Professional Documents

Culture Documents

Hempel'S Galvosil 15780: Description

Uploaded by

EngTamerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hempel'S Galvosil 15780: Description

Uploaded by

EngTamerCopyright:

Available Formats

Product Data

HEMPEL'S GALVOSIL 15780

15780: LIQUID 15789: HEMPEL’S ZINC METAL PIGMENT 97170/97140

Description: HEMPEL’S GALVOSIL 15780 is a two-component, medium-zinc, solvent-borne, selfcuring inorganic

zinc silicate coating. Applicable by airless spray.

Hempel's Zinc metal pigment 97170 is in full compliance with ISO 3549 and ASTM D520 type I,

Hempel's Zinc metal pigment 97140 is additionally in compliance with ASTM D520 type II.

Recommended use: As a general purpose rust-preventing primer in paint systems for long-life protection of steel exposed to

moderately to severely corrosive environment. In compliance with SSPC-Paint 20, type 1, level 2.

Service temperature: Resistant to permanent (non-cyclic) dry temperatures as well as occasionally dry peak temperatures up

to maximum: 500°C/932°F.

It is of advantage to apply a topcoat of HEMPEL'S SILICONE ALUMINIUM 56914 in case of service

temperatures above: 400°C/752°F.

Resistant to cyclic dry temperatures up to 400°C/752°F.

Certificates/Approvals: Meets the requirements laid down in ASTM A-490 Class "B" for Slip-Co-efficient and Creep Resistance.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 19840 / Metal grey

Finish: Flat

Volume solids, %: 66 ± 1

Theoretical spreading rate: 12.2 m2/l [489.2 sq.ft./US gallon] - 50 micron/2 mils

Flash point: 14 °C [57.2 °F]

Specific gravity: 2.4 kg/litre [20 lbs/US gallon]

Dry to touch: 0.5 approx. hour(s) 20°C/68°F (75% RH)

Fully cured: 16 approx. hour(s) 20°C/68°F (75% RH)

VOC content: 441 g/l [3.7 lbs/US gallon]

Shelf life: 6 months for the LIQUID and 3 years for HEMPEL'S ZINC METAL PIGMENT (stored in closed

container) (25°C/77°F) from time of production.

Shelf life is dependent on storage temperature. Shelf life is reduced at storage temperatures above

25°C/77°F. Do not store above 40°C/104°F. Shelf life is exceeded if the liquid is gelled or if the mixed

product forms gels before application.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

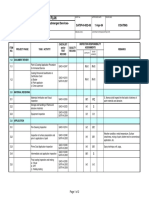

APPLICATION DETAILS:

Version, mixed product: 15780

Mixing ratio: LIQUID 15789: HEMPEL’S ZINC METAL PIGMENT

97170/97140

4.1 : 5.9 by weight

(by volume - see REMARKS overleaf)

Application method: Airless spray / Air spray / Brush (touch up)

Thinner (max.vol.): 08700 (30%) / 08700 (50%) / 08700 (10%)

Pot life: 4 hour(s) 20°C/68°F

Nozzle orifice: 0.019 - 0.023 "

Nozzle pressure: 100 bar [1450 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S THINNER 08700

Indicated film thickness, dry: 50 micron [2 mils] see REMARKS overleaf

Indicated film thickness, wet: 75 micron [3 mils]

Recoat interval, min: According to separate APPLICATION

INSTRUCTIONS

Recoat interval, max: According to separate APPLICATION

INSTRUCTIONS

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: August 2014 Page: 1/2 Product Data Sheet

-

HEMPEL'S GALVOSIL 15780

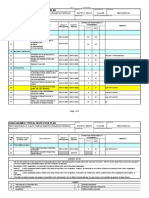

SURFACE PREPARATION: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other contaminants

by high pressure fresh water cleaning. Abrasive blasting with sharp abrasive to minimum Sa 2½ (ISO

8501-1:2007) with a surface profile equivalent to Rugotest No. 3, BN10, Keane-Tator Comparator, min.

3.0 G/S, or ISO Comparator rough Medium (G). In case of new steel to be exposed to no more than

medium aggressive (industrial) environment and without any extraordinary demands to lifetime, a

surface preparation degree of SSPC-SP6 may suffice.

See separate APPLICATION INSTRUCTIONS

APPLICATION CONDITIONS: The surface must be completely clean and dry at the time of application and its temperature must be

above the dew point to avoid condensation. At temperatures ranging from 0°C/32°F to 40°C/105°F,

curing needs minimum 50% relative humidity.

Curing is retarded at lower temperature and lower humidity.

See separate APPLICATION INSTRUCTIONS

SUBSEQUENT COAT: According to specification.

REMARKS:

Weathering/service temperatures: Note: If used as anticorrosive protection under insulation of high temperature equipment it is very

important that NO moisture can penetrate during slow-down periods. This to avoid risk of "wet

corrosion" when the temperature rises.

Induction time: For application at high temperatures, a special thinner is available.

Application(s) When mixing part of the content in a can the mixing ratio on volume should be made as follows: 8.0

parts of the BASE and then add HEMPEL'S ZINC METAL PIGMENT up to a total of 10.00 parts by

volume.

Film thicknesses/thinning: If topcoated with a heavy- duty system it is recommended to apply: 50-80 micron/2.0-3.2 mils dry film

thickness (75-125 micron/3-5 mils wet.(Consult the separate APPLICATION INSTRUCTIONS)

High temperature service: Dry film thicknesses should not exceed: 40-50 micron/1.6-2 mils to avoid

cracking, especially in cases where service conditions include sudden temperature changes.

(The dry film thickness range does not take into account the correction factors for rough surfaces as

listed in ISO 19840).

Recoating intervals: Recoating intervals are strongly dependent on both temperature and humidity. Deviations from the

standard conditions may shorten or prolong the recoating intervals.

Full curing will be obtained after:

0°C/32°F and minimum 75% RH: 3 days

10°C/50°F and minimum 75% RH: 36 hour(s)

20°C/68°F and minimum 75% RH: 16 hour(s)

(A certain curing does take place at temperatures below 0°C/32°F, but at an extremely low speed)

(Consult the separate APPLICATION INSTRUCTIONS)

The state of curing should be checked before overcoating, a resistance rating of minimum 4 by ASTM

D4752 is required. MEK (Methyl Ethyl Ketone) may be substituted by Hempel Thinner 08700 for the

test.

Note: HEMPEL'S GALVOSIL 15780 For professional use only.

ISSUED BY: HEMPEL A/S 1578019840

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet represent only test results

or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions of any intended use of the Products herein

must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing.

The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said GENERAL CONDITIONS for all

results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise. Product data are subject to change without notice

and become void five years from the date of issue.

Date of issue: August 2014 Page: 2/2 Product Data Sheet

-

You might also like

- Saudi Aramco Concrete Coating ProcedureDocument10 pagesSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- Sodium Silicate Handbook PDFDocument24 pagesSodium Silicate Handbook PDFelio100% (1)

- Coating CardDocument15 pagesCoating CardAnton Thomas PunzalanNo ratings yet

- Renovation Coating Inspection PlanDocument10 pagesRenovation Coating Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Approved Coating SupervisorDocument2 pagesSaudi Aramco Approved Coating SupervisorMohamed Reda100% (2)

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pages09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Worksheet - Chapter 12 - Acids and BasesDocument5 pagesWorksheet - Chapter 12 - Acids and BasesKatrina EstradaNo ratings yet

- Aldol Condensation of 4-Chlorobenzaldehyde and 4-MethoxyacetophenoneDocument4 pagesAldol Condensation of 4-Chlorobenzaldehyde and 4-MethoxyacetophenonePhillip WachowiakNo ratings yet

- Hempel's ZP Alkyd Primer 12090Document2 pagesHempel's ZP Alkyd Primer 12090EngTamerNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Ai Hempadur 87540 EnglishDocument2 pagesAi Hempadur 87540 EnglishAmilcar BolagNo ratings yet

- 355 SaDocument2 pages355 Sakhalid764100% (1)

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- Hempel's Epoxy Knifing Filler - DatasheetDocument2 pagesHempel's Epoxy Knifing Filler - Datasheetmuhammedemraan100% (2)

- APPROVED SIGMA EPOXY PAINT SYSTEMDocument1 pageAPPROVED SIGMA EPOXY PAINT SYSTEMChiller jnglNo ratings yet

- CV - Faisal Coating Combained-QCIDocument13 pagesCV - Faisal Coating Combained-QCIMuthu SaravananNo ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- 09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsDocument4 pages09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsFiras AlbaweiNo ratings yet

- Saes H 004Document8 pagesSaes H 004kaleeswaran s100% (1)

- SAEP-303: 2 Conflicts and DeviationsDocument19 pagesSAEP-303: 2 Conflicts and DeviationsnasirNo ratings yet

- Abu Ali project-APCS 1D Using Hempel Paint REV.01Document10 pagesAbu Ali project-APCS 1D Using Hempel Paint REV.01ravi ajithNo ratings yet

- SAES-H-101V: Hempel's Galvosil 15780 inorganic zinc primerDocument3 pagesSAES-H-101V: Hempel's Galvosil 15780 inorganic zinc primerjinujoseNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Sika Grout - 114 SaDocument3 pagesSika Grout - 114 SaGavriel NgNo ratings yet

- PROJECT-TGP Package 14 Sulfur Handling Facilities: Procedure For Coating of Concrete FoundationsDocument9 pagesPROJECT-TGP Package 14 Sulfur Handling Facilities: Procedure For Coating of Concrete FoundationsMohamed Reda Hussein Sengar100% (2)

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Document2 pagesSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliNo ratings yet

- Hempadur XP 87550: DescriptionDocument2 pagesHempadur XP 87550: DescriptionEngTamer50% (4)

- SAES-H-102-Safety Requirements For Coating Applications2Document12 pagesSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNo ratings yet

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic H 2023Document2 pagesSaic H 2023Sivaratnam NavatharanNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Apcs 113a Rev 3 Pid ApprovalDocument19 pagesApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Procedure of Apcs-113cDocument8 pagesProcedure of Apcs-113cNoman AhmedNo ratings yet

- 10270Document2 pages10270Mekhman50% (2)

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- 658 - Eng - Sigma Phenguard 935 BaseDocument1 page658 - Eng - Sigma Phenguard 935 BasetariqueNo ratings yet

- Coating Procedure GuideDocument8 pagesCoating Procedure Guidedeva0170% (2)

- Aramco Apcs 1bDocument55 pagesAramco Apcs 1bSadek Sad100% (2)

- Saudi Aramco Field Coating Inspection ReportDocument3 pagesSaudi Aramco Field Coating Inspection Reportravi ajith100% (1)

- Medium Curing Cutback Product Data SheetDocument1 pageMedium Curing Cutback Product Data SheetRaheelHashmiNo ratings yet

- SATR-H-2004 Rev 7Document3 pagesSATR-H-2004 Rev 7josephNo ratings yet

- Abu Ali project-APCS 1D Using Hempel Paint REV.01 PDFDocument10 pagesAbu Ali project-APCS 1D Using Hempel Paint REV.01 PDFravi ajith100% (1)

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Coating Procedure For Bituminous Material Rev 01Document5 pagesCoating Procedure For Bituminous Material Rev 01moytabura96No ratings yet

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNo ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VNo ratings yet

- 6-Blasting and Painting Procedure - BP006Document14 pages6-Blasting and Painting Procedure - BP006mohd as shahiddin jafriNo ratings yet

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Document7 pagesMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- General Instruction Manual: Abrasive Blasting OperationsDocument6 pagesGeneral Instruction Manual: Abrasive Blasting OperationsAbhilashNo ratings yet

- HEMPEL'S GALVOSIL 15790 Product Data SheetDocument2 pagesHEMPEL'S GALVOSIL 15790 Product Data SheetRoberto_PrrNo ratings yet

- PDS Hempel's Galvosil 15700 en-GBDocument2 pagesPDS Hempel's Galvosil 15700 en-GBbayuNo ratings yet

- Galvosil 15700 DSDocument2 pagesGalvosil 15700 DSIssam TrikiNo ratings yet

- Hempel's Galvosil 15780: High-Performance Zinc Primer for Steel ProtectionDocument2 pagesHempel's Galvosil 15780: High-Performance Zinc Primer for Steel ProtectionRaghu VamshiNo ratings yet

- PDS 15700Document2 pagesPDS 15700altipatlarNo ratings yet

- Galvosil 15680 Data SheetDocument2 pagesGalvosil 15680 Data Sheetn00b1810No ratings yet

- 32 Samss 100Document38 pages32 Samss 100EngTamerNo ratings yet

- E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pagesE-17 Model l60-6d Wrought 6d 60o ElbowEngTamerNo ratings yet

- Elcometer 130 SSP Bresle Equivalence Report 2015Document26 pagesElcometer 130 SSP Bresle Equivalence Report 2015EngTamerNo ratings yet

- Jotamastic Protective Brochure 2011 Tcm279 1592Document24 pagesJotamastic Protective Brochure 2011 Tcm279 1592EngTamerNo ratings yet

- Asm Stag PDFDocument1 pageAsm Stag PDFRajiv SinghNo ratings yet

- 32 Samss 100Document38 pages32 Samss 100EngTamerNo ratings yet

- Safety Data Sheet: Jotun Peroxide 1Document12 pagesSafety Data Sheet: Jotun Peroxide 1EngTamerNo ratings yet

- Norox KP-9Document2 pagesNorox KP-9EngTamerNo ratings yet

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- Norox Mekp-925hDocument2 pagesNorox Mekp-925hEngTamerNo ratings yet

- Integrated Air Control Modules: Instructions-PartsDocument14 pagesIntegrated Air Control Modules: Instructions-PartsEngTamerNo ratings yet

- Norpol Accelerator 9802 PDocument12 pagesNorpol Accelerator 9802 PEngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part69Document2 pagesSigma Marine Coatings Manual - Part69EngTamerNo ratings yet

- Butanox M 50Document4 pagesButanox M 50EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part70Document2 pagesSigma Marine Coatings Manual - Part70EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part67Document2 pagesSigma Marine Coatings Manual - Part67EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part59Document2 pagesSigma Marine Coatings Manual - Part59EngTamerNo ratings yet

- Integrated Air Control Modules: Instructions-PartsDocument16 pagesIntegrated Air Control Modules: Instructions-PartsEngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part66Document2 pagesSigma Marine Coatings Manual - Part66EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part65Document2 pagesSigma Marine Coatings Manual - Part65EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part68Document2 pagesSigma Marine Coatings Manual - Part68EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part57Document2 pagesSigma Marine Coatings Manual - Part57EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part61Document2 pagesSigma Marine Coatings Manual - Part61EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part58Document2 pagesSigma Marine Coatings Manual - Part58EngTamerNo ratings yet

- Sigma Part50Document2 pagesSigma Part50EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part60Document2 pagesSigma Marine Coatings Manual - Part60EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part64Document2 pagesSigma Marine Coatings Manual - Part64EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part56Document2 pagesSigma Marine Coatings Manual - Part56EngTamerNo ratings yet

- Sigma Marine Coatings Manual - Part55Document2 pagesSigma Marine Coatings Manual - Part55EngTamerNo ratings yet

- Sigmacover 525: Description Principal CharacteristicsDocument2 pagesSigmacover 525: Description Principal CharacteristicsEngTamerNo ratings yet

- Detergents: A Guide To The Properties and Uses of Detergents in Biological SystemsDocument51 pagesDetergents: A Guide To The Properties and Uses of Detergents in Biological SystemsFavour OgbonnaNo ratings yet

- Chemical Admixtures GuideDocument56 pagesChemical Admixtures Guidefhsn84No ratings yet

- QP-Chemistry-12-Practice Paper-1Document8 pagesQP-Chemistry-12-Practice Paper-1piyushchampion2006No ratings yet

- Silo - Tips - Personal Care ProductsDocument5 pagesSilo - Tips - Personal Care Productscontentdrive4 drive4No ratings yet

- Worksheet 25 Redox KeyDocument7 pagesWorksheet 25 Redox KeysamareshcmondalNo ratings yet

- Cyclic Corrosion Tests Under Modern Environmental Conditions For The Automotive - Steel - and Aluminum IndustriesDocument27 pagesCyclic Corrosion Tests Under Modern Environmental Conditions For The Automotive - Steel - and Aluminum IndustriesVlad ChalapcoNo ratings yet

- Worksheet 1 Acids, Bases & IndicatorsDocument4 pagesWorksheet 1 Acids, Bases & IndicatorsJohnny JobbyNo ratings yet

- Macromolecules 10 (3), 532-535, 1977Document4 pagesMacromolecules 10 (3), 532-535, 1977Fernanda DiasNo ratings yet

- Toughest JEE Advanced Maths QuestionsDocument25 pagesToughest JEE Advanced Maths Questionsudaya bhasakrNo ratings yet

- Calcium PhosphateDocument3 pagesCalcium PhosphateMarsha Fendria PrastikaNo ratings yet

- Experiments 11 15 NotesDocument16 pagesExperiments 11 15 NotesJoshuel MontecilloNo ratings yet

- Unit 7 Operon ConceptDocument18 pagesUnit 7 Operon ConceptSarah PavuNo ratings yet

- Melting, Remelting, and Casting For Clean Steel: July 2016Document14 pagesMelting, Remelting, and Casting For Clean Steel: July 2016tabibkarimNo ratings yet

- Chemicals Zetag DATA Powder Magnafloc LT 25 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc LT 25 - 0410PromagEnviro.com100% (2)

- Weld On Industrial Brochure DEC2015Document40 pagesWeld On Industrial Brochure DEC2015SREENATH SREEDHARANNo ratings yet

- Chemicals From C3 Compounds - 2Document8 pagesChemicals From C3 Compounds - 2आदेश मीणाNo ratings yet

- Removal of Erionyl Blue A-R and Solophenyl Black FR TextileDocument5 pagesRemoval of Erionyl Blue A-R and Solophenyl Black FR TextileEdith Chavez BravoNo ratings yet

- Class 12 Chemistry SQP 4Document5 pagesClass 12 Chemistry SQP 4Amaan KhanNo ratings yet

- Ammissione Allievi Ordinari CONCORSO GEM 2021-2022 Test ScrittoDocument13 pagesAmmissione Allievi Ordinari CONCORSO GEM 2021-2022 Test ScrittoGiorgio OrniNo ratings yet

- Buku Latihan Kimia f5Document50 pagesBuku Latihan Kimia f5Hajar Norasyikin Abu BakarNo ratings yet

- D and F BlockDocument40 pagesD and F Blockmithramithun001No ratings yet

- Presentation on MineralsDocument8 pagesPresentation on MineralsTitiksha NegiNo ratings yet

- J Fluorine Chem 106 (2000) 153-161Document9 pagesJ Fluorine Chem 106 (2000) 153-161Luciano PaoloNo ratings yet

- Chemistry Notes Class 10Document8 pagesChemistry Notes Class 10nejihyuga997No ratings yet

- Silica Molybdate EqDocument11 pagesSilica Molybdate Eqdafteri11100% (1)

- IIT-JEE HALOALKANES SN1 REACTIONS TARGETDocument44 pagesIIT-JEE HALOALKANES SN1 REACTIONS TARGETHarsh VardhanNo ratings yet