Professional Documents

Culture Documents

Title Page: Modeling & Load Rating of Two Bridges Designed With AASHTO and Florida I-Beam Girders

Uploaded by

عبدالوهاب بركاتOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Title Page: Modeling & Load Rating of Two Bridges Designed With AASHTO and Florida I-Beam Girders

Uploaded by

عبدالوهاب بركاتCopyright:

Available Formats

Catbas, Darwash, Fadul 1/13

1 Title Page:

2

3 Modeling & Load Rating of Two Bridges Designed with

4 AASHTO and Florida I-Beam Girders

5

6 F.N. Catbas, H. Darwash and M. Fadul

7

8

9 Dr. F. Necati Catbas, P.E.

10 Associate Professor & Associate Chair

11 Civil and Environmental Engineering Department

12 University of Central Florida, Orlando, FL 32816

13 Phone: 407-823-3743; Fax: 407-823-3315 ; e-mail: catbas@ucf.edu

14 (corresponding author)

15

16 Mr. Haider Darwash

17 Ph.D. Student and Research Assistant

18 Civil and Environmental Engineering Department

19 University of Central Florida, Orlando, FL 32816

20 Phone: 407-823-4122; Fax: 407-823-4553

21

22 Ms. Manar Fadul

23 Ph.D. Student and Research Assistant

24 Civil and Environmental Engineering Department

25 University of Central Florida, Orlando, FL 32816

26 Phone: 407-823-4122; Fax: 407-823-4553

27

28

29

30

31

32

33

34 Word Count:

35 Abstract, Manuscript & References = 3,743

36 Figures and Tables (8+3) = 2,750

37 TOTAL = 6,493

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 2/13

1 ABSTRACT

2 Florida I-Beam (FIB) girders provide a number of advantages such as higher load

3 carrying capacity, more efficient fabrication, safer construction, increased lateral stiffness, larger

4 vertical clearance and reduction in the overall cost of bridges. A comparative study incorporating

5 two bridges, one with AASHTO Type III and the other with new Florida I-Beam (FIB) girders is

6 presented. The first bridge is a 3 span bridge designed with 6 AASHTO Type III girders. The

7 second bridge has the same length, width and girder depth; however, it has 4 FIB girders. Both

8 bridges are analyzed using the conventional AASHTO LRFD girder line analysis method and

9 also with a more sophisticated finite element method using a commercial software. The details of

10 the FE model are also presented with the critical considerations of link elements, boundary

11 conditions, pre-stressing tendons. Based on the FE model results, it is shown that it is possible to

12 expect 20% higher live load capacity for interior girders and 40% higher live load capacity for

13 exterior girders using FIB-45 girders compared to AASHTO Type III girders, while also

14 reducing the cost by about 24%.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 3/13

1 INTRODUCTION

2 Concrete bridges are commonly used in the US. Initially, short and single span bridge

3 superstructures were designed and constructed using concrete girders until the middle of the 20th

4 century when the pre-stressed bridge girders gained more acceptance and longer spans with pre-

5 stressed concrete bridges increased dramatically. Today, almost 50% of all the new bridges built

6 in the US are pre-stressed concrete bridges [1]. Prestressed concrete bridges are considered due

7 to their high strength and durability. Pre-stressed concrete girders perform well for longer spans

8 by the application of a tensile force to reinforcing tendons. This application increases the internal

9 compression in the concrete beam where the tension is anticipated under the given loading

10 conditions. The pre-stressing force can be applied before the concrete is poured (beam is

11 pretensioned) or after the concrete is cured (beam is post-tensioned). There are a number of

12 different pre-stressed concrete girders with a variety of cross-sectional geometries and strands for

13 a required span length and loading. AASHTO I-beams and bulb T-beams have been employed

14 by a many Departments of Transportation as concrete bridge girders.

15 While the AASHTO I-beam and Bulb T-beam girders are commonly used in the state of

16 Florida, Florida Department of Transportation (FDOT), in collaboration with Prof. M. Tadros,

17 developed a new prestressed beam called the Florida I-beam (FIB) to replace these beams in

18 order to enhance the efficiency, to provide a larger vertical clearance and to reduce the overall

19 cost of bridges. FIBs are designed to have higher load carrying capacity, more efficient

20 fabrication, safer construction, increased lateral stiffness because of thicker top and bottom

21 flanges. In addition, FIBs are more economical in comparison to the prestressed beams that are

22 currently being used [2,3]. FIBs are designed to have high concrete strength, ranging from 8 to

23 10 ksi, and a large bottom flange compared to the traditional AASHTO and Bulb T-beams, to

24 allow a larger space for more prestressing strands that are usually needed in longer span girders

25 or wider girder spacing. The enhanced design of FIBs is expected to allow bridge designers to

26 reduce the number of beams needed and to reduce the bridge cost. FIBs have improved stability

27 during handling, storage and erection than the other prestressed beams due to a significantly

28 wider bottom flange and low center of gravity. One of the advantages is that FIBs with shallower

29 depth may be used in place of their deeper AASHTO equivalents. This in turn provides a larger

30 vertical clearance that has been a concern for many bridges. In addition, FIBs have identical top

31 and bottom flange shapes for their full range of standard sizes, and since the only varied

32 dimension between FIB standard sizes is the height of the web. The option of using adjustable

33 height forms during fabrication process of all FIB standard sizes is applicable for ease of

34 manufacturing. FIBs can accommodate the largest number of prestressing strands in the USA (up

35 to 72 – 0.6 in diameter strands). Based on the development and progressive studies of FDOT on

36 FIBs, the FDOT developed design bulletins for designers and manufacturers. As a result, FDOT

37 recommended FIBs to be used in all new bridges and bridge widening designs where applicable,

38 while AASHTO beams and Bulb T-beams will no longer be used for any new design [2].

39 Objectives and Scope of the Paper

40 FDOT prepared a comparative design of AASHTO Type III beam, which can span

41 approximately 90 feet (6 beams with a depth of 45” and spacing of 7’-6”) with a FIB 45” (4

42 beams with a depth of 45” and a spacing of 11’-9”) which can accomplish the same span by

43 reducing the number of girders. The bridge sections under investigation were used in a

44 comparative cost analysis in the FDOT design bulletin. It was found that estimated savings by

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 4/13

1 using four FIB girders for this specific structure is about 24% of the original cost when

2 AASHTO type III girders are used instead [2,3]. This saving increases when the number of

3 required girders of the bridge increases. Such cost reduction has a significant effect on the

4 overall cost of bridges given that the large number of bridges that are built in Florida state each

5 year.

6 In the study presented in this paper, the structural responses and the load rating factors of

7 these two bridges are presented along with the cost saving information given in the FDOT design

8 bulletin. The first bridge has six AASHTO type III girders (Figure 1) and the second bridge with

9 the same general geometry and load-carrying characteristics has four FIBs (Figure 2). Both of

10 these bridges are analyzed using the standard AASHTO LRFD girder line analysis as well as

11 using finite element (FE) analysis with a commercial software. The critical details for the

12 appropriate FE modeling of the prestressed sections are presented with the necessary

13 assumptions made for this study. The flexural responses and load rating factors from these

14 analyses are presented in a comparative fashion.

15

16 Figure 1: AASHTO Type III Bridge

17

18

19 Figure 2: Florida I-Beam (FIB) 45 Bridge

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 5/13

1 DESCRIPTION OF THE TWO BRIDGES

2 The bridges, which are studied in this paper, consist of three simply supported spans

3 made up of pre-stressed girders. Each span is 90-ft long and supported by a 41.5- ft long beam

4 cap and this beam cap is supported by three circular columns. The 43’-1” wide cross section is

5 the same for both bridges as shown in Figure 1 and Figure 2. Only two 12’-0” lanes are

6 considered to be loaded with an additional 10’-0” emergency lane and another 6’-0” pedestrian

7 lane. Both types of girders are 45 in. deep, the first being AASHTO Type III girders, and the

8 second being Florida I-beams. The FIB bridge utilizes four 45-in. I-beams spaced at 11’-9”.

9 Each FIB contains 42- 0.6 in low-relaxation strands (Figure 3). The AASHTO cross section

10 contains six girders spaced at 7’-6” in each with 26-0.6 in low-relaxation prestressing strands

11 (Figure 4). The deck is 8” thick and topped with a 3” bituminous wearing surface, and has end

12 barriers that are 1 ft-6 ½ in. wide. The pretensioned girders have a 2” thick haunched beam in

13 order to control the camber. The prestressing strands are assumed to be straight with eccentricity

14 equal to 11.65 in for AASHTO bridge and 15.08 in for FIB bridge. These eccentricities are

15 computed by the AASHTO LRFD calculation method and all stresses are checked with the

16 allowable stresses. In addition, the moment capacity is also checked to be within the allowable

17 capacity range. The concrete strength is 8.5 ksi concrete (6 ksi at release) and the ultimate tendon

18 strength is taken as 270 Ksi.

19

20

21

22 Figure 3: Florida I-Beam (FIB) Typical Cross-Section

23

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 6/13

1

2 Figure 4: AASHTO Type III Girder

3

4 A generalized cost calculation for these two bridges (one with AASHTO Type III Girder,

5 and other with FIB-45) are provided in the FDOT Design Bulletin C09-01 [2] as follows:

6

7 3 Span Bridge with 6 AASHTO Type III Beams:

8 Total Linear Foot = (90 ft long beams) x (3 spans) x (6 beams per span) = 1620 LF

9 Approximate Cost = (1620 LF) x ($185 /LF) = $299,700

10

11 3 Span Bridge with 4 Florida I-Beams (FIB-45):

12 Total Linear Foot = (90 ft long beams) x (3 spans) x (4 beams per span) = 1080 LF

13 Approximate Cost = (1080 LF) x ($210 /LF) = $226,800

14

15 Estimated Savings = 24% = ($299,700-$226,800)/$299,700

16

17 It is noted that costs per linear foot were determined using price estimates from

18 manufacturers and contractors. The values above include only bridge items affected by differing

19 beam types. These items include beam fabrication, beam placement, placed bearing pads, placed

20 diaphragms, placed stay-in-place forms and deck rebar seats [2]. While the total cost can vary

21 based on many other factors, this calculation provides a reasonably accurate comparison.

22 MODELING AND ANALYSIS OF THE BRIDGES

23 AASHTO Girderline Analysis and Calculations

24 As part of the comparative analysis for the structural responses, the AASHTO methods

25 are utilized as engineers commonly, and in fact, this approach can be used as the first approach

26 in many cases even before detailed modeling methods such as FEMs. In this paper, the authors

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 7/13

1 also conduct calculations and provide results according to the AASHTO LRFD Bridge Design

2 Specifications [4]. The same loading considerations and assumptions are employed for the

3 analysis of the bridges, which are designed to carry interstate traffic in Florida. The AASHTO

4 and FIB girder sections are evaluated for HL-93 Design Truck and Design Lane Loads. A

5 dynamic load allowance of 33% is considered, distribution and load rating factors for moment

6 are calculated according to the AASHTO Guide. Strength I and Service I limit states are

7 considered. The load effects, load rating, and the distribution factors results are all shown later in

8 Tables 2, 3 and 4, respectively.

9 Overview of the Full Finite Element Model

10 FE Modeling of pre-stressed girder structures has been shown on a number of studies. In

11 one such study, the author and his colleagues presented pre-stressed and post-tensioned monorail

12 guideway structures by accurately modeling using a FE package for load rating and reliability

13 analyses [7,8]. In this current paper, AASHTO Type III and FIB girder bridges are modeled

14 using a commercial FE package (CSiBridge) specifically developed for bridge analysis and

15 design [10,11]. The two lane loaded case is assumed according to the previous study by the

16 FDOT bulletin. Slab thickness is taken as 8 in with 2 in haunch and 3 in bitumen wearing.

17 Compressive strength of 4 ksi is used for the regular concrete, which is used for the deck, the

18 columns, and the beam cap. For the precast girders, 8.5 ksi (6 ksi at release) compressive

19 strength is used. Cross diaphragms with 19 in depth and 12 in width also used every one third

20 points of each span with no cross diaphragms at the abutments. Further list of the assumptions

21 considered for the finite elements models can be seen in Table 1.

22

23 Table 1: List of Parameters and Assumptions

Value

Barrier load 0.32 kips/ft length

Wearing load 0.035 kip/ft2

Column dimension 3 circular column 4.5ft dia. (20 - #8 grade 60 steel)

Beam Cab dimension Depth (56 in), width (60 in)

Prestress steel 0.6 in low relaxation strands

fpu 270 ksi

Diaphragm Dimensions Depth (19 in), Width (12 in)

Jacking force 0.7 𝑓!"

24 Modeling of Deck and Girders

25 Shell elements with three degrees of freedom are chosen to model the deck section.

26 Frame elements are used to model the precast pretension girders, the columns, and the beam cap.

27 For the AASHTO type III Bridge, 18 precast pre-tensioned AASHTO type III girders are defined

28 with one hundred and fifty six tendons for the entire length of the bridge. For the FIB Bridge, 12

29 45” deep precast FIB girders are defined with one hundred and sixty eight tendons. Each bridge

30 has three piers with 41.5 ft long beam cap. The pier and the abutment foundations are assumed to

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 8/13

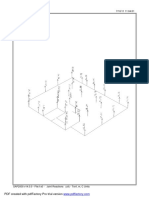

1 be fixed for both bridges. Figure 5 and Figure 6 show the finite elements model of AASHTO

2 type III bridge and FIB bridge, respectively with model characteristics and model statistics.

3

4

5 Figure 5: The FE Model of the Bridge with AASHTO Type III Girders

6

7 Figure 6: The FE Model of the Bridge with Florida I-Beams

8

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 9/13

1 Modeling of the Link Elements

2 The concrete deck and girder connection is a critical detail to be modeled properly for the

3 effective utilization of the composite connection. As a result, rigid links are used to represent the

4 connection between the girders and the deck. The same type of link is used to model the columns

5 and the beam cap connection. Abutment bearings links (link elements) are used to model the

6 abutments by fixing the vertical and transverse translation of the abutment bearings. All other

7 abutment bearing components are modeled as free since the abutment restraint is assumed to be

8 free in the longitudinal direction. Bent bearings links (link elements) are used to model the

9 bearing plates and the connection between the girders and the beam cap by fixing all the

10 translations of the bent bearings. All the other bent bearing components are defined as free,

11 including the rotation along the layout line. To help visualize the abutment geometry, the

12 drawing shown in Figure 7 illustrates the location of the abutment bearings and the substructure.

13 It also shows the location of the action point, which is the location where the bearing will

14 translate or rotate depending on the bearing definitions.

15

16

17 Figure 7: FE Modeling of the Links

18 Modeling of the Tendons

19 Eighteen precast girders are defined in the FE model of the AASHTO type III bridge.

20 Each girder has 26 0.6 in low relaxation pre-tensioned strands. On the other hand, twelve precast

21 girders are defined in the FE model of the FIB bridge. Each girder has 42 0.6 in low relaxation

22 pre-tensioned strands. Pre-tensioned tendons are modeled as separate elements with 44 kips force

23 embedded in the precast girders to satisfy the design criteria, strength limit state check and for

24 checking the tendon stresses. Because the CSiBridge FEM software provides only bonded post-

25 tension tendons, the bonded pre-tensioning tendons are modeled by jacking the post-tensioned

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 10/13

1 tendons from both sides and specifying zero value for the curvature loss coefficient, wobble loss

2 coefficient, and anchorage slip loss coefficient. Figure 8 shows the distribution of the tendons in

3 AASHTO type III beams and Florida I-Beams.

4

5

6 Figure 8: Distribution of the Tendons in AASHTO Type III Beams and Florida I-Beams

7

8 DISTRIBUTION FACTORS AND LOAD RATING

9 Movable Bridge Load Rating

10 After the completion of the FE model and the simple girder line model, the load rating

11 factors of the bridges are computed. Load rating of the bridges is calculated following the

12 AASHTO Guide [5]. The load factors rating procedure is commonly used in identifying the live

13 load carrying capacity of bridges. Bending moment capacity of the bridges under investigation

14 is calculated at the critical position of HL-93 (with design truck and lane load) following the

15 AASHTO Guide. Since each span is considered as a simply supported, the locations of

16 maximum live and dead load moments are located at the midspan section.

17 The load rating can be expressed as the factor of the critical live load effect to the

18 available capacity for a certain limit state. The general formula for the rating factor is [5];

C − γ DC DC − γ DW DW ± γ p P

19 RF = (1)

γ L LL (1 + IM )

20 where C is the factored load carrying capacity, DC is the dead load of structural

21 components, DW is the dead load of the wearing surface, P is a dead load concentrated at a

22 single point, LL is the live load effect, IM is the impact factor, and γ’s are the load factors. The

23 calculated load ratings for the critical locations are presented in the following sections.

24 The load factors values depend on the type of load rating, i.e. inventory or operating load

25 rating. The load rating for the girder is calculated at the critical section, located at the midspan.

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 11/13

1 The section moment capacity is calculated for both AASHTO and FIB sections and for the

2 exterior and the interior girders as well. The calculated moment capacity, the moments at the

3 critical section due to live and dead load, and also the load rating factors are all presented in

4 Table 2 and Table 3.

5

6 Table 2: Moment Values Obtained from the FEM and AASHTO LRFD Analyses

FIB Girder

AASHTO Type III Girder

Ext. Girder Int. Girder Ext. Girder Int. Girder

(K.ft) (K.ft) (K.ft) (K.ft)

Moment Values

AASHTO 5587 5624 8707 8770

Section Capacity

LRFD results 1812 1851 2552 2704

(Girderline Max. D.L

Analysis) 1750 1537 2285 2217

Max. L.L

4659 4715 8229 8320

Section Capacity

FEM results 1672 1716 2484 2762

Max. D.L

902 970 1281 1538

Max. L.L

7

8 Table 2 indicates that the values of the calculated section capacity and the dead load

9 using LRFD method are close to their corresponding values calculated using FEM. The

10 difference in the dead load values is about 4% on the average. However, the live load values

11 show a significant difference and it is about 40% when the AASHTO LRDF and FEM results are

12 compared. This difference (reduction in LL moments in FEM) can be attributed to better load

13 distribution by means of FE software that represents all the elements of the bridge. When the

14 results of the AASHTO and FIB girder bridges are compared, the FIB has much higher load

15 carrying capacity even though the dead and live load responses are higher for the FIB. Table 3

16 presents the load rating factors obtained using the capacity and demand calculations presented

17 previously. The results given in Table 3 imply that AASHTO LRFD girderline analysis

18 underestimate the load rating and provides lower load rating factors than those obtained using FE

19 model. The ratios of load rating factors (FEM/girderline) for all types of girders variy between

20 1.22 to 1.65, meaning a 22% to 65% more live load carrying possibility. It should also be noted

21 that the girderline method underestimates the load rating factors of the FIB girder bridge more

22 than AASHTO Type III girder bridge.

23 A more significant observation is that the bridge with FIB girders has higher load rating

24 factors than the bridge with AASHTO type III girder regardless of the AASHTO LRFD

25 Girderline analysis or FE analysis. When the two bridges are considered, the exterior and

26 interior girders have 17% and 13%, respectively, more live load capacity using AASHTO

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 12/13

1 girderline analysis. When the two bridges are compared using the FE model results, the exterior

2 and interior girders have 41% and 20% more live load capacity, respectively.

3

4 Table 3: Load Rating of the Bridges Using FEM and AASHTO LRFD

FIB Girder

AASHTO Type III Girder

Load Rating

Int. Girder

Ext. Girder Int. Girder Ext. Girder

AASHTO Inventory 1.36

1.07 1.20 1.36

LRFD results

Operating

(Girderline

1.76

Analysis) 1.50 1.56 1.76

Inventory 1.77

1.59 1.47 2.25

FEM results

Operating 2.30

2.06 1.91 2.91

5

6 SUMMARY AND CONCLUSIONS

7 Florida I-Beam (FIB) bridges were developed to be the choice for girder type for new

8 designs in Florida. These girders provide a larger vertical clearance and to reduce the overall cost

9 of bridges. FIBs are designed to have higher load carrying capacity, more efficient fabrication,

10 safer construction, increased lateral stiffness because of thicker top and bottom flanges.

11 In this study, a comparative analysis of two bridges is presented. The first bridge is a 3

12 span bridge designed with 6 AASHTO Type III girders. The second bridge has the same length,

13 width and girder depth; however, it has 4 FIB girders. Both bridges are analyzed using the

14 conventional AASHTO LRFD girderline analysis method and also more sophisticated finite

15 element method using a commercial software. The details of the FE model are also presented

16 with the critical considerations of link elements, boundary conditions, pre-stressing tendons.

17 The cost comparison of these two bridges was presented by FDOT and it is stated that the

18 FIB provides an estimated saving of about 24%. The results provided in this paper also indicate

19 that the bridge with FIB girders has higher load rating factors than the bridge with AASHTO

20 type III girder regardless of the method (AASHTO LRFD Girderline analysis or FE analysis) to

21 calculate the rating factors. The AASHTO girderline analysis underestimates the load rating

22 factors for both AASHTO Type III girder bridge and the FIB bridge. Based on the FE results, it

23 can be stated that it is possible to expect 20% higher live load capacity for interior girders and

24 40% higher live load capacity for exterior girders using FIB-45 girders compared to AASHTO

25 Type III girders, while also reducing the cost by about 24%.

26 ACKNOWLEDGMENTS

27 The authors would like to thank Mr. Sam Fallaha, P.E. from FDOT Structures Research

28 Center and Mr. Neil Kenis, P.E. from FDOT D5 Design Office for their feedback and input for

29 the study presented in this paper. The authors would also like to acknowledge the contributions

30 of Ms. Cara Brown for the FE model development at the initial stages of this study.

TRB 2013 Annual Meeting Paper revised from original submittal.

Catbas, Darwash, Fadul 13/13

1 The opinions, findings, and conclusions expressed in this publication are those of the

2 authors and do not necessarily reflect the views of the sponsoring or anyother organizations.

3 REFERENCES

4

5 1. PCA (2004), “Market Research-The Bridge Market,” Portland Cement Association, October

6 2004.

7 2. Florida department of Transportation (FDOT). Temporary Design Bulletin C09-01. January.

8 2009.

9 3. Florida department of Transportation (FDOT). Temporary Design Bulletin C09-03. June.

10 2009.

11 4. American Association of State Highway and Transportation Officials (AASHTO). (2007).

12 Standard specifications for highway bridges, AASHTO 4th Ed., Washington, D.C.

13 5. AASHTO Guide (2007). "Guide Manual for Condition Evaluation and Load and Resistance

14 Factor Rating (LRFR) of Highway Bridges"

15 6. Barr, P. J., Eberhard, M. O. and Stanton, J. F. “Live-Load Distribution Factors in

16 Prestressed Concrete Girder Bridges.” Journal of Bridge Engineering, ASCE .

17 September/October. 2001.

18 7. Shmerling, R.Z. and Catbas, F.N. (2009), “Load Rating and Reliability Analysis of An

19 Aerial Guideways,” Journal of Bridge Engineering, Volume 14, Issue 4, pp. 247-256

20 (July/August 2009) ASCE, 2009.

21 8. Shmerling, R.Z. and Catbas, F.N. (2010), “Visualization, Finite Element Modeling and

22 Analysis of Aerial Guideways,” Structure and Infrastructure Engineering Journal, SIE,

23 Structure and Infrastructure Engineering: Maintenance, Management, Life-Cycle Design

24 and Performance, Volume 6, Issue 4, First published 2010, Pages 447 – 465

25 9. Barker, R. M. and Puckett, J. A. (2007). Design of Highway Bridges An LRFD Approach,

26 Wiley, N. Y.

27 10. CSiBridge Introduction to CSiBridge. (1995). Computers & Structures, Inc. Berkeley,

28 California 94704 USA.

29 11. CSiBridge Bridge Seismic Design. (1995). Computers & Structures, Inc. Berkeley,

30 California 94704 USA.

TRB 2013 Annual Meeting Paper revised from original submittal.

You might also like

- Al Fadul 2020 IOP Conf. Ser. Mater. Sci. Eng. 888 012027Document11 pagesAl Fadul 2020 IOP Conf. Ser. Mater. Sci. Eng. 888 012027Juan Carlos Quispe CharaNo ratings yet

- Finite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresDocument9 pagesFinite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresVietnhut PhanNo ratings yet

- 2019 6 1 2 AwwadDocument14 pages2019 6 1 2 AwwadSinishaw NegaNo ratings yet

- Failure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge DecksDocument10 pagesFailure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge Decksalemteka97No ratings yet

- Fiber Reinforced Polymer Composites in Bridge IndustryDocument14 pagesFiber Reinforced Polymer Composites in Bridge IndustryShin JoonHoNo ratings yet

- ACI Structural: Prepublished PaperDocument43 pagesACI Structural: Prepublished PaperAbderrahman LahkaimiNo ratings yet

- Ali 2021Document12 pagesAli 2021AliReza ZiaratiNo ratings yet

- TRBRakoczyResidualCapacityofDamagedGirder RevisedDocument17 pagesTRBRakoczyResidualCapacityofDamagedGirder RevisedabdulNo ratings yet

- Portable Bridge PaperDocument8 pagesPortable Bridge PaperFuad PrasetyaNo ratings yet

- Comarison Between Aci 440 and Fib 14 Design GuidelinesDocument10 pagesComarison Between Aci 440 and Fib 14 Design GuidelinesShuvo ShahaNo ratings yet

- PVC Plastic Tube With Concrete Infill Strengthened With FRP: A State-Of-The-Art ReviewDocument9 pagesPVC Plastic Tube With Concrete Infill Strengthened With FRP: A State-Of-The-Art ReviewCelina Birta SantosoNo ratings yet

- Optimum Design of Cold-Formed Steel Portal Frame Buildings by Phan 2017Document16 pagesOptimum Design of Cold-Formed Steel Portal Frame Buildings by Phan 2017fahmi aballiNo ratings yet

- Badie Paper On NCHRP 12-65Document19 pagesBadie Paper On NCHRP 12-65houstonhimselfNo ratings yet

- Design, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsDocument11 pagesDesign, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsHamza AldaeefNo ratings yet

- Evaluation of Sandwich Panels With Various Polyurethane Foam-Cores and RibsDocument15 pagesEvaluation of Sandwich Panels With Various Polyurethane Foam-Cores and RibsJesûs FreîreNo ratings yet

- Study The Behaviour of Box Type Bridge With Different Height and Same Width For The IRC LoadingsDocument6 pagesStudy The Behaviour of Box Type Bridge With Different Height and Same Width For The IRC LoadingsIJRASETPublicationsNo ratings yet

- Drilled Shafts Lateral AnalysisDocument10 pagesDrilled Shafts Lateral AnalysisAlejandro García GuillénNo ratings yet

- Upgrading The Transportation Infrastructure SolidDocument16 pagesUpgrading The Transportation Infrastructure Soliddavy kizNo ratings yet

- Shear Strength of Hollow-Core SlabsDocument5 pagesShear Strength of Hollow-Core SlabsSulaiman Mohsin AbdulAzizNo ratings yet

- Design, Construction, and Maintenance of BridgeDocument72 pagesDesign, Construction, and Maintenance of BridgeLeonichevNo ratings yet

- A Ataei M Bradford 10thconferencepaperDocument9 pagesA Ataei M Bradford 10thconferencepapermdkmlNo ratings yet

- Stochastic Shear Strength of Plate Girder in Highway BridgeDocument40 pagesStochastic Shear Strength of Plate Girder in Highway BridgeAbdulrasheed Muhammad KardiNo ratings yet

- Construction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckDocument12 pagesConstruction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckVergor Dominic Cueto EbiteNo ratings yet

- Implication of Using The British Standards On The Design of Precast, Prestressed Concrete Aashto GirdersDocument18 pagesImplication of Using The British Standards On The Design of Precast, Prestressed Concrete Aashto Girdersmohammed boraNo ratings yet

- Design of Box Girder Bridge by Transverse Analysis (BS 5400)Document9 pagesDesign of Box Girder Bridge by Transverse Analysis (BS 5400)Rey Balza TornoNo ratings yet

- 2011zakaibetal - InfluenceofConnectionsonCFFTStrengthDocument18 pages2011zakaibetal - InfluenceofConnectionsonCFFTStrengthArthur DahokloryNo ratings yet

- Lightweight Materials For DeepwaterDocument8 pagesLightweight Materials For DeepwaterJoseph BimoNo ratings yet

- Behavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsDocument16 pagesBehavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsBatisxuta MichaelNo ratings yet

- LTRC Technical Summary 443 Elimination of Deck Joints Using A Corrosion Resistant FRP ApproachDocument2 pagesLTRC Technical Summary 443 Elimination of Deck Joints Using A Corrosion Resistant FRP ApproachwalaywanNo ratings yet

- RC ColumnDocument42 pagesRC ColumnyanimuhammadNo ratings yet

- Bridge Strengthening Using Advanced Composite SystemDocument103 pagesBridge Strengthening Using Advanced Composite SystemSravaniChintalapani100% (1)

- 1179 FinalDocument21 pages1179 Finaltsitsi bizaNo ratings yet

- A Case Study of Life Cycle Cost Based On A Real FRP BridgeDocument4 pagesA Case Study of Life Cycle Cost Based On A Real FRP BridgeHikari ChanNo ratings yet

- Girdre Concrette FileDocument36 pagesGirdre Concrette FileisomonteNo ratings yet

- BD545 09Document120 pagesBD545 09Boonme ChinnaboonNo ratings yet

- Design of Box CulvertDocument11 pagesDesign of Box Culvertjs kalyana ramaNo ratings yet

- Full TextDocument135 pagesFull TextTriet TruongNo ratings yet

- Accepted Manuscript: Composite StructuresDocument44 pagesAccepted Manuscript: Composite StructuresDavid MartinsNo ratings yet

- Continous Post-Tensioned Bulb-Tee Girder BridgesDocument23 pagesContinous Post-Tensioned Bulb-Tee Girder BridgesChristopher Matthews100% (1)

- Edinburgh Research Explorer: The Condition of The Aberfeldy Footbridge After 20 Years in ServiceDocument12 pagesEdinburgh Research Explorer: The Condition of The Aberfeldy Footbridge After 20 Years in ServiceAlin NegarăNo ratings yet

- Life Cycle Analysis of Precast ConcreteDocument8 pagesLife Cycle Analysis of Precast ConcreteSolomon Gmedhin100% (1)

- 111 CR PDFDocument35 pages111 CR PDFfandhiejavanov2009No ratings yet

- The Carbon Footprint Calculation of The GFRP Pedestrian Bridge at Tai-Jiang National ParkDocument17 pagesThe Carbon Footprint Calculation of The GFRP Pedestrian Bridge at Tai-Jiang National Parkkrzysztofdul.kdNo ratings yet

- Full TextDocument108 pagesFull TextHemanth RaoNo ratings yet

- Rehabilitation of Concrete Structures with Fiber-Reinforced PolymerFrom EverandRehabilitation of Concrete Structures with Fiber-Reinforced PolymerNo ratings yet

- Increased of The Capacity Integral Bridge With Reinforced Concrete Beams For Single SpanDocument10 pagesIncreased of The Capacity Integral Bridge With Reinforced Concrete Beams For Single SpanHabeeb ShaikNo ratings yet

- Dowel Bar Size and Spacing For Rigid Pavements PDFDocument8 pagesDowel Bar Size and Spacing For Rigid Pavements PDFTim Lin100% (1)

- Evaluation of Existing Strut-and-Tie Methods and Recommended ImprovementsDocument47 pagesEvaluation of Existing Strut-and-Tie Methods and Recommended ImprovementsFreddy GonzalesNo ratings yet

- Composite Steel Bridges - CorusDocument28 pagesComposite Steel Bridges - CorusRui OliveiraNo ratings yet

- Alnahhal 2008 Composite-StructuresDocument18 pagesAlnahhal 2008 Composite-Structuresandri.kusbiantoro9761No ratings yet

- Fiber-Reinforced Polymer (FRP) DecksDocument1 pageFiber-Reinforced Polymer (FRP) DecksSanjay GargNo ratings yet

- Prestressed Concrete Bridges PDFDocument8 pagesPrestressed Concrete Bridges PDFedisonmalahitoNo ratings yet

- Comparative Design of Flexible Pavement Using Different Countries' MethodologiesDocument4 pagesComparative Design of Flexible Pavement Using Different Countries' MethodologiesIJSTENo ratings yet

- Universities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDocument44 pagesUniversities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDuta LiviuNo ratings yet

- Nonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsDocument18 pagesNonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsJamal Eddine HamiltonNo ratings yet

- Nonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsDocument18 pagesNonlinear Finite Element Modeling of FRP-wrapped UHPC ColumnsJamal Eddine HamiltonNo ratings yet

- On Punching Shear Strength of Steel Fiber-Reinforced Concrete Slabs-on-GroundDocument12 pagesOn Punching Shear Strength of Steel Fiber-Reinforced Concrete Slabs-on-GroundErnie SitanggangNo ratings yet

- Behavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer SheetsDocument20 pagesBehavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer SheetsmarkicivanNo ratings yet

- Fadaee M., Et. Al. - 2018Document10 pagesFadaee M., Et. Al. - 2018Felipe DornellesNo ratings yet

- Template Course Specs 2017 - 2108 - 2Document4 pagesTemplate Course Specs 2017 - 2108 - 2عبدالوهاب بركاتNo ratings yet

- Key Features and Benefits by ProductDocument6 pagesKey Features and Benefits by Productعبدالوهاب بركاتNo ratings yet

- Nvidia Smi.1Document17 pagesNvidia Smi.1shakabrahNo ratings yet

- RocksDocument12 pagesRocksRajat WadhwaniNo ratings yet

- أعمال الحدادةDocument3 pagesأعمال الحدادةعبدالوهاب بركاتNo ratings yet

- Proj 1Document2 pagesProj 1Ahmed Huessien SuleimanNo ratings yet

- Mats 02Document1 pageMats 02عبدالوهاب بركاتNo ratings yet

- B C OFS F: Earing Apacity Hallow OundationsDocument4 pagesB C OFS F: Earing Apacity Hallow OundationsAleksiey PellicciaNo ratings yet

- FE Civil CBT SpecsDocument4 pagesFE Civil CBT SpecsBarry OcayNo ratings yet

- Problem 1 021Document2 pagesProblem 1 021عبدالوهاب بركاتNo ratings yet

- Single Pile 09Document1 pageSingle Pile 09عبدالوهاب بركاتNo ratings yet

- Pile Skin Friction PDFDocument1 pagePile Skin Friction PDFعبدالوهاب بركاتNo ratings yet

- HW 3Document2 pagesHW 3Ahmed Huessien SuleimanNo ratings yet

- ReferencesDocument1 pageReferencesعبدالوهاب بركاتNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial Versionعبدالوهاب بركاتNo ratings yet

- WWW - Fermanagh.gov - Uk - Pubuploads - Health and Safety Policy StatementDocument11 pagesWWW - Fermanagh.gov - Uk - Pubuploads - Health and Safety Policy StatementProf C.S.PurushothamanNo ratings yet

- Shape Factors For Bearing Capacity EquationsDocument1 pageShape Factors For Bearing Capacity Equationsعبدالوهاب بركاتNo ratings yet

- Compaction - 09Document1 pageCompaction - 09عبدالوهاب بركاتNo ratings yet

- 1-2-How To Print A ReportDocument1 page1-2-How To Print A Reportعبدالوهاب بركاتNo ratings yet

- BC Factors PDFDocument1 pageBC Factors PDFعبدالوهاب بركاتNo ratings yet

- BC Exg1 PDFDocument2 pagesBC Exg1 PDFعبدالوهاب بركاتNo ratings yet

- Phase - 19: SolutionDocument1 pagePhase - 19: Solutionعبدالوهاب بركاتNo ratings yet

- كويز ماتريالDocument4 pagesكويز ماتريالعبدالوهاب بركاتNo ratings yet

- Permit To Work Sample ConfinedDocument7 pagesPermit To Work Sample Confinedعبدالوهاب بركاتNo ratings yet

- كويز ماتريال - Copy ملوش لازمةDocument4 pagesكويز ماتريال - Copy ملوش لازمةعبدالوهاب بركاتNo ratings yet

- كويز ماتريال - Copy ملوش لازمةDocument4 pagesكويز ماتريال - Copy ملوش لازمةعبدالوهاب بركاتNo ratings yet

- BDP 4Document56 pagesBDP 4yenebeb tarikuNo ratings yet

- RocksDocument12 pagesRocksRajat WadhwaniNo ratings yet

- Rizal MonumentDocument5 pagesRizal Monumentmark_torreonNo ratings yet

- Introduction To Structural Analysis For Architecture StudentsDocument120 pagesIntroduction To Structural Analysis For Architecture StudentsHarold Taylor100% (2)

- Slab Opening Details: - Ar. Vergel Angelo P. PauleDocument1 pageSlab Opening Details: - Ar. Vergel Angelo P. PauleMark Roger II HuberitNo ratings yet

- Location Plan Schedule of Loads: SymbolsDocument1 pageLocation Plan Schedule of Loads: SymbolsJim Lesle Valdehuesa Bullecer100% (1)

- Lotsafee House: Bigbucks PLC Pilecap G14Document53 pagesLotsafee House: Bigbucks PLC Pilecap G14Nicholas ThompsonNo ratings yet

- EUROPA 2 - EuroconfortDocument4 pagesEUROPA 2 - EuroconfortPeradNo ratings yet

- The DLL Import Library ToolDocument3 pagesThe DLL Import Library Tool陳力綸No ratings yet

- CSLtraining MikroTik Class 1Document85 pagesCSLtraining MikroTik Class 1JoesHouseNo ratings yet

- SingleRAN GSM UMTS LTE - New Product Introduction v2.0Document9 pagesSingleRAN GSM UMTS LTE - New Product Introduction v2.0angicar100% (3)

- TBE 105 Specimen PaperDocument4 pagesTBE 105 Specimen PaperDada ThainNo ratings yet

- A3.8 Planning Scheduling - 20090812 - 115626 PDFDocument60 pagesA3.8 Planning Scheduling - 20090812 - 115626 PDFSuhaidi Alias100% (1)

- Frontend Exercise - Rocket MediaDocument4 pagesFrontend Exercise - Rocket MediajayantNo ratings yet

- Biomimicry in The Built EnvironmentDocument68 pagesBiomimicry in The Built EnvironmentThilluNo ratings yet

- Krier-Peter Eisenman DialogueDocument3 pagesKrier-Peter Eisenman DialogueAndreea CarabusNo ratings yet

- How To Use Git With Android StudioDocument124 pagesHow To Use Git With Android StudioCHU KIMNo ratings yet

- Signalling Manager User GuideDocument78 pagesSignalling Manager User GuideJayanta BanerjeeNo ratings yet

- Psycho Robert BlochDocument50 pagesPsycho Robert BlochAmandeep SinghNo ratings yet

- Precast Catch BasinDocument4 pagesPrecast Catch BasinJanetCablaoNo ratings yet

- Hygene EPIHANIOU Faucets INT EN-1 PDFDocument55 pagesHygene EPIHANIOU Faucets INT EN-1 PDFattikourisNo ratings yet

- Arbab Samuel Resume 2019Document2 pagesArbab Samuel Resume 2019api-494454512No ratings yet

- Jurnal 1 (Penelitian Murni)Document11 pagesJurnal 1 (Penelitian Murni)Angga Tirta N. PNo ratings yet

- Manual Do ProprietárioDocument51 pagesManual Do ProprietárioRonaldo FariaNo ratings yet

- Databook Mvd-V5x Cl23300-307 enDocument212 pagesDatabook Mvd-V5x Cl23300-307 enmquaiottiNo ratings yet

- Project & Contract Management (Lab) : Name # Bashir Ahmad REG NO # 2016-CIV-130Document33 pagesProject & Contract Management (Lab) : Name # Bashir Ahmad REG NO # 2016-CIV-130MikoNo ratings yet

- Oscg Odoo en Simp 2015Document41 pagesOscg Odoo en Simp 2015Drago K.No ratings yet

- RNC Migration To A New SGSNDocument2 pagesRNC Migration To A New SGSNEunice Bid MNo ratings yet

- Ufc 3 600 01-Fire Prot EngrDocument158 pagesUfc 3 600 01-Fire Prot EngrcarlcrowNo ratings yet

- Profile BMFDocument188 pagesProfile BMFCiprian S.No ratings yet

- Olar Energy The Renewable Source of Energy: Prepared ByDocument28 pagesOlar Energy The Renewable Source of Energy: Prepared ByNilaya SinghNo ratings yet

- NetBrain POC Installation GuideDocument13 pagesNetBrain POC Installation GuideTanveerNo ratings yet