Professional Documents

Culture Documents

Aspen HYSYS: Steady States and Dynamic Simulator (EG Plant Exercise)

Uploaded by

Micaela Flores LanzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aspen HYSYS: Steady States and Dynamic Simulator (EG Plant Exercise)

Uploaded by

Micaela Flores LanzaCopyright:

Available Formats

Aspen HYSYS :

Steady states and Dynamic Simulator

Chemical Process and Product Design

(EG Plant Exercise)

Seoul National University

Spring Semester, 2014

TA : Ikhyun Kim

(onlysmile@pslab.snu.ac.kr)

Instructor : En Sup Yoon

Basic Steps for HYSYS

• Select the components

• Choose a property package (Thermodynamic model)

Basic

Environment • Define Reactions

• Create a unit set

• Create and Specify the streams

Simulation

Environment • Install and Define the unit operation and column

• DOF & Specification

• Analyzing the Result (Case Study, Verification, Optimization, etc.)

Analysis

Chemical Process and Product Design (2/20)

Seoul National University

Example – Ethylene Glycol Plant

Ethylene glycol has many industrial uses: a feed stock for polyester resins,

a hydrate inhibitor in natural gas pipelines, an all-weather antifreeze and

coolant, or an industrial solvent. Ethylene oxide and water are fed to a

reactor to produce ethylene glycol. The product stream is fed to a

distillation column where the excess water and ethylene oxide are stripped

off the top and the ethylene glycol is the bottom product.

Chemical Process and Product Design (3/20)

Seoul National University

Defining the Simulation Basis

Fluid Package : NRTL Activity Model.

Components : Ethylene Oxide (C2H4O), Water (H2O)

and Ethylene Glycol (C2H6O2).

On the Binary Coeffs tab,

Select UNIFAC VLE as the Coeff. Estimation method to estimate the missing

binary coefficients and press Unknowns Only.

On the Rxns tab,

Add the following reaction (Kinetic) to the Fluid Package :

C2H4O + H2O C2H6O2

Basis and

Parameters pages,

Chemical Process and Product Design (4/20)

Seoul National University

Defining the Simulation Basis

No reverse reaction is defined in this example.

Return to the Simulation Basis Manager by closing the Kinetic Reaction window.

Return to the Rxns tab of the Fluid Package. Press the Add Set button to add the

Global Rxn Set to the Current Reaction Sets group. Close the Fluid Package

view.

Press the Enter Simulation Environment button.

Chemical Process and Product Design (5/20)

Seoul National University

Adding the Feed Stream

(Mole Fraction)

Chemical Process and Product Design (6/20)

Seoul National University

Adding the CSTR Reactor

On the Reactions tab, select the Global Rxn Set and Rxn-1 as the Reaction.

Specify the temperature of stream Rx Liquid to be 65°C (150°F).

From the Reaction results, what is the % Conversion of Ethylene Oxide?

_______99.70

Chemical Process and Product Design (7/20)

Seoul National University

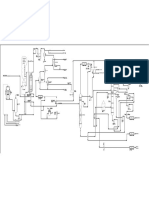

Ethylene Glycol Tower - Overview

Chemical Process and Product Design (8/20)

Seoul National University

Adding the Ethylene Glycol Tower

No. of Trays

Chemical Process and Product Design (9/20)

Seoul National University

Adding the Ethylene Glycol Tower

Press the Run Button

In stead of Specifying the Distillate Rate, Specify the reboiler Temperature

Chemical Process and Product Design (10/20)

Seoul National University

Adding the Ethylene Glycol Tower

In stead of Specifying the Distillate Rate,

Specify the reboiler temperature !!

Chemical Process and Product Design (11/20)

Seoul National University

Adding the Ethylene Glycol Tower

On the Performance tab, analyze the column result !

Chemical Process and Product Design (12/20)

Seoul National University

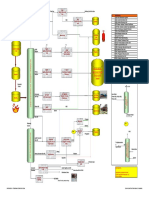

Installing the Recycle

The stream Distillate contains mostly unreacted water. This water can be recycle

d to the reactor in order to reduce the feed water requirements

Chemical Process and Product Design (13/20)

Seoul National University

Installing the Recycle

A Recycle operation is a mathematical unit operation and is installed as

any other. It has an inlet (calculated) stream and an outlet (assumed)

stream. The operation is called/calculated whenever changes to the

inlet stream fall outside of the converged tolerance.

• HYSYS uses the conditions of the assumed stream (outlet)

and solves the flowsheet up to the calculated stream (inlet).

• HYSYS then compares the values of the calculated stream to

those in the assumed stream.

• Based on the difference between the values, HYSYS modifies

the values in the calculated stream and passes the modified

values to the assumed stream.

Chemical Process and Product Design (14/20)

Seoul National University

Installing the Recycle

• Attach the Stream

• Delete the specified molar flow rate of the Water Feed stream. This value will

be back-calculated from the outlet of the mixer.

• Specify the molar flow of the mixer outlet stream, Water to Reactor, as 150

kgmole/h (330 lbmole/hr). Once the flow rate in this stream is set, HYSYS will

automatically calculate the flowrate of the Water Feed stream.

Chemical Process and Product Design (15/20)

Seoul National University

Installing the Recycle

Chemical Process and Product Design (16/20)

Seoul National University

Recycles

What is a Recycle operation?

– mathematical / logical unit operation

Assumed Calculated

R

When to use a Recycle operation?

– Required when downstream material stream(s) mix with

upstream material stream(s) and when there is mass I/O across

the flowsheet

Chemical Process and Product Design (17/20)

Seoul National University

Adding Recycle Operations (1)

Procedure 1

1. Solve flowsheet without recycled stream

2. Add Recycle, and only attach the calculated stream

(calculated = estimated)

3. Connect assumed stream to flowsheet

2 1

Chemical Process and Product Design (18/20)

Seoul National University

Adding Recycle Operations (2)

Procedure 2

1. Guess (estimate) assumed stream

2. Solve flowsheet up to calculated stream

3. Add and connect recycle operation

Chemical Process and Product Design (19/20)

Seoul National University

Tear Locations

To minimize the number of tear locations, add recycles

– Downstream of gathering points (mixer)

– Upstream of distribution points (column, tee, separator)

To minimize the number of recycle variables (T, P, etc.)

– Choose a tear location that maximizes number of fixed variables

– Add recycle operations at separator inlets

– Compressor after cooler outlets

Choose a stable tear location

– To minimize effect of fluctuations

Chemical Process and Product Design (20/20)

Seoul National University

You might also like

- Sand ControlDocument61 pagesSand ControlYassir Hindi100% (6)

- Process Modeling Using HYSYS NGL Fractionation TrainDocument18 pagesProcess Modeling Using HYSYS NGL Fractionation TrainNasroNo ratings yet

- Planning For The Integrated Refinery Subsystems PDFDocument187 pagesPlanning For The Integrated Refinery Subsystems PDFkhaled_behery9934No ratings yet

- P&id HydrocrackerDocument1 pageP&id HydrocrackerchintanNo ratings yet

- CBB3024 FlowsheetingDocument66 pagesCBB3024 Flowsheetingfatiehah93No ratings yet

- Aspen Plus Hydrocracker - User's Guide V7.3 PDFDocument127 pagesAspen Plus Hydrocracker - User's Guide V7.3 PDFtuan.huu20070% (1)

- Design of Circular Walls-AnilDocument11 pagesDesign of Circular Walls-Anilnavneet3bawaNo ratings yet

- Majalah BancoNotaDocument32 pagesMajalah BancoNotaMillerIndigoNo ratings yet

- MV & HV Motors PDFDocument9 pagesMV & HV Motors PDFMochammad Waris SNo ratings yet

- Melt CrystallizationDocument10 pagesMelt Crystallizationarsh19706636No ratings yet

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Ethylene Glycol PlantDocument18 pagesEthylene Glycol Plantezasukekun50% (2)

- Aspen HYSYSDocument6 pagesAspen HYSYSLuis Rodriguez GonzalesNo ratings yet

- TOC AnalyzerDocument5 pagesTOC Analyzeranilkumar995472No ratings yet

- 1932 3248rs-Service PDFDocument150 pages1932 3248rs-Service PDFGuillermo Conrad100% (1)

- Convective Heat Transfer Coefficients Table ChartDocument4 pagesConvective Heat Transfer Coefficients Table Chartmiguel_vera6592No ratings yet

- 04 Reactive DistillationDocument16 pages04 Reactive DistillationJaJar Yaneeporn PatcharavorachotNo ratings yet

- Material BalanceDocument78 pagesMaterial Balanceusman0553100% (4)

- Scale-Up of Chemical Engineering Process: Prof H R ShahDocument27 pagesScale-Up of Chemical Engineering Process: Prof H R Shahatgtegtrhrh100% (1)

- Maintenance Guide HA-20,22, VETDocument43 pagesMaintenance Guide HA-20,22, VETAyaovi Jorlau75% (8)

- CHE572 Chapter 7 Gas CycloneDocument23 pagesCHE572 Chapter 7 Gas CycloneMuhd FahmiNo ratings yet

- 01 Hysys IntroDocument21 pages01 Hysys Introsyamsudin2006No ratings yet

- Chapter 2Document40 pagesChapter 2Halkawt G MuhammadNo ratings yet

- Heterogeneous Azeotropic Distillation Column DesignDocument67 pagesHeterogeneous Azeotropic Distillation Column Designvenkatesh801100% (1)

- Troubleshooting Liquid Carryover in Gas Compression Systems MySep White PaperDocument11 pagesTroubleshooting Liquid Carryover in Gas Compression Systems MySep White Paperthlim19078656No ratings yet

- DIN 11864-3 Aseptic Clamp Unions For BS 4825 / ISO 2037 & ASME BPE 2002Document7 pagesDIN 11864-3 Aseptic Clamp Unions For BS 4825 / ISO 2037 & ASME BPE 2002hari.suryanto8417No ratings yet

- Natural Gas Liquids Recovery Processes in Natural Gas ProcessingDocument27 pagesNatural Gas Liquids Recovery Processes in Natural Gas ProcessingVictor Ali MentaNo ratings yet

- Modeling and Simulation of Ethyl Acetate Reactive Distillation Column Using Aspen PlusDocument5 pagesModeling and Simulation of Ethyl Acetate Reactive Distillation Column Using Aspen PlusSalim ChohanNo ratings yet

- Heat and Power Optimization in Ammonia PlantDocument23 pagesHeat and Power Optimization in Ammonia PlantDaniel Puello RodeloNo ratings yet

- A Guide of Refinery ProcessDocument1 pageA Guide of Refinery ProcessSubramani DuraikannuNo ratings yet

- ATM CDU Distillation in Aspen HYSYS V10Document27 pagesATM CDU Distillation in Aspen HYSYS V10Ahmad Deyab100% (2)

- Design and Simulation of A Reactive Distillation Process To Produce High-Purity Ethyl AcetateDocument9 pagesDesign and Simulation of A Reactive Distillation Process To Produce High-Purity Ethyl AcetateAjib Sari PutraNo ratings yet

- Aqua 1Document324 pagesAqua 1staryklt100% (1)

- Use of Dynamic Simulation To ConvergeDocument8 pagesUse of Dynamic Simulation To ConvergeneftNo ratings yet

- Lec SimulationDocument80 pagesLec SimulationDr Tajammal MunirNo ratings yet

- Aspen ConvergenceDocument40 pagesAspen ConvergenceKaushal SampatNo ratings yet

- ChemExpo 2023Document22 pagesChemExpo 2023Gulshan Mishra100% (1)

- Parte 3.-Piping Design Carrier HandBookDocument122 pagesParte 3.-Piping Design Carrier HandBookNestor Sanchez Villasmil100% (8)

- Flare Line Failure CaseDocument20 pagesFlare Line Failure CaseHitesh PanchalNo ratings yet

- Process Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFDocument33 pagesProcess Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFramesh pokhrelNo ratings yet

- Aspen Estimating Physical PropertiesDocument12 pagesAspen Estimating Physical PropertiesStheh Ka NkosiNo ratings yet

- Ethyleneglycol Design 2520of 2520equipmentsDocument41 pagesEthyleneglycol Design 2520of 2520equipmentsHardik Gandhi100% (1)

- Aspen Plus 12.1 TutorialDocument72 pagesAspen Plus 12.1 TutorialJoão SequeiraNo ratings yet

- Chemical Engineering 422 Simulation With Hysys: NotesDocument9 pagesChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqNo ratings yet

- Process Analytics in PE PlantsDocument9 pagesProcess Analytics in PE PlantsdavidNo ratings yet

- The Structure and Synthesis of Process Flow Diagrams: INDG1030 Chemical Plant Design II Term 2019Document58 pagesThe Structure and Synthesis of Process Flow Diagrams: INDG1030 Chemical Plant Design II Term 2019Jean Carlos GomezNo ratings yet

- Aspen DynamicsDocument311 pagesAspen DynamicsHoang-Vu BuiNo ratings yet

- Can We Believe The Simulation ResultsDocument7 pagesCan We Believe The Simulation Resultsken910076100% (1)

- Dynamic Model of A Scrubber Using Aspen PlusDocument11 pagesDynamic Model of A Scrubber Using Aspen PluschetanNo ratings yet

- Process Simulation For Distillation DesignDocument34 pagesProcess Simulation For Distillation Designstudyendless100% (1)

- Energy BalanceDocument45 pagesEnergy Balanceusman055360% (15)

- Chapter OneDocument29 pagesChapter Oneﺄڪۧہۙرم ﺄلہعہلہوي، 'ۦNo ratings yet

- Rating of An Existing Absorption TowerDocument9 pagesRating of An Existing Absorption TowerKvspavan KumarNo ratings yet

- Aspen Plus® Simulation of A Coal Gasification Process (Geometric Analysis)Document5 pagesAspen Plus® Simulation of A Coal Gasification Process (Geometric Analysis)Hotib PerwiraNo ratings yet

- Reciprocating Compressors in A Hydrogen Plant 2016Document5 pagesReciprocating Compressors in A Hydrogen Plant 2016Lucas SondreNo ratings yet

- Aspen HYSYS - Steady States and Dynamic Simulator (Introduction) PDFDocument24 pagesAspen HYSYS - Steady States and Dynamic Simulator (Introduction) PDFtuan.huu2007No ratings yet

- Process Simulation & Modeling Aspen Hysys BasicDocument5 pagesProcess Simulation & Modeling Aspen Hysys BasicMuhammad KhurramNo ratings yet

- Dynamic Modeling Using UniSim Design 2013engDocument129 pagesDynamic Modeling Using UniSim Design 2013engHari PurwitoNo ratings yet

- Hysys, Absorption Column DesignDocument13 pagesHysys, Absorption Column Designrarunr1No ratings yet

- A Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsDocument6 pagesA Comprehensive Investigation On High-Pressure LDPE Manufacturing: Dynamic Modelling of Compressor, Reactor and Separation UnitsAbdul SamadNo ratings yet

- Energy BalanceDocument10 pagesEnergy Balanceazzatul amiraNo ratings yet

- Sablin Alpha Raab FDocument3 pagesSablin Alpha Raab Fsk281No ratings yet

- Sulfur Condensation in Claus CatalystDocument6 pagesSulfur Condensation in Claus Catalystashoka23No ratings yet

- Methods To Determine The Number of Plates in DistillationDocument5 pagesMethods To Determine The Number of Plates in DistillationFahad Bin AliNo ratings yet

- Ethylene Glycol PFD ProcessDocument1 pageEthylene Glycol PFD ProcessKim HanaNo ratings yet

- AT-05197 - HYSYS - Study Guide - 2 PDFDocument8 pagesAT-05197 - HYSYS - Study Guide - 2 PDFahmedNo ratings yet

- Plant Design 2 Part 1Document75 pagesPlant Design 2 Part 1fareez aqmalNo ratings yet

- 2013 Modelling and Simulation of Continuous Reactive DistillationDocument24 pages2013 Modelling and Simulation of Continuous Reactive DistillationmppatilmayurNo ratings yet

- Numerical Simulation of A Pressure Swing Adsorption PDFDocument12 pagesNumerical Simulation of A Pressure Swing Adsorption PDFGustavo PalaciosNo ratings yet

- A List of Catalytic Reactions in Petrochemical Industry For Important Base ChemicalsDocument63 pagesA List of Catalytic Reactions in Petrochemical Industry For Important Base ChemicalssithvincentNo ratings yet

- ETACRDDocument53 pagesETACRDSampathkumar AttuluriNo ratings yet

- Oslen, Svrcek & Young 2005 - Plantwide Control Study of A Vinyl Acetate Monomer Process DesignDocument16 pagesOslen, Svrcek & Young 2005 - Plantwide Control Study of A Vinyl Acetate Monomer Process DesignBenedict LimNo ratings yet

- Integrated Process Design and Control of Cyclic Distillation ColumnsDocument6 pagesIntegrated Process Design and Control of Cyclic Distillation ColumnsMaythee SaisriyootNo ratings yet

- Bridge To Ch. 5 - More On Recycle and PurgeDocument17 pagesBridge To Ch. 5 - More On Recycle and PurgeMwanarusi MwatondoNo ratings yet

- CSTR 40lDocument22 pagesCSTR 40lafnan_lion94No ratings yet

- Energies 15 03964Document25 pagesEnergies 15 03964tuan.huu2007No ratings yet

- Sustainable Operations For Distillation Columns: Chemical Engineering & Process TechniquesDocument15 pagesSustainable Operations For Distillation Columns: Chemical Engineering & Process Techniquestuan.huu2007No ratings yet

- Source Energy and Emission Factors For Energy Use in BuildingsDocument39 pagesSource Energy and Emission Factors For Energy Use in Buildingstuan.huu2007No ratings yet

- Aspen Plus PFR Reactors Tutorial Using Styrene With Multiple Reactions With Langmuir-Hinshelwood-Hougen-Watson Kinetics PDFDocument4 pagesAspen Plus PFR Reactors Tutorial Using Styrene With Multiple Reactions With Langmuir-Hinshelwood-Hougen-Watson Kinetics PDFtuan.huu2007No ratings yet

- A Guide To Using The Aspen OLI Interface - Featuring Aspen PLUS V7.2 PDFDocument94 pagesA Guide To Using The Aspen OLI Interface - Featuring Aspen PLUS V7.2 PDFtuan.huu2007No ratings yet

- Recent Advances in Sand CastingDocument25 pagesRecent Advances in Sand Casting9591007896No ratings yet

- Kalcret BTX Lining Classifier RM 1Document2 pagesKalcret BTX Lining Classifier RM 1Safrin SangiaNo ratings yet

- Válvula de SeguridadDocument8 pagesVálvula de Seguridadmark_59No ratings yet

- CMP ManualDocument65 pagesCMP Manualnarayanan.um2640100% (2)

- Mechanical Seal PumpDocument24 pagesMechanical Seal PumpPhanhai KakaNo ratings yet

- Heat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDocument2 pagesHeat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDimas PalgunadiNo ratings yet

- FG - BDER-78 Technical Catalogue - Technical - UNDocument8 pagesFG - BDER-78 Technical Catalogue - Technical - UNAnh Le NgocNo ratings yet

- Elastomeric Impression MaterialsDocument6 pagesElastomeric Impression MaterialsMarlene CasayuranNo ratings yet

- Polyamino AcidsDocument2 pagesPolyamino AcidsRichard J. GrayNo ratings yet

- 650 731rev1Document3 pages650 731rev1RobinReyndersNo ratings yet

- A Project On Dealers Perception On Kajaria Ceramics CoimbatoreDocument47 pagesA Project On Dealers Perception On Kajaria Ceramics CoimbatoreMohamed SanferNo ratings yet

- Piping - Canada Culvert CSP ManualDocument12 pagesPiping - Canada Culvert CSP ManualRotax_KidNo ratings yet

- F006-F008 Metals Reclamation Rule: Presentation To SBA Environmental Roundtable MeetingDocument18 pagesF006-F008 Metals Reclamation Rule: Presentation To SBA Environmental Roundtable MeetingbillNo ratings yet

- D1 Internal Corner DetailDocument1 pageD1 Internal Corner DetailRodrigo Andres Merellado BustosNo ratings yet

- Flexible Electronics: Presented by Ashwin.k 4SN14EC704Document16 pagesFlexible Electronics: Presented by Ashwin.k 4SN14EC704Aswin PrEmrajNo ratings yet

- H2o BossterDocument137 pagesH2o Bosstertlolor833No ratings yet

- 02 - The Most Common Types of Bricks Used For ConstructionDocument6 pages02 - The Most Common Types of Bricks Used For ConstructionConcetto SpadaroNo ratings yet

- 02 Introduction To VLSI and ASIC DesignDocument23 pages02 Introduction To VLSI and ASIC DesignSiva Kumar T SNo ratings yet