Professional Documents

Culture Documents

Analysis PDF

Analysis PDF

Uploaded by

rhp1989Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis PDF

Analysis PDF

Uploaded by

rhp1989Copyright:

Available Formats

Atmospheric and Low Pressure Tank Venting Spreadsheet

(based on API Standard 2000)

PROJECT TITLE : RELOCATION OF T-25000A TRANSFER / BOOSTER PUMPS AT IZOMBE FLOW STATION

CALCULATION TITLE : Low Press Tank Venting Capacity SHEET NO : 1 of 1

Emergency Venting

Vessel type Vertical tank 2

Diameter mm 21234

T/T length if horizontal, or Wall height if vertical mm 13000

Elevation of base above grade mm 672

End (head) type, for horizontal vessel only flat 1 NOT relevant

If vertical tank elevated above grade, engineering

judgment to be used to estimate % of base exposed to

fire (refer to API Standard 2000) % 0

Design pressure barg 1.016

2

Awet (wetted surface area based on selected tank type) m 564.9

Q (heat input from fire exposure) W 7799972

F (environmental factor -obtain from API Standard 2000) 1

L (latent heat of vap of stored liquid at relieving P & T) kJ/kg 334.9

o

T (temp of relieving vapour - normally Tbp at relieving P) C 37.8

M.W g/mol 86.16

3

Emergency Venting Required For Fire Exposure Nm /h of air 39005

Normal and Thermal Venting

Maximum outflow of liquid from tank m3/h 99.4

3

Normal inbreathing required due to liquid outflow Nm /h 93

Maximum inflow of liquid to tank m3/h 33.12

Flash or boiling point criteria (if both available, use flash point) F.P>37.8 or B.P>148.9 degC 1

3

Normal outbreathing required due to liquid inflow Nm /h 33

3

Tank capacity m 3974.68

3

Thermal inbreathing (Note 2) Nm /h 643.6

3

Thermal inbreathing rate selected Nm /h 647

3

Thermal outbreathing (Note 2) Nm /h obtain from graph or table

3

Thermal outbreathing rate selected Nm /h 472

3

Total Normal Venting Capacity Required Nm /h of air 740 Based on inbreathing

Notes

1. This spreadsheet is based on API Standard 2000 and should be used in conjunction with it.

You might also like

- Inbreathing OutbreathingDocument17 pagesInbreathing OutbreathingInggit100% (3)

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- PIP Line ListDocument2 pagesPIP Line Listomgmatt100% (1)

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- The Good Ventilation of Switchgear and Transformer RoomsDocument8 pagesThe Good Ventilation of Switchgear and Transformer RoomsjayamenggalaNo ratings yet

- Airside Eurovent PresentationDocument38 pagesAirside Eurovent PresentationAmro Metwally El HendawyNo ratings yet

- Storage Vacuum CollapseDocument7 pagesStorage Vacuum CollapsebehnamhfNo ratings yet

- Brochure DaikinDocument16 pagesBrochure DaikinrocinguyNo ratings yet

- Cooling Tower: Instruction ManualDocument9 pagesCooling Tower: Instruction ManualAliyu AbdulqadirNo ratings yet

- Roof Top PDFDocument12 pagesRoof Top PDFEduardgabrielescuNo ratings yet

- Air On Coil TemperatureDocument8 pagesAir On Coil TemperatureMohamed RiyaazNo ratings yet

- Storage Vacuum Collapse PDFDocument7 pagesStorage Vacuum Collapse PDFKyriakos MichalakiNo ratings yet

- Dry Type TransformersDocument12 pagesDry Type Transformersraul_bsuNo ratings yet

- Application Note: Dimensioning Cabinet Airflow For Cooling Frequency ConvertersDocument5 pagesApplication Note: Dimensioning Cabinet Airflow For Cooling Frequency ConvertersOton SilvaNo ratings yet

- GE Cycles Lecture Info 2009Document18 pagesGE Cycles Lecture Info 2009Sayantan Datta Gupta100% (1)

- AHU Eurovent ISKID Part 1Document27 pagesAHU Eurovent ISKID Part 1Joaquim MonteiroNo ratings yet

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDocument8 pagesArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNo ratings yet

- Compressor 190cfm/ 7bars: Zone2 Rated DNV 2.7-1/EN12079Document1 pageCompressor 190cfm/ 7bars: Zone2 Rated DNV 2.7-1/EN12079Teknik MarinaNo ratings yet

- Insulation CalcDocument4 pagesInsulation Calcjacok22No ratings yet

- Questionnaire For Pyroprocessing ModificationDocument8 pagesQuestionnaire For Pyroprocessing ModificationVijay BhanNo ratings yet

- Fired Heater - 2013 FW TalkDocument38 pagesFired Heater - 2013 FW TalkSong Hoe100% (2)

- Design of Heat ExchangerDocument26 pagesDesign of Heat ExchangerSatish YadavNo ratings yet

- York Rooftops EngDocument14 pagesYork Rooftops EngBulclimaNo ratings yet

- Basic Refinery Equipment - Heat Exchanger (E003/1)Document27 pagesBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- Watlow Air HeatersDocument32 pagesWatlow Air HeatersEliasNo ratings yet

- 09 Plume Temperature Calculations Sup1 SiDocument4 pages09 Plume Temperature Calculations Sup1 Siuki12345100% (1)

- Airflow Duplex 15000 H RVDocument8 pagesAirflow Duplex 15000 H RVAnthony AmarraNo ratings yet

- Rahul Kumar B Electrical Dept. Abhijeet Projects LimitedDocument23 pagesRahul Kumar B Electrical Dept. Abhijeet Projects LimitedrahulengineerNo ratings yet

- Calculation Storage Tank1000 KL PDFDocument58 pagesCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- Heat Loss Calculations and Heater Selection Air and GasDocument7 pagesHeat Loss Calculations and Heater Selection Air and GastgimranNo ratings yet

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- Pressure Safety Valves: Selection, Sizing & DesignDocument19 pagesPressure Safety Valves: Selection, Sizing & DesignAbdulAbdulNo ratings yet

- Coolling System CalculusDocument33 pagesCoolling System CalculusȘtefan PravățNo ratings yet

- The Good Ventilation of Switchgear and Transformer RoomsDocument7 pagesThe Good Ventilation of Switchgear and Transformer RoomsJosé SánchezNo ratings yet

- Pin Fin Apparatus EditedDocument10 pagesPin Fin Apparatus EditedS S S REDDYNo ratings yet

- Datasheet of Equipment - ANNAMDocument8 pagesDatasheet of Equipment - ANNAMhuyly34No ratings yet

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- The Good Ventilation of Switchgear and Transformer RoomsDocument7 pagesThe Good Ventilation of Switchgear and Transformer RoomsJosé SánchezNo ratings yet

- Finned Tube Heat Exchangers Type WRW and WRW-WDocument8 pagesFinned Tube Heat Exchangers Type WRW and WRW-WBOREBGKNo ratings yet

- 02.2 Temperature FVDocument16 pages02.2 Temperature FVjovanivanNo ratings yet

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- Project Standards and Specifications Design of Furnace Systems Rev01Document10 pagesProject Standards and Specifications Design of Furnace Systems Rev01Jay LawsonNo ratings yet

- ROBERTSON - Swift Ventilator: Smoke & Heat Ventilation - Design Calculations Project:-Steel Fabrication 25/6/14Document1 pageROBERTSON - Swift Ventilator: Smoke & Heat Ventilation - Design Calculations Project:-Steel Fabrication 25/6/14razahNo ratings yet

- Flat Plate Solar Collector Performance PDFDocument60 pagesFlat Plate Solar Collector Performance PDFMaduike Ifeanyichukwu SampsonNo ratings yet

- Cooling Towers ProjectDocument25 pagesCooling Towers ProjectSuhail A MansooriNo ratings yet

- Kidon: Air Handling Unit Data SheetDocument3 pagesKidon: Air Handling Unit Data SheetMihaela CimpeanuNo ratings yet

- ME 4226 Heat Exchanger Compiled WconclusionDocument26 pagesME 4226 Heat Exchanger Compiled Wconclusionhamish888No ratings yet

- ROBERTSON - Swift Ventilator: Smoke & Heat Ventilation - Design Calculations Project:-Sheet Metal 25/6/14Document1 pageROBERTSON - Swift Ventilator: Smoke & Heat Ventilation - Design Calculations Project:-Sheet Metal 25/6/14razahNo ratings yet

- Cubic Unit Cooler: SKB Semi-Industrial RangeDocument8 pagesCubic Unit Cooler: SKB Semi-Industrial RangeMohammad AmerNo ratings yet

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- Performance Evaluation of A V-Groove Solar Air Collector For Drying ApplicationsDocument10 pagesPerformance Evaluation of A V-Groove Solar Air Collector For Drying ApplicationsRamasamikannan RamasamikannanNo ratings yet

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- 21Document101 pages21Udaivir YadavNo ratings yet

- B 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterDocument7 pagesB 84567 SB Mm1 DSR ST 60 0021 1 Aoc GTG Fuel Gas HeaterpragatheeskNo ratings yet

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- A200 Amine System English A4 PDFDocument4 pagesA200 Amine System English A4 PDFMuhammad ZubairNo ratings yet

- LPG Bullets Safety RefineryDocument12 pagesLPG Bullets Safety Refinerysatnam1979100% (1)

- Name: M.Araiz Rafi Roll# Bees/S13/0218Document1 pageName: M.Araiz Rafi Roll# Bees/S13/0218Muhammad ZubairNo ratings yet

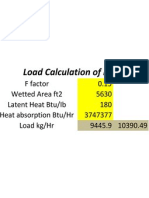

- Load Cal PSVDocument1 pageLoad Cal PSVMuhammad ZubairNo ratings yet