Professional Documents

Culture Documents

Fork Lift Truck Technical Specification

Uploaded by

jajang nurjamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fork Lift Truck Technical Specification

Uploaded by

jajang nurjamanCopyright:

Available Formats

16-QMP-05-3C

INDIAN OIL CORPORATION LIMITED

(MARKETING DIVISION)

UP STATE OFFICE-II, NOIDA

DEVELOPMENT OF FACILITIES TO ENHANCE DRUM

FILLING CAPACITY AT BITUMEN DRUM FILLING PLANT

(BDFP), MATHURA

TECHNICAL SPECIFICATION

FOR

FORK LIFT TRUCK

B 20.01.16 Reissued for comments / approval DNG HAS RAPS

A 19.10.15 Issued for comments / approval KJL HAS RAPS

Rev. Date Description Prpd. Chkd. Appd.

Std. / Doc. Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Word

Triune Energy Services Pvt. FORK LIFT TRUCK

Ltd., New Delhi Sheet 1of 14

16-QMP-05-3C

TABLE OF CONTENTS

1.0 INTENT .........................................................................................................................................3

2.0 ORDER OF PRECEDENCE......................................................................................................4

3.0 DEFINITIONS ..............................................................................................................................4

4.0 CODES, STANDARDS AND SPECIFICATIONS ...................................................................4

5.0 STATUTORY AND REGULATORY AUTHORITY REQUIREMENT...................................5

6.0 SCOPE OF SUPPLY AND WORK ...........................................................................................5

7.0 DEVIATION ..................................................................................................................................6

8.0 TECHINCAL & DESIGN REQUIREMENTS ...........................................................................7

9.0 SPARE PARTS AND SPECIAL TOOLS................................................................................11

10.0 INSPECTION AND TESTING .................................................................................................11

11.0 PAINTING AND MARKING .....................................................................................................12

12.0 PACKING AND TRANSPORT ................................................................................................12

13.0 SUPPLIER DATA REQUIREMENTS .....................................................................................13

14.0 GUARANTEE / WARRANTY...................................................................................................14

15.0 PERFORMANCE GUARANTEE .............................................................................................14

16.0 FACTORY TRAINING ..............................................................................................................14

17.0 OPTIONAL ITEMS ....................................................................................................................14

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 2 of 14

16-QMP-05-3C

1.0 INTENT

1.1 The intent of this specification is to define the total responsibility of design,

procurement of material, manufacturing, assembly, inspection & testing, painting,

packaging, guarantee (Performance as well Mechanical) supply & transportation up

to site of following Diesel Engine Fork Lift trucks.

Sr.

Description Item Nos. Capacity Quantity

No.

Fork Lift Truck, Diesel Engine

1. FLT 001 to 010 3.0 Ton 10 nos.

operated together with

2 Drum Grab Attachment. FLTA 001 to 010 3.0 Ton 10 nos

1.2 Any items not specified in referenced documents but required for completion of

supply of Forklift truck & its accessories shall also be in the scope of supply of

Vendor without any commercial implication to Purchaser.

1.3 Vendor shall have single point responsibility for all activities, i.e. project management,

coordination, design, supply of all materials, Pre-Fabrication, stage wise & final

inspection, testing, painting guarantee of the material supplied by Vendor through self

/ sub-vendors and transportation of material at site.

1.4 This specification brings out broadly the requirements given in the specifications, data

sheets, and other applicable codes / standards referred / attached with the

requisition.

1.5 Vendor shall make all possible efforts to comply with the requirements of this

requisition. In case deviation is considered essential by the vendor (after exhausting

all possible efforts), these shall be clearly brought out and furnished in consolidated

form under the heading List of Deviation in the format attached. Vendor shall note

that equipment and deviations other than those acceptable to Purchaser shall not be

accepted.

1.6 No deviations to the specified requirements shall be considered after order

placement. If considered imperative, vendor shall propose the deviations after the

order placement only with Concession Request Format along with all supporting

documentation; reasons justifying the advantages accrued to the purchaser & effect

on the cost & schedule and shall obtain purchasers written approval prior to

implementing these deviations. A deviation implemented prior to the purchasers

written approval shall be subject to rejection.

1.7 Purchasers approval and inspection release note shall not relieve the Vendor of his

responsibility of furnishing the materials and accessories of proper & proven design,

materials and workmanship to meet the specified intended service and operating

conditions.

1.8 Vendor shall furnish in his proposal details of similar supply references and design

duly filled in the standard list of reference.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 3 of 14

16-QMP-05-3C

1.9 Compliance with this specification shall not relieve vendor from the responsibilities of

furnishing proper design, materials and workmanship to meet the intended purpose of

the project.

2.0 ORDER OF PRECEDENCE

3.1 In case of any conflict in the requirements specified in the documents attached and /

or referenced in the requisition, in general, the following order of precedence of

documents accompanying the requisition shall govern:

Statutory/Regulatory Requirements

Data Sheet

This Specification

Other referred/ attached specification

Referred Codes and Standards

Vendor shall bring to notice of the Purchaser, such conflicts in writing for clarification

and confirmation. Purchasers interpretation in this regard shall be final and binding

on the Vendor.

3.0 DEFINITIONS

Project : Development of Facilities to Enhance Drum Filling

Capacity at Bitumen Drum Filling Plant (BDFP), Mathura.

Company / Owner : Indian Oil Corporation Ltd., Mathura Refinery.

Engineering Consultant: Triune Energy Services Pvt. Ltd. (TESPL)

Third Party : All other authorized parties contributing to the project.

Supplier / Vendor : (Seller) Party with which Company has an agreement for

the Design, Engineering, manufacturing, service and

delivery etc. of the equipment and auxiliaries laid down

in this specifications and attachments.

Sub Vendor : (Sub Seller) Party with which vendor has an

arrangement for manufacture and delivery etc. of

components and / or services. Contractor remains

responsible for all aspects of quality, delivery schedules,

technical performance etc of sub-vendors supply.

4.0 CODES, STANDARDS AND SPECIFICATIONS

5.1 Fork Lift Trucks together with its accessories shall be designed, manufactured &

assembled, inspected and tested in accordance with the requirements of this

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 4 of 14

16-QMP-05-3C

specification, referenced/ attached specifications and international code /standards

/recommended practices together with all current applicable regulations.

Where no code or standard is specified in the Project Specification and other

reference documents, the Supplier shall propose applicable codes and/ or standards

on which the Suppliers design and manufacturing is based, for review and approval

by Purchaser.

The following is broad list of applicable international codes / Standards. Latest

Edition (as on award of job) of the international codes / standards shall be

applicable.

Code / Standard Description

Load Rating IS :6765 / 72

IS : 10000 (1-12) and IS : 10002-1981 or BS : 5514 or

Engine

BSAU 141A

Acceptance Criteria IS : 10517

Stability Testing IS : 4357 / 74

Fork Lift Truck Fork IS : 6876

Mounting Dimensions for

attachments to the extent IS : 7525

applicable

5.0 STATUTORY AND REGULATORY AUTHORITY REQUIREMENT

5.1 All statutory and regulatory requirement, as applicable, for design, manufacturing of

Fork Lift Truck shall be complied by vendor in order to meet environmental norms.

6.0 SCOPE OF SUPPLY AND WORK

7.1 Vendors scope of supply and work includes, but not limited to design, detail

engineering, material procurement, fabrication & assembly, stage wise & final

inspection and testing including NDTs, TPI, surface preparation & painting,

packaging, preparation for shipment, supply, guarantee (Performance as well

Mechanical) for Fork Lift Trucks & its accessories as per the data sheet,

specifications, codes & standards, etc. referenced/ attached with this requisition.

7.2 Vendors scope of supply & services includes, but not limited to, following items:

i. Compliance with all reference Documents, Specifications, Data Sheet, Applicable

Standards and Codes mentioned in this requisition.

ii. Fork Lift Truck with 4 stroke Diesel Engine, water cooled complete with all

accessories as per Data sheet & other specifications attached with this

requisition.

iii. Drum Grabbing Attachment for 4nos Drums lifting in single lift.

iv. Material procurement with test certificates.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 5 of 14

16-QMP-05-3C

v. Final Inspection and tests as per codes/ specifications.

vi. Inspection and testing certificates.

vii. Submission of all drawings/ documents as per this specification & other referred

documents in this requisition.

viii. Final inspection and testing as per approved Inspection Test Plan. ITP shall be

prepared, as per Inspection Methodology, covering all required inspection &

tests, test report.

ix. Third party inspection (TPI) by Purchaser appointed/approved TPI agency.

However Vendor to provide requisite facilities to carry out the same at Vendor/

sub-vendor premises.

x. List of recommended spares with price for two years (2 years) of smooth,

continuous & normal operation shall be submitted along with proposal. Validated

period for the price shall also to be mentioned in the price list.

xi. Special tools & tackles, as required. List shall be submitted along with Bid.

xii. Surface preparation and painting as per manufacturing standard. Vendor shall

submit the painting procedure for company / consultant approval prior to start of

job.

xiii. Marking, packing and preparation for shipment.

xiv. Quality Assurance and Quality Control.

xv. AMC of Diesel Engine Fork lift for 5 years after warranty period expiry.

xvi. Proper design, Material & Workmanship Guarantee.

xvii. Supply of Fork Lift trucks along with all accessories and other items to purchaser

designated place.

7.0 DEVIATION

7.1 Vendor shall make all possible efforts to comply with the requirements of this

requisition. In case deviation is considered essential by the Vendor, these shall be

clearly brought out with reasons/ recommendations and furnished in consolidated

form in the format List of Deviation attached with requisition for Purchasers review

and acceptance. Purchasers interpretation in this regard shall be final and binding

on the vendor. Deviations to the requirement of requisition shall not be permitted

except for those accepted in writing by Purchaser.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 6 of 14

16-QMP-05-3C

8.0 TECHINCAL & DESIGN REQUIREMENTS

9.1 Fork Lift Truck shall be Designed, Manufactured & Assembled and shall confirm in all

respect to high standard of engineering, design, workmanship and be capable of

performing in continuous commercial operation in a manner acceptable to the

purchaser.

9.2 For all technical requirements, refer details specified in data sheet, specifications,

codes & standards, etc. referenced/ attached with this requisition.

9.3 All material used shall be new and of first quality and shall be duly supported with

material test certificates from the original material manufacturer. Complete chemical

composition of all elements including the impurities shall be reported in the test

certificates.

9.4 Material of construction for equipment shall be as per Data Sheet and standards

attached with requisition. Vendor may propose superior alternative material; however

final decision shall be by Purchaser.

9.5 Name plate for the individual Fork Lift in SS304 shall be provided at appropriate

place.

9.6 Frame & Body

Chassis shall have twin box envelope design with integral tanks. Components shall

be protected from damage. It should be made from heavy steel plates with superior

quality welding process to avoid crack in joints and oxidation. Variant fluid tanks such

as Hydraulic, fuel etc should be provided with the suitable strainer and magnetic

drain plugs along with necessary transparent level indicators wherever necessary

and possible.

Necessary Tow Hooks / Eye will be provided in the Truck. There should be

arrangement of over head guard to the driver / operator.

9.7 Counter Weight

Counter weight shall be low profile, vertical sides and rear face complete with inset

tow bar.

9.8 Engine

i) Engine shall be suitable water cooled, 4 stroke diesel engine of adequate

horsepower, Fuel efficient Diesel engine with alternator with 12 volts charging

battery.

ii) Engine shall be proven model of reputed indigenous manufacturer of BS-III or

latest best in class.

iii) Heavy duty radiator shall be provided in the engine cooling system which should

be able to work for at least continuous 8 hours working without getting overheated.

iv) Fuel Tank should have diesel storing facility of at least 8 hours continuous

working.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 7 of 14

16-QMP-05-3C

9.9 Transmission and Axle

Forklift should be provided with Automatic Torque converting type Transmission with

neutral start switch facility to the operator. It should be capable of frequent stop /

starts and directional reversal and withstand jerks of loading / unloading, un / downs

and steeps of roads.

9.10 Inching

Full power inching shall be controlled. Slow forward speed with full power to

hydraulics for fast lift speeds and easy precision maneuvering and stacking combined

inch/brake pedal

9.11 Brakes

i) Service :

Hydraulically operated drum brakes (self adjusting) on transaxle for light,

responsive braking. Asbestos free brake linings.

ii) Parking :

Ratchet type hand brake, mechanically linked to drum brakes.

9.12 Steer Axle

Steer Axle shall be large steel beam mounted on high energy absorbing bearing to

protect the single double-ended steer cylinder. This connects through steel links with

Sealed spherical bearings to the stub axles. Stub end hubs shall have taper roller

bearings. The steering geometry shall give a small turning radius.

9.13 Hydraulics

It should be able to provide sturdy and even power in all Truck operations such as

Tilt, lift and other auxiliary operations. Inching control should be standard feature

of the system. The system should be provided with system protection valve / over

load protection or relief valve as an integral part. Tilt lock value should also be

provided to ensure the fail safe operation in all the Mast positions. The mast lift

and lowering operation should be able to hold and control the rated load at various

desirable inch heights and without fail. The system diagram should be imbedded

on the truck in easy to understand symbols and at a convenient place where it

could be seen without dismantling or removal of any assembly part.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 8 of 14

16-QMP-05-3C

i) Pump :

Pump shall be heavy duty gear pump, shaft driven from transmission power take

off. Incorporates flow divider for priority oil supply to steering.

ii) Control Valve :

Fine metering control valves are operated by hand levers having a long sweep for

smooth accurate control and feathering of all functions, integral pressure relief

valve prevents system overload.

iii) Cylinders :

All hydraulic cylinders shall have suitable pistons bearings and heavy duty wiper

seals. Fine-honed bores and hard chromium plated piston rods for long life and

trouble free operation. Hydraulic oil used shall be suitable for hazardeous area.

9.14 Mast

Mast shall be constructed from specially designed medium tensile rolled steel nesting

sections with lateral cross ties, positioned to ensure correct strength. Mast shall be

mounted on large diameter pins that are secured to the transaxle hook mountings for

reliable and ease of removal. The mast sections and two high-mounted tilt cylinders

shall combine to resist mast racking. Lift cylinders shall be positioned behind the

mast uprights to maximize visibility.

9.15 Carriage and forks

Carriage and forks shall be narrow profile plate type built to ISO standards to allow

maximum visibility for fork tips and load, easy adjustment of fork spread.

9.16 Drum Grabber Attachment

i) Drum grabber shall be designed to handle four (4) nos of filled bitumen drums having

500mm dia x 860mm ht. each in single lift.

ii) Each drum shall be clamped individually and the grabbing operation shall be

actuated automatic by individual hydraulic cylinders.

iii) Drum grabber attachment shall be designed with an essential safety feature

considered if the hydraulic system fails, the attachment will not let go the drums.

iv) Drum grabber shall be of sturdy construction and be capable for continuous

commercial operation.

v) Attachment shall be designed & manufactured in such a way that removability / fixing

of attachment at site shall be done by forklift operator/driver itself with normal tools

supplied by manufacturer.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 9 of 14

16-QMP-05-3C

9.17 Electrical system

A 12 V battery with heavy duty alternator and starter motor of reputed make shall be

provided. The wiring shall be in conduits and number coded.

The system diagram should be imbedded on the truck in easy to understand symbols

and at a convenient place where it could be seen without dismantling or removal of

any assembly / part.

The battery of the system should be charged by the alternator fitted with the Engine

and engine should be started by a heavy duty self-motor for starting. The battery

should be of adequate volts and AH rating. The system should be able to transmit the

battery discharge and charged condition signal to the instrument panel for information

of operator. All standard accessories such as warning signals, gauges front and rear

light, low battery indicator light. Rear view mirror & horn also to be supplied with the

truck.

9.18 Controls

The following minimum controls shall be provided :

i) Foot pedals Accelerator and inching / brake.

ii) Electrically operated forward / reverse direction control

iii) Hydraulic control levers and key switch for neutral start.

iv) Hoisting & lowering controls

9.19 Battery

Maintenance free battery of adequate capacity will be provided. Battery should be

housed in a separate compartment to avoid its earthing with other body part of the

truck. The battery compartment should be located at a place which could ensure easy

and safe removal and installation of the battery by without disturbing / dismantling

other accessories / parts / assemblies. Battery cable should not be in contact with

exhaust pipe or nearby to avoid any melting from exhaust generated heat.

9.20 Instrument Panel, control Levers & Pedals

The feedback on the working status of various electrical systems should be given to

the instrument panel by way of necessary gauges, warning signals etc and should be

installed in front of the operator seat. The instrument panel should be installed in

such a way that it should be within easy physical & eye reach of the operator but

should not act as hindrance to his working & movements. The instrument panel

should also be able of self-illuminating type for night / dark alleys operations,

Necessary Engine oil pressure, water temperature, Hrs cum Kms, Fuel level, Coolant

level, Battery charged / discharged condition gauges etc should form part of

instrument panel.

9.21 Cabin / Driver Seat

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 10 of 14

16-QMP-05-3C

Drivers seat shall be adjustable cushioned type which could be adjusted in

accordance to the operators physique in vertical and horizontal side should be

provided. There shall be sufficient leg room space to the operator. All control levers /

pedals should be within the easy reach of the operator. Load back rest should also be

provided.

9.0 SPARE PARTS AND SPECIAL TOOLS

9.1 Two (2) Years Normal Operational Spares

Vendor to recommend and furnish only the list of spares with price required for two

(2) year normal, smooth and safe operation of the each equipment. Separate quote

for these spares is required along with proposal. Validity period of these spares price

shall also be mentioned in offer.

9.2 All spare parts shall be wrapped and packaged to preserve the parts as in original

condition. The same parts shall be properly tagged using stainless steel tags and

coded so that later identification as to their intended equipment usage will be easily

facilitated.

9.3 All items supplied shall be packaged separately and clearly marked as Spare Parts.

Packing lists shall be furnished complete and in detail so that parts can be handled

without uncrating.

9.4 Special Tools and Tackles

A complete unused and new set of special purpose tools, tackles and accessories

along with detailed instructions and maintenance manual shall be supplied. Each tool

and wrench shall be stamped so as to identify easy for its use. The tools shall be

supplied in steel box and with a copy of instruction manual. The items supplied shall

be of the best quality and specially protected against rusting in tropical climate.

List of these spares shall be furnished by vendor along with his proposal. The price

for these spares shall be in Vendors base offer.

Note:-

The manufacturer should ensure availability of spares for a minimum period of 05

years from the date of installation.

10.0 INSPECTION AND TESTING

10.1 Vendor shall be responsible for the Quality assurance and Quality control for Fork lift

trucks together with all attachments and accessories.

10.2 Vendor shall generate Inspection and Test Plan (ITP) covering complete details of all

required inspection and tests to be carried out at works at various stages along with

final performance test procedure with guaranteed parameters for customer approval

during contract stage in consolidated form, within two (2) weeks of placement of

Purchase Order/ Letter of Intent and shall obtain Owner/ Purchaser approval. Vendor

shall prepare Inspection & Test plan for the equipment and sub-vendor items under

his supply scope covering all required inspection and tests in line with the

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 11 of 14

16-QMP-05-3C

requirements specified in this requisition. Procurement and manufacturing activities

shall only be taken up by vendor after approval of ITP from Purchaser.

10.3 Vendor shall be responsible for carrying out all required inspection, tests and checks

as per the approved ITP.

10.4 Vendor shall coordinate/cooperate with Purchasers inspector/Inspection agencies to

be present when required. Vendor shall carryout various tests as per approved ITP.

10.5 Purchaser/ its authorized representative shall have access to inspect the Fork lift

truck at any stage during manufacture. Purchaser shall specify hold points / witness

points while approving ITP. During inspection, material certificates, shop test data,

certificates for bought out components and other relevant information shall be

furnished for purchasers perusal so as to ascertain that the specifications and quality

are complied with.

10.6 The witnessing and/or acceptance of inspection and tests by Owner/ Purchaser or

their authorized representatives shall not relieve the Vendor from his responsibilities

of furnishing proper equipment nor shall it relieve the Vendor of any guarantees/

warrantees or other contractual obligations.

11.0 PAINTING AND MARKING

11.1 Surface preparation and painting shall be carried out as per manufacturers standard

which shall be suitable for existing climatic conditions at site. Forklift truck shall be

painted in yellow & black colour.

Vendor shall submit the painting procedure for company / consultant approval prior to

start of job.

11.2 Stainless steel name plate shall be provided for the Forklift with letters etched on its

body in English language to show requisite details including equipment name, tag

numbers, its capacity, etc.

12.0 PACKING AND TRANSPORT

12.1 All items and materials supplied for Fork lift trucks shall be wrapped and suitably

protected to prevent any damage during transportation. Packing should be suitable

for the specified duration in the existing climatic conditions at the site. Packing list

shall be attached at the outside of the crate as per standard practice and one packing

list shall be placed inside the box.

12.2 Unless otherwise specified, the shipment shall be protected for outdoor storage of 6

months at site. If any extra precaution is required for storage beyond 6 months the

same shall be explicitly indicated in the operation and maintenance manuals.

12.3 Packaging of spare parts shall be suitable for long period storage and same shall be

indicated in the vendors proposal with special instructions, if any, required to

facilitate the same.

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 12 of 14

16-QMP-05-3C

12.4 The package along with spares and other accessories shall be transported as per the

instructions of the Purchaser to the site.

13.0 SUPPLIER DATA REQUIREMENTS

13.1 Vendor shall include in his scope, all documents and drawings required during

proposal stage & detail engineering to establish technical suitability of all the items

supplied under this requisition. However, as minimum vendor has to submit all

documents as mentioned in Supplier Data requirement (SDR) attached with the

requisition. Vendor shall submit the consolidated list of all the drawings/ documents

as required within 2 weeks after receiving the order.

13.2 The vendor drawings / documents shall be reviewed by purchaser/ consultant.

Vendor shall ensure to comply with all the requirements of purchaser and shall

incorporate all required changes based on their comments without any cost and / or

delivery implications to the purchaser.

13.3 As built drawings, inspection and test reports, operation manual and other relevant

documents, as covered in Supplier Data Requirements shall be submitted as part of

Equipment Data Folder.

13.4 All drawings/documents shall be thoroughly checked and duly signed before

submission to purchaser / its representative. Unchecked drawings and documents

without revisions clearly marked shall be returned unapproved.

13.5 Purchaser / its representative approval of vendors drawing/documents shall not

relieve the vendor of their responsibility.

13.6 All documents, drawings, manuals, reports and written instructions shall be in the

English language. Metric System units shall be used, unless otherwise specified.

13.7 Unless otherwise specified, Vendor shall furnish minimum three number of DVD/CD

containing soft copy of Manufacturers Data Book and 6 complete set in hard

binders of Manufacturers Data Book including certified prints, data for all items and

test reports. Index of Manufacturers Data Book shall be submitted for review to

Purchaser.

13.8 For drawing, data sheet and all graphic works AUTOCAD 2011 or later versions

and for all texts, MS Word 2007 shall only be used.

13.9 Document/drawing numbering and document/drawing templates shall be as

applicable for this project and provided by Purchaser to successful vendor.

13.10 Vendor drawings/documents shall indicate the following as minimum:

i) Clients Name

ii) Vendors Name

iii) Engineering Contractor Name

iv) Project No.

v) Clients Purchase Order No.

vi) Drawing Number

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 13 of 14

16-QMP-05-3C

vii) Rev. number with revision history

viii) Revision marking

ix) Reference Document No. etc.

14.1 GUARANTEE / WARRANTY

Vendor / supplier of fire trucks shall have final and total responsibility for supply of

defect free material with respect to design (as applicable), workmanship, material and

operations.

Vendor / supplier shall replace all material and/or part (at his expense) that are found

to be faulty or which do not meet the specified requirements during the guarantee

period. In case the need arises, vendor shall also depute an experienced service

representative to supervise the necessary repairs and replacements. The guarantee

period shall be as specified in the commercial document.

Year wise AMC of Diesel Engine Fork lift for 5 years after warranty shall be included in

Price Bid. Separate call-up orders shall be placed by Location after completion of

warranty period.

Scope of AMC includes the following:

i) Preventive Maintenance & Servicing.

ii) One planned visit per month plus any visit for breakdown maintenance.

iii) Cost of Spares is not included. The same shall be paid extra.

15.0 PERFORMANCE GUARANTEE

Forklift along with its drives, controls and other accessories shall be guaranteed for

the rated capacity against the rated speed of motions and for the service conditions

specified.

16.0 FACTORY TRAINING

Five days Factory Training on operation and maintenance of the vehicle shall be

provided for three operators.

17.0 OPTIONAL ITEMS

Vendor shall quote following optional items applicable to each forklift.

Oxy catalytic converter / purifier

Spark arrestor

Fork Extension

Towing Coupler

Load back seat

Std. / Doc. Number Rev

TECHNICAL SPECIFICATION

FOR 9610-02-TS-204 B

Triune Energy Services Pvt.

Word

FORK LIFT TRUCK

Ltd., New Delhi Sheet 14 of 14

You might also like

- MARI PETROLEUM FLARE KNOCKOUT DRUM SPECIFICATIONDocument68 pagesMARI PETROLEUM FLARE KNOCKOUT DRUM SPECIFICATIONAbdur RehmanNo ratings yet

- Project Execution Plan PDFDocument21 pagesProject Execution Plan PDFBhavanishankar shetty80% (5)

- Technical Specification For Storage Tanks & Vessels PDFDocument635 pagesTechnical Specification For Storage Tanks & Vessels PDFaravind grandhi100% (1)

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet

- Requisition of PumpDocument8 pagesRequisition of PumpGunturMudaAliAkbarNo ratings yet

- Technical Specification for ElevatorDocument185 pagesTechnical Specification for Elevatorvishal100% (1)

- Construction of Balance Works of Main Plant Civil Work in Solapur STPPDocument100 pagesConstruction of Balance Works of Main Plant Civil Work in Solapur STPPPratik GuptaNo ratings yet

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- ENVIRONMENTAL HEALTH (Compiled) PDFDocument119 pagesENVIRONMENTAL HEALTH (Compiled) PDFHarlyn PajonillaNo ratings yet

- Methanol injection package requisitionDocument19 pagesMethanol injection package requisitionAyahKenzieNo ratings yet

- SRF Limited Proposed BOPP Film Line Plant Tender for PEB WorksDocument37 pagesSRF Limited Proposed BOPP Film Line Plant Tender for PEB WorksRavi ShrivastavaNo ratings yet

- HT Cable BhelDocument49 pagesHT Cable BhelSumit TyagiNo ratings yet

- 8188-MD-FEA-RFQ-001 Rev-0Document24 pages8188-MD-FEA-RFQ-001 Rev-0sridharNo ratings yet

- VDR G4 Manual Steinsohn PDFDocument185 pagesVDR G4 Manual Steinsohn PDFVariya Dharmesh100% (1)

- PDIL LPG Bullet PDFDocument1,033 pagesPDIL LPG Bullet PDFNilesh Pathare100% (3)

- Offshore Pipeline Field Joint Coating SpecificationDocument12 pagesOffshore Pipeline Field Joint Coating SpecificationkatfyNo ratings yet

- MoS For Piping Support InstallationDocument19 pagesMoS For Piping Support Installationilliasuddin100% (1)

- QAP of Chain Pully Block Technical Specification PE-TS-401-563-A001Document38 pagesQAP of Chain Pully Block Technical Specification PE-TS-401-563-A001Anonymous gr5Pr9AVNo ratings yet

- This Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionDocument10 pagesThis Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionVidyut UjalaNo ratings yet

- VENDOR DIRECTORY For - 1st JULY2019 To 31 Dec PDFDocument262 pagesVENDOR DIRECTORY For - 1st JULY2019 To 31 Dec PDFsumitshyamalNo ratings yet

- Gas Turbine and Auxiliaries Technical SpecificationDocument59 pagesGas Turbine and Auxiliaries Technical Specificationajo zinzoNo ratings yet

- Altered Ventilatory Function Assessment at Pamantasan ng CabuyaoDocument27 pagesAltered Ventilatory Function Assessment at Pamantasan ng Cabuyaomirai desuNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document50 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Project Execution Planpdf PDF FreeDocument21 pagesProject Execution Planpdf PDF FreeCedie SieterealesNo ratings yet

- Dev OpsDocument28 pagesDev Opsdeb galangNo ratings yet

- Tech SpecDocument31 pagesTech SpecakhilNo ratings yet

- NTPC Workshop Equipment SpecificationDocument68 pagesNTPC Workshop Equipment SpecificationAnonymous uXdS9Y7No ratings yet

- Specification For Tank To Tank Transfer Pump (Rev.0) - (P-1501)Document9 pagesSpecification For Tank To Tank Transfer Pump (Rev.0) - (P-1501)Panisa BanimaNo ratings yet

- Ed Brown CatalogDocument44 pagesEd Brown CatalogssnvetNo ratings yet

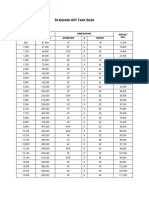

- Standard Api Tank Sizes PDFDocument2 pagesStandard Api Tank Sizes PDFjajang nurjamanNo ratings yet

- Gartner CRM Handbook FinalDocument0 pagesGartner CRM Handbook FinalghanshyamdassNo ratings yet

- LH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageDocument277 pagesLH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageSumantrra Chattopadhyay100% (2)

- 31-3 ITP For Welder Qualification Tests - Offshore Pipeline WeldingDocument15 pages31-3 ITP For Welder Qualification Tests - Offshore Pipeline Weldingvenkatesh67% (3)

- OM Manual For Wiring and AccDocument54 pagesOM Manual For Wiring and Accmukilanarul12No ratings yet

- SCC PDFDocument16 pagesSCC PDFSaptarshi ChatterjeeNo ratings yet

- TATA PROJECTS LIMITED Tilting & Drum Transfer Unit Technical SpecificationDocument6 pagesTATA PROJECTS LIMITED Tilting & Drum Transfer Unit Technical SpecificationSridhar VedulaNo ratings yet

- Technicalspecification1of2 2021 07 13 04 - 35 - 18Document180 pagesTechnicalspecification1of2 2021 07 13 04 - 35 - 18replyrajanNo ratings yet

- SPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Document7 pagesSPECIFICATION FOR GENERAL ROTARY PD PUMPS (Rev.0) (P-1201 To P-1206, P-1402 To P-1405)Panisa BanimaNo ratings yet

- MQ SP M 4039Document6 pagesMQ SP M 4039jaseel k0% (1)

- 5 Specification For General Technical Requirements GTS 01Document6 pages5 Specification For General Technical Requirements GTS 01shaliq28No ratings yet

- MQ SP M 4028 PDFDocument12 pagesMQ SP M 4028 PDFjaseelNo ratings yet

- Mechanical - Jan'19 To Jun'19 PDFDocument270 pagesMechanical - Jan'19 To Jun'19 PDFsumitshyamalNo ratings yet

- Vendor Directory - 1stjuly - 31stdecember PDFDocument269 pagesVendor Directory - 1stjuly - 31stdecember PDFJaay VelNo ratings yet

- SCC - Commercial - PART - 2 - March - 2021Document21 pagesSCC - Commercial - PART - 2 - March - 2021Shubham GuchaitNo ratings yet

- Technical Specification For Pa System 1447144254Document102 pagesTechnical Specification For Pa System 1447144254Charan SinghNo ratings yet

- Final VD QAM 8.1-1 Wef 1.1.2020 To 30.06.2020Document262 pagesFinal VD QAM 8.1-1 Wef 1.1.2020 To 30.06.2020sumitshyamalNo ratings yet

- Specification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Document9 pagesSpecification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Panisa Banima100% (1)

- MMC HBK p1 Mat e 0015Document435 pagesMMC HBK p1 Mat e 0015arshad alamNo ratings yet

- VD Qam July 2020Document258 pagesVD Qam July 2020Amit KumarNo ratings yet

- Tendernotice 1Document774 pagesTendernotice 1Hari Krishna RajuNo ratings yet

- MQ SP P 5024Document16 pagesMQ SP P 5024jaseel kNo ratings yet

- MQ SP M 4010 PDFDocument16 pagesMQ SP M 4010 PDFjaseelNo ratings yet

- Cooling Water PumpsDocument143 pagesCooling Water PumpszalabiNo ratings yet

- NIT Volume02Document205 pagesNIT Volume02vjrNo ratings yet

- Vendor Directory January 2018 PDFDocument264 pagesVendor Directory January 2018 PDFADME KRCANo ratings yet

- Technical Procurement Specification For: Fact - Udyogamandal ComplexDocument23 pagesTechnical Procurement Specification For: Fact - Udyogamandal ComplexHossam AlzubairyNo ratings yet

- MQ SP P 5002 PDFDocument44 pagesMQ SP P 5002 PDFjaseelNo ratings yet

- Technical Specification For AgitatorsDocument13 pagesTechnical Specification For AgitatorsINFO SAGANo ratings yet

- ConvergentLiners SOW 13MAR2019Document30 pagesConvergentLiners SOW 13MAR2019MASOUDNo ratings yet

- Tender Doc For LPG Bullet at BHEL TrichyDocument17 pagesTender Doc For LPG Bullet at BHEL TrichyRajesh Kumar MudimannanNo ratings yet

- Nit-Rinl-Vizag-Esp-Mech - C343aDocument78 pagesNit-Rinl-Vizag-Esp-Mech - C343akaranampraveenkumarNo ratings yet

- ES-30-99-23-0122 - Specification For Pipeline Barred TeeDocument16 pagesES-30-99-23-0122 - Specification For Pipeline Barred TeemaheshNo ratings yet

- 15963-0000-Me-Spc-0006 R0 PDFDocument20 pages15963-0000-Me-Spc-0006 R0 PDFSnehal SinhaNo ratings yet

- Method Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01Document13 pagesMethod Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01khalid khanNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Tensiometer Du NouyDocument1 pageTensiometer Du Nouyjajang nurjamanNo ratings yet

- Epa Water Treatment Manual PreliminaryDocument111 pagesEpa Water Treatment Manual PreliminaryTony GallacherNo ratings yet

- Inerting & BlanketingDocument5 pagesInerting & Blanketingbksree100% (1)

- CMAA Specification 70Document87 pagesCMAA Specification 70jajang nurjamanNo ratings yet

- Baja Profil C Cell FormDocument1 pageBaja Profil C Cell FormmazidpalazzoNo ratings yet

- PDFDocument4 pagesPDFjajang nurjamanNo ratings yet

- Constructivism improves a lesson on nounsDocument6 pagesConstructivism improves a lesson on nounsOlaniyi IsaacNo ratings yet

- Temenos Brochure - FormpipeDocument5 pagesTemenos Brochure - FormpipeDanial OngNo ratings yet

- Medication Calculation Examination Study Guide: IV CalculationsDocument2 pagesMedication Calculation Examination Study Guide: IV Calculationswaqas_xsNo ratings yet

- MMME 21 1st Long Exam Lecture NotesDocument74 pagesMMME 21 1st Long Exam Lecture NotesGraver lumiousNo ratings yet

- Determination of Atenolol in Pharmaceutical Dosages by Fourier Transform Infrared Spectrometry (FTIR)Document11 pagesDetermination of Atenolol in Pharmaceutical Dosages by Fourier Transform Infrared Spectrometry (FTIR)Geovas GomezNo ratings yet

- SocorexDocument6 pagesSocorexTedosNo ratings yet

- Textbook of Heat Transfer Sukhatme S PDocument122 pagesTextbook of Heat Transfer Sukhatme S PSamer HouzaynNo ratings yet

- Sunera Best Practices For Remediating SoDsDocument7 pagesSunera Best Practices For Remediating SoDssura anil reddyNo ratings yet

- Consumer Behavior PP Chapter 4Document36 pagesConsumer Behavior PP Chapter 4tuongvyvyNo ratings yet

- Osda Solar Module - Installation ManualDocument21 pagesOsda Solar Module - Installation ManualIOZEF1No ratings yet

- Ventilator Modes - WEANINGDocument3 pagesVentilator Modes - WEANINGAlaa OmarNo ratings yet

- Desk PiDocument21 pagesDesk PiThan LwinNo ratings yet

- Curriculam VitaeDocument3 pagesCurriculam Vitaeharsha ShendeNo ratings yet

- 06 Dielectrics Capacitance 2018mkDocument41 pages06 Dielectrics Capacitance 2018mkTrần ĐứcAnhNo ratings yet

- Unit 2 - Chapter 04 - Working With FormsDocument24 pagesUnit 2 - Chapter 04 - Working With FormsSnr Berel ShepherdNo ratings yet

- Sato Printer Api Reference DocumentDocument34 pagesSato Printer Api Reference Documentsupersteel.krwNo ratings yet

- The Completely Randomized Design (CRD)Document16 pagesThe Completely Randomized Design (CRD)Rahul TripathiNo ratings yet

- Lesson 2Document10 pagesLesson 2angeliquefaithemnaceNo ratings yet

- 6 An Indian American Woman in Space 2Document11 pages6 An Indian American Woman in Space 2Manju YadavNo ratings yet

- Online Test Series Syllabus Class 10 2019Document6 pagesOnline Test Series Syllabus Class 10 2019ABHISHEK SURYANo ratings yet

- IGNOU MBA MS-11 Solved AssignmentDocument5 pagesIGNOU MBA MS-11 Solved AssignmenttobinsNo ratings yet

- Agent Orange Dioxin Military BasesDocument4 pagesAgent Orange Dioxin Military BasesChildren Of Vietnam Veterans Health AllianceNo ratings yet

- Year 12 Holiday Homework Term 3Document4 pagesYear 12 Holiday Homework Term 3Lucas GauciNo ratings yet

- Chapter 25 (10) Capital Investment Analysis: ObjectivesDocument40 pagesChapter 25 (10) Capital Investment Analysis: ObjectivesJames BarzoNo ratings yet