Professional Documents

Culture Documents

QA/QC Coordinator Job Description

Uploaded by

Irvansyah RazadinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA/QC Coordinator Job Description

Uploaded by

Irvansyah RazadinCopyright:

Available Formats

QA/QC Coordinator

Job Description:

• Provide a local focal point for all delegated QAQC matters relating to Bids, Projects and

other Quality functions as instructed.

• Align, support and communicate with TRS/DwC Teams on Project specific issues including

equipment preparation reviews.

• Prepare, issue for use and update Project Quality Plans.

• Ensure compliance with contract quality requirements.

• Liaise with Customer and Third Party QM representatives in pursuance of and compliance

with contractual obligations.

• Support, conduct and report on internal, external & project specific audits, where required, in

accordance with an approved audit schedule and specific Project requirements. Issue and

follow up on NCR’s / Findings (if any) resulting from these.

• Assist the functional areas in the process improvement activities required to close out any

Findings raised during internal audits/NCR issues and submit to Quality Locker team.

• Conduct ad hoc audits or investigations into particular quality problems so that root causes

are identified and effective corrective and preventive measures are put in place.

• Assist in the maintenance and revision of the company processes and procedures relating to

the functional areas of the TRS/DwC business.

• Provision of direction, guidance, control, support and development of a Quality culture

through the induction process and Service Alerts/Product Alerts/Quality bulletins.

• To support any new Quality Initiatives as required

• To conduct, collect, maintain and support all internal TRS/DwC QAQC documents in place

such as CoC, Data Book, MIR, PD.

• Maintain, monitor and follow up all related calibration process of the equipment and its

documentation.

Desired Skills & Experience

• 5 years experiences with QAQC related with Oil & Gas industry.

• Have good knowledge in API, BS EN/DNV product & specification

• Able to communicate & work with people as a team

• Fluent in English both oral & written

asic Function:

• Monitor and to manage, on behalf of DSLNG, the plant deterioration, such as wall thickness

of equipment and piping, painting, insulation and to suggest preventive, active or passive

resolution to maintain the asset integrity

• Review and optimize the plant inspection plan, both risk based and condition based

inspection work

• Finalize the risk based inspection plan and conditional inspection plan,

• Train the inspectors during commissioning phase

• Manage the initial measurements of equipment/piping system

• Monitor the deterioration of the plant and revise the inspection plan as needful.

• Maintain proper inspection and documentation for SKKP and SKPI renewal by getting an

approval from GOI.

• Implement QHSE regulation within his/her area of responsibility in order to minimize any

possible risk and comply with company and government regulation.

Requirement:

• Graduate with a BSc in metallurgy or mechanical Engineering

• Knowledge of applicable codes and standards for design and engineering purposes

• Belonging or have belonged to the international organization such as NACE

• Experienced with MIGAS for the certificate updates/extension

General requirement for all positions:

• Willing be on contractual basis

• Willing be on fixed pattern of work schedule

• Be proficient in oral and written English

• Work Location – Site Office, Central Sulawesi

You might also like

- Mitigation of External Corrosion on Buried Carbon Steel PipelinesDocument20 pagesMitigation of External Corrosion on Buried Carbon Steel PipelinesIrvansyah RazadinNo ratings yet

- Welding FundamentalsDocument44 pagesWelding FundamentalsDhinasuga DhinakaranNo ratings yet

- Lets PDFDocument20 pagesLets PDFAugusto Manuel Inga SánchezNo ratings yet

- ASME VIII Div.1 clamp connection designDocument6 pagesASME VIII Div.1 clamp connection designIrvansyah RazadinNo ratings yet

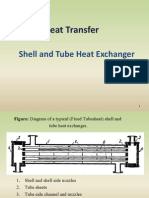

- Shell and Tube Heat ExchangerDocument34 pagesShell and Tube Heat ExchangerTamoor Tariq50% (4)

- PHMSA Form 10 Standard Breakout Tank Insp 2008Document21 pagesPHMSA Form 10 Standard Breakout Tank Insp 2008Irvansyah RazadinNo ratings yet

- CS Issue06 2006Document16 pagesCS Issue06 2006Irvansyah RazadinNo ratings yet

- Geo Celtic and Geo Barents: SectionDocument20 pagesGeo Celtic and Geo Barents: SectionIrvansyah RazadinNo ratings yet

- State of North Carolina 5430-2 Department of Administration October 17, 1995 Purchase and Contract DivisionDocument11 pagesState of North Carolina 5430-2 Department of Administration October 17, 1995 Purchase and Contract DivisionIrvansyah RazadinNo ratings yet

- CS Issue02 2004Document7 pagesCS Issue02 2004Irvansyah RazadinNo ratings yet

- CS Issue09 2008Document16 pagesCS Issue09 2008Irvansyah RazadinNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Grit PDocument1 pageBlasting Abrasives Metallic Grit PIrvansyah RazadinNo ratings yet

- CS Issue07 2007Document16 pagesCS Issue07 2007Irvansyah RazadinNo ratings yet

- CS Issue04 2005Document7 pagesCS Issue04 2005Irvansyah RazadinNo ratings yet

- CS Issue03 2005Document7 pagesCS Issue03 2005Irvansyah RazadinNo ratings yet

- CS Issue05 2006Document9 pagesCS Issue05 2006Irvansyah RazadinNo ratings yet

- Surface Profile Measurement Surface Profile Comparator PDocument1 pageSurface Profile Measurement Surface Profile Comparator PIrvansyah RazadinNo ratings yet

- Garnet Abrasive: A Hard Non-Metallic Mineral GritDocument1 pageGarnet Abrasive: A Hard Non-Metallic Mineral GritIrvansyah RazadinNo ratings yet

- Surface Profile Measurement Needle Gauge PDocument1 pageSurface Profile Measurement Needle Gauge PIrvansyah RazadinNo ratings yet

- My Account ForumDocument1 pageMy Account ForumIrvansyah RazadinNo ratings yet

- The Whirling Hygrometer: Painting InspectionDocument1 pageThe Whirling Hygrometer: Painting InspectionIrvansyah RazadinNo ratings yet

- Ameron Calculation Manual For Bondstand GRE Pipe SystemsDocument16 pagesAmeron Calculation Manual For Bondstand GRE Pipe Systemsgbuckley9630No ratings yet

- Blasting Abrasives Metallic Shot and Grit PDocument1 pageBlasting Abrasives Metallic Shot and Grit PIrvansyah RazadinNo ratings yet

- Hypodermic Needle Gauge PDocument1 pageHypodermic Needle Gauge PIrvansyah RazadinNo ratings yet

- Wet Film CombsDocument1 pageWet Film CombsIrvansyah RazadinNo ratings yet

- Blasting Abrasives Metallic Grit PDocument1 pageBlasting Abrasives Metallic Grit PIrvansyah RazadinNo ratings yet

- Coating Inspection Copper Sulphate TestDocument1 pageCoating Inspection Copper Sulphate TestBOBNo ratings yet

- Blasting Abrasives Metallic Shot PDocument1 pageBlasting Abrasives Metallic Shot PIrvansyah RazadinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DE712-014 Parts Manual - 712014 1 en Rev 1Document248 pagesDE712-014 Parts Manual - 712014 1 en Rev 1Emi DominguezNo ratings yet

- Literature ReviewDocument2 pagesLiterature ReviewFaith Arpon AbogandaNo ratings yet

- 8-Input Multiplexer Selects One of Eight InputsDocument3 pages8-Input Multiplexer Selects One of Eight InputsKang RoyNo ratings yet

- Mixed Use DevelopmentDocument3 pagesMixed Use DevelopmentMark Darcy UngsonNo ratings yet

- Omron Photoelectric Sensor E3jk 5M1Document8 pagesOmron Photoelectric Sensor E3jk 5M1harishsharma22No ratings yet

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (1)

- 17 The Tarrying TimeDocument22 pages17 The Tarrying Timeapi-303147801100% (1)

- Grundfos CR 5 4 A A A e HqqeDocument10 pagesGrundfos CR 5 4 A A A e HqqePrejit RadhakrishnaNo ratings yet

- GeographyDocument12 pagesGeographyGabriela Lizeth Durán RuizNo ratings yet

- Intel Processors PDFDocument33 pagesIntel Processors PDFbiplab royNo ratings yet

- 456/1 Mathematics Paper 1 June /july 2012 HoursDocument4 pages456/1 Mathematics Paper 1 June /july 2012 HoursBaguma MichaelNo ratings yet

- Philosophical Transactions of The Royal Society of LondonDocument716 pagesPhilosophical Transactions of The Royal Society of Londonab opt100% (1)

- Incremental and Newton Methods Lab ReportDocument10 pagesIncremental and Newton Methods Lab ReportAbde RrahimNo ratings yet

- Taoism and The KabbalahDocument26 pagesTaoism and The KabbalahJim Weaver100% (2)

- Atoms & Ions Worksheet 1 /63: Atomic Number and Mass NumberDocument4 pagesAtoms & Ions Worksheet 1 /63: Atomic Number and Mass Numbercate christineNo ratings yet

- Review of oxidative stress and antioxidants in dentistryDocument4 pagesReview of oxidative stress and antioxidants in dentistrySeeptianMaulanaNo ratings yet

- Ymfc Al SetupDocument18 pagesYmfc Al SetupredaNo ratings yet

- KSB ETN GM 80-200 - DomasDocument6 pagesKSB ETN GM 80-200 - Domasmuttawali arsyi han bugisNo ratings yet

- Des 415 Research 01Document29 pagesDes 415 Research 01Just scribble me For funNo ratings yet

- AmadiDocument18 pagesAmadijawad bello aNo ratings yet

- Facts on Timber Engineering and StructuresDocument73 pagesFacts on Timber Engineering and StructuresNaresworo NugrohoNo ratings yet

- Referencia 8Document130 pagesReferencia 8Kimiko SullonNo ratings yet

- Process Modeling in The Pharmaceutical Industry Using The Discrete Element MethodDocument29 pagesProcess Modeling in The Pharmaceutical Industry Using The Discrete Element MethodRonaldo MenezesNo ratings yet

- 2K6 Ec 307 (P) : Basic Electronics Lab: Sessional Work AssessmentDocument1 page2K6 Ec 307 (P) : Basic Electronics Lab: Sessional Work AssessmentJoseph JohnNo ratings yet

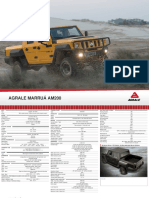

- Off Road and Military Vehicles Off Road Vehicles Agrale Marruaam200 1Document2 pagesOff Road and Military Vehicles Off Road Vehicles Agrale Marruaam200 1Victor SilvaNo ratings yet

- Man and Mystery Vol 13 - Monsters and Cryptids (Rev06)Document139 pagesMan and Mystery Vol 13 - Monsters and Cryptids (Rev06)Pablo Jr AgsaludNo ratings yet

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Q's For CONS VivaDocument251 pagesQ's For CONS VivaHanin AbukhiaraNo ratings yet

- Week 05 - Mechanical Properties Part 1Document48 pagesWeek 05 - Mechanical Properties Part 1Dharshica MohanNo ratings yet

- Different Project Topics of BSNLDocument3 pagesDifferent Project Topics of BSNLAbhijit Tripathy0% (1)