalaNo ratings yet

- Week 3 Ipe Review ModuleDocument2 pagesWeek 3 Ipe Review ModuleDarren Ian MaalihanNo ratings yet

- Compact and Efficient: Rotary KilnsDocument4 pagesCompact and Efficient: Rotary KilnsNhaca100% (1)

- Thermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlDocument11 pagesThermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlOLANIYINo ratings yet

- Resumen en Ingles Del Diario Ana Frank Chisaguano EmilyDocument16 pagesResumen en Ingles Del Diario Ana Frank Chisaguano EmilyChisaguano EmilyNo ratings yet

- MAYTAG MDE28PNCGW0 TechSheet-W10589718-RevADocument8 pagesMAYTAG MDE28PNCGW0 TechSheet-W10589718-RevAAngel MartinezNo ratings yet

- Taller de Calor EstDocument2 pagesTaller de Calor EstDiegoMuñozNo ratings yet

- Industrial Coupling and HoseDocument57 pagesIndustrial Coupling and HoseCesar CoronelNo ratings yet

- Herman Pardamean Hutabarat: Mechanical EngineerDocument3 pagesHerman Pardamean Hutabarat: Mechanical EngineerHerman HutabaratNo ratings yet

- Morteza MirzaeiDocument3 pagesMorteza MirzaeiUmitNo ratings yet