Professional Documents

Culture Documents

UK1111if 10132 PDF

Uploaded by

AdeImanudinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UK1111if 10132 PDF

Uploaded by

AdeImanudinCopyright:

Available Formats

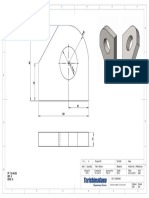

Belzona 1111

FN10132 (SUPER METAL)

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR 3. MIXING SMALL QUANTITIES

For mixing small quantities of Belzona 1111 use:

WELD 3 parts Base to 1 part Solidifier by volume

5 parts Base to 1 part Solidifier by weight

APPLY ONLY TO CLEAN, FIRM, DRY AND WELL

ROUGHENED SURFACES 4. VOLUME CAPACITY OF MIXED BELZONA 1111

24.3 cu.in. (398 cm) per kg.

a) Brush away loose contamination and degrease with a rag

soaked in Belzona 9111 (Cleaner/degreaser) or any other

effective cleaner which does not leave a residue e.g. methyl 3. APPLYING BELZONA 1111

ethyl ketone (MEK). Use a flame to sweat out oil from

deeply impregnated surfaces. FOR BEST RESULTS

Do not apply when:

b) Roughen surfaces by blast cleaning, deeply scoring or (i) The temperature is below 41F (5C) or the relative humidity

grinding. is above 90%.

(ii) Rain, snow, fog or mist is present.

c) Stabilize cracks by drilling the extremities. Long cracks (iii) There is moisture on the metal surface or is likely to be

should be drilled, tapped and bolted every 3-4 inches deposited by subsequent condensation.

(77-103 mm). (iv) The working environment is likely to be contaminated by

oil/grease from adjacent equipment or smoke from

d) Vee-out all cracks using a rotary file. kerosene heaters or tobacco smoking.

e) Finally degrease again. Use clean rags to avoid spreading a) Apply the Belzona 1111 directly on to the prepared

contamination. surface with the plastic applicator or spatula provided.

b) Press down firmly to fill all cracks, remove entrapped air,

WHERE BELZONA 1111 SHOULD NOT ADHERE

and ensure maximum contact with the surface.

Brush on a thin layer of Belzona 9411 (Release Agent) and

allow to dry for 15-20 minutes before proceeding to step 2.

c) Over cracks, gaps and holes, stipple in Belzona 9341

(Reinforcement Tape).

2. COMBINING THE REACTIVE

COMPONENTS d)

Contour the Belzona 1111 to the correct profile with the

plastic applicator or alternatively allow to cure and then

Transfer the entire contents of the Base and Solidifier modules machine down.

on to the Belzona Working Surface. Mix thoroughly together

to achieve a uniform material free of any streakiness. CLEANING

Mixing tools should be cleaned immediately after use with

1. MIXING AT LOW TEMPERATURES Belzona 9111 or any other effective solvent e.g. Methyl ethyl

To ease mixing when the material temperature is below 41F ketone (MEK). Brushes, injection guns, spray equipment and

(5C), warm the Base and Solidifier modules until the contents any other application tools should be cleaned using a suitable

attain a temperature of 68-77F (20-25C). solvent such as Belzona 9121, MEK, acetone or cellulose

thinners.

2. WORKING LIFE

From the commencement of mixing, Belzona 1111 must be

used within the times shown below.

Temperature 41F (5C) 59F (15C) 77F (25C)

Use all material within 35 min. 25 min. 15 min.

www.belzona.com Publication No. 15-06-14

4. COMPLETION OF THE MOLECULAR 5. EFFECTING THE SECONDARY

REACTION MOLECULAR REACTION

Allow Belzona 1111 to solidify as below subjecting it to the The mechanical properties, heat resistance and chemical

conditions indicated. resistance of Belzona 1111 will be improved by post curing.

Temper- Movement or Machining Full Immersion After 2 - 4 hours of applying Belzona 1111, post cure the

ature use involving and/or light mechanical in material using forced air heaters, heat lamps, etc. for a minimum

no loading or loading or thermal chemicals of 4 hours at 140-212F (60-100C).

immersion loading

41F/ 5C 4 hours 6 hours 4 days 5 days

Generally, the higher the post cure temperature adopted, the

50F/10C 3 hours 4 hours 2 days 4 days

59F/15C 2 hours 3 hours 1 days 3 days

higher the properties attained.

68F/20C 1 hours 2 hours 1 day 2 days

77F/25C 1 hour 1 hours 20 hours 1 days 6. APPLICATION OF A FURTHER LAYER OF

86F/30C hour 1 hour 16 hours 1 day BELZONA 1111

These times are for a thickness of approximately 0.25 inch Where this is required it should be applied as soon as possible

(6 mm); they will be reduced for thicker sections and extended after application of the first layer and certainly while the first layer

for thinner sections. is still soft.

If the Belzona 1111 is no longer soft the surface must be

roughened by abrading or flash blasting before applying further

Belzona 1111.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Material Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is ISO 9001:2008

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify Q 09335

the technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of ISO 14001:2004

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of EMS 509612

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a Manufactured under an ISO 9000

particular purpose. Registered Quality Management System

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright 2014 Belzona International Limited. Belzona is a registered trademark. Belzona is a registered trademark

Belzona 1111 - Instructions for Use - (2) Printed in England Publication No. 15-06-14

You might also like

- Belzona 1121: Instructions For UseDocument2 pagesBelzona 1121: Instructions For UseMinhas ArshadNo ratings yet

- Benzola 1311Document2 pagesBenzola 1311vanduongNo ratings yet

- Belzona 1151: Instructions For UseDocument2 pagesBelzona 1151: Instructions For UseIrvansyah RazadinNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseEnrique MurgiaNo ratings yet

- 1111 IfDocument2 pages1111 IfMithun NandanNo ratings yet

- UK3111if_10134Document2 pagesUK3111if_10134VPN NetworkNo ratings yet

- Benzona 1511Document2 pagesBenzona 1511Dia Putranto HarmayNo ratings yet

- Belzona 1321Document2 pagesBelzona 1321GabrielNo ratings yet

- Belzona Fluid ElastomerDocument2 pagesBelzona Fluid Elastomergacm98No ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 4131: Instructions For UseDocument2 pagesBelzona 4131: Instructions For UsecodozinhoNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Belzona 1311: Instructions For UseDocument2 pagesBelzona 1311: Instructions For UserobertomaleoNo ratings yet

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseMAMI RAKOTOMAHANINANo ratings yet

- Belzona 1321: Instructions For UseDocument2 pagesBelzona 1321: Instructions For UserobertomaleoNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- Belzona 4341: Instructions For UseDocument2 pagesBelzona 4341: Instructions For UseSagysm Hotmarx MarvaugNo ratings yet

- Belzona Know-How: For Bonding and Grouting Tiles and Wear PlatesDocument2 pagesBelzona Know-How: For Bonding and Grouting Tiles and Wear PlatesArthurNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- Belzona 1341 (Supermetalglide) - Instructions For UseDocument2 pagesBelzona 1341 (Supermetalglide) - Instructions For Usevangeliskyriakos8998No ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening CompoundAshvin ParmessurNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- UK5892if 10106Document2 pagesUK5892if 10106mrashid286No ratings yet

- Nerolac-Beauty GoldDocument2 pagesNerolac-Beauty GoldMahend RanNo ratings yet

- Belzona 5831: Instructions For UseDocument2 pagesBelzona 5831: Instructions For UseVippin Kumar RanaNo ratings yet

- Protect and Seal Concrete FloorsDocument2 pagesProtect and Seal Concrete FloorstalatzahoorNo ratings yet

- UK1391Tif 10034Document2 pagesUK1391Tif 10034Deepak YadavNo ratings yet

- Technical Proposal: (Application of Belzona Tank Preformed Patch Repair)Document8 pagesTechnical Proposal: (Application of Belzona Tank Preformed Patch Repair)Bambang IrawanNo ratings yet

- Davco K11 Flex - Brochure (Brochure)Document2 pagesDavco K11 Flex - Brochure (Brochure)John Joseph IdanoNo ratings yet

- Nerolac Beauty Smooth MergedDocument6 pagesNerolac Beauty Smooth MergedRishiNo ratings yet

- Nerolac-Beauty SmoothDocument2 pagesNerolac-Beauty SmoothMahend RanNo ratings yet

- Pf-1811.en 10039Document2 pagesPf-1811.en 10039Александр ПлаксаNo ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening Compoundengramir07No ratings yet

- Flexiclad Er PDFDocument2 pagesFlexiclad Er PDFVincent AndiNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- 1391 T Belzona Instruction - UseDocument0 pages1391 T Belzona Instruction - UseSds Mani SNo ratings yet

- Fosroc Nitocote SN511 TDSDocument2 pagesFosroc Nitocote SN511 TDSmrameshceNo ratings yet

- Velosit PA 911: Universal Primer For Mortars and AdhesivesDocument2 pagesVelosit PA 911: Universal Primer For Mortars and AdhesivesZammar ShahidNo ratings yet

- Fosroc Nitoflor EU50: High Strength Epoxy UnderlayDocument4 pagesFosroc Nitoflor EU50: High Strength Epoxy UnderlayVincent JavateNo ratings yet

- Nitoflor Levelcrete: Cementitious Floor Levelling CompoundDocument4 pagesNitoflor Levelcrete: Cementitious Floor Levelling CompoundChandan MirajkarNo ratings yet

- Nitoflor EU50Document4 pagesNitoflor EU50m.elsanee.cubicNo ratings yet

- Nitoflor Levelcrete IndiaDocument4 pagesNitoflor Levelcrete IndiaArun KumarNo ratings yet

- Sika Seal - 109Document2 pagesSika Seal - 109Mohamed Osama AshmawyNo ratings yet

- Datasheet Epidermix 344Document2 pagesDatasheet Epidermix 344Vicky MunienNo ratings yet

- Impression 24 Carat-MergedDocument12 pagesImpression 24 Carat-MergedRishiNo ratings yet

- Impression 24 CaratDocument2 pagesImpression 24 CaratMahend RanNo ratings yet

- Nerolac Excel-Anti Peel 1Document2 pagesNerolac Excel-Anti Peel 1Mahend RanNo ratings yet

- Nitoflor FC100Document2 pagesNitoflor FC100m.elsanee.cubicNo ratings yet

- Monneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Document3 pagesMonneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Maha MuflehNo ratings yet

- Fosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundDocument4 pagesFosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundVincent JavateNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Nerolac Pearls EmulsionDocument2 pagesNerolac Pearls EmulsionAdib NawazNo ratings yet

- Nitoflor LVBGDocument4 pagesNitoflor LVBGm.elsanee.cubicNo ratings yet

- Steel Frame Structure Bill of MaterialsDocument1 pageSteel Frame Structure Bill of MaterialsAdeImanudinNo ratings yet

- Daily Report Installation: Description of Work in The FieldDocument2 pagesDaily Report Installation: Description of Work in The FieldAdeImanudinNo ratings yet

- Bon Pengantar Barang Dan Barang Return BFP LA SO 19000195Document2 pagesBon Pengantar Barang Dan Barang Return BFP LA SO 19000195AdeImanudinNo ratings yet

- AR-Casing Cover - Diameter Inspection ReportDocument1 pageAR-Casing Cover - Diameter Inspection ReportAdeImanudinNo ratings yet

- PT Trieka Aimex Reciprocating Pump Repair ReportDocument18 pagesPT Trieka Aimex Reciprocating Pump Repair ReportAdeImanudinNo ratings yet

- Frame P7 1 PDFDocument1 pageFrame P7 1 PDFAdeImanudinNo ratings yet

- Base P8 Plate 8Document1 pageBase P8 Plate 8AdeImanudinNo ratings yet

- Base Engine P9 PDFDocument1 pageBase Engine P9 PDFAdeImanudinNo ratings yet

- Format List Pengalaman - TRIEKA - REVISI 3Document10 pagesFormat List Pengalaman - TRIEKA - REVISI 3AdeImanudinNo ratings yet

- Base Engine P9Document1 pageBase Engine P9AdeImanudinNo ratings yet

- Lifting EyeDocument1 pageLifting EyeAdeImanudinNo ratings yet

- Lifting Eye RoofDocument1 pageLifting Eye RoofAdeImanudinNo ratings yet

- Se P4Document1 pageSe P4AdeImanudinNo ratings yet

- Base P8 Plate 8 PDFDocument1 pageBase P8 Plate 8 PDFAdeImanudinNo ratings yet

- Se P2 PDFDocument1 pageSe P2 PDFAdeImanudinNo ratings yet

- FP 7.5-04/03 REF. 0 Edisi. ADocument1 pageFP 7.5-04/03 REF. 0 Edisi. AAdeImanudinNo ratings yet

- Key of Rubber CouplingDocument1 pageKey of Rubber CouplingAdeImanudinNo ratings yet

- 20 Thru: FP 7.5-04/03 REF. 0 Edisi. ADocument1 page20 Thru: FP 7.5-04/03 REF. 0 Edisi. AAdeImanudinNo ratings yet

- FP 7.5-04/03 REF. 0 Edisi. ADocument1 pageFP 7.5-04/03 REF. 0 Edisi. AAdeImanudinNo ratings yet

- Se P2.2Document1 pageSe P2.2AdeImanudinNo ratings yet

- 26 Thru: FP 7.5-04/03 REF. 0 Edisi. ADocument1 page26 Thru: FP 7.5-04/03 REF. 0 Edisi. AAdeImanudinNo ratings yet

- Ecs 14-006 Casing Compressor HPDocument1 pageEcs 14-006 Casing Compressor HPAdeImanudinNo ratings yet

- Frame P7 1Document1 pageFrame P7 1AdeImanudinNo ratings yet

- Bom Material MHG 5-8 PT - DssDocument40 pagesBom Material MHG 5-8 PT - DssAdeImanudinNo ratings yet

- Bom Material MHG 5-8 PT - DssDocument1 pageBom Material MHG 5-8 PT - DssAdeImanudinNo ratings yet

- Base Engine 2 Assy DimensionalDocument1 pageBase Engine 2 Assy DimensionalAdeImanudinNo ratings yet

- High-performance engine parts specificationsDocument1 pageHigh-performance engine parts specificationsAdeImanudinNo ratings yet

- Engineering Communication Sheet: Pt. Torishima Guna Engineering Engineering Service DivisionDocument2 pagesEngineering Communication Sheet: Pt. Torishima Guna Engineering Engineering Service DivisionAde ImanudinNo ratings yet

- BOM Southern Cross Pump SupremeDocument2 pagesBOM Southern Cross Pump SupremeAdeImanudinNo ratings yet

- Bom Pompa MHG PLN TarahanDocument2 pagesBom Pompa MHG PLN TarahanAdeImanudinNo ratings yet

- Cyberpunk 2020 - Net - Adventure - Road Warriors by Lisa SmedmanDocument20 pagesCyberpunk 2020 - Net - Adventure - Road Warriors by Lisa SmedmanFabricio MoreiraNo ratings yet

- Galvastop - TDSDocument3 pagesGalvastop - TDSThanh Hoàng GiaNo ratings yet

- The Manufacture of Composites Based On Synthetic Resins (Fibreglass)Document62 pagesThe Manufacture of Composites Based On Synthetic Resins (Fibreglass)kinfeNo ratings yet

- Product and Company Identification: Flammability HealthDocument7 pagesProduct and Company Identification: Flammability HealthAbbi LoneNo ratings yet

- SDS PVC PrimerDocument2 pagesSDS PVC PrimerAhmad AnthonyNo ratings yet

- Ghs Safety Data Sheet: ParabondDocument2 pagesGhs Safety Data Sheet: Parabondmanoj_sitecNo ratings yet

- 2-Butanone: Production, Properties and Uses of Methyl Ethyl KetoneDocument4 pages2-Butanone: Production, Properties and Uses of Methyl Ethyl KetoneAli González100% (2)

- #ZQ) A, B,: Development and Commercial Application of Methyl-Ethyl-Ketone Production TechnologyDocument9 pages#ZQ) A, B,: Development and Commercial Application of Methyl-Ethyl-Ketone Production TechnologyNishant Kumar GuptaNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument64 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- 1Document16 pages1shamsjahangirNo ratings yet

- 300-1005-100 Solvent, Case 4, 1 Liter, MEK-United States - SOLUCION - LAVADODocument6 pages300-1005-100 Solvent, Case 4, 1 Liter, MEK-United States - SOLUCION - LAVADOAlexander MamaniNo ratings yet

- Butyl AcetateDocument7 pagesButyl AcetateJames KabugoNo ratings yet

- UK1111if 10132 PDFDocument2 pagesUK1111if 10132 PDFAdeImanudinNo ratings yet

- The Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFDocument10 pagesThe Dehydrogenation of 2-Butanol Over Copper-Based Catalysts-Optimising Catalyst Composition and Determining Kinetic Parameters PDFYohana MelianthaNo ratings yet

- The Separation of Acetone-Methanol Mixture by Extractive DistillationDocument13 pagesThe Separation of Acetone-Methanol Mixture by Extractive DistillationpaulaNo ratings yet

- 01-75PAA-2-4-6 PropellerDocument269 pages01-75PAA-2-4-6 Propellerhunger gamesNo ratings yet

- United Initiators Mutli Component Peroxides MEKP Is Not MEKP NoroxDocument6 pagesUnited Initiators Mutli Component Peroxides MEKP Is Not MEKP NoroxvasucristalNo ratings yet

- Mek Eu 26Document3 pagesMek Eu 26Jeisson_Zapata_547No ratings yet

- Chapter - 2 Literature Review: 2.1 Regeneration of Used Lubricating OilsDocument23 pagesChapter - 2 Literature Review: 2.1 Regeneration of Used Lubricating OilsEl Sayed ZakariaNo ratings yet

- Chloromethanes: Anfred Ossberg Ilhelm Endle Erhard Fleiderer GelDocument28 pagesChloromethanes: Anfred Ossberg Ilhelm Endle Erhard Fleiderer Gelgeek0No ratings yet

- Drug Precursors BookletDocument64 pagesDrug Precursors BookletAlex FaasseNo ratings yet

- 77001-00001 Reach PDFDocument5 pages77001-00001 Reach PDFHector GaracheNo ratings yet

- PTS 31.38.01.15a - Piping Classes - Exploration and Production PDFDocument43 pagesPTS 31.38.01.15a - Piping Classes - Exploration and Production PDFNguyễn Văn Tây91% (11)

- Perfectim Msds Die Hard Thin L 149 0113Document2 pagesPerfectim Msds Die Hard Thin L 149 0113Anonymous gUySMcpSqNo ratings yet

- Tds Chivacure 1256Document2 pagesTds Chivacure 1256api-308404168No ratings yet

- Unik Spray Solutions MSDSDocument7 pagesUnik Spray Solutions MSDSSyedFarhanNo ratings yet

- Jet Airways Aircraft Cleaning GuideDocument53 pagesJet Airways Aircraft Cleaning GuideRamakrishnan AmbiSubbiahNo ratings yet

- Production of Methyl Ethyl Ketone From Secondary ButanolDocument207 pagesProduction of Methyl Ethyl Ketone From Secondary ButanolNoman Aslam100% (3)

- My Project ReportDocument51 pagesMy Project ReportVishnu Prasad75% (4)

- Williamson Ether SynthesisDocument2 pagesWilliamson Ether SynthesisShahid Iqbal Sanghi100% (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- One Health: Integrated Approach to 21st Century Challenges to HealthFrom EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet