Professional Documents

Culture Documents

Toepc71061748 F

Uploaded by

GUILHERMEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toepc71061748 F

Uploaded by

GUILHERMECopyright:

Available Formats

GA800 Quick Setup Procedure for Models GA80U2004 to 2211 and 4002 to 4168

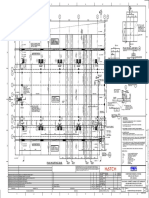

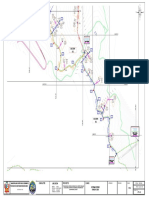

6 Select the Correct Wires, Wire Strip Length, Tightening Torque, and Branch Circuit Protection

GA80UXXXXABM 18mm

GA80UXXXXABAA-CAAAAA X.X~X.X N•m

X.Xmm 10mm

5.5mm

GA

800

https://www.yaskawa.com/ga800qsp1

GA800

TOE

PC71

TOE

PC71

ON-SITE UL Compliance: Install one of these types of short circuit protection devices to comply with UL 508C. Semiconductor protective type fuses are recommended, but the table also

shows alternative short circuit protection devices. When you use MCCBs, RK1, or RK5 fuses as UL listed drive protection devices, you must mount the drive in a ventilated enclosure

VIDEO

TOE 0617 0617

P C71 48 41-4

0617

37 6 according to the minimum enclosure volume specified in this document.

Molded Case Circuit Breaker (MCCB) and Non-Semiconductor Fuse Ratings: Maximum MCCB rating is 200% of the Normal-Duty drive full load output amp (FLA) rating. Maximum

Read and follow the safety and installation procedures in the Installation & Primary Operation CC, J, T, RK1, or RK5 fuse rating is 175% of the Normal-Duty drive full load output amp (FLA) rating. You can substitute an alternate UL listed current limiting type MCCB where the

(TOEPC71061737) manual packaged with the drive. peak let-through current and I²t of the alternate MCCB is not greater than the specified MCCB in this table.

Short Circuit Current Rating (SCCR): The maximum SCCR provided by drive and fuse, or drive and MCCB combinations in this document, is 100,000 RMS symmetrical amps. Use

1 Confirm the Drive and Motor Specifications

the protection specified in this document to prepare the drive for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amps and not more than 240 Vac

(240 V models) and 480 Vac (480 V models) when there is a short circuit in the power supply.

VOLTS ≥ HP

RPM

Induction Motor Nameplate

AMPS

DUTY

0.75

2.8

1765

Cont

40

VOLTS 230

HERTZ 60

3 PH

VOLTS AMPS ≥ HP

Induction Motor Nameplate

AMPS

RPM

DUTY

0.75

2.8

1765

Cont

40

VOLTS 230

HERTZ 60

3 PH

AMPS XXXXXXXXX

XXXXXXXXX

AC3PH 200-240V

AC3PH 380-480V Class RK1 or

Uin (nameplate)

Uin MCCB

Semiconductor Fuse Class CC, J,

+10% MAX

-15% MIN

L1 RK5 Fuse Enclosure Volume

L2

50/60Hz R/L1, S/L2, T/L3 U/T1, V/T2, W/T3 — +1 +2 +3 B1, B2 Manufacturer: or T Fuse Maximum

Maximum Minimum Size (in³)

≥ ≥

L3

Model Size (Amps)

HP HP HERTZ HERTZ Eaton/Bussmann Maximum

Induction Motor Nameplate Induction Motor Nameplate

Size (Amps)

3 PH 3 PH

HP 0.75 HP 0.75

AMPS 2.8 VOLTS 230 AMPS 2.8 VOLTS 230

RPM 1765 HERTZ 60 RPM 1765 HERTZ 60

DUTY Cont DUTY Cont

40 40

Part Number Size (Amps)

AWG (Recommended Value in Parentheses) Ventilated Protected Enclosure Required

2 Collect the Required Tools and Equipment

2004

Three-Phase 240 V

FWH-45B 7 15 7 4195

2006 14 - 6 (14) 14 - 3 (14) FWH-45B 10 15 10 4195

2008 FWH-45B 12 15 12 4195

2010 14 - 6 (12) 14 - 6 (14) 14 - 3 (12) 14 - 8 (10) FWH-45B 15 15 15 4195

14 - 10 (14) FWH-50B

2012 14 - 6 (10) 14 - 6 (12) 14 - 3 (10) 20 20 20 4195

or FWH-80B

FWH-80B

2018 14 - 6 (10) 14 - 6 (10) 30 35 30 4195

or FWH-100B

14 - 3 (8)

FWH-80B

2021 14 - 6 (8) 14 - 6 (10) 12 - 8 (10) 35 40 35 4195

3

or FWH-100B

Confirm the Correct Drive Installation Environment*

n/a FWH-100B

2030 14 - 6 (6) 14 - 6 (8) 14 - 3 (6) 14 - 10 (12) 50 60 50 4195

? +50 °C 2042 14 - 6 (6) 14 - 3 (3) 14 - 10 (10)

10 - 8 (8) or FWH-125B

FWH-150B 70 80 70 4195

(122 °F) 95 RH

2056 8 - 3 (3) 10 - 4 (4) 8 - 1 (1) 8 - 6 (6) FWH-200B 90 110 90 4195

≤ Pollution

%

14 - 8 (8) FWH-200B

Degree 2 2070 6 - 1 (1) 6 - 3 (3) 4 - 1/0 (1/0)

or FWH-225A

110 125 110 4195

-10 °C FWH-225A

(14 °F) ≤1000 m 2082 6 - 1/0 (1/0) 6 - 2 (2) 4 - 2/0 (2/0) 14 - 6 (6) 6 - 4 (6)

or FWH-250A

125 150 125 4195

0 RH • 10 Hz to 20 Hz: 1 G

(3281 ft)

(9.8 m/s², 32.15 ft/s²) FWH-225A

2110 6 - 1/0 (1/0) 2 - 2/0 (2/0) 10 - 4 (4) 175 200 175 10121

or FWH-250A

• 20 Hz to 55 Hz: 0.6 G

(5.9 m/s², 19.36 ft/s²) FWH-275A

*Refer to the drive manual for installations that exceed these conditions. 2138 2 - 2/0 (2/0) 2 - 4/0 (4/0) 10 - 3 (3) 4 (4) 225 250 225 10121

or FWH-300A

n/a

1 - 2/0 FWH-275A

2169 2/0 - 250 (4/0) 3/0 - 300 (4/0) 1/0 - 2/0 (1) 250 300 250 10121

(1/0) or FWH-350A

n/a 4 - 1/0 (4)

4 Mount the Drive Vertically 2211 2/0 - 250 (250) 3/0 - 300 (300) 1/0 - 2/0 (2/0)

1 - 2/0

(2/0)

FWH-325A

or FWH-450A

350 400 350 10121

Three-Phase 480 V

FWH-40B

4002 3.5 15 3.5 4195

or FWH-50B

6m

14 - 8 (12)

m Ø5.

(0.2

4 in 5 mm

4x ) (0

M5

[#1 .22

0] in)

10 8.2

2m mm

19 m (0.3

m (4.0

(0.7 m 2 in) 2 in

5 in )

4004 FWH-50B 7 15 7 4195

)

Ø11

(0.4 .7 mm 19

6 in m

(0.7 m

248 mm (9.76 in)

14 - 3 (14)

) 5 in

)

TO

4005 14 - 6 (14) FWH-50B 9 15 9 4195

14 - 10 (14)

14

0m

E ≥ 30 L8

PC mm-35

m

(5.5

x2

(1. = 0 1 in

x2

2 in)

710

)

50 mm (2 in)

4007 FWH-60B 12 15 12 4195

L8

≥ 2-35

617

=

< 30mm (0.1

260 mm (10.24 in)

mm 08

(1. in)

41-

120 2 in)

mm in)

(4.7

46

in)

50 mm (2 in)

19

m

4009 14 - 8 (10) FWH-60B 15 15 15 4195

(0.7 m

5 in 30

) 50

mm 30

mm

mm (1.2 in) (1.

(2 2 in)

in)

120

mm

(4.7

mm 6 in)

(0.2 102 m

GA

70

0 Te 4 in m

mpl ) (4.0

4012 14 - 3 (10) FWH-60B 20 20 20 4195

ate 2 in

TO ) 19

EP m

C71 (0.7 m

06

17 5 in

99 )

4018 14 - 6 (10) 14 - 3 (8) FWH-80B 30 35 30 4195

x2 x2 4023 14 - 6 (8) 14 - 6 (10) 14 - 3 (8) 14 - 10 (12) 12 - 8 (10) FWH-90B 40 45 40 4195

n/a FWH-125B

4031 8 -3 (6) 10 - 4 (8) 8 - 1 (6) 14 - 8 (10) 10 - 6 (8) 50 60 50 4195

or FWH-150B

4038 8 - 3 (6) 10 - 4 (8) 8 - 1 (4) 14 - 8 (10) 10 - 6 (8) FWH-200B 60 75 60 4195

5 Remove the Keypad, Front Cover, and Wiring Cover 4044

4060

10 - 4 (4)

10 - 4 (4)

10 - 6 (6) 10 - 3 (3)

10 - 3 (3)

14 - 8 (8) 8 - 4 (6)

FWH-200B

FWH-225A

70

100

80

110

70

100

4195

4195

1 4075 10 - 2 (2) 10 - 2 (2) 6 - 4 (6) FWH-250A 125 150 125 10121

14 - 6 (6) FWH-250A

4089 10 - 2 (2) 6 - 1/0 (1/0) 150 175 150 10121

or FWH-275A

2 2 6 - 4 (4)

1 FWH-250A

4103 2 - 2/0 (1/0) 2 - 2/0 (1) 2 - 4/0 (2/0) n/a 10 - 3 (3) 175 200 175 10121

or FWH-275A

1/0 - 2/0

4140 2/0 - 250 (3/0) 3/0 - 300 (2/0) 1/0 - 2/0 (2) 4 - 1/0 (4) FWH-300A 225 250 225 10121

(2)

n/a

1/0 - 2/0 FWH-325A

4168 2/0 - 250 (4/0) 3/0 - 300 (4/0) 1/0 - 2/0 (1/0) 4 - 1/0 (4) 250 300 250 10121

(1/0) or FWH-400A

Flip Over for Steps 7 to 14

GA800 Quick Setup Procedure TOEPC71061748F Sheet 1

7 Install the Motor Wiring and Power Wiring 11 Collect and Record Auto-Tuning Data from Motor Nameplate

3 PHASE INVERTER DUTY AC INDUCTION MOTOR NAMEPLATE EXAMPLE T1-xx Parameter

Reference Motor Nameplate Data Motor Nameplate Value

(Ex-xx Parameter¹)

MODEL XX 123AAAA123XX-X0 X FRAME 123AX

E

POLES X ENC XXX CODE X DES A TYPE ABC INS X0 A Motor Rated Power kW T1-02 (E2-11)

(HP x 0.746)

B F C

FL FL

VOLTS XXX RPM

XXXX AMPS

XX/XX B Motor Rated Voltage V T1-03 (E1-05)

MAX TEMP.

SF 1.0 DUTY CONT

AMB °C

XX SENSORS

T-STATS C Motor Rated Current (FLA) A T1-04 (E2-01)

G

SERIAL N.L. AMPS XX.X/X.X Motor Rated Frequency (Base

D Hz T1-05 (E1-04/E1-06)

MAX S.E. O.S.E. ROTOR Frequency)

RPM

4200 BRG. 309 BRG.

XXX WK²

X.X

E Motor Pole Count - T1-06 (E2-04)

HZ HP RPM

TORQUE VOLTS AMPS

(LB FT) (HIGH CONN) (HIGH CONN)

F Motor Rated RPM RPM T1-07

1 - 0 XX.X - XX.X

D A

60 XX XXXX XX.X XXX XX.X G Motor No-Load Current² A T1-09 (E2-03)

6 120 XX XXXX XX.X XXX XX.X

- Motor Rated Slip² ³ 0.000 Hz T1-10 (E2-02)

OHMS

R1: .XXX R2: .XXX X1: X.XX X2: X.XX XM: XX.X

R/L1

PH.

S/L2

- Test Mode Selection² - T1-12

T/L3

P/N XXXXXXX

- Motor No-Load Voltage V T1-13

6

IM ¹Auto-Tuning will automatically set the E1-xx and E2-xx parameters. You can manually adjust Ex-xx parameters after Auto-Tuning.

²These values are only necessary for Stationary Auto-Tuning (T1-01 = 1).

³If you do not know this value, leave at the default value of 0.000.

Refer to the Technical Reference

(SIEPC71061737) for more

12

8

9 Energize the Drive and Confirm It Is Ready

information about GFCIs.

/T1

U/T1 R/L1 U/T1

R/L1 U/T1

L1 V/T

R/L1 V/T2 W/T3 S/L2 T/L3 V/T2 W/T3 or READY

S/L2 T/L3 V/T2 W/T3

S/L2 T

T/L3

Spacing per local electrical codes

EF3

8 Remove the Tabs and Install the Wiring Cover G

External Fault (terminal S3)

Reset

2017/01/01 10:00

F

READY

R/L

1

S/L

2

T/L

3 13

8

9 Use Auto-Tuning Data from Motor Nameplate to Set Parameters and Auto-Tune the Drive

(AI)

Home Menu

Control Tuning

5x

9 Install the Front Cover and Keypad

Rdy

Enter motor rated power. RUN key : Tuning Start *** EXECUTE AUTO-TUNING ***

Home key : Cancel

Rotational Auto-Tuning End

Stationary Auto-Tuning 1

Stationary Line-Line Resistance 0000.55 kW The motor turns. ... Auto-Tuning Successful

Please be careful.

Range : 0.00~650.00 XX.XXHz/ X.XXA

1 2

14 Set the Drive for LOCAL Control and Check the Motor Rotation Direction

(KPD)

10

(KPD)

Determine the Correct Auto-Tuning Method Home JOG 6.00

Motor Connection and Load Condition

6.00

0.02

6.00

(KPD)

6.00 6.00

6.00

0.02 0.02

F A

Use Stationary Auto-Tuning Use Rotational Auto-Tuning READY

T1-01 = 1 T1-01 = 0

GA800 Quick Setup Procedure TOEPC71061748F Sheet 2

A

8

9 If the Motor Does Not Rotate in the Correct Direction D

9

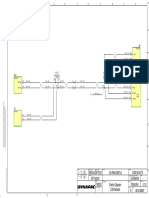

8 Connection Diagram and Terminal Functions

DC Link Terminal Type Signal Level Default

Choke Option Braking Resistor

S1 MFDI 1 Forward run/Stop

U X Option

S2 MFDI 2 Reverse run/Stop

S3 MFDI 3 External fault

2169, 2211 only U

+3 +2 + 1 _ B1 B2 U/T1 S4 MFDI 4 Fault reset

V Photocoupler

2004-2082 V/T2 S5 MFDI 5 24 V, 6 mA Multi-step speed 1

W

4002-4044 W/T3 S6 MFDI 6 Multi-step speed 2

S7 MFDI 7 Jog command

only

R/L1 Baseblock

S8 MFDI 8

command

S/L2

T/L3

GA800 SN MFDI power 0 V -

SC MFDI common -

24 V, 150 mA maximum

S1 MFDI power +

SP -

B

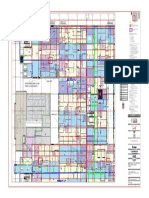

8

9 Control Circuit Configuration and Accessibility

S2

MA 24 VDC

Safe disable

MB H1

input 1

-

MC Safe disable

24 V, 6 mA

S3 H2

input 2

Internal impedance: 4.7 kΩ -

Minimum OFF time: 2 ms

M1 Safe disable

≤ 0.4 mm S4 HC

common

-

(0.01 in) M2

5.5 mm (0.21 in) Response frequency: 0 ~ 32 kHz

Master

≤ 2.5 mm (0.1 in) S5 M3 H level duty: 30 ~ 70%

frequency

RP H level voltage: 3.5 ~ 13.2 V -

M4 reference pulse

L level voltage: 0.0 ~ 0.8 V

S6 train input

Input impedance: 3 kΩ

M5 +V Frequency setting 10.5 V (20 mA maximum) -

S7 M6 -V power supply -10.5 V (20 mA maximum) -

-10 V ~ +10 V/-100% ~ +100% Master frequency

S8 A1 MFAI 1

0 V ~ 10 V/100% reference

2004-2082 (input impedance 20 kΩ)

4005-4044 SN MP 4 mA ~ 20 mA/100%

A2 MFAI 2 0 mA ~ 20 mA/100% Combined w/A1

C/C : GA80XXXXXABAA AC (input impedance 250 Ω)

8 XXXXX SC

0V -10 V ~ +10 V/-100% ~ +100%

SP SINK 0 V ~ 10 V/100%

+24 V FM (input impedance 20 kΩ) Auxiliary

A3 MFAI 3/PTC input 4 mA ~ 20 mA/100% frequency

E (G) - + 0 mA ~ 20 mA/100% reference

FM

(input impedance 250 Ω)

PTC input

RP AC Common 0V -

2110-2138 +V Connect

4060-4103 0-10 V E(G) - -

A1 AM shielded cable

2 kΩ

C/C : GA80XXXXXABAA 4 mA to MA Fault

8 XXXXX

20 mA AC - + Fault relay out 30 VDC, 10 mA ~ 1 A

A2 AM MB 250 VAC, 10 mA ~ 1 A Fault

0-10 V 0V MC Common Minimum load: 5 V, 10 mA -

A3 M1

E (G) M2

MFDO During run

AC 30 VDC, 10 mA ~ 1 A

M3

MFDO 250 VAC, 10 mA ~ 1 A Zero speed

0V M4

C

8

9 Switches and Jumpers on the Control Board

DC -V M5

Minimum load: 5 V, 10 mA

24 V PS (120 Ω, 1/2 W) M6

MFDO Speed agree 1

PS

700 mA MP Pulse train out 32 kHz maximum Output frequency

D+

FM MFAO 1 0 V ~ +10 V/0% ~ 100% Output frequency

A3

RS-485 D- -10 V ~ +10 V/-100% ~ +100%

D+ D- AM MFAO 2 Output current

AC 4 mA ~ 20 mA

AC Common 0V -

0V

H1 External 24 V PS

PS 21.6 VDC ~ 26.4 VDC, 700 mA -

H2 input

External 24 V PS

HC AC

ground

0V -

D+ D-

A1 SN D+ Communication + MEMOBUS/Modbus, RS-485 -

D- Communication - 115.2 kbps maximum -

A1 A2 A3 FM AM AC Common 0V -

A2

A3

GA800 Quick Setup Procedure TOEPC71061748F Sheet 3

E

9

8 If You Push the Run Button but the Motor Does Not Spin G

8

9 Troubleshooting Resources for Drive Faults and Alarms

(KPD) EF3

External Fault (terminal S3)

2017/01/01 10:00

Reset

READY

READY

Resource Choose This When: URL QR Code

You have access to the paper copy of the manual that was packaged with the drive.

This manual lists all drive faults and alarms, and offers a selection of causes and

solutions.

Parameters GA800

(KPD) Reference 1

Home d1-01

0

000.00 Hz Installation & Primary https://www.yaskawa.com/

Default : 0.00 Hz Operation toepc71061737

Range : 0.00~60.00 TOEPC71061737

Back Default Min/Max

PDF download

GA800

Parameters Parameters

Reference 1

d1-01

1

000.00 Hz Entry Accepted You want to use your smartphone or tablet and use the embedded help to look up the

Default : 0.00 Hz full complement of causes and solutions to all drive faults and alarms.

Range : 0.00~60.00

Back Default Min/Max

DriveWizard Mobile

https://www.yaskawa.com/dwm

10.00

(KPD)

App

0.00

0.00 READY

10 Hz App download

You want to download a PDF of the manual to your smartphone or tablet.

This manual lists the full complement of causes and solutions to all drive faults and

F

9

8 Parameter Groups alarms and also includes detailed information about drive maintenance, wiring, and

programming.

A: Initialization d: Reference Settings H: Terminal Functions n: Special Adjustment q: DriveWorksEZ Parameters

A1 Initialization d1 Frequency Reference H1 Digital Inputs n1 Hunting Prevention r: DriveWorksEZ Connections

A2 User Parameters d2 Reference Limits H2 Digital Outputs n2 Auto Freq. Regulator (AFR) T: Motor Tuning

b: Application d3 Jump Frequency H3 Analog Inputs n3 High Slip/Overexcite Braking U: Monitors TOEPYAIXXX001.pdf

Maintenance &

b1 Operation Mode Selection d4 Freq. Ref. Up/Down & Hold H4 Analog Outputs n4 AOLV Tuning U1 Operation Status Monitors Drive https://www.yaskawa.com/

Troubleshooting

DC Injection Braking and toepyaiga8001

b2 d5 Torque Control H5 Modbus Communication n5 Feed Forward Control U2 Fault Trace Manual XXX00

Short Circuit Braking XXX00

b3 Speed Search d6 Field Weakening/Forcing H6 Pulse Train Input/Output n6 Online Tuning U3 Fault History

XXX00

PDF download

b4 Timer Function d7 Offset Frequency H7 Virtual Inputs/Outputs n7 EZ Drive U4 Maintenance Monitors

XXX00

b5 PID Control E: Motor L: Protection Functions n8 PM Motor Control Tuning U5 PID Monitors

b6 Dwell Function E1 V/f Pattern for Motor 1 L1 Motor Protection o: Keypad-Related Settings U6 Operation Status Monitors

b7 Droop Control E2 Motor 1 Parameters L2 Power Loss Ride Through o1 Keypad Display U8 DriveWorksEZ Monitors

b8 Energy Saving E3 V/f Pattern for Motor 2 L3 Stall Prevention o2 Keypad Operation

b9 Zero Servo E4 Motor 2 Parameters L4 Speed Detection o3 Copy Keypad Function

C: Tuning E5 PM Motor Settings L5 Fault Restart o4 Maintenance Monitors

C1 Accel & Decel Time E9 Motor Setting L6 Torque Detection o5 Log Function

C2 S-Curve Characteristics F: Options L7 Torque Limit H

8

9 Additional Resources I

9

8 Customer Feedback

C3 Slip Compensation F1 PG Option Setup (Encoder) L8 Drive Protection

Comments or questions about this document? Please consider following us on social media:

C4 Torque Compensation F2 Analog Input Option L9 Drive Protection 2 Fill out our online form:

C5 Auto Speed Regulator (CSR) F3 Digital Input Option Mobile App Product Manuals www.youtube.com/yaskawayea

C6 Duty & Carrier Frequency F4 Analog Output Option www.linkedin.com/company/18822

F5 Digital Output Option

www.twitter.com/yaskawa

F6 Communication Option

F7 Ethernet Options Headquarters Address:

or

DriveWizard® Mobile •PDFs

Commissioning •Online HTML5-Searchable Email us: technical_documentation@yaskawa.com YASKAWA AMERICA, INC.

Smartphone App •Manuals App Call us: 1-800-YASKAWA (927-5292) 2121 Norman Drive South

www.yaskawa.com/DRV-F-0006

https://www.yaskawa.com/dwm https://www.yaskawa.com/ga800manuals Waukegan, IL 60085

GA800 Quick Setup Procedure TOEPC71061748F Sheet 4 USA

You might also like

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- Unifilar Interlegis 2022205Document1 pageUnifilar Interlegis 2022205Diego LeiteNo ratings yet

- 1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMDocument12 pages1.1.1 PID For DEMINERALIZED WATER TREATMENT SYSTEMShilu GhoshNo ratings yet

- Cable Track Sizing and Locations PDFDocument1 pageCable Track Sizing and Locations PDFiqbal husseinNo ratings yet

- Dokumen - Tips Chasis 8895 7fu7Document1 pageDokumen - Tips Chasis 8895 7fu7Ricardo Castro100% (1)

- BONJENfixxxxDocument1 pageBONJENfixxxxAnjasmara IdhamNo ratings yet

- Low Pressure Low Pressure: Hydraulic Hoses OverviewDocument1 pageLow Pressure Low Pressure: Hydraulic Hoses OverviewNaseema SulaimanNo ratings yet

- Etihad Rail - 2F2 Package - Protection & Rerouting of Existing 400 Dia GRP Pipe in 3 Locations - Detail 1&2 - Sheet-2 - Design Drawing - ReviewedDocument1 pageEtihad Rail - 2F2 Package - Protection & Rerouting of Existing 400 Dia GRP Pipe in 3 Locations - Detail 1&2 - Sheet-2 - Design Drawing - Reviewedabdullah fararjehNo ratings yet

- IQ360-000-M6-SG-00001_04Document1 pageIQ360-000-M6-SG-00001_04mustafa1989ocNo ratings yet

- Abts Industrial Case Study-Layout2Document1 pageAbts Industrial Case Study-Layout2shantanu daleNo ratings yet

- Dokumen - Tips - Chasis 8895 7fu7Document1 pageDokumen - Tips - Chasis 8895 7fu7HenryRamirezNo ratings yet

- 01 Hydraulic Circuit PDFDocument1 page01 Hydraulic Circuit PDFVicente TanNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- Sewer Pipe Line (DIA: Ø1800MM)Document1 pageSewer Pipe Line (DIA: Ø1800MM)ashis maityNo ratings yet

- D038 Evs Co000 1091 - 00Document1 pageD038 Evs Co000 1091 - 00Mussarat BabasahebNo ratings yet

- Apc Back-Ups RS500 Br500i Rev.5.0Document4 pagesApc Back-Ups RS500 Br500i Rev.5.0Joaquin Koki VenturaNo ratings yet

- Draw HehaDocument1 pageDraw Hehaanugerahjaya elektrindoNo ratings yet

- Heha DrawingDocument1 pageHeha Drawinganugerahjaya elektrindoNo ratings yet

- 98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverDocument2 pages98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverAnonymous XnufDzrpoNo ratings yet

- OPTIM778 Schematic Diagram: AmamcDocument2 pagesOPTIM778 Schematic Diagram: AmamcGabriel MirciuNo ratings yet

- Pro Desarrollo Constructora: Planta de Tratamiento de Aguas ResidualesDocument1 pagePro Desarrollo Constructora: Planta de Tratamiento de Aguas ResidualesCarlos CupaNo ratings yet

- NRL Network Study 01 - 12 - 22Document1 pageNRL Network Study 01 - 12 - 22sameed bhaiNo ratings yet

- 310-Navtex Cobham Sailor 6390 QuickRef ManualDocument2 pages310-Navtex Cobham Sailor 6390 QuickRef ManualAbdoulKarimiFatihiNo ratings yet

- NRL Network Study 23 - 12 - 22 ModelDocument1 pageNRL Network Study 23 - 12 - 22 Modelsameed bhaiNo ratings yet

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Niwaha IvanDocument1 pageNiwaha IvanTwebazibwe EdsonNo ratings yet

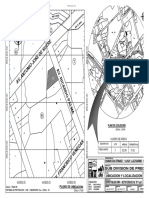

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- ES102Document1 pageES102Juan Luis Nuñez HuayllapumaNo ratings yet

- Canalización y AlimentadoresDocument9 pagesCanalización y AlimentadoresLEONEL VILCANo ratings yet

- 20240217_24F_FFP (Rev-4)Document1 page20240217_24F_FFP (Rev-4)phyo7799No ratings yet

- Brqva Sftleo 190923 CA-RAW-QSF3.8 Confidential CA25/30/35 T3 - 1 A SFT190537 13 ProductionDocument13 pagesBrqva Sftleo 190923 CA-RAW-QSF3.8 Confidential CA25/30/35 T3 - 1 A SFT190537 13 ProductionMauro PerezNo ratings yet

- Ayaccasi village land records 1978-1980Document66 pagesAyaccasi village land records 1978-1980Abner Ezequiel valdivieso palmaNo ratings yet

- B00802 0036 Layout1Document1 pageB00802 0036 Layout1lucas schneiderNo ratings yet

- PPH310510002P00CDocument1 pagePPH310510002P00Chameed abdulNo ratings yet

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE CDocument1 pageOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE CAhmed SolankiNo ratings yet

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- Untitled 1 DDocument1 pageUntitled 1 DMargraf EditoraNo ratings yet

- Siteplan ErDocument1 pageSiteplan ErDody SubaktiyoNo ratings yet

- A Seccion / Section A-ADocument1 pageA Seccion / Section A-AomarNo ratings yet

- STP Exhaust Piping PlanDocument1 pageSTP Exhaust Piping Planbernard alcorizaNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06003 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06003 (A)hemanthsridharaNo ratings yet

- Linea de trazo n° 8 plano finalDocument1 pageLinea de trazo n° 8 plano finalCarlos Mamani CondoriNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06002 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06002 (A)hemanthsridharaNo ratings yet

- Foundation - Recover FoundationDocument2 pagesFoundation - Recover FoundationBernard KiruiNo ratings yet

- Plano de Localización: Asociacion Club 21Document1 pagePlano de Localización: Asociacion Club 21Gianfranco Cairo LópezNo ratings yet

- José_Domingo_EspinarDocument1 pageJosé_Domingo_EspinarVanessa MartinezNo ratings yet

- Ground Floor - AREA - 2627 SQ.M First Floor - AREA - 2627 SQ.MDocument1 pageGround Floor - AREA - 2627 SQ.M First Floor - AREA - 2627 SQ.MAr. KapilNo ratings yet

- Plan On Bollard MK'D B1: N O R HDocument1 pagePlan On Bollard MK'D B1: N O R Hshashank sharmaNo ratings yet

- Arch 1Document3 pagesArch 1Alfred BermudezNo ratings yet

- Sistem Sumatera Bagian Utara: Single Line DiagramDocument1 pageSistem Sumatera Bagian Utara: Single Line DiagramDaniel VerjuandNo ratings yet

- Acrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Document1 pageAcrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Lines art StudioNo ratings yet

- Homeinvasionmapfinal 1Document1 pageHomeinvasionmapfinal 1The Natomas Buzz100% (1)

- PROY AM-Layout3Document1 pagePROY AM-Layout3Cangatron 14No ratings yet

- Sector 03: Consultor Ubicación Proyecto: PlanoDocument1 pageSector 03: Consultor Ubicación Proyecto: PlanoeeeNo ratings yet

- Unidades Hidrográficas de La Cuenca Del Rimac PDFDocument1 pageUnidades Hidrográficas de La Cuenca Del Rimac PDFKarla PmNo ratings yet

- Unidades Hidrograficas de La Cuenca Del RimacDocument1 pageUnidades Hidrograficas de La Cuenca Del RimaceducobainNo ratings yet

- Male CR: Section 1 Section 2Document1 pageMale CR: Section 1 Section 2alezandro del rossiNo ratings yet

- Ubic - Loc 3DDocument1 pageUbic - Loc 3DRolan Yañez ParionaNo ratings yet

- Yamaha PDX-50Document34 pagesYamaha PDX-50HN100% (1)

- 7SG16 Ohmega Catalogue SheetDocument16 pages7SG16 Ohmega Catalogue SheetAkinbode Sunday OluwagbengaNo ratings yet

- Ametek MTC ManualDocument57 pagesAmetek MTC Manualauto etrustNo ratings yet

- Moeller ManualDocument12 pagesMoeller ManualAlexandre DiasNo ratings yet

- ExcitationDocument45 pagesExcitationRajesh Kumar100% (1)

- PCNC Maintenance Manual 6-15Document301 pagesPCNC Maintenance Manual 6-15Claiton Costa NunesNo ratings yet

- Instruction Manual: Tel: 800-821-2177/ Fax: 913-322-1729Document12 pagesInstruction Manual: Tel: 800-821-2177/ Fax: 913-322-1729juanNo ratings yet

- GE Evolution Series E9000 Motor Control Center Renewal Parts BulletinDocument16 pagesGE Evolution Series E9000 Motor Control Center Renewal Parts BulletinAnonymous Aj7PenNo ratings yet

- DBU Fuse CurvesDocument1 pageDBU Fuse CurveslifgarygarciaNo ratings yet

- Differentiation AssessmentDocument56 pagesDifferentiation Assessmentapi-477959451No ratings yet

- Man Inst Mru Z r2Document140 pagesMan Inst Mru Z r2Jack ClouseNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- Revolutionize LV network management with the smart BIDOYNG fuseDocument6 pagesRevolutionize LV network management with the smart BIDOYNG fusejwrodgersNo ratings yet

- 00543000Document172 pages00543000Dhilip AnNo ratings yet

- OPERA PLUS QR CODE Manual Rev1 2018 ENG-ITA + RED 2019Document65 pagesOPERA PLUS QR CODE Manual Rev1 2018 ENG-ITA + RED 2019ltaif zalaaniNo ratings yet

- 30 Volt 100 Ah Lead Acid BatteryDocument12 pages30 Volt 100 Ah Lead Acid BatterySandip AhireNo ratings yet

- Installation Guide for Wall Mounted Package Air ConditionersDocument26 pagesInstallation Guide for Wall Mounted Package Air ConditionersMukti AwanNo ratings yet

- Presentation by Shubham Mishra University Roll Nos. 1513231170 ID: 150117 Greater Noida Institute of TechnologyDocument20 pagesPresentation by Shubham Mishra University Roll Nos. 1513231170 ID: 150117 Greater Noida Institute of TechnologyShubham MishraNo ratings yet

- Eurotherm 3216 PDFDocument6 pagesEurotherm 3216 PDFRoyalty GouldNo ratings yet

- 1 FD Fan SOP DCRTPP PDFDocument14 pages1 FD Fan SOP DCRTPP PDFanilNo ratings yet

- 20 - Hpl2010-En. CiDocument104 pages20 - Hpl2010-En. CiMarco Antonio AvilaNo ratings yet

- Unique 4Document23 pagesUnique 4kavitapatil12No ratings yet

- Sig 00 07 06C.4 (165 174)Document10 pagesSig 00 07 06C.4 (165 174)Ricardo TorrezNo ratings yet

- O&m Manual For LV SwitchgearDocument131 pagesO&m Manual For LV Switchgearmukilanarul12No ratings yet

- 30GXR170-640 Compressor - Carrier ChillerDocument34 pages30GXR170-640 Compressor - Carrier ChillercafonchoNo ratings yet

- Industrial SwitchboardDocument41 pagesIndustrial SwitchboardSiva Kathikeyan100% (2)

- 5793 - Mobily - Rise 2019 - TSSR TemplateDocument63 pages5793 - Mobily - Rise 2019 - TSSR TemplateMohammed Imran100% (1)

- C15 Adapter Board A612 PDFDocument22 pagesC15 Adapter Board A612 PDFOleg KuryanNo ratings yet

- Nintendo ChecksDocument26 pagesNintendo ChecksDavid Kidd Ortega100% (2)

- Ca Vcontact-Vsc (En S2) D 1VCP000532 PDFDocument56 pagesCa Vcontact-Vsc (En S2) D 1VCP000532 PDFGustavo Rodrigo SantanaNo ratings yet