Professional Documents

Culture Documents

Belzona 1151: Instructions For Use

Uploaded by

Irvansyah RazadinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belzona 1151: Instructions For Use

Uploaded by

Irvansyah RazadinCopyright:

Available Formats

Belzona 1151

FN10017

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR 2. COMBINING THE REACTIVE

WELD COMPONENTS

APPLY ONLY TO BLAST CLEANED SURFACES a) Transfer approximately half of the contents of the Belzona®

1151 Solidifier can to the Belzona® 1151 Base unit.

a) Brush away loose contamination and degrease with a rag

soaked in Belzona® 9111 (Cleaner/Degreaser) or any other b) Mix until a uniform consistency is achieved.

effective cleaner which does not leave a residue e.g. methyl

ethyl ketone (MEK). c) Add the remainder to the Solidifier and mix thoroughly to a

uniform streak free material.

b) Select an abrasive to give the necessary standard of

cleanliness and a minimum depth of profile of 3 mils NOTES

(75 microns). 1. MIXING AT LOW TEMPERATURES

To ease mixing when the material temperature is below 41°F

Use only an angular abrasive. (5°C), warm the Base and Solidifier components until the

contents attain a temperature of 68-77°F (20-25°C).

c) Blast clean the metal surface to achieve the following

standard of cleanliness: 2. WORKING LIFE

ISO 8501-1 Sa 2½ very thorough blast cleaning From the commencement of mixing, Belzona® 1151 must be

American Standard near white finish SSPC SP 10 used within the times shown below.

Swedish Standard Sa 2½ SIS 05 5900

Temperature 41°F (5°C) 59°F (15°C) 77°F (25°C)

d) After blasting, metal surfaces should be coated before any Use all material within 50 min. 40 min. 30 min.

oxidation of the surface takes place.

3. MIXING SMALL QUANTITIES

SALT CONTAMINATED SURFACES For mixing small quantities of Belzona® 1151 use:

Metal surfaces that have been immersed for any periods in salt 4 parts Base to 1 part Solidifier by volume

solutions e.g. sea water, should be blasted to the required 10.8 parts Base to 1 part Solidifier by weight

standard, left 24 hours to allow any ingrained salts to sweat to

the surface and then washed prior to a further brush blast to 4. VOLUME CAPACITY OF MIXED BELZONA® 1151

remove these. This process may need to be repeated to ensure 25.0 cu.in. (409 cm³) per kg.

complete removal of salts.

WHERE BELZONA® 1151 SHOULD NOT ADHERE

Brush on a thin layer of Belzona® 9411 (Release Agent) and

allow to dry for 15-20 minutes before proceeding to step 2.

www.belzona.com Publication No. 12-08-19

3. APPLYING BELZONA® 1151 4. COMPLETION OF THE MOLECULAR

REACTION

FOR BEST RESULTS

Do not apply when: Allow Belzona® 1151 to solidify as below before subjecting it to

i) The temperature is below 41°F (5°C) or the relative the conditions indicated.

humidity is above 90%.

ii) Rain, snow, fog or mist is present. Temperature Overcoating Machining Full

iii) There is moisture on the metal surface or is likely to and/or light mechanical or

be deposited by subsequent condensation. loading thermal

iv) The working environment is likely to be loading

contaminated by oil/grease from adjacent equipment 41°F/ 5°C 5 hours 18 hours 7 days

or smoke from kerosene heaters or tobacco 59°F/15°C 3½ hours 9 hours 2 days

smoking. 77°F/25°C 2½ hours 4½ hours 24 hours

a) Apply the Belzona® 1151 directly on to the prepared These times are for a thickness of approximately 0.25 inch

surface with the plastic applicator or spatula provided. (6 mm); they will be reduced for thicker sections and extended

for thinner sections.

b) Press down firmly to fill all cracks, remove entrapped air,

and ensure maximum contact with the surface. 5. APPLICATION OF A FURTHER LAYER OF

BELZONA®

c) Contour the Belzona® 1151 to the correct profile with the

plastic applicator. Where this is required it should be applied as soon as possible

after the first layer and certainly while the first layer is still soft

CLEANING (less than 6 hours at 68°F (20°C)).

Mixing tools should be cleaned immediately after use with

Belzona® 9111 or any other effective solvent e.g. Methyl ethyl If the above overcoating time is exceeded the surface of

ketone (MEK). Application tools should be cleaned using a Belzona® 1151 must be roughened by abrading or flash blasting

suitable solvent such as Belzona® 9121, MEK, acetone or before applying further Belzona®.

cellulose thinners.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is Belzona products are

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify

the technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of manufactured under an

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of ISO 9001 Registered

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a

particular purpose.

Quality Management System

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright © 2019 Belzona International Limited. Belzona® is a registered trademark.

Belzona 1151 - Instructions for Use - (2) Publication No. 12-08-19

You might also like

- Benzola 1311Document2 pagesBenzola 1311vanduongNo ratings yet

- 1111 IfDocument2 pages1111 IfMithun NandanNo ratings yet

- Belzona 1311: Instructions For UseDocument2 pagesBelzona 1311: Instructions For UserobertomaleoNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Benzona 1511Document2 pagesBenzona 1511Dia Putranto HarmayNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- UK1111if 10132 PDFDocument2 pagesUK1111if 10132 PDFAdeImanudinNo ratings yet

- Belzona 1121: Instructions For UseDocument2 pagesBelzona 1121: Instructions For UseMinhas ArshadNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseMAMI RAKOTOMAHANINANo ratings yet

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- Belzona 4341: Instructions For UseDocument2 pagesBelzona 4341: Instructions For UseSagysm Hotmarx MarvaugNo ratings yet

- Belzona 1321Document2 pagesBelzona 1321GabrielNo ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Belzona 1321: Instructions For UseDocument2 pagesBelzona 1321: Instructions For UserobertomaleoNo ratings yet

- Belzona 4131: Instructions For UseDocument2 pagesBelzona 4131: Instructions For UsecodozinhoNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- UK3111if 10134Document2 pagesUK3111if 10134VPN NetworkNo ratings yet

- UK5892if 10106Document2 pagesUK5892if 10106mrashid286No ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseEnrique MurgiaNo ratings yet

- Belzona 1341 (Supermetalglide) - Instructions For UseDocument2 pagesBelzona 1341 (Supermetalglide) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK1391Tif 10034Document2 pagesUK1391Tif 10034Deepak YadavNo ratings yet

- Belzona Fluid ElastomerDocument2 pagesBelzona Fluid Elastomergacm98No ratings yet

- Belzona 1321 (Ceramic S-Metal) - Instructions For UseDocument2 pagesBelzona 1321 (Ceramic S-Metal) - Instructions For Usevangeliskyriakos8998No ratings yet

- Belzona 5831: Instructions For UseDocument2 pagesBelzona 5831: Instructions For UseVippin Kumar RanaNo ratings yet

- Belzona Know-How: For Bonding and Grouting Tiles and Wear PlatesDocument2 pagesBelzona Know-How: For Bonding and Grouting Tiles and Wear PlatesArthurNo ratings yet

- 1391 T Belzona Instruction - UseDocument0 pages1391 T Belzona Instruction - UseSds Mani SNo ratings yet

- Denso Protal 7200 Brush Application SpecDocument2 pagesDenso Protal 7200 Brush Application SpecTino VelázquezNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- Interline 921+ds+eng PDFDocument4 pagesInterline 921+ds+eng PDFMohamed NouzerNo ratings yet

- Belzona 1212Document2 pagesBelzona 1212faridNo ratings yet

- PDS-POLYKEN-1039 PrimerDocument2 pagesPDS-POLYKEN-1039 PrimerSenthilkumar NarayananNo ratings yet

- Interline 984+ds+eng PDFDocument4 pagesInterline 984+ds+eng PDFMohamed NouzerNo ratings yet

- Ceilcote 505 Coroline+ds+engDocument4 pagesCeilcote 505 Coroline+ds+englivefreakNo ratings yet

- Ceilcote 282 Flakeline+ds+engDocument4 pagesCeilcote 282 Flakeline+ds+engMohamed NouzerNo ratings yet

- Ceilcote - 2000 InternationalDocument4 pagesCeilcote - 2000 InternationalAjay RanganathanNo ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 2000 FlakelineDocument4 pagesCeilcote 2000 FlakelineAhmet GözübüyükNo ratings yet

- Ceilkote 2000Document4 pagesCeilkote 2000Anwar MdNo ratings yet

- Veetagrout V71 Instruction Manual - New Format V 2Document3 pagesVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezNo ratings yet

- Ceilcote 2000 Flakeline: Epoxy NovolacDocument4 pagesCeilcote 2000 Flakeline: Epoxy Novolacshakeel ahmedNo ratings yet

- Enviroline 50Document4 pagesEnviroline 50Ahmed IbrahimNo ratings yet

- Nerolac-Beauty GoldDocument2 pagesNerolac-Beauty GoldMahend RanNo ratings yet

- Nitoflor FC110: Constructive SolutionsDocument2 pagesNitoflor FC110: Constructive SolutionstalatzahoorNo ratings yet

- Ceilcote 242AR Flakeline+ds+engDocument4 pagesCeilcote 242AR Flakeline+ds+englivefreakNo ratings yet

- Ceilcote 180 Flakeline+ds+engDocument4 pagesCeilcote 180 Flakeline+ds+englivefreakNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- Davco K11 Flex - Brochure (Brochure)Document2 pagesDavco K11 Flex - Brochure (Brochure)John Joseph IdanoNo ratings yet

- Ceilcote 242 Flakeline Eng A4 20180219Document4 pagesCeilcote 242 Flakeline Eng A4 20180219Cuong Nguyen ManhNo ratings yet

- 315 UkDocument4 pages315 UkAhmed IbrahimNo ratings yet

- Ceilcote 232 Flakeline+ds+engDocument4 pagesCeilcote 232 Flakeline+ds+engMohamed NouzerNo ratings yet

- Celcote 242Document4 pagesCelcote 242Anwar MdNo ratings yet

- QA/QC Coordinator Job DescriptionDocument2 pagesQA/QC Coordinator Job DescriptionIrvansyah RazadinNo ratings yet

- 5 Asme Viii A 24 Clamp ConnectionDocument6 pages5 Asme Viii A 24 Clamp ConnectionIrvansyah RazadinNo ratings yet

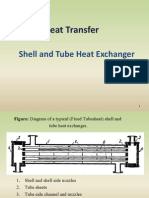

- Shell and Tube Heat ExchangerDocument34 pagesShell and Tube Heat ExchangerTamoor Tariq50% (4)

- Welding FundamentalsDocument44 pagesWelding FundamentalsDhinasuga DhinakaranNo ratings yet

- Lets PDFDocument20 pagesLets PDFAugusto Manuel Inga SánchezNo ratings yet

- Mitigation of External CorrosionDocument20 pagesMitigation of External CorrosionIrvansyah RazadinNo ratings yet

- CS Issue06 2006Document16 pagesCS Issue06 2006Irvansyah RazadinNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- State of North Carolina 5430-2 Department of Administration October 17, 1995 Purchase and Contract DivisionDocument11 pagesState of North Carolina 5430-2 Department of Administration October 17, 1995 Purchase and Contract DivisionIrvansyah RazadinNo ratings yet

- Geo Celtic and Geo Barents: SectionDocument20 pagesGeo Celtic and Geo Barents: SectionIrvansyah RazadinNo ratings yet

- CS Issue09 2008Document16 pagesCS Issue09 2008Irvansyah RazadinNo ratings yet

- Hypodermic Needle Gauge PDocument1 pageHypodermic Needle Gauge PIrvansyah RazadinNo ratings yet

- PHMSA Form 10 Standard Breakout Tank Insp 2008Document21 pagesPHMSA Form 10 Standard Breakout Tank Insp 2008Irvansyah RazadinNo ratings yet

- CS Issue07 2007Document16 pagesCS Issue07 2007Irvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Grit PDocument1 pageBlasting Abrasives Metallic Grit PIrvansyah RazadinNo ratings yet

- CS Issue04 2005Document7 pagesCS Issue04 2005Irvansyah RazadinNo ratings yet

- CS Issue05 2006Document9 pagesCS Issue05 2006Irvansyah RazadinNo ratings yet

- Ameron Calculation Manual For Bondstand GRE Pipe SystemsDocument16 pagesAmeron Calculation Manual For Bondstand GRE Pipe Systemsgbuckley9630No ratings yet

- My Account ForumDocument1 pageMy Account ForumIrvansyah RazadinNo ratings yet

- CS Issue02 2004Document7 pagesCS Issue02 2004Irvansyah RazadinNo ratings yet

- Surface Profile Measurement Needle Gauge PDocument1 pageSurface Profile Measurement Needle Gauge PIrvansyah RazadinNo ratings yet

- Surface Profile Measurement Surface Profile Comparator PDocument1 pageSurface Profile Measurement Surface Profile Comparator PIrvansyah RazadinNo ratings yet

- Wet Film CombsDocument1 pageWet Film CombsIrvansyah RazadinNo ratings yet

- CS Issue03 2005Document7 pagesCS Issue03 2005Irvansyah RazadinNo ratings yet

- Blasting Abrasives Garnet PDocument1 pageBlasting Abrasives Garnet PIrvansyah RazadinNo ratings yet

- Coating Inspection Copper Sulphate TestDocument1 pageCoating Inspection Copper Sulphate TestBOBNo ratings yet

- The Whirling Hygrometer: Painting InspectionDocument1 pageThe Whirling Hygrometer: Painting InspectionIrvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Grit PDocument1 pageBlasting Abrasives Metallic Grit PIrvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Shot PDocument1 pageBlasting Abrasives Metallic Shot PIrvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Shot and Grit PDocument1 pageBlasting Abrasives Metallic Shot and Grit PIrvansyah RazadinNo ratings yet

- Periodic Table of ElementsDocument2 pagesPeriodic Table of ElementsJaira Canelas MitraNo ratings yet

- G3632-50T NDocument2 pagesG3632-50T Nfathan jefriansyahNo ratings yet

- Safety Data Sheet - EN - (89985628) DIHYDRO-3 - (TETRAPROPENYL) FURAN-2,5-DIONE (26544-38-7)Document7 pagesSafety Data Sheet - EN - (89985628) DIHYDRO-3 - (TETRAPROPENYL) FURAN-2,5-DIONE (26544-38-7)castasoftNo ratings yet

- Resin Based Restorative Dental Materials. Characteristics and Future PerspectivesDocument13 pagesResin Based Restorative Dental Materials. Characteristics and Future PerspectivesDan MPNo ratings yet

- Industrial Materials: Instructed By: Dr. Sajid ZaidiDocument13 pagesIndustrial Materials: Instructed By: Dr. Sajid ZaidiarulmuruguNo ratings yet

- Dynatrans Ac 30: Safety Data SheetDocument10 pagesDynatrans Ac 30: Safety Data SheetDany LeaNo ratings yet

- Major Advances and Challenges in Heterogeneous CatalysisDocument26 pagesMajor Advances and Challenges in Heterogeneous CatalysisJuan Lopez HernándezNo ratings yet

- Class 10 Ahaguru Science Model Paper SolutionsDocument14 pagesClass 10 Ahaguru Science Model Paper Solutionsfsdf ffdhrtNo ratings yet

- Index: Combustion Technology: Essential of Flames and Burners, First Edition SDocument3 pagesIndex: Combustion Technology: Essential of Flames and Burners, First Edition SirNo ratings yet

- SCIE 4 LP 7es ChemistryDocument7 pagesSCIE 4 LP 7es ChemistryzachharveyneilNo ratings yet

- Vincento Frazier - Gizmos Lab - Protein SynthesisDocument6 pagesVincento Frazier - Gizmos Lab - Protein SynthesisToxic KikiNo ratings yet

- CHEM 104 Week 1 3Document35 pagesCHEM 104 Week 1 3JOSE ANGELO ESPLANA100% (2)

- Controlled Star Poly (2-Oxazoline) S Synthesis, CharacterizationDocument12 pagesControlled Star Poly (2-Oxazoline) S Synthesis, CharacterizationSimon LeluyerNo ratings yet

- US4417079 KurarayDocument16 pagesUS4417079 Kuraray黃英婷No ratings yet

- AB Emultech Private LimitedDocument18 pagesAB Emultech Private LimitedamistalokNo ratings yet

- Earthquake Resistance BuildingDocument11 pagesEarthquake Resistance BuildingAnirudra Sharma100% (1)

- COrrosion Inhibitor BS 6580Document4 pagesCOrrosion Inhibitor BS 6580rizky andrianNo ratings yet

- Bostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Document4 pagesBostik UltraFinish Pro Premium Portland Cement Repair Patch Product Data 1848181Arturo Jr. TorresNo ratings yet

- Fibre Identification by Chemical Method 2Document5 pagesFibre Identification by Chemical Method 2sayedNo ratings yet

- Copeland ZP24K5E PFV 830Document16 pagesCopeland ZP24K5E PFV 830Reynnier MendozaNo ratings yet

- 40 Lesson Plan 8608 Phy, Chem, Math (Matric)Document70 pages40 Lesson Plan 8608 Phy, Chem, Math (Matric)mc200200839100% (1)

- CGE653-Chapter 2-Part 1 PDFDocument79 pagesCGE653-Chapter 2-Part 1 PDFAbdul Halim AsmungiNo ratings yet

- 9 Class FaceDocument8 pages9 Class FaceViswaNo ratings yet

- Arunkumar 2013Document6 pagesArunkumar 2013Virender KumarNo ratings yet

- Question 1: Feedback - Graded Quiz #1 (Symmetry 3 Part I)Document13 pagesQuestion 1: Feedback - Graded Quiz #1 (Symmetry 3 Part I)Shaun Raphael LeeNo ratings yet

- Physical Science Week 5 - 6Document14 pagesPhysical Science Week 5 - 6Aleli Joy Profugo Dalisay100% (1)

- Corrosion Resistance Properties of Glow-Discharge Nitrided Aisi 316L Austenitic Stainless Steel in Nacl SolutionsDocument15 pagesCorrosion Resistance Properties of Glow-Discharge Nitrided Aisi 316L Austenitic Stainless Steel in Nacl Solutionso_l_0No ratings yet

- CollisionTheorySE Revised For MYP-GizmosDocument9 pagesCollisionTheorySE Revised For MYP-GizmosNo HumorNo ratings yet

- PERNO 1.2 X 1 1.2Document1 pagePERNO 1.2 X 1 1.2benedicto soto mestanzaNo ratings yet

- 05/30/2022 1 DR R HaldarDocument62 pages05/30/2022 1 DR R HaldarSuman GhoshNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)