Professional Documents

Culture Documents

239 PDF

Uploaded by

ChristianGuerreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

239 PDF

Uploaded by

ChristianGuerreroCopyright:

Available Formats

contents

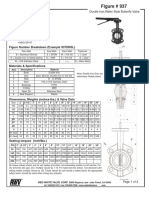

section 13 | level gauges and sight glasses 239

econ sight glasses

BSPP threaded ends

flat faced flanges to DIN PN 16

single window

cast iron body, threaded ends: fig. 625 1 )

bronze body, threaded ends: fig. 626 2 )

cast iron body, flanged ends: fig. 630 1 )

fig. 625 fig. 630 fig. 626

double window (see-through type) internally white internally white

brass/bronze body, threaded ends: fig. 628 2 ) enamelled enamelled

cast iron body, flanged ends: fig. 635 1 )

bronze body, flanged ends: fig. 636 1 )

1 ) standard with soda lime glass

2 ) standard with boro-silicate glass

fig. 628 fig. 635/636

/ ” to 1”: brass

1 2

11/ 4” to 2”: bronze

application: The small sizes are generally used to check the operation of the steam traps.

For checking the liquid flow in open systems as well as a possible discolouring of

liquids in open and closed systems (such as lubricating oil).

pressure/temperature rating: fig. 626 and 628 : 6 bar - 20 °C | 3.5 bar - 150 °C

fig. 625, 630 and 635 : 10 bar - 120 °C | 8 bar - 200 °C

fig. 636 : 16 bar - 120 °C | 13 bar - 200 °C

materials: cast iron - GG-25 (Ws.no. 0.6025)

bronze - G-CuSn5ZnPb (Ws.no. 2.1096.01)

brass - CuZn39Pb3 (Ws.no. 2.0401)

on request: ● in stead of soda lime glasses we can supply boro-silicate glasses; these have a

better resistance against erosion and corrosion.

● all of carbon steel with flanges, pressure class PN 10 - 16 - 25 and 40: fig. 1621

● all of stainless steel

dimensions (mm): DN 15 20 25 32 40 50 65 80 100 125 150

1 3

d /2” / 4” 1” 11/ 4” 1 1/2” 2”

fig. 625 L 130 130 135 175 185 210 – – – – –

fig. 626 L 90 90 90 – – – – – – – –

fig. 628 L 89 90 90 108 108 114 – – – – –

fig. 630 A 95 105 115 140 150 165 185 200 220 – –

L 130 150 160 180 200 230 270 290 300 – –

fig. 635/636 A 95 105 115 140 150 165 185 200 220 250 285

L 140 140 150 165 185 185 230 240 305 310 410

fig. 625 1.7 1.7 2.2 3.2 4.2 6.2 – – – – –

fig. 630 wt 2.4 3 4.4 5.8 7 11 15 17.5 24.8 – –

fig. 635 (kg) 3.4 3.9 4.1 5.5 7.2 8.1 14 17 21 35 54

fig. 625/626/628 fig. 630/635/636 fig. 636 3.6 4.2 4.9 6.1 8.2 9.3 16 18 23 38 58

You might also like

- How To Make An Atomic BombDocument30 pagesHow To Make An Atomic Bombarjun vijay100% (3)

- Standard Hook Details: in Accordance With ACI 318 Building CodeDocument2 pagesStandard Hook Details: in Accordance With ACI 318 Building CodeEric Gardner100% (1)

- Electrolysis ProcessesDocument180 pagesElectrolysis ProcessesEngineering Office Shahrak100% (1)

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFRhio CruzNo ratings yet

- Mts Floating ValvesDocument1 pageMts Floating ValvesAndersson Benito HerreraNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFIsmael PerezNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Astm A692 PDFDocument2 pagesAstm A692 PDFgaminNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFmaeNo ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- Wrought Ironwork: A Manual of Instruction for CraftsmenFrom EverandWrought Ironwork: A Manual of Instruction for CraftsmenRating: 5 out of 5 stars5/5 (1)

- Taifeng Catalogue and Price Lists (0104)Document46 pagesTaifeng Catalogue and Price Lists (0104)Hazim HaNo ratings yet

- Elements and Compounds PowerPointDocument19 pagesElements and Compounds PowerPointRelayer 66No ratings yet

- Clarus500 580UserGuideDocument442 pagesClarus500 580UserGuideSelvaraj VenkatesanNo ratings yet

- AbrivationsDocument1 pageAbrivationsArkhan KhanNo ratings yet

- WP PH Control in Crude Desalting e LR HCProcessingDocument5 pagesWP PH Control in Crude Desalting e LR HCProcessingmdeffanNo ratings yet

- Econ Sight Glasses With Indicator: Valves & FittingsDocument1 pageEcon Sight Glasses With Indicator: Valves & FittingsChristianGuerreroNo ratings yet

- Fig. 292 ® Gate Valve: Also Available in PN16Document2 pagesFig. 292 ® Gate Valve: Also Available in PN16TamNo ratings yet

- Installation Components: TubingDocument31 pagesInstallation Components: TubingZahir KhiraNo ratings yet

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocument2 pagesWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNo ratings yet

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNo ratings yet

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01No ratings yet

- Carbone 2191 ISO Graphite Spec SheetDocument6 pagesCarbone 2191 ISO Graphite Spec Sheetmichaelstarr1969No ratings yet

- Features: Water WaterDocument1 pageFeatures: Water WaterajsdlkasjdklNo ratings yet

- Check Swing Cast Steel A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 150: Pressure Temperature Ratingsbreyca4 bcrNo ratings yet

- Flanges - Composite Type: See Larger ImageDocument18 pagesFlanges - Composite Type: See Larger Imagemishaqazhar824No ratings yet

- 4403 2 PDFDocument24 pages4403 2 PDFAnonymous PIqdeNp8No ratings yet

- Globe: ValvesDocument2 pagesGlobe: ValvesMASOUDNo ratings yet

- Avk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Document3 pagesAvk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Ariane Joy LucasNo ratings yet

- Datasheet - Uk Sigma Pimp KDocument7 pagesDatasheet - Uk Sigma Pimp KAlejandroNo ratings yet

- A New Era In: Filtration Performance and InnovationDocument6 pagesA New Era In: Filtration Performance and InnovationCARLOS SARMIENTONo ratings yet

- Mueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver2Document2 pagesMueller Flanged End Simplex Basket Strainer Models 125F CI 125F B Spec Sheet Ver21819 Roy GordonNo ratings yet

- F58 CraneDocument1 pageF58 CraneMarco DiazNo ratings yet

- Standars Size&Fitting DimensionsDocument19 pagesStandars Size&Fitting DimensionsTran Anh TuanNo ratings yet

- 937 - Válvula Mariposa (Bridada)Document2 pages937 - Válvula Mariposa (Bridada)Rafael SalazarNo ratings yet

- Ficha Tecnica Valvula de Globo Rex PDFDocument2 pagesFicha Tecnica Valvula de Globo Rex PDFCCASELLANo ratings yet

- Stag en MainDocument8 pagesStag en MainFederico AlarconNo ratings yet

- Performance Curve Notes: Viking Universal Seal PumpsDocument2 pagesPerformance Curve Notes: Viking Universal Seal PumpsErick GoyesNo ratings yet

- Ae Pillar HydrantDocument1 pageAe Pillar HydrantRaton121 RahmanNo ratings yet

- r200 CatalogoDocument2 pagesr200 CatalogoEu_einNo ratings yet

- K-823-A, SCVDocument1 pageK-823-A, SCVamir shokrNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFJose R Birmighan S100% (1)

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMMisael AlejandroNo ratings yet

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMSatyajit GhateNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFJulio Eder LopezNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFKhris SamejonNo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFIshmael WoolooNo ratings yet

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMAnonymous ANo ratings yet

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFOrcha Dan ArcamoNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- PAK AMIN PARAMETRIkDocument525 pagesPAK AMIN PARAMETRIkandratheshithandNo ratings yet

- 05263G Sample ChapterDocument1 page05263G Sample ChapterBambangIrawan48No ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- SERIES 4380: Vertical In-Line Pumps Closed-CoupledDocument4 pagesSERIES 4380: Vertical In-Line Pumps Closed-CoupledsuhasNo ratings yet

- POSCO Korea - Galvanized SheetDocument27 pagesPOSCO Korea - Galvanized SheetFrancis BoeyNo ratings yet

- U.S. Tsubaki Bs/Din Roller ChainDocument6 pagesU.S. Tsubaki Bs/Din Roller ChainAnandhi ChidambaramNo ratings yet

- FlowBiz 3 Piece Design Metal Seated Ball Valve 150Document2 pagesFlowBiz 3 Piece Design Metal Seated Ball Valve 150Shakir AnsariNo ratings yet

- Check Swing Cast Steel A216 WCB Class 300 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 300 Mod. XXXXX: Pressure Temperature RatingsTania Milagros Mego JimenezNo ratings yet

- Gjs GGG AstmDocument17 pagesGjs GGG AstmmakmuntohirNo ratings yet

- Y-Strainer PDFDocument2 pagesY-Strainer PDFShoaib AhmedNo ratings yet

- Figure # 204A: Product FeaturesDocument1 pageFigure # 204A: Product FeaturesEsteban CastellanoNo ratings yet

- Cast Steel Y-Strainer - Ansi Class 300: YS-2-B.REV.ADocument1 pageCast Steel Y-Strainer - Ansi Class 300: YS-2-B.REV.AFery FebryantoNo ratings yet

- Felker LineCard-WebView 100319Document4 pagesFelker LineCard-WebView 100319vineethNo ratings yet

- R/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01NagLakshmananNo ratings yet

- General CalculationsDocument6 pagesGeneral CalculationsGanesh GawdeNo ratings yet

- Econ Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300Document1 pageEcon Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300ChristianGuerreroNo ratings yet

- Econ Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800Document1 pageEcon Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800ChristianGuerrero0% (1)

- BAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800Document1 pageBAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800ChristianGuerreroNo ratings yet

- Econ Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimDocument1 pageEcon Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimChristianGuerreroNo ratings yet

- Econ Check Valves Tilting Disc Type ANSI Class 150: ApplicationDocument1 pageEcon Check Valves Tilting Disc Type ANSI Class 150: ApplicationChristianGuerreroNo ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Econ Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339Document1 pageEcon Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339ChristianGuerreroNo ratings yet

- Econ Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800Document1 pageEcon Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800ChristianGuerrero0% (1)

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Econ Gate Valves Bronze Union Bonnet NPT Threaded Ends: Pressure/temperature RatingDocument1 pageEcon Gate Valves Bronze Union Bonnet NPT Threaded Ends: Pressure/temperature RatingChristianGuerreroNo ratings yet

- Flange Dimensions and Drilling To JIS B 2210 (1984)Document1 pageFlange Dimensions and Drilling To JIS B 2210 (1984)ChristianGuerreroNo ratings yet

- Econ Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300Document1 pageEcon Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300ChristianGuerreroNo ratings yet

- Econ Gate Valves Forged Steel Stainless Steel Trim ANSI Class 800Document1 pageEcon Gate Valves Forged Steel Stainless Steel Trim ANSI Class 800ChristianGuerreroNo ratings yet

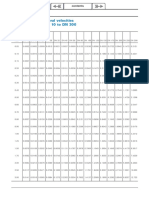

- Flow of Water at Several Velocities Through Pipelines DN 10 To DN 300Document1 pageFlow of Water at Several Velocities Through Pipelines DN 10 To DN 300ChristianGuerreroNo ratings yet

- 248 PDFDocument1 page248 PDFChristianGuerreroNo ratings yet

- Econ Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingDocument1 pageEcon Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingChristianGuerreroNo ratings yet

- Linear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)Document1 pageLinear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)ChristianGuerreroNo ratings yet

- Temperature Conversion Table Degrees Centigrades - FahrenheitDocument1 pageTemperature Conversion Table Degrees Centigrades - FahrenheitChristianGuerreroNo ratings yet

- 367Document1 page367ChristianGuerreroNo ratings yet

- Sizing of Pipelines For Saturated Steam: Section 21 Technical DataDocument1 pageSizing of Pipelines For Saturated Steam: Section 21 Technical DataChristianGuerreroNo ratings yet

- 376 PDFDocument1 page376 PDFChristianGuerreroNo ratings yet

- ANSI Flange DimensionsDocument1 pageANSI Flange DimensionsFabio GoncalvesNo ratings yet

- 366 PDFDocument1 page366 PDFChristianGuerreroNo ratings yet

- 374Document1 page374ChristianGuerreroNo ratings yet

- Flange Dimensions and Drilling To DIN 2501: Section 21 Technical DataDocument1 pageFlange Dimensions and Drilling To DIN 2501: Section 21 Technical DataChristianGuerreroNo ratings yet

- Steam Table For Saturated Steam: (Continued)Document1 pageSteam Table For Saturated Steam: (Continued)ChristianGuerreroNo ratings yet

- 367Document1 page367ChristianGuerreroNo ratings yet

- Dimond Structural Systems Manual Aug2016Document272 pagesDimond Structural Systems Manual Aug2016Erwin Mars UyNo ratings yet

- 0708 0369Document27 pages0708 0369iledinamo1No ratings yet

- Electrolysis O LevelDocument17 pagesElectrolysis O LevelInnocent EbilNo ratings yet

- © Ncert Not To Be Republished: Hemical QuilibriumDocument7 pages© Ncert Not To Be Republished: Hemical QuilibriumSoumik MukhopadhyayNo ratings yet

- Biofoam: Dosage Rate Application InformationDocument2 pagesBiofoam: Dosage Rate Application InformationDhilNo ratings yet

- PS-08 Painting System MSDSDocument20 pagesPS-08 Painting System MSDSGiorgi KOGOSHVILINo ratings yet

- Dicti of Phy and ElectronicsDocument1,357 pagesDicti of Phy and Electronicsrahul106No ratings yet

- European Cat 08 2009-10Document92 pagesEuropean Cat 08 2009-10sitiodossitesNo ratings yet

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Document10 pagesSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqNo ratings yet

- 6th SEM - Sep-22Document4 pages6th SEM - Sep-22Jay RanjanNo ratings yet

- Food Che. W1-4Document177 pagesFood Che. W1-4mihael jhnsNo ratings yet

- Safety Analysis For The Production of MethanolDocument14 pagesSafety Analysis For The Production of MethanolTauseef Aamere RoseNo ratings yet

- Effect of Irrigation and Stainless Steel Drills On Dental Implant Bed Heat GenerationDocument10 pagesEffect of Irrigation and Stainless Steel Drills On Dental Implant Bed Heat GenerationIsabel XochihuaNo ratings yet

- Green Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlDocument25 pagesGreen Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlteguhwidiartoNo ratings yet

- Chinook-Services-Wellsite GeologyDocument6 pagesChinook-Services-Wellsite Geologyincharge geologistNo ratings yet

- Crude Oil Desalter and Electrostatic Dehydrator MarketDocument7 pagesCrude Oil Desalter and Electrostatic Dehydrator MarketAnonymous bHh1L1No ratings yet

- Opportunities and Limits of 2k Injection MouldingDocument22 pagesOpportunities and Limits of 2k Injection Mouldingsa_arunkumarNo ratings yet

- KIMO HQ210 BrochureDocument4 pagesKIMO HQ210 BrochurebolsjhevikNo ratings yet

- An 31.2 Care and Maintenance of Hot Dip GalvanizingDocument4 pagesAn 31.2 Care and Maintenance of Hot Dip GalvanizingnarmathaNo ratings yet

- Centigrade Fahrenheit Equivalent Cone Heated at 150C/hr Visual Colour NotesDocument1 pageCentigrade Fahrenheit Equivalent Cone Heated at 150C/hr Visual Colour NotesGogu7778 Gogu7778No ratings yet

- CHM-101 Chapter 1Document23 pagesCHM-101 Chapter 1razan136No ratings yet

- Evs MCQDocument8 pagesEvs MCQraj kundraNo ratings yet

- USP-NF Atorvastatin CalciumDocument8 pagesUSP-NF Atorvastatin CalciumPhạm Đức LộcNo ratings yet

- Butadine Extraction Unit: FC LC TIDocument1 pageButadine Extraction Unit: FC LC TIAtwadin SatriadaniNo ratings yet

- Pre-Lab 8Document1 pagePre-Lab 8SaulS.DiazNo ratings yet

- RAC Assignments 24062016 091508AMDocument37 pagesRAC Assignments 24062016 091508AMsakalidhasavasanNo ratings yet