0% found this document useful (0 votes)

71 views8 pagesAccident Prevention Guidelines for Employees

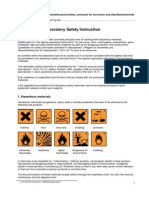

Every employee must be aware of workplace dangers and protect themselves and others from harm. Sources of danger must be immediately removed or secured. Supervisors must brief employees on potential dangers, and safety representatives can provide assistance applying safety regulations. Proper order and cleanliness of the workplace is required. Traffic routes, escape routes, and life-saving routes must remain clear, and hazards must be clearly marked with signs. Protective devices on machines must be reliably maintained.

Uploaded by

saquib_jamadarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

Topics covered

- warning signs,

- continuous testing,

- emergency procedures,

- supervisor responsibilities,

- safety procedures,

- safety management,

- hazardous materials,

- accident prevention,

- safety awareness,

- safety training

0% found this document useful (0 votes)

71 views8 pagesAccident Prevention Guidelines for Employees

Every employee must be aware of workplace dangers and protect themselves and others from harm. Sources of danger must be immediately removed or secured. Supervisors must brief employees on potential dangers, and safety representatives can provide assistance applying safety regulations. Proper order and cleanliness of the workplace is required. Traffic routes, escape routes, and life-saving routes must remain clear, and hazards must be clearly marked with signs. Protective devices on machines must be reliably maintained.

Uploaded by

saquib_jamadarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

Topics covered

- warning signs,

- continuous testing,

- emergency procedures,

- supervisor responsibilities,

- safety procedures,

- safety management,

- hazardous materials,

- accident prevention,

- safety awareness,

- safety training