Professional Documents

Culture Documents

General Workshop Safety 1.0 Home Hazard Management

Uploaded by

Sarah0 ratings0% found this document useful (0 votes)

24 views2 pagesOriginal Title

GENERAL WORKSHOP SAFETY

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pagesGeneral Workshop Safety 1.0 Home Hazard Management

Uploaded by

SarahCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

GENERAL WORKSHOP SAFETY

1.0 Home Hazard Management

1.1 Workshops are non-laboratory situations where machinery and/or tools are used, in an

indoor or outdoor situation. This advice also applies to fabrication, maintenance or other

workshop-type activities not in the boundaries of a defined workshop area.

1.2 This information is not intended to replace risk/hazard identification. There must be a

hazard register for each workshop identifying the specific machines and hazards for that

area.

2.0 Safety in a workshop

2.1 All workshops and stores must be under the direct control of a supervisor, who is

responsible for ensuring they are maintained and used in a safe and healthy manner. Only

those authorized to do so may enter or work in workshops or stores, and must comply with

the requirements of the supervisor whilst in that area.

2.2 All persons using workshops and stores should apply good housekeeping practices, wear

appropriate clothing and footwear, and use the workshop or store only for its intended

purpose.

2.3 A tidy workplace makes it easier to spot and avoid hazards, and does not interfere with

normal work operations. Good housekeeping is fundamental to workshop safety

management, and the time allocated to a job must include cleaning up afterwards. This

applies to both individual and shared areas.

2.4 Personal items, food, drink or cigarettes are not to be taken into workshops and stores,

unless a clean work-free area has been set aside for this purpose. Where necessary, lockers

should be provided and used.

2.5 The store or workshop must be suited to the proposed task. The supervisor shall make the

decision as to what tasks are appropriate for each situation.

3.0 Safe storage

3.1 `Liquid, solid or gaseous substances, equipment and fittings may all be stored. Corrosion or

damage of containers may cause product leakage, which contaminates surfaces below,

creates slip hazards and may react to form a fire or fume hazard. Other items may have a

limited shelf life, and become more hazardous as they age.

3.2 The physical process of storage also has hazards via manual handling, slips, trips and falls

from inappropriately stored items and objects falling from a height.

4.0 Managing hazards

4.1 Wherever practicable, a clean-bench policy should be adopted, with all items returned to

their designated storage location on completion of a task. This requires suitable and

sufficient shelves, cupboards, wall hangings and space to be available.

4.2 Materials used for workshop activities should be held at the work area in appropriate

quantities. Bulk storage at the work area is generally unnecessary and contributes to

congestion.

4.3 Segregation in storage must be practiced for incompatible materials. Flammable substances

in particular must be held within a flammable store, which is suitably constructed, marked

and located.

4.4 Heavy large or awkward items should be stored so as to avoid bending or excessive reaching

when moving them. They should not be stored above shoulder height or below knee height.

4.5 All substances must be clearly labelled to avoid confusion or inadvertent contact with

incompatible substances. When re-using containers, remove or obscure the old label after

cleaning the container and relabel. In particular, food containers must not be used for the

storage of solvents or chemicals.

4.6 Materials should be stored in appropriate containers. Broken glass and sharps must be held

in a labelled steel or heavy plastic bin (never cardboard). Rigid containers must be used in

preference to flimsy cardboard boxes or cartons.

4.7 Shelving must be secure and never overloaded. Ensure that freestanding shelves and

cupboards are secured to walls.

4.8 Materials must be stored in such a manner to avoid spillage, leakage, breakage or falls.

4.9 Stored items should be periodically reviewed to rationalize their storage and dispose of

obsolete items. Effective stock rotation should identify items that are deteriorating, or of no

use, or not required.

5.0 Emergency procedures

5.1 In the case of a:

Hazardous substance spillage, leakage, escape or exposure

- Follow the guidance on the Material Safety Data Sheets.

Major liquid escape

- Contain and avoid entry into drains where possible and safe to do so. If hazardous

substances are released follow departmental evacuation drill and notify the local council if

substance enters the drains.

Major gas escape

- Follow departmental evacuation drill, and warn those adjacent and downwind.

Fire

- Follow departmental evacuation drill.

You might also like

- Model Guidance For The Storage and Transport of TTSPPDocument4 pagesModel Guidance For The Storage and Transport of TTSPPSteven John SantiagoNo ratings yet

- 3-Laboratory Safety General GuidelinesDocument7 pages3-Laboratory Safety General GuidelinesAndrés PacompíaNo ratings yet

- Histo Histopath Safety ManualDocument14 pagesHisto Histopath Safety ManualJanielle Medina FajardoNo ratings yet

- Risk Management Laboratory Standard Operating ProceduresDocument10 pagesRisk Management Laboratory Standard Operating ProceduresaKureishiNo ratings yet

- Safety Precautions Inside The LaboratoryDocument5 pagesSafety Precautions Inside The LaboratoryDr. Navya Pakalapati100% (1)

- Health Safety ProceduresDocument5 pagesHealth Safety ProceduresneilypeelieNo ratings yet

- Standard Operating Procedure For Laboratory and Chemical SafetyDocument4 pagesStandard Operating Procedure For Laboratory and Chemical Safetyahmed alghrablyNo ratings yet

- Analytical Chemistry Laboratory GuideDocument9 pagesAnalytical Chemistry Laboratory GuideElprince MidoNo ratings yet

- Current Practices Being Used in Their Manufacturing ProcessDocument5 pagesCurrent Practices Being Used in Their Manufacturing ProcessjaredjoeNo ratings yet

- Edu560 Assignment SumeetDocument28 pagesEdu560 Assignment SumeetJoanne ToaniNo ratings yet

- Procedure Preservation SOP-011Document4 pagesProcedure Preservation SOP-011Justin Terry100% (1)

- Emergency Preparedness For Chemical SpillDocument2 pagesEmergency Preparedness For Chemical SpillRandy PedrozaNo ratings yet

- GMP Behavior RequirementsDocument5 pagesGMP Behavior RequirementsFrankMartinezNo ratings yet

- Safety in LaboratoryDocument11 pagesSafety in LaboratorybassamqabahaNo ratings yet

- Good Laboratory PracticesDocument19 pagesGood Laboratory PracticesVasant HiremathNo ratings yet

- CHEM 503 Lab Manual-2024Document85 pagesCHEM 503 Lab Manual-2024Hussain RazaNo ratings yet

- Storage & Handling of Dangerous GoodsDocument5 pagesStorage & Handling of Dangerous GoodsJonasNo ratings yet

- Lab Safety RulesDocument2 pagesLab Safety RulesAnonymous G2cXwwSNo ratings yet

- LAB SAFETY GUIDEDocument5 pagesLAB SAFETY GUIDEHafeez AliNo ratings yet

- Radiation Safety Lab RulesDocument1 pageRadiation Safety Lab Rulesmyco samNo ratings yet

- Laboratory Specific Training and Checklist To FollowDocument8 pagesLaboratory Specific Training and Checklist To FollowArabella LinganayNo ratings yet

- Practicing Occupational Safety and HealthDocument2 pagesPracticing Occupational Safety and HealthCyrelle Joy RemogatNo ratings yet

- Biosafety Level 1Document2 pagesBiosafety Level 1Bob MadewellNo ratings yet

- 1.7 Stacking and StorageDocument4 pages1.7 Stacking and StorageAnonymous iI88Lt100% (1)

- General Lab Safety ProcedureDocument16 pagesGeneral Lab Safety ProcedureMin ingNo ratings yet

- Purpose: Responsible Manager And/or Environmental Health and Safety Manager Is Responsible ForDocument2 pagesPurpose: Responsible Manager And/or Environmental Health and Safety Manager Is Responsible ForJamil ur rahmanNo ratings yet

- Special Safety Practices For CSL2Document1 pageSpecial Safety Practices For CSL2ipliprensNo ratings yet

- Lab Safety AgreementDocument13 pagesLab Safety AgreementwilliamsmarrenNo ratings yet

- Hygiene Code of PracticeDocument4 pagesHygiene Code of PracticeLouis ManaloNo ratings yet

- Good StorageDocument20 pagesGood Storageziaddd100% (1)

- Laboratory Safety ManualDocument23 pagesLaboratory Safety ManualVilas PadhiyarNo ratings yet

- GEOTECHNICAL LAB SAFETYDocument4 pagesGEOTECHNICAL LAB SAFETYWherlyne Lyka IslaNo ratings yet

- Chemical Handling SOP GuideDocument7 pagesChemical Handling SOP Guideibnu wicaksonoNo ratings yet

- Mayor, Royal and Pontifical University of San Francisco Xavier of ChuquisacaDocument4 pagesMayor, Royal and Pontifical University of San Francisco Xavier of ChuquisacaJuan José Tirado BalcasNo ratings yet

- Safety Briefing On Young Scientist at Pengerang LaboratoryDocument30 pagesSafety Briefing On Young Scientist at Pengerang Laboratorykingleoric90No ratings yet

- Safe Keep of Tools, Materials and Outfits Cleaning of Tools and EquipmentDocument2 pagesSafe Keep of Tools, Materials and Outfits Cleaning of Tools and EquipmentVan TotNo ratings yet

- SOP 5-Reactive Solids and LiquidsDocument4 pagesSOP 5-Reactive Solids and LiquidsGeorgeNo ratings yet

- Emergency Preparedness For Chemical SpillDocument2 pagesEmergency Preparedness For Chemical SpillRandy PedrozaNo ratings yet

- Laboratory Housekeeping 2009Document3 pagesLaboratory Housekeeping 2009Shanaka Paranahewage100% (1)

- CGMP Responsibilities Quality Control Head DepartmentDocument36 pagesCGMP Responsibilities Quality Control Head DepartmentAdelio MercadejasNo ratings yet

- House Keeping ProcedureDocument3 pagesHouse Keeping ProcedureREBAA HatemNo ratings yet

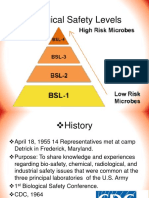

- Biological Safety Levels: Endia Ford Lori Gladney Izabella OsakweDocument34 pagesBiological Safety Levels: Endia Ford Lori Gladney Izabella OsakweSheerin Sulthana100% (1)

- Module 2lesson2. 2Document2 pagesModule 2lesson2. 2J MonicaNo ratings yet

- Science Laboratory ManualDocument8 pagesScience Laboratory ManualJedidiah ZonioNo ratings yet

- Housekeeping and Material Storage: NotesDocument8 pagesHousekeeping and Material Storage: NotesBry AsuncionNo ratings yet

- Laboratory Safety PracticesDocument20 pagesLaboratory Safety PracticesYuki SalemNo ratings yet

- Autoclaving SOPDocument4 pagesAutoclaving SOPXiang LiuNo ratings yet

- Annexure 2-2 Safety in Blasting:: 1. SupervisionDocument2 pagesAnnexure 2-2 Safety in Blasting:: 1. SupervisionManoj BishtNo ratings yet

- Mercury and Mercury Compounds-Contingency PlanDocument7 pagesMercury and Mercury Compounds-Contingency PlanNeil John Lequigan100% (4)

- Junt Lo5Document5 pagesJunt Lo5Ran CasamayorNo ratings yet

- تعليمات السلامة للمعاملDocument8 pagesتعليمات السلامة للمعاملFady EmadNo ratings yet

- تعليمات السلامة للمعاملDocument8 pagesتعليمات السلامة للمعاملFady EmadNo ratings yet

- Biosafety 2020Document37 pagesBiosafety 2020Sara Emad100% (1)

- Here Are The Safety Rules That Most Commonly Came Up in Our Look at Several LaboratoriesDocument4 pagesHere Are The Safety Rules That Most Commonly Came Up in Our Look at Several LaboratoriesLovely RingorNo ratings yet

- Guidance Chemical Storage PDFDocument22 pagesGuidance Chemical Storage PDFOula HatahetNo ratings yet

- PE Lab Safety Rules and Regulations PDFDocument2 pagesPE Lab Safety Rules and Regulations PDFAmira NabillaNo ratings yet

- Bio F3 New Curr NotesDocument380 pagesBio F3 New Curr NotesreunkosiNo ratings yet

- AE Lab Safety Rules SummaryDocument4 pagesAE Lab Safety Rules SummarycokavolitangoNo ratings yet

- Pt-592 Pharmacognosy-II Manual 18601919003Document129 pagesPt-592 Pharmacognosy-II Manual 18601919003KOUSHIK PAULNo ratings yet

- Living within planetary boundaries to save the environment (38Document3 pagesLiving within planetary boundaries to save the environment (38SarahNo ratings yet

- Wk12 Reading 1 - Sample Research AssignmentDocument3 pagesWk12 Reading 1 - Sample Research Assignmentsanjeet kumarNo ratings yet

- LNG501 Week 9 Task - CompulsoryDocument1 pageLNG501 Week 9 Task - CompulsorySarahNo ratings yet

- LN501 Blended Wk5 Lecture 1 - LD Edit (16!7!19)Document10 pagesLN501 Blended Wk5 Lecture 1 - LD Edit (16!7!19)SarahNo ratings yet

- Wk13 Activity 1Document1 pageWk13 Activity 1SarahNo ratings yet

- Wk12 Reading 2 - Sample Research Assignment - COMMENTSDocument3 pagesWk12 Reading 2 - Sample Research Assignment - COMMENTSsanjeet kumarNo ratings yet

- LN501 Blended wk4 Lecture 1 - LD Edit (16-7-19)Document19 pagesLN501 Blended wk4 Lecture 1 - LD Edit (16-7-19)SarahNo ratings yet

- WWT Week 6 Tutorial Solutions - SV - 2012001899Document3 pagesWWT Week 6 Tutorial Solutions - SV - 2012001899SarahNo ratings yet

- Lecture 1 - Timber DefectDocument47 pagesLecture 1 - Timber DefectSarahNo ratings yet

- Week 9 Tutorial - Timber PreservationDocument1 pageWeek 9 Tutorial - Timber PreservationSarahNo ratings yet

- Lecture 1 - Timber PreservationDocument23 pagesLecture 1 - Timber PreservationSarahNo ratings yet

- Lecture 2 - Week 3 - Hand ToolsDocument23 pagesLecture 2 - Week 3 - Hand ToolsSarahNo ratings yet

- Week 7 Tutorial Timber DefectsDocument1 pageWeek 7 Tutorial Timber DefectsSarahNo ratings yet

- Week 6 Tutorial Timber Seasoning - 2012001899Document6 pagesWeek 6 Tutorial Timber Seasoning - 2012001899SarahNo ratings yet

- Sample Cutting and Prepared List for Furniture PartsDocument1 pageSample Cutting and Prepared List for Furniture PartsSarahNo ratings yet

- Scan 24 - 04 - 2020-CompressedDocument6 pagesScan 24 - 04 - 2020-CompressedSarahNo ratings yet

- WWT552SEM Course Outline: Prepared By: Silivio Vueti (ALE, I/Arts)Document13 pagesWWT552SEM Course Outline: Prepared By: Silivio Vueti (ALE, I/Arts)SarahNo ratings yet

- Scan 1 - 05 - 2020 (1) - CompressedDocument3 pagesScan 1 - 05 - 2020 (1) - CompressedSarahNo ratings yet

- Atomic Structure: Mst554Sem - Materials ScienceDocument14 pagesAtomic Structure: Mst554Sem - Materials ScienceSarahNo ratings yet

- Timber Finishing TechniquesDocument21 pagesTimber Finishing TechniquesSarahNo ratings yet

- Atomic Bonding LectureDocument15 pagesAtomic Bonding LectureSarahNo ratings yet

- Cubic StructureDocument1 pageCubic StructureSarahNo ratings yet

- Over-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDDocument29 pagesOver-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDSarahNo ratings yet

- Measuring & MarkingDocument123 pagesMeasuring & MarkingWasif Ali SindhuNo ratings yet

- The Making of Iron & Steel PDFDocument50 pagesThe Making of Iron & Steel PDFalammasoodNo ratings yet

- Atomic Bonding LectureDocument15 pagesAtomic Bonding LectureSarahNo ratings yet

- Materials Through The Ages.Document7 pagesMaterials Through The Ages.SarahNo ratings yet

- Atomic Structure: Mst554Sem - Materials ScienceDocument14 pagesAtomic Structure: Mst554Sem - Materials ScienceSarahNo ratings yet

- Orthographic Projection ViewsDocument14 pagesOrthographic Projection ViewsSarahNo ratings yet

- General Hospital Philosophy and ObjectivesDocument26 pagesGeneral Hospital Philosophy and ObjectivesTanu GulatiNo ratings yet

- Persuasive Speech TextDocument2 pagesPersuasive Speech TextAnindya Azzahra0% (1)

- Radam, Sandralane C., Journal ReviewDocument3 pagesRadam, Sandralane C., Journal ReviewSandralane C. RadamNo ratings yet

- Guide To Patient Support and Regional Cancer ServicesDocument76 pagesGuide To Patient Support and Regional Cancer Servicesgiovanna2004No ratings yet

- Intrathecal MTX & Cytarabine & Hydrocortisone V4 2.15Document2 pagesIntrathecal MTX & Cytarabine & Hydrocortisone V4 2.15GabrielNo ratings yet

- Managing Painful Diabetic NeuropathyDocument26 pagesManaging Painful Diabetic NeuropathyAthalia TalawayNo ratings yet

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Solution Focused TherapyDocument8 pagesSolution Focused Therapyrimpa29No ratings yet

- Obamacare Ushers in New Era For The Healthcare IndustryDocument20 pagesObamacare Ushers in New Era For The Healthcare Industryvedran1980No ratings yet

- CV 2020Document3 pagesCV 2020api-519861494No ratings yet

- Affidavit of Accident Dominador Rosario BagamaspadDocument2 pagesAffidavit of Accident Dominador Rosario BagamaspadJaime GonzalesNo ratings yet

- Melidiosis FDocument24 pagesMelidiosis FVyramuthu AtputhanNo ratings yet

- A Study To Assess The Effectiveness of Hydrabadi Mix Ball On Nutritional Status Among Malnourished Under Five Year Children at Selected Anganwadi in Barabanki, Uttar PradeshDocument15 pagesA Study To Assess The Effectiveness of Hydrabadi Mix Ball On Nutritional Status Among Malnourished Under Five Year Children at Selected Anganwadi in Barabanki, Uttar PradeshEditor IJTSRDNo ratings yet

- Can Mindfulness in Health Care Professionals Improve Patient Care An Integrative Review and Proposed Model.Document15 pagesCan Mindfulness in Health Care Professionals Improve Patient Care An Integrative Review and Proposed Model.ALIXNo ratings yet

- Chapt01 The Sudy of ChangeDocument34 pagesChapt01 The Sudy of ChangeIkhsan Abdul HanifNo ratings yet

- Meat Inspection Certificate For Export of Pork/Pork Products To MalaysiaDocument2 pagesMeat Inspection Certificate For Export of Pork/Pork Products To MalaysiaLingSiewyingNo ratings yet

- Press Final - Abstract Book PDFDocument157 pagesPress Final - Abstract Book PDFAmbesh JhaNo ratings yet

- Narrative ReportDocument23 pagesNarrative ReportErnest Gerard Baiño Durano100% (2)

- Child Abuse Research JournalDocument9 pagesChild Abuse Research JournaladrianekattnerNo ratings yet

- Ecg 01Document103 pagesEcg 01Bandar al ghamdi100% (1)

- 2023 AHAR: PIT Estimates of Homelessness in The U.S.Document117 pages2023 AHAR: PIT Estimates of Homelessness in The U.S.Santiago Adolfo OspitalNo ratings yet

- Low Endotoxin Recovery (LER) in Drug Products - Original - 31428Document2 pagesLow Endotoxin Recovery (LER) in Drug Products - Original - 31428Putri DozanNo ratings yet

- Hum. Reprod.-1999-Tesarik-1318-23Document6 pagesHum. Reprod.-1999-Tesarik-1318-23Meilana Sapta DNo ratings yet

- 100 Item Exam On Fundamentals of Nursing - Pulse - Blood Pressure PDFDocument12 pages100 Item Exam On Fundamentals of Nursing - Pulse - Blood Pressure PDFJawad AkbarNo ratings yet

- Assist LetterDocument2 pagesAssist Lettertashy richardsNo ratings yet

- CUI Texto Examen Multimedia Nivel 6 Curso BasicoDocument2 pagesCUI Texto Examen Multimedia Nivel 6 Curso BasicobertoniramiroNo ratings yet

- Unit 1-Omd553-Telehealth TechnologyDocument53 pagesUnit 1-Omd553-Telehealth TechnologyjgjeslinNo ratings yet

- 50 Human Studies Identify High Risks of Prenatal Ultrasound - The Healthy Home EconomistDocument26 pages50 Human Studies Identify High Risks of Prenatal Ultrasound - The Healthy Home EconomistkromotNo ratings yet

- Taping Techniques: Moazzam Hussain Khan M.P.T. Sports Medicine New DelhiDocument38 pagesTaping Techniques: Moazzam Hussain Khan M.P.T. Sports Medicine New DelhiMeena SharmaNo ratings yet

- Synthesis 3 Jay VillasotoDocument6 pagesSynthesis 3 Jay VillasotoJay VillasotoNo ratings yet