Professional Documents

Culture Documents

SEW Brakes: Service and Maintenance

SEW Brakes: Service and Maintenance

Uploaded by

Manuel ParraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEW Brakes: Service and Maintenance

SEW Brakes: Service and Maintenance

Uploaded by

Manuel ParraCopyright:

Available Formats

SEW Brakes

Service and Maintenance

SEW-EURODRIVEDriving the world

Product Training

2

Objectives

Upon completion of this session, you will be able to do

the following:

- Identify the components of an SEW brakemotor

- Explain the operation of the SEW brakemotor

- Apply basic troubleshooting procedures

SEW-EURODRIVEDriving the world

Product Training

3

Brake Purpose

To Stop Motion

- The brake engages when power is removed from the motor

- The brake applies force to an object in motion until friction

either slows or stops the motion.

- Motor slows and finally stops

To Prevent Motion

- Brake engages after motor has come

to complete stop

- Brake merely holds motor to prevent

rotation.

SEW-EURODRIVEDriving the world

Product Training

4

Brake Features

SEW features:

Fail-safe operation

Rectifier for conversion of AC into DC current

DC controlled brake coil

Without a fail-safe brake,

what would happen to

machinery in the event of

a power loss?

What about the product?

SEW-EURODRIVEDriving the world

Product Training

5

Brake Operation

Coil functions like an electromagnet when energized

Brake Coil

SEW-EURODRIVEDriving the world

Product Training

6

Brake Operation

De-energized Energized

When the coil is de-energized, the When the coil is energized, its

springs apply force to the magnetic field pulls the plate

stationary plate. towards the coil.

This force presses against the The magnetic force compresses

brake disc to create friction. the springs.

Friction stops the motor and/or The motor can now rotate freely.

prevents it from rotating. VIDEO

SEW-EURODRIVEDriving the world

Product Training

7

Brake Operation

Coil:

- The brake coil actually consists of two separate parts: an

Accelerator coil (BS) and a Fractional holding coil (TS).

- An SEW brake rectifier controls both coils.

Fractional

Accelerator

Brake Coil

SEW-EURODRIVEDriving the world

Product Training

8

Brake Operation

Step 1

- Initially, the rectifier energizes the Accelerator (BS) coil very

quickly, due to its low resistance.

Low resistance = High Current

High Current = Strong Electromagnetism

Strong Electromagnetism = Fast Reaction

Rectifier

Brake

Motor

Input

Power

SEW-EURODRIVEDriving the world

Product Training

9

Brake Operation

Step 2

- After 120 ms, the rectifier energizes both coils. Combined coils

have a higher resistance, allowing the coils to de-energize faster

when power is removed.

High resistance = Low Current

Low Current = Weak Electromagnetism

Weak Electromagnetism = Quick Coil Collapse

Rectifier

Brake

Motor

Input

Power

SEW-EURODRIVEDriving the world

Product Training

10

Brake Operation

Step 1 Rectifier

Brake

Motor

Input

Power

Step 2 120ms

SEW-EURODRIVEDriving the world

Product Training

11

Brake Operation

Starting

1. The rectifier energizes the brake coil.

2. The brake coil attracts the stationary disc, removing pressure

between stationary disc and brake disc.

3. Motor rotates freely.

Stopping

1. Rectifier de-energizes the coil.

2. Brake springs create pressure between stationary disc and

brake disc.

3. Friction stops motor and prevents it from rotating.

SEW-EURODRIVEDriving the world

Product Training

12

Brake Components

Brake Disc (rotates) Air Gap

Spring

Brake End Shield Brake Coil

Brake Carrier

(rotates)

Coil Body

Brake Rotor Shaft

(rotates)

Stationary Disc Dampening Plate

(moves) (BMG only)

SEW-EURODRIVEDriving the world

Product Training

13

Brake Components

Disc

Disc

Coil

Spring

Coil

Spring

SEW-EURODRIVEDriving the world

Product Training

14

Brake Components

Rectifiers and relays that mount in Motor Conduit Box

SEW-EURODRIVEDriving the world

Product Training

15

Brake Components

Rectifiers that mount in Control Panel

SEW-EURODRIVEDriving the world

Product Training

16

Brake Components

Typical wiring diagram

SEW-EURODRIVEDriving the world

Product Training

17

Troubleshooting

Troubleshooting an SEW

brake

SEW-EURODRIVEDriving the world

Product Training

18

Troubleshooting

Always follow the proper

lockout/tagout procedures.

Use the proper safety

equipment at all times

SEW-EURODRIVEDriving the world

Product Training

19

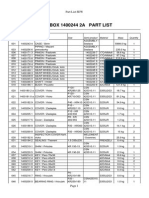

Troubleshooting

Resources needed

- Nameplate data from motor

- Brakemotor operating instructions

- Motor/Brakemotor parts list

- Digital multi-meter

SEW-EURODRIVEDriving the world

Product Training

20

Troubleshooting

Possible Faults

- Rectifier is damaged.

- Rectifier is wired incorrectly.

- AC brake voltage is incorrect or not applied.

- Brake coil is damaged or malfunctioning.

- Brake is mechanically locked.

- Air gap is outside of tolerance.

- Brake disc is worn or damaged. FAULT

...

SEW-EURODRIVEDriving the world

Product Training

21

Troubleshooting

Brake rectifier is damaged

- Incorrect voltage or wiring of the rectifier causes internal or

external damage

Rectifier received

incorrect voltage

Components are

damaged

SEW-EURODRIVEDriving the world

Product Training

22

Troubleshooting

Rectifier is wired incorrectly.

- Refer to nameplate for correct type of

connection (Conn Dia)

- Refer to the operating instructions for wiring

diagrams

SEW-EURODRIVEDriving the world

Product Training

23

Troubleshooting

AC brake voltage is incorrect or not applied

- Refer to nameplate for correct brake voltage

460 AC

AC Voltage that should be

applied to the brake rectifier

SEW-EURODRIVEDriving the world

Product Training

24

Troubleshooting

Check voltage at brake contactor

- If rectifier power does not come from motor terminals, measure

the voltage at the brake contactor

Check the activation of the brake contactor

- Verify that the brake contactor functions properly and changes

position when energized

SEW-EURODRIVEDriving the world

Product Training

25

Troubleshooting

Brake coil is damaged or malfunctioning

- Wrong voltage applied to brake coil causes internal and

external damage

Coil received

wrong voltage

SEW-EURODRIVEDriving the world

Product Training

26

Troubleshooting

Look up the correct values in the SEW

Obtain normal coil resistances Brakemotor Operating Instructions.

SEW-EURODRIVEDriving the world

Product Training

27

Troubleshooting

Measure the actual resistances of accelerator coil and

fractional coil

14-white w/

blue stripe

13-14 (accelerator coil)

15-blue 14-15 (fractional coil)

13-15 (total coil)

13-red

Accelerator coil winding resistance = of winding resistance

Fractional coil winding resistance = of winding resistance

Total coil winding resistance = sum of accelerator and holding coil resistance

SEW-EURODRIVEDriving the world

Product Training

28

Troubleshooting

Brake is mechanically locked

- Verify the free play on the release

arm. Loosen the locking nuts as

needed to achieve 1.5 2.0 mm

gap. (S Dimension)

Caution!

There must always be clearance

on the lever.

Note: The brake release

mechanism is not used to change

the brakes torque setting.

SEW-EURODRIVEDriving the world

Product Training

29

Troubleshooting

Air gap is outside of tolerance

- Insufficient air gap between the dampening plate (BMG brakes)

and the brake coil. (For BM brakes, there is no dampening

plate, so air gap lies between stationary disc and brake coil).

Air-gap

SEW-EURODRIVEDriving the world

Product Training

30

Troubleshooting

Obtain correct value for air gap.

Look up the correct values in the SEW Brakemotor Operating Instructions.

SEW-EURODRIVEDriving the world

Product Training

31

Troubleshooting

Adjust the Brake Air Gap (Method 1)

1. Insert feeler gauge between

dampening plate and coil

(BMG) or between stationary

plate and coil (BM).

2. Tighten (3) hex nuts until there

is minimal air gap (clearance)

equally around the disc

Attention:

When using a feeler gauge

on a BMG brake, measure

from a dimple on the

dampening plate!

SEW-EURODRIVEDriving the world

Product Training

32

Troubleshooting

Adjust the Brake Air Gap (Alternate Method 2)

1. Tighten the three adjustment nuts equally to establish zero air gap.

2. Loosen the adjustment nuts according to the figures below.

Degree of Approximate Rotation

Brake Size Rotation Amount

BM(G)05, BM(G)1 160 7/16 Turn

BM(G)2, BM4 135 3/8 Turn

BM(G)8 180 1/2 Turn

BM15, BM30, BM31 145 2/5 Turn

BM32, BM62 135 3/8 Turn

BMG61, BMG122 145 2/5 Turn

Note: Chart is based on the middle air gap tolerance.

However, all SEW brakes fall within the air gap tolerance

range if the degree of rotation is turn.

SEW-EURODRIVEDriving the world

Product Training

33

Troubleshooting

Brake disc is worn or damaged

- Sliding friction causes carbon-based brake disc to wear

- High cycle rates require more frequent disc replacement

Carbon

- Overheating can cause stationary disc to warp composite

material

SEW-EURODRIVEDriving the world

Product Training

34

Troubleshooting

Check thickness of brake disc

1. Measure the brake disc with

calipers to determine the actual

disc thickness.

2. If the disc is below tolerance,

replace it.

3. If the disc is acceptable, reinstall it

according to the parts list and

operating instructions.

SEW-EURODRIVEDriving the world

Product Training

35

Review

What are the components of an SEW brake?

SHOW ME

How does an SEW brake function?

SHOW ME

What possible faults could occur when an SEW

brake does not operate properly?

SHOW ME

SEW-EURODRIVEDriving the world

Product Training

36

Brake Operation

Starting

1. The rectifier energizes the brake coil.

2. The brake coil attracts the stationary disc, removing pressure

between stationary disc and brake disc.

3. Motor rotates freely.

Stopping

1. Rectifier de-energizes the coil.

2. Brake springs create pressure between stationary disc and

brake disc.

3. Friction stops motor and prevents it from rotating.

SEW-EURODRIVEDriving the world

Product Training

37

Review

What are the components of an SEW brake?

SHOW ME

How does an SEW brake function?

SHOW ME

What possible faults could occur when an SEW

brake does not operate properly?

SHOW ME

SEW-EURODRIVEDriving the world

Product Training

38

Brake Components

Brake Disc (rotates) Air Gap

Spring

Brake End Shield Brake Coil

Brake Carrier

(rotates)

Coil Body

Brake Rotor Shaft

(rotates)

Stationary Disc Dampening Plate

(moves) (BMG only)

SEW-EURODRIVEDriving the world

Product Training

39

Review

What are the components of an SEW brake?

SHOW ME

How does an SEW brake function?

SHOW ME

What possible faults could occur when an SEW

brake does not operate properly?

SHOW ME

SEW-EURODRIVEDriving the world

Product Training

40

Troubleshooting

Possible Faults

- Rectifier is damaged.

- Rectifier is wired incorrectly.

- AC brake voltage is incorrect or not applied.

- Brake coil is damaged or malfunctioning.

- Brake is mechanically locked.

- Air gap is outside of tolerance.

- Brake disc is worn or damaged.

SEW-EURODRIVEDriving the world

You might also like

- Master Validation Plan PDFDocument26 pagesMaster Validation Plan PDFIlayaraja Boopathy100% (4)

- Master Validation Plan PDFDocument26 pagesMaster Validation Plan PDFIlayaraja Boopathy100% (4)

- CompTIA A+ Cheat SheetDocument17 pagesCompTIA A+ Cheat Sheetsharaf jaber92% (12)

- His Personal AssistantDocument338 pagesHis Personal Assistantmanna_aiya100% (8)

- Dinamove VerlindeDocument9 pagesDinamove Verlindehubert patiño monroy100% (1)

- CMXC007 Upgrade Kit ManualDocument97 pagesCMXC007 Upgrade Kit ManualJESUSCALVILLONo ratings yet

- Demag 20 DH20 HoistDocument4 pagesDemag 20 DH20 HoistnikkoNo ratings yet

- Ainf280x - en Manual Acs880 InglesDocument596 pagesAinf280x - en Manual Acs880 InglesLucasSantos100% (1)

- BOSCH Preferred Products CatalogDocument33 pagesBOSCH Preferred Products CatalogJamin SmtpngNo ratings yet

- Ansaldo Drive 15-30kWDocument4 pagesAnsaldo Drive 15-30kWMr.K ch50% (2)

- Service and Maintenance. SEW-EURODRIVE Driving The WorldDocument40 pagesService and Maintenance. SEW-EURODRIVE Driving The Worldraduro100% (1)

- Ion Energy BMS WiringDocument11 pagesIon Energy BMS WiringIlayaraja BoopathyNo ratings yet

- Revalidation SOPDocument12 pagesRevalidation SOPIlayaraja Boopathy100% (2)

- Geared MotorsDocument477 pagesGeared MotorsmacNo ratings yet

- IGBT EquivalenteDocument49 pagesIGBT EquivalenteJOPONTESLIMANo ratings yet

- Technical Guide: Revision 2005Document43 pagesTechnical Guide: Revision 2005Dan VekasiNo ratings yet

- Catalog AEG-Lafert Motors - enDocument112 pagesCatalog AEG-Lafert Motors - enRudianto0% (1)

- TMV Dyna400 - CXT Applications Training BinderDocument22 pagesTMV Dyna400 - CXT Applications Training BinderDante WilliamsNo ratings yet

- Diagran Masterdrive 500 KWDocument30 pagesDiagran Masterdrive 500 KWemiljanlazeNo ratings yet

- Mitsubishi FR F700Document52 pagesMitsubishi FR F700chuhopNo ratings yet

- Abb Acs800 02 ManualDocument156 pagesAbb Acs800 02 Manualjosega123No ratings yet

- SKF Motor Encoder UnitsDocument2 pagesSKF Motor Encoder UnitsHector MaldonadoNo ratings yet

- XT Series PRO3V120 Service ManualDocument106 pagesXT Series PRO3V120 Service ManualErc Nunez V100% (2)

- Servo: Application ManualDocument150 pagesServo: Application Manualfrancisco pizarroNo ratings yet

- Hardware Manual ACS800-07 Drives (500 To 2800 KW)Document193 pagesHardware Manual ACS800-07 Drives (500 To 2800 KW)Bhanu Prakash100% (1)

- Teknic MCPV Manual Frame 56Document209 pagesTeknic MCPV Manual Frame 56jnbxyzNo ratings yet

- Service Instruction For Using Thermal CompoundDocument4 pagesService Instruction For Using Thermal CompoundSebastianCicognaNo ratings yet

- Part List SEWDocument3 pagesPart List SEWjosechr6No ratings yet

- Ad Man Afe HW SW en 8000001213 CDocument208 pagesAd Man Afe HW SW en 8000001213 CMohamed AlkharashyNo ratings yet

- ACS880-01 Democase: User's ManualDocument16 pagesACS880-01 Democase: User's ManualVoicu MarinNo ratings yet

- Operating Manual: Planetary Gearbox EP - 45Document51 pagesOperating Manual: Planetary Gearbox EP - 45Ravi RamdeoNo ratings yet

- En MultiBlockProgApplFW CDocument274 pagesEn MultiBlockProgApplFW Cnhocp123No ratings yet

- M3628PCF Portable Capacitor FormerDocument2 pagesM3628PCF Portable Capacitor FormerfghjfghjNo ratings yet

- P 05Document38 pagesP 05reza515hei0% (1)

- PSR Cycloconverter: Active Classic Limited ObsoleteDocument2 pagesPSR Cycloconverter: Active Classic Limited Obsoletearh ,No ratings yet

- ACS800 Multidrive 6-And 12 - Pulse OperationDocument3 pagesACS800 Multidrive 6-And 12 - Pulse OperationPuneet JoshiNo ratings yet

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Document90 pagesDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNo ratings yet

- Technical Manual HPU4S 15146Document46 pagesTechnical Manual HPU4S 15146Fadi Muhamed100% (1)

- Programa de Mantenimiento Preventivo ACS880Document2 pagesPrograma de Mantenimiento Preventivo ACS880JaimeNo ratings yet

- Linear ScaleDocument19 pagesLinear ScaleHà ChínhNo ratings yet

- 4e HydraulischePressenDocument28 pages4e HydraulischePressenTirtheshwar Singh100% (1)

- Abus Electric Wire Rope HoistsDocument23 pagesAbus Electric Wire Rope HoistsChristian Andrés Cortés SuárezNo ratings yet

- ABB ACS800 MultiDrive SafetyDocument12 pagesABB ACS800 MultiDrive SafetyLeonardo SpártacoNo ratings yet

- Kollmorgen KBM Series 2011 CatalogDocument80 pagesKollmorgen KBM Series 2011 CatalogElectromateNo ratings yet

- Tm4 Sumo HD: Motor / Inverter SystemDocument2 pagesTm4 Sumo HD: Motor / Inverter SystemFire Library0% (1)

- 1.ACS800 Structure1Document9 pages1.ACS800 Structure1Andi Dwi Andre OktavianNo ratings yet

- AC80 - ACS600's Presentation - 1998Document19 pagesAC80 - ACS600's Presentation - 1998edgardomichlig100% (1)

- Vc1100e PDFDocument102 pagesVc1100e PDFOscar Pérez NotarioNo ratings yet

- ACS880 ManualDocument632 pagesACS880 ManualpavankeeralaNo ratings yet

- Maintenance Instruction 2Document18 pagesMaintenance Instruction 2Purwanto ritzaNo ratings yet

- Sew EncoderDocument24 pagesSew EncodersanatikalaNo ratings yet

- G7 Gearmotor For HoistDocument16 pagesG7 Gearmotor For Hoistnaren1202No ratings yet

- Vib ScannerDocument76 pagesVib ScannerJunior BalabarcaNo ratings yet

- Abb MotorDocument38 pagesAbb MotorsanjayNo ratings yet

- Troubleshooting Manual: ACS 2000 AD Medium Voltage DrivesDocument72 pagesTroubleshooting Manual: ACS 2000 AD Medium Voltage DrivesAlexandrNo ratings yet

- SEW Eurodrive MOVITRAC LT InvertersDocument2 pagesSEW Eurodrive MOVITRAC LT InverterscealrofaNo ratings yet

- NTNISA Win2000 ReadMe PDFDocument98 pagesNTNISA Win2000 ReadMe PDFAhmed Moustafa100% (1)

- Motor IspDocument136 pagesMotor IspKnjigescribd100% (1)

- Abb Acs5000Document18 pagesAbb Acs5000amk2009No ratings yet

- 3 Afe 68392519Document40 pages3 Afe 68392519ABDUL GHAFOORNo ratings yet

- 10 tm21-m tm126b 201309 dn-3zw214-bDocument60 pages10 tm21-m tm126b 201309 dn-3zw214-bkosmitoNo ratings yet

- 5SYA2034-02 June 07 Gate Drive Recommendations For PCTDocument12 pages5SYA2034-02 June 07 Gate Drive Recommendations For PCTKanhaiya NavaleNo ratings yet

- ABB Broschure Power Semiconductors 2019 72dpi PDFDocument64 pagesABB Broschure Power Semiconductors 2019 72dpi PDFMarcos FaleiroNo ratings yet

- Brake Service and Maintenance PDFDocument40 pagesBrake Service and Maintenance PDFJose MarcanoNo ratings yet

- Final SEW Hollogram Brake Notes PDFDocument131 pagesFinal SEW Hollogram Brake Notes PDFVictorNo ratings yet

- General Instructions and Conditions For RO Cleaning PDFDocument1 pageGeneral Instructions and Conditions For RO Cleaning PDFIlayaraja BoopathyNo ratings yet

- Tomasetto MultivalveDocument44 pagesTomasetto MultivalveIlayaraja Boopathy100% (1)

- Tomasetto Multivalve Full Manual PDFDocument44 pagesTomasetto Multivalve Full Manual PDFIlayaraja Boopathy100% (1)

- 2133 Separate Horn Speakers & Driver Units Brochure Brochure PDFDocument8 pages2133 Separate Horn Speakers & Driver Units Brochure Brochure PDFIlayaraja BoopathyNo ratings yet

- BTG20Document2 pagesBTG20Ilayaraja BoopathyNo ratings yet

- STARS Drive System - EV Display DS9532-48Document1 pageSTARS Drive System - EV Display DS9532-48Ilayaraja BoopathyNo ratings yet

- Rivet AnalysisDocument79 pagesRivet AnalysisIlayaraja BoopathyNo ratings yet

- Profile: Sttar Engineering ServicesDocument4 pagesProfile: Sttar Engineering ServicesIlayaraja BoopathyNo ratings yet

- Iso 11607Document18 pagesIso 11607Ilayaraja BoopathyNo ratings yet

- Consultancy Project DetailsDocument516 pagesConsultancy Project DetailsIlayaraja BoopathyNo ratings yet

- Needle SiliconizatonDocument5 pagesNeedle SiliconizatonIlayaraja BoopathyNo ratings yet

- Relevant ISO StandardsDocument19 pagesRelevant ISO StandardsIlayaraja BoopathyNo ratings yet

- TocDocument7 pagesTocIlayaraja Boopathy0% (1)

- Extrusion ValidationDocument5 pagesExtrusion ValidationIlayaraja BoopathyNo ratings yet

- 4 Alison StewartDocument16 pages4 Alison StewartIlayaraja BoopathyNo ratings yet

- AHU Val ProtocolDocument53 pagesAHU Val ProtocolPalani Arumugam100% (1)

- Nasense SitemasterplanDocument34 pagesNasense Sitemasterplanvineet guptaNo ratings yet

- 4.cleanroom Qualification (Mark)Document14 pages4.cleanroom Qualification (Mark)mci_rathod100% (1)

- Application of Non-PVC Film in Sodium Bicarbonate InjectionDocument3 pagesApplication of Non-PVC Film in Sodium Bicarbonate InjectionIlayaraja BoopathyNo ratings yet

- Product Catalog v2010Document36 pagesProduct Catalog v2010Ilayaraja BoopathyNo ratings yet

- PATIENT CASE HPI J.O. Is A 5 Yo Girl Who Is Brought To The PediatricDocument5 pagesPATIENT CASE HPI J.O. Is A 5 Yo Girl Who Is Brought To The PediatricKyla ValenciaNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- US Botanical Gardens Greenhouse Manual PDFDocument76 pagesUS Botanical Gardens Greenhouse Manual PDFLinda Mirelez-Huca100% (1)

- Fabrication of Hydraulic Scissor Lift: February 2020Document10 pagesFabrication of Hydraulic Scissor Lift: February 2020atashi baran mohantyNo ratings yet

- G.O.Ms - No.62 - Incentives To State Training InstitutionsDocument2 pagesG.O.Ms - No.62 - Incentives To State Training InstitutionsMahendar ErramNo ratings yet

- Angle Modulation (Part 2)Document7 pagesAngle Modulation (Part 2)Ryan Anthony AndalNo ratings yet

- MobiVi VietnamDocument10 pagesMobiVi VietnamMiguel Angel GarciaNo ratings yet

- N ButaneDocument1 pageN ButaneLenis SalcedoNo ratings yet

- Forms+Surfaces Architectural SurfacesDocument128 pagesForms+Surfaces Architectural SurfacesMarija MilosavljevicNo ratings yet

- Call Deposit Receipt Meezan BankDocument22 pagesCall Deposit Receipt Meezan BankNabeel KhanNo ratings yet

- Lab ManualDocument148 pagesLab ManualGabriela AldunateNo ratings yet

- Validity and Reliability of A Novel Wearable Sensor System For Documenting Clinical Outcome Measure of The Knee in Healthy Individuals - A Piolet StudyDocument5 pagesValidity and Reliability of A Novel Wearable Sensor System For Documenting Clinical Outcome Measure of The Knee in Healthy Individuals - A Piolet StudyInternational Journal of Innovative Science and Research Technology100% (1)

- Tally - ERP 9: Major Features of - Power of SimplicityDocument8 pagesTally - ERP 9: Major Features of - Power of SimplicityfawwazNo ratings yet

- Pandora File RecoveryDocument3 pagesPandora File Recoveryzansue abutamNo ratings yet

- Space Suit ComponentsDocument21 pagesSpace Suit ComponentsanatomykofiNo ratings yet

- Ve Project DebutDocument8 pagesVe Project DebutpkmwNo ratings yet

- Small Scale Industries in IndiaDocument12 pagesSmall Scale Industries in IndiaSangram AsabeNo ratings yet

- Trade Test Prep PlumbingDocument2 pagesTrade Test Prep PlumbingChikondi KanamaNo ratings yet

- Comparison of Operating Systems Tinyos and Contiki: Tobias ReusingDocument7 pagesComparison of Operating Systems Tinyos and Contiki: Tobias ReusingGan MichiNo ratings yet

- Composers: Life and Works Music Grade 9 - Quarter 1 /week 2 Lesson 2Document20 pagesComposers: Life and Works Music Grade 9 - Quarter 1 /week 2 Lesson 2Michael Gutierrez dela PenaNo ratings yet

- Soa Interview1Document18 pagesSoa Interview1anilandhraNo ratings yet

- High Voltage Lab: Experiment No. 2 TITLE: Study of The Characteristics of Impulse VoltageDocument12 pagesHigh Voltage Lab: Experiment No. 2 TITLE: Study of The Characteristics of Impulse VoltageTanmoy Saha100% (1)

- Norwegian Road Tunnel 3Document87 pagesNorwegian Road Tunnel 3hungNo ratings yet

- Rotary Joint User Manual - (E)Document20 pagesRotary Joint User Manual - (E)Nguyễn Văn ĐộNo ratings yet

- Jurassic World DominionDocument18 pagesJurassic World Dominionmimahin116004No ratings yet

- DBR Winning ApproachDocument9 pagesDBR Winning ApproachDiego Andrés Triana RodríguezNo ratings yet

- Reviewer AccountingDocument58 pagesReviewer AccountingNevan NovaNo ratings yet

- TEMS Pocket 7.3.2 For Sony Ericsson W995 and W995a - User's ManualDocument226 pagesTEMS Pocket 7.3.2 For Sony Ericsson W995 and W995a - User's ManualpavlodeNo ratings yet