Professional Documents

Culture Documents

Soma Porteur Rack Instr DLX 2015

Uploaded by

johnnyrossasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soma Porteur Rack Instr DLX 2015

Uploaded by

johnnyrossasCopyright:

Available Formats

Soma Fabrications

Porteur Rack Instructions

Congratulations on your purchase of the Soma Porteur Rack. Our rack is designed with versatility in mind.

While no rack can fit every bike, we have designed a level of adjustability that will fit most 700c and 26” wheel

bicycles. Please read ALL the instructions before starting installation.

General Considerations:

The rack should sit as low as possible just above the

fender for best appearance and bike handling. If you

are attaching your rack to the fender, we recommend

the use of a leather washer between the fender and

rack mounting bolt. Note: Mounting the rack to fend-

er is optional and adds a level of complexity to the fit

process. The rack platform should be level or tilted a

couple of degrees back. It should not tilt forward. An-

gling it too far back may cause load to interfere with

cables or bars. Note: With so many styles and sizes fo

bikes out there, it is impossible for any rack (even a

rack with adjustability) to fit every bike.

FIGURE 1: Parts List

A)1- Rack Body

B) 4 - Stainless screw M5x 14mm (thread) (built-in

washer) with stainless Nylock nut

C) 1 - Stainless screw M5x 36mm (thread) with stain-

less nut and washer

D) 4- Stainless screw M5x 8mm (thread) with stainless

washer

E) 3 - Stainless screw M5 x 5mm (thread)

(H)

F) 2 - Stainless screw M5 x 10mm (thread) with stain-

less washer

(I) (C)

G) 2 - Stainless screw M6 x 12mm (thread) with stain-

(L)

(D) (E) less washer

(G) (F)

H)1 - L-Bend Rear Tang

I) 1 - Stepped Rear Tang

(K)

J) 2 - Axle mount plates

K) 2 - Mid fork stays w/plastic end cap

(J)

(B) L) 2 - Spacer and nut for mid fork stays

FIGURE 2:

Tools Needed:

- 4 and 5mm hex keys

- 7mm (or adjustable) open wrench

Determining Compatibility and Fit:

The fork must have a drilled crown and an axle and axle

to crown distance of 365 to 400mm. Some forks with

lugged dropouts may interfere with mounting, but there

are workarounds depending on the fork design. Some bi-

cycles with slack head angles or fork offsets above 50mm

may have difficulties mounting this rack.

Mounting the Rack:

Mounting the rack to Mini Rack

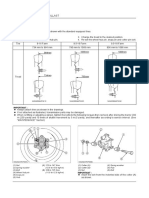

Mounting the Rack To The Hub Axle: Braze-Ons or Pannier rack eyelets

The axles plates have 4 holes to provide a small amount of Optional: The 2nd generation Porteur Rack has

height adjustment to your rack. After selecting the correct an additional mounting point on the mini rack

height of your set-up, tighten the axle plates to the inside braze-ons that some touring forks have (Fig. 4). Us-

of the lower rack tangs with slots facing rearward using the ing this mount is optional. The rack is safe to use

M5x14 screws with Nylock nuts(B). (Use 2 per side. It is not safe without it. But it does help make the rack stronger

to use just one bolt per side). (The M5x14 have built-in washers) and more stable.

Loosen your hub quick release (or hub axle nuts if you have a

track hub) and slide the rack on. Avoid resting the rack on the Follow the Fig. 3 for hardware order and orienta-

QR’s springs. Tighten the QR slightly. IF your fork has eyelets tion of the stay. Use the M5 x 10mm screws with

at the fork ends, it might be possible to mount the rack to those washer (F). in this step to attach mid fork stay to

eyelet instead. See “Mounting the Rack to Fork Eyelets” rack. Use the M5 x 8mm to attach the stay to the

fork. If fork uses M6, a pair of those bolts may be

Mounting the Rear Tang: included as well.

The next step is to attach the rear tang to the eyelets under-

neath the rack. Select the correct one to use. Mounting the Metal Fenders TO BOTTOM

OF RACK PLATFORM

The Stepped Tang (I) is bikes with a caliper brake equipped Mounting your rack to your fender is an optional

bike. The tang should mount in between the brake and the fork step, but can help to prevent the fender from rat-

crown using the brake mounting bolt. Some bending of the tling when going over rough roads.

tang may be needed to make it fit correctly. Decide how you will attach the fender struts. The

fork’s own dropout eyelets are ideal. Having the

The L-Bend tang(H) is for forks that have a drilled crown, but fenders already attached will make it easier to

perhaps use cantilever brakes. Again some bending of the tang mount them to the rack.

may be needed to make the rack fit optimally.

If your fork does not have eyelets, you can secure

Attach the tang to the fork with the included M5x36mm bolt, it with one of the bolts that attach the axle plate to

washer, and nut (C). If this bolt is not long enough for your par- the rack. If you choose that route, we recommend

ticular fork crown, you will need to source something on your a slightly longer machine screw, so there is ad-

own. If your fork is not drilled, but instead has a fender boss equate thread engagement. This also means you

under the fork, you would need to straighten the tang to make might have to mount the rack before you com-

it attach to the fender boss. pletely mount the fenders.

Then attach the tang to the rack using the M4x 5mm screws Loosely mount the rack to the axle so it is within

and washers (E). Three are included. For safety use at least 2. a few mm’s of the top of the fender. The fourth

threaded hole from the rear of the rack is ideal

FIGURE 4:

connection point for the fender, if the rear tang

doesn’t block it. Level the rack and see if that hole

lines up with the highest part of the fender. If so,

mark the position on the fender, so you can drill

a hole that lines up with the hole under the rack.

Mini-rack Remove the wheel and fender and drill the hole

braze- in the fender at the marked position. Re-install the

ons fender and place a leather washer (optional but

reduces rattling) between the fender and the rack.

Pannier Mount with M5 x 8 screw and washer. (the M5 x 5

Rack screw may be too short.)

braze-

ons

FIGURE 3: Midfork stays

FINISHING UP:

After the rack looks installed in an ideal position for load-

ing, tighten all bolts to 5.5 Newton meters or 45 in. lbs.

And clamp down your hub quick-release to manufacturer

specs.

Depending on your fork, you may have leftover bolts

after you finish. If you have difficulty with any part of the

installation process, bring your rack and bike to a profes-

sional bike mechanic.

Warnings:

• Do not open your hub quick-release while your rack is

loaded. This will put the full load of the rack on your axle

FIGURE 5: When mounting to fork which may bend it. Only operate your quick-release with

eyelets you could turn the axle plates the rack unloaded.

upside down. For smaller wheels, you

could just skip using the axle plates. • Riding with any load on the front of your bike will make

the bike harder to steer and operate. Some bikes are

more adversely affected than others. Be very cautious

Mounting the Rack to Fork Eyelets:

when you are learning to ride with a front load. Do not

On 26” wheels you can mount the rack directly

ride in traffic until you are comfortable controlling your

to the fork eyelets. (Skip the axle plates) On

bike while carrying a front load.

larger wheels you may need to used the axle

plates in an upside down position (Fig. 5).

• Do not overload your rack. The rack can handle up to

Mount the axle plates inverted as shown. Use

30 lbs, but many cyclists will have difficulty controlling a

the M5 x 8mm screw and washer (D) to mount

load that heavy.

axle plate to fork eyelet. If you are attaching

fender struts to the same eyelets, you may need

• Be extra careful when carrying a load wider than your

find a slightly longer machine screw to safely

rack and handlebars.

mount.

• Always strap down your load to prevent it from shifting,

swaying or falling off. Do not allow parts of your load to

dangle into the wheels or brakes.

• Regularly check bolts for tightness. A loose rack can

cause a serious accident.

FIGURE 6

• Regular inspect front hub quick-release is tight and the

lever is correctly clamped down

• An auxiliary nylon strap (“manny” strap) lashed around

the bike and the back of the rack can be an extra layer of

safety, in case your rack hardware fails unexpectedly.

Questions? E-mail somainfo(at)somafab.com

Mounting the Fence:

There is an optional fence (Fig. 6) for our Porteur Rack. It

attaches via the four eyelets on the right and left sides of

the platform. Bolts come with the fence. Since the rack

and fence are constructed by hand and not popped out

of the mold, you may need to do a little stretching of

fence struts to get all 4 bolt holes to line up. Do not fully

tighten any bolt until you get all 4 partially threaded in.

You might also like

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Dedacciai Ran-Eng 2016Document14 pagesDedacciai Ran-Eng 2016pk50sNo ratings yet

- Front Derailleur: Dealer's ManualDocument29 pagesFront Derailleur: Dealer's Manualtester1972No ratings yet

- V-Slot Corexy 3D Printer: Assembly InstructionsDocument21 pagesV-Slot Corexy 3D Printer: Assembly InstructionsCuong Nguyen VanNo ratings yet

- John Deere Walker MAV - 300/310 Rotor and Floor Upgrade Installation GuideDocument14 pagesJohn Deere Walker MAV - 300/310 Rotor and Floor Upgrade Installation Guidealaynnastaabx786No ratings yet

- Shore "X" 11-Kip Shoring SystemDocument4 pagesShore "X" 11-Kip Shoring SystematiNo ratings yet

- Workshop Manual: TBR SeriesDocument60 pagesWorkshop Manual: TBR Seriesfrankhil ramosNo ratings yet

- Aluminum Boat House Lift: Installation ManualDocument8 pagesAluminum Boat House Lift: Installation ManualJosef MadronaNo ratings yet

- Assembling The Printrbot Play Kit (Model 1505)Document29 pagesAssembling The Printrbot Play Kit (Model 1505)Vishal PaiNo ratings yet

- 2014 RMB Tech Manual Rev Apr 8Document71 pages2014 RMB Tech Manual Rev Apr 8muzNo ratings yet

- Encoder Instructions: M3-3 Thru M3-9 M3-A Thru M3-JDocument4 pagesEncoder Instructions: M3-3 Thru M3-9 M3-A Thru M3-JCharoon SuriyawichitwongNo ratings yet

- Ancon Tapered Thread Couplers International Version PDFDocument16 pagesAncon Tapered Thread Couplers International Version PDFAhmadHamdyNo ratings yet

- SUCOOT Access Facade ScaffoldDocument24 pagesSUCOOT Access Facade ScaffoldhadipurnomoputraNo ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Ancon - Tapered Thread CouplersDocument12 pagesAncon - Tapered Thread CouplersAntonio BrasilNo ratings yet

- Base de Corte Transveral para SierraDocument60 pagesBase de Corte Transveral para SierraJaime MontielNo ratings yet

- Hypercube 3D Printer Using RatRig Frame KitDocument13 pagesHypercube 3D Printer Using RatRig Frame KitceovcdkqgdheqgauwaNo ratings yet

- Structural Connections: Head D Shank D DDocument9 pagesStructural Connections: Head D Shank D DHaftom GebreegziabiherNo ratings yet

- Manual - AR4 Travel TrackDocument22 pagesManual - AR4 Travel TrackKshitijNo ratings yet

- 742263Document4 pages742263Lu Ad YunNo ratings yet

- Portabee 3D Assembly InstructionsDocument84 pagesPortabee 3D Assembly InstructionsbillyboyclydeNo ratings yet

- Manual Carro ElectricoDocument2 pagesManual Carro ElectricoGONZALO RIVERA ORELLANANo ratings yet

- Coupling - Machine DesignDocument73 pagesCoupling - Machine DesignAk GamingNo ratings yet

- Rear Derailleur: Dealer's ManualDocument20 pagesRear Derailleur: Dealer's Manualnadeem javedNo ratings yet

- Crash Bar - HONDA NC750X Product InstructionsDocument8 pagesCrash Bar - HONDA NC750X Product InstructionsromaNo ratings yet

- STAND-V100H REV1 OnlineDocument8 pagesSTAND-V100H REV1 OnlineDavid NavaNo ratings yet

- Rear Wheels: Tires, Wheels and Ballast 38Document1 pageRear Wheels: Tires, Wheels and Ballast 38Buciu Ioan BogdanNo ratings yet

- Ps Faq Frames 2013 03Document16 pagesPs Faq Frames 2013 03Maria TresedNo ratings yet

- FOR RELEASE: BFP Design Notes and Documentation PDFDocument39 pagesFOR RELEASE: BFP Design Notes and Documentation PDFHassan ZiaNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Openergo: A Self-Build Rowing Machine For More Details Go ToDocument7 pagesOpenergo: A Self-Build Rowing Machine For More Details Go ToRaffaele RizziNo ratings yet

- PATTA Rivet Nuts Cat2018 6Document20 pagesPATTA Rivet Nuts Cat2018 6Manuel Antonio Oñate CarvajalNo ratings yet

- Installation & Maintenance: RIM Tach Shaft Grounding BrushDocument8 pagesInstallation & Maintenance: RIM Tach Shaft Grounding BrushAndrewNo ratings yet

- Fy Smcs-1 Q. Bank Sem 1 2023-24Document12 pagesFy Smcs-1 Q. Bank Sem 1 2023-24raju.sharmqNo ratings yet

- Shimano Hydraulic Disc Brakes: Chapter Navigator Manual Navigator Model NavigatorDocument20 pagesShimano Hydraulic Disc Brakes: Chapter Navigator Manual Navigator Model NavigatorEliézer LimaNo ratings yet

- SplineDocument22 pagesSplinekshripNo ratings yet

- 818306-01 Recommended Mating Shafts Manual enDocument14 pages818306-01 Recommended Mating Shafts Manual enBruno FerreiraNo ratings yet

- Single Rope Timber Grab - OPERATION MANUALDocument12 pagesSingle Rope Timber Grab - OPERATION MANUALSlamet SusantoNo ratings yet

- 035 - 37 - Technical Manual - Road Brakes - CampagnoloDocument10 pages035 - 37 - Technical Manual - Road Brakes - Campagnolodcy536No ratings yet

- Joints in Steel Construction - Simple Connections - Part 04 PDFDocument72 pagesJoints in Steel Construction - Simple Connections - Part 04 PDFkakem61No ratings yet

- Manual - 2022 02 10 - 13 18 42 - A6461c488be55c7f7711723c1aa8567Document2 pagesManual - 2022 02 10 - 13 18 42 - A6461c488be55c7f7711723c1aa8567mnik33444No ratings yet

- Conveyor ComponentsDocument26 pagesConveyor Componentswmacadd100% (6)

- Catalogo CMIDocument14 pagesCatalogo CMIAlaan MauNo ratings yet

- Hausler 450 Se V2 Carbon Fiber Kit Builder's ManualDocument11 pagesHausler 450 Se V2 Carbon Fiber Kit Builder's ManualRiccardo StoccaNo ratings yet

- Sprockets: Types of Sprockets GDocument44 pagesSprockets: Types of Sprockets GAlejandro RodriguezNo ratings yet

- V-Core 3 - Ballscrews Z UpgradeDocument18 pagesV-Core 3 - Ballscrews Z Upgradetobajej752No ratings yet

- Crane Wheel Systems Sra / SRNDocument28 pagesCrane Wheel Systems Sra / SRNKovács Endre100% (1)

- Timber Construction: Connection Design According To Nzs 3603 Using Spax ScrewsDocument12 pagesTimber Construction: Connection Design According To Nzs 3603 Using Spax Screwstimur sibaevNo ratings yet

- Rounded & Notched D' or W'Document3 pagesRounded & Notched D' or W'GadNo ratings yet

- Hak Retrofit Instalacja ENDocument16 pagesHak Retrofit Instalacja ENiwo3211231No ratings yet

- Maya Pedal Trailer BicicletaDocument8 pagesMaya Pedal Trailer BicicletaFran de VediaNo ratings yet

- ASS2004000301 - E Roxtec Ex Frames Installation Instruction ENDocument12 pagesASS2004000301 - E Roxtec Ex Frames Installation Instruction ENNam DHNo ratings yet

- Compatibilidad Race Face PDFDocument4 pagesCompatibilidad Race Face PDFPepe GoteraNo ratings yet

- Slapdriver Interference Screwdriver SystemDocument8 pagesSlapdriver Interference Screwdriver SystemFreddy Churata SuriNo ratings yet

- VOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFDocument20 pagesVOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFsekfsekmddde60% (5)

- Armado de FixturesDocument36 pagesArmado de FixturesJuanNo ratings yet

- Gantrex Raillok w30 Data Sheet ImperialDocument2 pagesGantrex Raillok w30 Data Sheet ImperialSergio HernandezNo ratings yet

- 3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsFrom Everand3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsNo ratings yet

- CD Stereo System: Operating InstructionsDocument28 pagesCD Stereo System: Operating InstructionsjohnnyrossasNo ratings yet

- Catalog KENDA-2015 NA FinalDocument80 pagesCatalog KENDA-2015 NA FinaljohnnyrossasNo ratings yet

- Sunrace2016 2017Document60 pagesSunrace2016 2017Ahmed ShaabanNo ratings yet

- Catalog SunRace 2013-2014Document100 pagesCatalog SunRace 2013-2014johnnyrossasNo ratings yet

- Catalog Alhonga 2015Document39 pagesCatalog Alhonga 2015johnnyrossasNo ratings yet

- Catalog KENDA-2013 FinalDocument68 pagesCatalog KENDA-2013 FinaljohnnyrossasNo ratings yet

- Catalog Dia Compe 2016 2017Document40 pagesCatalog Dia Compe 2016 2017johnnyrossasNo ratings yet

- Catalog Alhonga 2015Document39 pagesCatalog Alhonga 2015johnnyrossasNo ratings yet

- 00 Diversos 2014 25 - 09Document14 pages00 Diversos 2014 25 - 09johnnyrossasNo ratings yet

- Soma Fender Instructions FinalDocument1 pageSoma Fender Instructions FinaljohnnyrossasNo ratings yet

- IV Festival Cuca Independente (Out e Nov 2015)Document6 pagesIV Festival Cuca Independente (Out e Nov 2015)johnnyrossasNo ratings yet

- Physics, Chapter 39: Optical Instruments: Robert Katz PublicationsDocument18 pagesPhysics, Chapter 39: Optical Instruments: Robert Katz PublicationsXin YiNo ratings yet

- Examples of Chines 00 JoneDocument204 pagesExamples of Chines 00 JonejohnnyrossasNo ratings yet

- UKFT - Colour & Textiles 2014 - RDocument22 pagesUKFT - Colour & Textiles 2014 - RjohnnyrossasNo ratings yet

- Automatic Transmission/Transaxle: Service and Repair Overhaul (Disassembly)Document15 pagesAutomatic Transmission/Transaxle: Service and Repair Overhaul (Disassembly)josmaisea33No ratings yet

- California DMV Test QuestionsDocument5 pagesCalifornia DMV Test Questionsgamermvp2480% (5)

- Outlet Temperature HighDocument5 pagesOutlet Temperature HighOzan Gürcan100% (3)

- 9-Baja DN150 BR150 Owners ManualDocument55 pages9-Baja DN150 BR150 Owners ManualoakstrNo ratings yet

- Discover 100 M SPC-Provisional OCTOBER 2013 PDFDocument72 pagesDiscover 100 M SPC-Provisional OCTOBER 2013 PDFHARSH AUTO CARESNo ratings yet

- 2012 Sea-Doo 210 WakeDocument2 pages2012 Sea-Doo 210 Wakesendmattanemail4346No ratings yet

- Kingpin and Thrust BearingsDocument6 pagesKingpin and Thrust BearingsInnov8 OilNo ratings yet

- Body, Lock & Security System: SectionDocument226 pagesBody, Lock & Security System: SectionskpppNo ratings yet

- SRV-TSB-22-008 CR233 Rear Brake Hose Replacement If RequiredDocument47 pagesSRV-TSB-22-008 CR233 Rear Brake Hose Replacement If Requiredcarlos antonio gonzalez abregoNo ratings yet

- Chevrolet Captiva 2013 PDFDocument63 pagesChevrolet Captiva 2013 PDFJuan Pablo Leon Ruales86% (21)

- Transmission and Transfer CaseDocument1,062 pagesTransmission and Transfer CaseAriel MercochaNo ratings yet

- ES16RS Part ManualDocument112 pagesES16RS Part ManualM DJNo ratings yet

- Schémas Électriques XJ6 Service Manual Vol 5 PDFDocument695 pagesSchémas Électriques XJ6 Service Manual Vol 5 PDFTACHONNo ratings yet

- E85 M54 Engine: 2005 BMW Z4 2005 BMW Z4Document18 pagesE85 M54 Engine: 2005 BMW Z4 2005 BMW Z4sebarm86No ratings yet

- Audi A6 C5 InteriorDocument70 pagesAudi A6 C5 Interiorrwyllie100% (3)

- New Volvo & Caterpillar KitsDocument5 pagesNew Volvo & Caterpillar KitsMIGUELNo ratings yet

- JCB 535-95 Telescopic ForkliftDocument2 pagesJCB 535-95 Telescopic ForkliftAmbaNo ratings yet

- Motor Vehicle Accident Investigation Report Rev-00Document22 pagesMotor Vehicle Accident Investigation Report Rev-00SamNo ratings yet

- Wheeled Excavators: StageDocument24 pagesWheeled Excavators: StageLAli100% (1)

- HITACHI Training Text Engine Isuzu 6WG1X PDFDocument101 pagesHITACHI Training Text Engine Isuzu 6WG1X PDFMarwellOkay100% (11)

- TNT300 Service manual-QJDocument218 pagesTNT300 Service manual-QJAlfonso MoscosoNo ratings yet

- Kyron 2 Chasis 013 01 007Document4 pagesKyron 2 Chasis 013 01 007Osmar Franco PiresNo ratings yet

- HSR Tuning Manual 050102Document16 pagesHSR Tuning Manual 050102tomektomek6347No ratings yet

- Oil Chart UsDocument3 pagesOil Chart UsJoeCruzNo ratings yet

- 03 Buying A Safer Car 811360Document25 pages03 Buying A Safer Car 811360api-309082881No ratings yet

- Crankshaft - RemoveDocument7 pagesCrankshaft - RemoveJose Fernando Huaman RosalesNo ratings yet

- RulebookDocument184 pagesRulebookYashNo ratings yet

- IPL, Partner, Colibri Plus, 1997-01, TrimmerDocument3 pagesIPL, Partner, Colibri Plus, 1997-01, TrimmerEduard VečenajNo ratings yet

- A0 EngineDocument125 pagesA0 Engineazry_alqadryNo ratings yet

- Especificaciones Excavadora Sany 465C (Folleto)Document8 pagesEspecificaciones Excavadora Sany 465C (Folleto)prueba100% (1)