Professional Documents

Culture Documents

Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17A

Uploaded by

jinujoseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17A

Uploaded by

jinujoseCopyright:

Available Formats

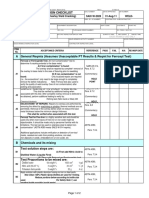

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

Manufacturer - Approved Saudi Aramco Data Sheet

APCS-1A/1D/11A/17A

Type of Coating : Inorganic Zinc Primer, Solvent-Based

Manufacturer : Hempel Paints (Saudi Arabia) W.L.L.

Product Name : Hempel’s Galvosil 15780

SAP M/N (SAMS S/N) : 1000194146 (09-611-958)

1. Storage

1.1 Shelf life, sheltered storage @ 35°C maximum : 6 months

2. Mixing

2.1 No. of Components : 2

2.1.1 Base : 15789 Liquid

2.1.2 Hardener (Curing Agent) : 97170 / 97140 Zinc Dust

2.2 Mixing Ratio (Base: Curing Agent) : 10 L liquid: 17 Kg Zinc Dust

2.3 Thinner : Hempel’s 08700

SAP M/N (SAMS S/N) : 1000198445 (09-738-220)

2.4 Minimum-Maximum Thinning Requirements : up to 50% by Volume

2.5 Induction Time : Nil

2.6 Pot Life : 9 hours @ 25ºC

3 hours @ 40ºC

3. Application

3.1 Minimum-Maximum Allowable Substrate Temperature : 0-40°C

3.2 Minimum-Maximum Allowable Relative Humidity : 50-75%

3.3 Typical Wet Film Thickness Per Coat : 100 microns

3.4 Typical Dry Film Thickness Per Coat : 65 microns

Page 168 of 428

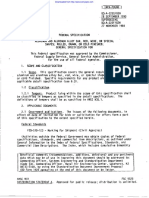

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

Manufacturer - Approved Saudi Aramco Data Sheet

APCS-1A/1D/11A/17A - Hempel’s Galvosil 15780 (Cont'd)

3.5 Theoretical Coverage @ 25 Micrometers : 26.4 m2/L

Dry Film Thickness

3.6 Minimum Number of Coats : 1

3.7 Applicable Substrate : Carbon steel

3.8 Surface Preparation Requirements:

Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting with sharp

abrasive to minimum Sa 2½ (ISO8501-1:2007) with a surface profile equivalent to

Rugotest No. 3, BN10, Keane-Tator Comparator, min.3.0 G/S, or ISO Comparator rough

Medium (G). In case of new steel to be exposed to no more than medium aggressive

(industrial) environment and without any extraordinary demands to lifetime, a surface

preparation degree of SSPC-SP6 may suffice.

3.9 Drying Time at specified DFT

Substrate Recoat Interval To Handle To Service Full Cure

Temperature Minimum Maximum

10°C 4 days None 4 hours

30°C 1 day None 1 hour

50°C 6 hours None ¼ hour

* Before overcoating after exposure in a contaminated environment, clean thoroughly

by high pressure sweet water hosing and allow to dry.

3.10 Recommended Application Equipment

Airless (A/L) Spray : Tip size: 0.019 to 0.023 inch

Fluid pressure: 1,500 psi

Conventional Spray : Tip size: 0.070 to 0.085 inch

Atomizing pressure: 20 to 35 psi

Brush : For stripe coating / touch-up only

Page 169 of 428

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

Manufacturer - Approved Saudi Aramco Data Sheet

APCS-1A/1D/11A/17A - Hempel’s Galvosil 15780 (Cont'd)

4. Physical Properties

4.1 Volume Solids (ASTM D2697) : 64 to 68%

4.2 Product Weight (ASTM D1475) : 2.37 to 2.43Kg/L

4.3 Viscosity (ASTM D562) : 67 to 73 KU

4.4 Flash Point (ASTM D93 or D56) : 14°C

4.5 Approved Color/s : 19840 Metal Gray

4.6 Finish : Flat

5. Special Instructions:

Topcoating is done when the inorganic zinc primer is fully cured.

The minimum overcoating time is valid @75% relative humidity and sufficient ventilation.

Approval Date:

Replaces: December 18, 2004

Page 170 of 428

You might also like

- Hempel'S Galvosil 15780: DescriptionDocument2 pagesHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Painting Report Cd1Document77 pagesPainting Report Cd1sivaNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationAjeetKumar100% (1)

- Replacing Part of Cement With Waste Material - ReviewDocument7 pagesReplacing Part of Cement With Waste Material - ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- SAEP-303: 2 Conflicts and DeviationsDocument19 pagesSAEP-303: 2 Conflicts and DeviationsnasirNo ratings yet

- Approved Sigma Paint System Apcs 1 BDocument1 pageApproved Sigma Paint System Apcs 1 BChiller jnglNo ratings yet

- Inspection Check List 2Document34 pagesInspection Check List 2r.devendranNo ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- CV - Faisal Coating Combained-QCIDocument13 pagesCV - Faisal Coating Combained-QCIMuthu SaravananNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Document12 pagesSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNo ratings yet

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323No ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- SP 18 Thoro Spot & Sweep 12-30-20Document7 pagesSP 18 Thoro Spot & Sweep 12-30-20Donzt Dontz FaujiNo ratings yet

- FireProofing SpecificationDocument10 pagesFireProofing SpecificationSalman ShaikhNo ratings yet

- Coating CardDocument15 pagesCoating CardAnton Thomas PunzalanNo ratings yet

- Audit Checklist Blasting PaintingDocument4 pagesAudit Checklist Blasting PaintingEyoh EffiongNo ratings yet

- smww.1060 Ed 24 2023Document10 pagessmww.1060 Ed 24 2023DenisVYNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Surface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)Document5 pagesSurface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)get5rajesh100% (1)

- CBT Questions 26022020Document43 pagesCBT Questions 26022020Shawn LeoNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- ABRASIVE BLASTING SM PRESENTATION 2017.ppsxDocument18 pagesABRASIVE BLASTING SM PRESENTATION 2017.ppsxIsaac SamuelNo ratings yet

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Saes H 004Document8 pagesSaes H 004kaleeswaran s100% (1)

- Hempel Curing Agent 98021 MsdsDocument10 pagesHempel Curing Agent 98021 MsdsM.FAIZAN ARSHADNo ratings yet

- SCM 400 Salt Contamination MeterDocument2 pagesSCM 400 Salt Contamination MeterJohn WatsonNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- Hempel's ZP Alkyd Primer 12090Document2 pagesHempel's ZP Alkyd Primer 12090EngTamerNo ratings yet

- 6-Blasting and Painting Procedure - BP006Document14 pages6-Blasting and Painting Procedure - BP006mohd as shahiddin jafriNo ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocument2 pagesSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanNo ratings yet

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27No ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Revision Questions PA 10 Specific Page 23-12Document2 pagesRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNo ratings yet

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocument46 pagesRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNo ratings yet

- Sika Grout - 114 SaDocument3 pagesSika Grout - 114 SaGavriel NgNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Schedule Q - Attachment VIDocument8 pagesSchedule Q - Attachment VISIVANo ratings yet

- Pentadur 5540 (F6A)Document3 pagesPentadur 5540 (F6A)SiDdu Kalashetti0% (1)

- Renderoc MPRDocument2 pagesRenderoc MPRtalatzahoorNo ratings yet

- OLD BGAS Grade-1 - Revision Questions - 2007Document11 pagesOLD BGAS Grade-1 - Revision Questions - 2007Alex joseph alexNo ratings yet

- Paint SystemDocument2 pagesPaint SystemYasir AsifNo ratings yet

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Document3 pagesChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Marathon XHBDocument4 pagesMarathon XHBeskim00No ratings yet

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikNo ratings yet

- Apcs 1B 1e HemDocument3 pagesApcs 1B 1e HemjinujoseNo ratings yet

- Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FDocument3 pagesManufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FjinujoseNo ratings yet

- Hempel Apcs113aDocument6 pagesHempel Apcs113aNoman AhmedNo ratings yet

- Sigma 1DDocument8 pagesSigma 1Dyogeshkumar121998No ratings yet

- Sigma 2aDocument5 pagesSigma 2ayogeshkumar121998No ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- PDS Hempaprime Multi 500 Summer en-GBDocument2 pagesPDS Hempaprime Multi 500 Summer en-GBFreddyNo ratings yet

- Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FDocument3 pagesManufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FjinujoseNo ratings yet

- Apcs 1B 1e HemDocument3 pagesApcs 1B 1e HemjinujoseNo ratings yet

- Apcs 1B 1e HemDocument3 pagesApcs 1B 1e HemjinujoseNo ratings yet

- Apcs 1B 1e HemDocument3 pagesApcs 1B 1e HemjinujoseNo ratings yet

- Materials: Investigation of Energy Absorbed by Composite Panels With Honeycomb Aluminum Alloy CoreDocument11 pagesMaterials: Investigation of Energy Absorbed by Composite Panels With Honeycomb Aluminum Alloy Coreafshin dadvarNo ratings yet

- Detection of Common Defects in Concrete Bridge Decks Using Nondestructive Evaluation TechniquesDocument11 pagesDetection of Common Defects in Concrete Bridge Decks Using Nondestructive Evaluation TechniquesnagarajuNo ratings yet

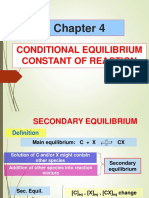

- K00337 - 20180906103219 - SKF3023 LECTURE 4aDocument33 pagesK00337 - 20180906103219 - SKF3023 LECTURE 4aAin SufizaNo ratings yet

- Physics - MatterDocument28 pagesPhysics - MatterDamimi 21No ratings yet

- Fiche Technique Garniture R-MGDocument2 pagesFiche Technique Garniture R-MGongoloNo ratings yet

- Grade 8 QuestionnaireDocument2 pagesGrade 8 QuestionnaireRenzo MarcellaNo ratings yet

- J Comput Chem - 2007 - Nikitin - New Six Site Acetonitrile Model For Simulations of Liquid Acetonitrile and Its AqueousDocument7 pagesJ Comput Chem - 2007 - Nikitin - New Six Site Acetonitrile Model For Simulations of Liquid Acetonitrile and Its AqueousLbmm Física MolecularNo ratings yet

- Advanced TreatmentDocument8 pagesAdvanced TreatmentangginoviariNo ratings yet

- G4 BasayaDocument2 pagesG4 BasayaDawn BasayaNo ratings yet

- Semi F21-95 Classification of Airborne Molecular ContaminantDocument4 pagesSemi F21-95 Classification of Airborne Molecular ContaminantzyatikNo ratings yet

- Design of RE WallDocument29 pagesDesign of RE WallraghuramammavajjalaNo ratings yet

- Hostapur OS LiquidDocument2 pagesHostapur OS Liquidrafaeldelperu1982No ratings yet

- Lab Report 1Document5 pagesLab Report 1Trịnh Gia HânNo ratings yet

- QQ-A-225G - GEN - Aluminum Alloy, Rolled, CD, CFDocument21 pagesQQ-A-225G - GEN - Aluminum Alloy, Rolled, CD, CFthomasNo ratings yet

- Biosensors: PDMS Bonding Technologies For Microfluidic Applications: A ReviewDocument28 pagesBiosensors: PDMS Bonding Technologies For Microfluidic Applications: A ReviewITISHREE PANDANo ratings yet

- Organozinc CompoundDocument8 pagesOrganozinc Compoundamanuel tafeseNo ratings yet

- B844 982021 2 04 Standard Guide For Silver Tin Oxide Contact MaterialDocument3 pagesB844 982021 2 04 Standard Guide For Silver Tin Oxide Contact MaterialShodji MabungaNo ratings yet

- Aeroquip HoseDocument0 pagesAeroquip Hosegbm2246No ratings yet

- The Periodic Ta-Wps OfficeDocument3 pagesThe Periodic Ta-Wps OfficeAlan Gandidze MotifNo ratings yet

- Pharmaceutical AnalysisDocument73 pagesPharmaceutical AnalysisChristinaNo ratings yet

- Chapter 4Document51 pagesChapter 4Hà Nguyễn Thị NgọcNo ratings yet

- BORLOGDocument4 pagesBORLOGKaren TrinitaNo ratings yet

- Capral AGS 425 Narrowline DG - BrochureDocument2 pagesCapral AGS 425 Narrowline DG - Brochurejr-nts ntsNo ratings yet

- Comparison Bet Stds For Diaphragm Gas MetersDocument34 pagesComparison Bet Stds For Diaphragm Gas MetersRam SudheerNo ratings yet

- Interval Discussion 42in & 26in PhaseDocument3 pagesInterval Discussion 42in & 26in PhaseAziz AndriyantoNo ratings yet

- PHOTOCATALYTIC DEGRADATION OF CHLOROPHENOL USING DOPED ON P25 DEGUSSA TiO2 NANOPARTICLE WITH ULTRAVIOLET RADIATIONDocument12 pagesPHOTOCATALYTIC DEGRADATION OF CHLOROPHENOL USING DOPED ON P25 DEGUSSA TiO2 NANOPARTICLE WITH ULTRAVIOLET RADIATIONEgah GodwinNo ratings yet

- Dna ExtractionDocument3 pagesDna ExtractionCetura VillaruzNo ratings yet

- CRH Cellular Respiration (Principles) - Measure Energy Consumption During Exercise Lab ManualDocument6 pagesCRH Cellular Respiration (Principles) - Measure Energy Consumption During Exercise Lab ManualVanesha AnesNo ratings yet