Professional Documents

Culture Documents

Mass SCR Pit

Uploaded by

Ammar FitriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mass SCR Pit

Uploaded by

Ammar FitriCopyright:

Available Formats

Continuous columns is classified by the nature of the feed that are processing (e.g.

binary

columns- 2 components)

Components in a bubble cap distillation column, is used to either transfer heat energy or

enhance mass transfer. The important component in a distillation column is the vertical shell

where separation of liquid take place.

Column internals such as tray plates and/or packing are used to enhance component

separation

Reboiler to provide the necessary vaporization, a condenser to cool and condense the vapor

leaving the top of the column

Reflux drum to hold condensed vapor from the top and the reflux is recycled back to the

column

The feed tray divides the column into a top(enriching) section and a bottom(stripping)

section.

Feed flows down the column where it is collected at the bottom in the reboiler.

Heat supplied to the reboiler to generate vapor

Vapor travels up the column and exits the top of the unit, it is cooled by the condenser and

liquid condensed is stored in a holding vessel known as reflux drum. The condensed liquid is

removed from the system is known as the top product/distillate

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

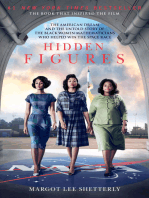

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Recycle PlasticDocument16 pagesRecycle PlasticAmmar FitriNo ratings yet

- Lubricant Additives Functions and ApplicationsDocument38 pagesLubricant Additives Functions and ApplicationsahmetNo ratings yet

- Flow Measurement FundamentalsDocument84 pagesFlow Measurement FundamentalsAmmar Fitri100% (1)

- 1 A PDFDocument116 pages1 A PDFjriacosqNo ratings yet

- Material Selection Part 2Document38 pagesMaterial Selection Part 2Ammar FitriNo ratings yet

- Mold&Die Report 1Document12 pagesMold&Die Report 1Ammar FitriNo ratings yet

- Exp 1 SoapconclusionsDocument2 pagesExp 1 SoapconclusionsAmmar FitriNo ratings yet

- Normal Table PDFDocument2 pagesNormal Table PDFAmmar FitriNo ratings yet

- Lubricants PDFDocument19 pagesLubricants PDFAmmar FitriNo ratings yet

- Emulsion (Intro) &suspensiontutoDocument1 pageEmulsion (Intro) &suspensiontutoAmmar FitriNo ratings yet

- Heat GraphDocument2 pagesHeat GraphAmmar FitriNo ratings yet

- Mold ResultDocument1 pageMold ResultAmmar FitriNo ratings yet

- Chap 1 Basic Probability ConceptDocument32 pagesChap 1 Basic Probability ConceptAmmar FitriNo ratings yet

- Exp 5Document2 pagesExp 5Ammar FitriNo ratings yet

- CSTR QuesitonDocument1 pageCSTR QuesitonAmmar FitriNo ratings yet

- Chap 1 Basic Probability ConceptDocument32 pagesChap 1 Basic Probability ConceptAmmar FitriNo ratings yet

- Chap 2 Probability DistributionDocument29 pagesChap 2 Probability DistributionAmmar FitriNo ratings yet

- Mole FractionDocument1 pageMole FractionAmmar FitriNo ratings yet

- Test Tube of Ethanol (ML) Volume of Deionized-Water (ML) Refractive Index (RI) Mole Fraction of Ethanol, XDocument1 pageTest Tube of Ethanol (ML) Volume of Deionized-Water (ML) Refractive Index (RI) Mole Fraction of Ethanol, XAmmar FitriNo ratings yet

- Exp 4 Plastic 1Document3 pagesExp 4 Plastic 1Ammar FitriNo ratings yet

- Assessment Form Mini Project II (Video Presentation and Final Report) JAN 2017Document2 pagesAssessment Form Mini Project II (Video Presentation and Final Report) JAN 2017Ammar FitriNo ratings yet

- AsddsaDocument15 pagesAsddsagudursrinath11No ratings yet

- Graph 1: Radiometer Reading Against Distance From Heat SourceDocument2 pagesGraph 1: Radiometer Reading Against Distance From Heat SourceAmmar FitriNo ratings yet

- Mechanical Engineering 370 Thermodynamics Homework SolutionsDocument8 pagesMechanical Engineering 370 Thermodynamics Homework SolutionsPerantara RieyAnaNo ratings yet

- AbsorptionDocument20 pagesAbsorptionRininta Triananda NoorNo ratings yet

- Exp - 2 Bubble Cap Distillation ColumnDocument13 pagesExp - 2 Bubble Cap Distillation ColumnAmmar FitriNo ratings yet

- 2014 Executive Tentative Summary EducationDocument16 pages2014 Executive Tentative Summary EducationAmmar FitriNo ratings yet

- Electrochem NotesDocument14 pagesElectrochem NotesAmmar FitriNo ratings yet

- Conclusion Exp 3Document1 pageConclusion Exp 3Ammar FitriNo ratings yet