Professional Documents

Culture Documents

SSP Pet PD PDF

Uploaded by

何恭彥Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSP Pet PD PDF

Uploaded by

何恭彥Copyright:

Available Formats

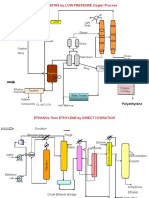

Process description – Thermal

Processes.

solid state polycondensation

(SSP) technology for PET.

Raw Material

crystallization Annealed PET

10mW

5mW

melting

glass transition

°C °C

50 100 150 200 250 300 50 100 150 200 250 300

Reactor

Crystallizer N2

Air/N2

5mW

5mW

°C °C

50 100 150 200 250 300 50 100 150 200 250 300

Annealer

N2

Cooler

Air

Final material

Before the raw material can be thermally processed, it must be crystallized and annealed, which allows the

necessary polymer molecular structure to form during thermal treatment in the reactor. However the main purpose

of SSP processing is to increase the intrinsic viscosity of the polymer to the desired level, and there are a number

of concomitant factors and reactions during this process. Some of the important factors include the content of

byproducts (acetaldehyde, oligomers, ethylene glycol), molecular structure (gel, uniformity of crystalline structure)

and the physical characteristics of the product (color L*, a*, b*, dust content, melt temperature, sintering of the

product, etc.). More than 30 years of know-how enabled Buhler to develop all the steps of PET processing while

taking advantage of the natural physical laws of material behavior.

Bühler AG

CH-9240 Uzwil, Switzerland

T +41 71 955 11 11

F +41 71 955 34 40

thermal.processes@buhlergroup.com

www.buhlergroup.com

You might also like

- Polyethylene Terephthalate (Pet) : HistoryDocument3 pagesPolyethylene Terephthalate (Pet) : HistoryMaleha SalimNo ratings yet

- Polyethylene Terephthalate PDFDocument18 pagesPolyethylene Terephthalate PDFJuan VargasNo ratings yet

- Hot Melt Adhesives - 2Document8 pagesHot Melt Adhesives - 2QUALITY CONTROL100% (1)

- Reactive Distillation Design and ControlFrom EverandReactive Distillation Design and ControlRating: 1 out of 5 stars1/5 (1)

- China Polyether Polyols Weekly Report (20130408-20130412)Document5 pagesChina Polyether Polyols Weekly Report (20130408-20130412)renagoncNo ratings yet

- BOTTLE PRODUCTION COST ANALYSIS FOR GLASS, PET & PPDocument6 pagesBOTTLE PRODUCTION COST ANALYSIS FOR GLASS, PET & PPaj iseNo ratings yet

- Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630ADocument2 pagesEneral-Purpose Injection Moulding Grade: POKETONE Polymer M630AmacNo ratings yet

- Ethylene Glycol versus Propylene Glycol Heat Transfer PropertiesDocument5 pagesEthylene Glycol versus Propylene Glycol Heat Transfer PropertiesPråveen SågittåŕiúśNo ratings yet

- EU: Polyethylene Terephthalate (In Primary Forms) - Market Report. Analysis and Forecast To 2020Document9 pagesEU: Polyethylene Terephthalate (In Primary Forms) - Market Report. Analysis and Forecast To 2020IndexBox MarketingNo ratings yet

- Molecular Weight Determination Using ViscometryDocument12 pagesMolecular Weight Determination Using ViscometryMahmoud HendawyNo ratings yet

- Macro PolymerDocument30 pagesMacro PolymerAman Sinha100% (1)

- Dimethyl TerephthalateDocument9 pagesDimethyl Terephthalatehung_metalNo ratings yet

- Alkyd GBDocument2 pagesAlkyd GBAhmad HamoudaNo ratings yet

- Calsol Process OilsDocument5 pagesCalsol Process OilsBen Karthiben NathanNo ratings yet

- Compressor Selection: Semi-Hermetic Reciprocating CompressorsDocument2 pagesCompressor Selection: Semi-Hermetic Reciprocating CompressorsMohammed ElhakeemNo ratings yet

- Reactol 1717 EDocument1 pageReactol 1717 EbuninaNo ratings yet

- DuPont Technology NG3 ProcessDocument1 pageDuPont Technology NG3 Processpradip_kothekarNo ratings yet

- Flow Chart Continous Polymerization and Direct Melt SpinningDocument2 pagesFlow Chart Continous Polymerization and Direct Melt Spinningrajeshdubey7100% (1)

- International Project References: Thyssenkrupp Industrial Solutions (India)Document8 pagesInternational Project References: Thyssenkrupp Industrial Solutions (India)Divyesh PatelNo ratings yet

- Operations & Maintenance Manual: ... Innovative Liquid Vaporizing and Gas Mixing SolutionsDocument64 pagesOperations & Maintenance Manual: ... Innovative Liquid Vaporizing and Gas Mixing SolutionsKALATUSNo ratings yet

- HTM Section (Area Code 3008)Document7 pagesHTM Section (Area Code 3008)Hamza RiazNo ratings yet

- Polyethylene Recycle ProessesDocument63 pagesPolyethylene Recycle Proessesهشام حدودNo ratings yet

- Acrylic Polymers: Versatile Water-Based Polymers for Paints, Coatings & MoreDocument8 pagesAcrylic Polymers: Versatile Water-Based Polymers for Paints, Coatings & MoreShivani UpadhyayNo ratings yet

- Polyethylene Terephthalate Plant CostDocument2 pagesPolyethylene Terephthalate Plant CostIntratec SolutionsNo ratings yet

- Flexible Low - Cost SSP TechnologyDocument17 pagesFlexible Low - Cost SSP TechnologyQuadrant727No ratings yet

- Sachit Liquid Glucose Bsi FinalDocument50 pagesSachit Liquid Glucose Bsi FinalSachit GambhirNo ratings yet

- POLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends DiluentDocument3 pagesPOLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends Diluentessakkiraj.mNo ratings yet

- Calculation of Pulverizer Minimum Primary Airflow and Proper Air To Fuel RelationshipDocument2 pagesCalculation of Pulverizer Minimum Primary Airflow and Proper Air To Fuel Relationshipank_mehraNo ratings yet

- mô tả chungDocument34 pagesmô tả chungTuấn Anh NguyễnNo ratings yet

- Ys-W01 Pet Chips Bottle Grade Water HainanDocument1 pageYs-W01 Pet Chips Bottle Grade Water HainanPhirate Dorind100% (1)

- MDI Plant CostDocument2 pagesMDI Plant CostIntratec SolutionsNo ratings yet

- Enzymes at WorkDocument76 pagesEnzymes at WorkLukas Cardeño CalleNo ratings yet

- Polypropylene PP PlasticDocument8 pagesPolypropylene PP PlasticRyan VasquezNo ratings yet

- Evaporation Rate of Solvents PDFDocument2 pagesEvaporation Rate of Solvents PDFsyamlokNo ratings yet

- Paper Cup Making MachineDocument4 pagesPaper Cup Making Machinesmail brihmatNo ratings yet

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Document12 pagesManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanNo ratings yet

- An Example: These Guidelines Applied To The Safe Automation of A Batch Polymerization ReactorDocument15 pagesAn Example: These Guidelines Applied To The Safe Automation of A Batch Polymerization ReactorIamsNo ratings yet

- Method To Determine Wesson LossDocument1 pageMethod To Determine Wesson Lossmasud.imtiaz3290No ratings yet

- Asian Paints Limited Penta Division CuddaloreDocument63 pagesAsian Paints Limited Penta Division CuddaloreChaudhryNaveedAnwar100% (1)

- Ptfe PDFDocument12 pagesPtfe PDFseeralan_1986No ratings yet

- Utilization of Polyethylene Terephthalate (PET) in Asphalt Pavement - A Review PDFDocument8 pagesUtilization of Polyethylene Terephthalate (PET) in Asphalt Pavement - A Review PDFAniel DiasNo ratings yet

- OH Determination For Polyether PolyolDocument4 pagesOH Determination For Polyether PolyolHoang Cong ThanhNo ratings yet

- MTBEDocument34 pagesMTBEruben ordoñezNo ratings yet

- Production of Butyl RubberDocument1 pageProduction of Butyl RubberRaj Sunil KandregulaNo ratings yet

- Paint Industry - Lecture 3Document7 pagesPaint Industry - Lecture 3U SANKAR TEJONo ratings yet

- Polyethylene Properties - VinidexDocument8 pagesPolyethylene Properties - VinidexalexNo ratings yet

- Vinyl Toluene Modified Resins for CoatingsDocument25 pagesVinyl Toluene Modified Resins for CoatingsAmr Abdelmegid abdelsalam hussein0% (1)

- Synthetic Resins Technology HandbookDocument15 pagesSynthetic Resins Technology HandbookniteshacharyaNo ratings yet

- Proper storage and handling of spandex yarnDocument4 pagesProper storage and handling of spandex yarnKasra Golban100% (1)

- UntitledDocument12 pagesUntitledapi-256504985No ratings yet

- Melt Blown TechnologyDocument15 pagesMelt Blown TechnologyKalyan Ray Gupta100% (2)

- Utility Consumptions in TBA-19Document1 pageUtility Consumptions in TBA-19Irfan JaferiNo ratings yet

- Pre Feasibility Study For MIBK Plant - IndiaDocument35 pagesPre Feasibility Study For MIBK Plant - IndiaShiv KothariNo ratings yet

- Techno-Economic Modelling and Cost Functions of CO Capture ProcessesDocument11 pagesTechno-Economic Modelling and Cost Functions of CO Capture ProcessesAlex MarkNo ratings yet

- ISO 5807 - 1985 (ENG) - Diagrama de Flujo (R2019)Document29 pagesISO 5807 - 1985 (ENG) - Diagrama de Flujo (R2019)YANET ALCANTARANo ratings yet

- Investigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFDocument13 pagesInvestigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFCarlosNo ratings yet

- Extruder Times 1Document4 pagesExtruder Times 1skimmer05No ratings yet

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball ValvesBibhu Ranjan MohantyNo ratings yet

- Kavaata Ball Valves Seat Material Selection GuideDocument2 pagesKavaata Ball Valves Seat Material Selection GuideBibhu Ranjan MohantyNo ratings yet

- Dvanced Anufacturing EchnologyDocument42 pagesDvanced Anufacturing EchnologymaxNo ratings yet

- International Process Plants: SSP4 InformationDocument25 pagesInternational Process Plants: SSP4 Information何恭彥No ratings yet

- Hombright S-Id (WD)Document6 pagesHombright S-Id (WD)何恭彥No ratings yet

- Solid State Polymerization Its Action On Thermal and Rheological Properties of PETPC Reactive BlendsDocument7 pagesSolid State Polymerization Its Action On Thermal and Rheological Properties of PETPC Reactive Blends何恭彥No ratings yet

- Multi-stage Steam Jet Vacuum Systems Technical GuideDocument5 pagesMulti-stage Steam Jet Vacuum Systems Technical Guide何恭彥No ratings yet

- Basic Pump Manual Feb09Document52 pagesBasic Pump Manual Feb09Dean ArdianNo ratings yet

- Synthetic Fibres (Encyclopedia of Hydrocarbon) PDFDocument14 pagesSynthetic Fibres (Encyclopedia of Hydrocarbon) PDF何恭彥No ratings yet

- Chemical Engg Calculation & Shortcut DeskbookDocument146 pagesChemical Engg Calculation & Shortcut Deskbooknagarajkaran100% (1)

- KSB Selecting Centrifugal Pumps En, Property FileDocument92 pagesKSB Selecting Centrifugal Pumps En, Property Filevisitabhinav100% (7)

- Introduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsDocument22 pagesIntroduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsAnkush BhandariNo ratings yet

- LD 5 30Document26 pagesLD 5 30何恭彥No ratings yet

- Super-Precision Angular Contact Ball Bearings High-Speed E Design 10112 3 enDocument52 pagesSuper-Precision Angular Contact Ball Bearings High-Speed E Design 10112 3 en何恭彥No ratings yet

- Mixing in TankDocument5 pagesMixing in TankWan Ling LeeNo ratings yet

- Process CostingDocument46 pagesProcess CostingRasyikah FitriaNo ratings yet

- Manual Sierra Durma DCB-S 560Document101 pagesManual Sierra Durma DCB-S 560Dawitt BadilloNo ratings yet

- Simplified Cost Models For Pre Feasibility Mineral EvaluationsDocument42 pagesSimplified Cost Models For Pre Feasibility Mineral Evaluationschris.mwabaNo ratings yet

- Paint Companies in IndiaDocument7 pagesPaint Companies in IndiaAnup PaulNo ratings yet

- Altracs: A Superior Thread-Former For Light AlloysDocument8 pagesAltracs: A Superior Thread-Former For Light AlloysSquidwardNo ratings yet

- GSE EnVision UsersListDocument2 pagesGSE EnVision UsersListasamad54No ratings yet

- Technical SpecificationDocument63 pagesTechnical Specificationgopvij1No ratings yet

- Astm A108Document4 pagesAstm A108scriptd_ozd3n100% (3)

- Ral BrandingDocument26 pagesRal BrandingkhushiYNo ratings yet

- Wage or Compensation DifferentialsDocument28 pagesWage or Compensation DifferentialsdollyguptaNo ratings yet

- Technical Presentation - Mechanical SealsDocument54 pagesTechnical Presentation - Mechanical SealsAlen Koo100% (2)

- Retail Marketing Definition, Function and ImportanceDocument4 pagesRetail Marketing Definition, Function and ImportanceSon VertucioNo ratings yet

- Astm F2435-12Document8 pagesAstm F2435-12Mariana Avila100% (1)

- Construction of FLD's On CuZn37 (Brass) Using Single Point Incremental Forming TechniqueDocument8 pagesConstruction of FLD's On CuZn37 (Brass) Using Single Point Incremental Forming TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sand Lime BricksDocument2 pagesSand Lime Bricksmaguvu100% (1)

- Distortions of Press Quenched Crown Wheels: Benjamin Brash Master ThesisDocument55 pagesDistortions of Press Quenched Crown Wheels: Benjamin Brash Master Thesisdwimukh360No ratings yet

- Port of Tacoma: Directory of Third-Party Logistic Service ProvidersDocument4 pagesPort of Tacoma: Directory of Third-Party Logistic Service ProvidersPort of TacomaNo ratings yet

- Hercules CatDocument52 pagesHercules CatGan Chin PhangNo ratings yet

- Chapdur 091228Document4 pagesChapdur 091228priyanithiNo ratings yet

- Project Management BooksDocument12 pagesProject Management BooksTanja L Slavuljica100% (1)

- Manufacturer Type Model/Type Remarks Temp Rating (Oc) Pressure Mat of Con Oil Droplet Size Type of Oil Nominal Flow (L/H)Document5 pagesManufacturer Type Model/Type Remarks Temp Rating (Oc) Pressure Mat of Con Oil Droplet Size Type of Oil Nominal Flow (L/H)Fransisca ChevalierNo ratings yet

- 03 11 00 - Concrete Forming PDFDocument9 pages03 11 00 - Concrete Forming PDFmasoodaeNo ratings yet

- ISO 9001 Quality ManualDocument29 pagesISO 9001 Quality ManualJoni Barjono0% (1)

- Internal Lining of Pressure VesselsDocument21 pagesInternal Lining of Pressure VesselsPattabhi Ramaraju100% (2)

- A Comparative Analysis of Carbon Emissions From Online Retailing of Fast Moving Consumer GoodsDocument9 pagesA Comparative Analysis of Carbon Emissions From Online Retailing of Fast Moving Consumer GoodsdadanalhakNo ratings yet

- ADVISE ON WASHING/DRYING - Before Using The Garments!Document1 pageADVISE ON WASHING/DRYING - Before Using The Garments!arkcgemNo ratings yet

- Global Business Practice Assignment - Benetton Management ReportDocument30 pagesGlobal Business Practice Assignment - Benetton Management ReportAmany HamzaNo ratings yet

- MBA IInd SEM POM Chapter 12 Product Design, Manufacturing TechnologyDocument75 pagesMBA IInd SEM POM Chapter 12 Product Design, Manufacturing TechnologyPravie92% (12)

- 5.1 Dawn of Industrial RevolutionDocument28 pages5.1 Dawn of Industrial RevolutionMissDangNo ratings yet

- Abrasive SDocument3 pagesAbrasive SmurusaNo ratings yet