Professional Documents

Culture Documents

Gasket Flanged Teadit Na1040

Uploaded by

hijodebudasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gasket Flanged Teadit Na1040

Uploaded by

hijodebudasCopyright:

Available Formats

TEADIT NA-1040 Rev.Nr.

: 03/131004

Construction:

TEADIT style NA-1040 is a non-asbestos jointing-sheet

material produced from cellulose fibres, bonded with

Nitrile rubber (NBR). It is being manufactured by means

of a hot calender process under rigorous quality control

standards, registered and certified under ISO 9001.

Application / service:

Style NA-1040 is an excellent general service sheet,

formulated to handle medium pressures and

temperatures. Suitable for water, petroleum derivatives,

diluted alkalis, brine, animal and vegetable oils,

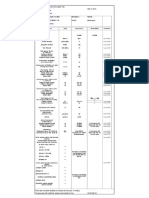

general chemicals, aliphatic and aromatic solvents, The P x T diagram indicates the service limits for NA-

neutral solutions etc. Style NA-1040 is also 1040 considering the simultaneous influence of

recommended as an economic insert for PTFE- pressure and temperature (chemical suitability

envelope-gaskets. assumed). The orange area represents the normal

service limits, while the yellow coloured area shows the

Typical physical properties of NA-1040 maximum application limits. For those cases, please

ASTM test Properties Values consult our technical department.

F 36 Compressibility 13%

NA 1040

F 36 Recovery 55% 120

F 38 Creep relaxation 29% 110

100

F 495 Ingnition loss 28% 90

F 146 Weight increase:: 80

press70

5h/ASTM IRM 903 @ + 150°C 11% ure 60

50

5h/ASTM Fuel B @ +21- 29°C 9 % 40

F 146 Thickness increase: 30

20

5h/ASTM IRM 903 @ +150°C 9% 10

0

5h/ASTM Fuel B @ +21- 29°C 8% 0 50 100 150 200 250 300 350

temperatur

F 152 Tensile strength (transverse) 8 N/mm²

- Density 1,8 g/cm³ Technical data:

Peak temperature: - 40 to + 210°C

Product standard: Constant temperature: +200°C

thickness: 1,0 / 1,5 / 2,0 / 2,5 and 3,0 mm Peak pressure: vacuum up to 50 bar

sheet size: 1.500 x 1.600 mm, 1.500 x 3.200 mm Constant working pressure: 20 bar

Colour: beige

You might also like

- Na NM gf300Document4 pagesNa NM gf300Bảo Trung LêNo ratings yet

- Temasil BlueDocument1 pageTemasil BluealkjghNo ratings yet

- Ifg 5500Document1 pageIfg 5500Amir100% (1)

- SikaGrout-215 2011-11 - 1Document2 pagesSikaGrout-215 2011-11 - 1Fajar SodiqNo ratings yet

- Temasil NG: CSF Sheet JointingDocument3 pagesTemasil NG: CSF Sheet JointingTài TrầnNo ratings yet

- Temafast RedDocument2 pagesTemafast RedalkjghNo ratings yet

- Jna 33Document1 pageJna 33jaskaran singhNo ratings yet

- Ba SDocument2 pagesBa SFajar SodiqNo ratings yet

- Compressed Sheet With Carbon Fibers, NBR Binder: ApplicationDocument2 pagesCompressed Sheet With Carbon Fibers, NBR Binder: ApplicationEmmanuelNo ratings yet

- PF63RDocument1 pagePF63RJavierNo ratings yet

- Toranit 410Document1 pageToranit 410vagner boldiNo ratings yet

- Style 2900 Data SheetDocument1 pageStyle 2900 Data SheetRicardo OrdoñezNo ratings yet

- Technical Data Sheet: Ferolite Nam 30Document2 pagesTechnical Data Sheet: Ferolite Nam 30johnNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Inexhaust Gasket SpecificationsDocument1 pageInexhaust Gasket Specificationsmuhammad0umar-4No ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNo ratings yet

- Asbestos Free Fibre Jointing Sheets Af154Document1 pageAsbestos Free Fibre Jointing Sheets Af154Johnson SingampallyNo ratings yet

- High Performance N8090Document1 pageHigh Performance N8090FirstLastNo ratings yet

- PG 23Document1 pagePG 23azeem bilalNo ratings yet

- Ab 139Document1 pageAb 139entesharat.tarasht3No ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- PG 20Document1 pagePG 20azeem bilalNo ratings yet

- Tema FastDocument1 pageTema FastPrzemek ...No ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Atriot: Technical Data SheetDocument1 pageAtriot: Technical Data Sheetazeem bilalNo ratings yet

- Temafast Economy Aj452471Document1 pageTemafast Economy Aj452471Pedja BekicNo ratings yet

- Erapol E90A: Technical DatasheetDocument2 pagesErapol E90A: Technical Datasheetmgamal1080No ratings yet

- Data Sheet: Standard and Test Method Unit PropertiesDocument2 pagesData Sheet: Standard and Test Method Unit PropertiesAfetNo ratings yet

- Tsa 125Document1 pageTsa 125vagner boldiNo ratings yet

- PG-GL Data SheetDocument1 pagePG-GL Data Sheetazeem bilalNo ratings yet

- BITUFLAME P 4180, P 4200 & P 4260: - DescriptionDocument2 pagesBITUFLAME P 4180, P 4200 & P 4260: - DescriptionTejinder KumarNo ratings yet

- Elastron TPE DatasheetDocument2 pagesElastron TPE DatasheetMateria by Purple AvenueNo ratings yet

- Ferolite Nam 32N1 PDFDocument2 pagesFerolite Nam 32N1 PDFMittapelly praveenNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Nam30y PDFDocument2 pagesNam30y PDFKalai SelvanNo ratings yet

- DML0033 v2-av-DIMERSIL 10Document1 pageDML0033 v2-av-DIMERSIL 10Luka BornaNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Ficha Tecnica Teadit 1082Document2 pagesFicha Tecnica Teadit 1082damianNo ratings yet

- Klinger C4401 PDFDocument2 pagesKlinger C4401 PDFArtur MkrtchyanNo ratings yet

- Product Data SheetDocument2 pagesProduct Data SheetshahneillNo ratings yet

- Pultruded Rod GRT GenesisDocument1 pagePultruded Rod GRT GenesismiraclelovesgamesNo ratings yet

- Beater-Add Specs HDN 260 (Rev. 9-14)Document1 pageBeater-Add Specs HDN 260 (Rev. 9-14)Ronald José Zavarce FloresNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- Fasit OmniaDocument1 pageFasit OmnianightmanirNo ratings yet

- Ferolite Nam 39 PDFDocument2 pagesFerolite Nam 39 PDFRenzo W. RuelasNo ratings yet

- Roop Polymers LTD (Unit Iii) : Laboratory Results On SlabsDocument1 pageRoop Polymers LTD (Unit Iii) : Laboratory Results On SlabsLALIT SHARMANo ratings yet

- Technical Data Sheet: Ferolite Nam 33Document2 pagesTechnical Data Sheet: Ferolite Nam 33Raul CalizayaNo ratings yet

- Donit Tesnit Ba-203 NewDocument2 pagesDonit Tesnit Ba-203 NewPrem KumarNo ratings yet

- Na NM 572Document4 pagesNa NM 572Bảo Trung LêNo ratings yet

- Sefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Document1 pageSefar Spécification: SEFAR TETEX MONO 03-1010-K 056 140 CM Numéro D' Article: 3B03-1000-140-00Bkiri AbderrahimNo ratings yet

- Ventilator Filter Unit BrochureDocument2 pagesVentilator Filter Unit BrochureChia Sze KiatNo ratings yet

- Superlite 111: Technical Data Sheet Material CompositionDocument4 pagesSuperlite 111: Technical Data Sheet Material CompositionSrikumar Krishnamuruthy100% (1)

- NBR 60.10-01Document1 pageNBR 60.10-01UcokNo ratings yet

- Technical Bulletin: Chloroprene RubberDocument5 pagesTechnical Bulletin: Chloroprene RubberPrashantha NandavarNo ratings yet

- TDB HPN - e - 08mm Rollen PDFDocument1 pageTDB HPN - e - 08mm Rollen PDFAnonymous 6VCG1YRdNo ratings yet

- Klingersil C 4300Document2 pagesKlingersil C 4300Feri KaruanaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Wilkopox 500Document1 pageWilkopox 500hijodebudasNo ratings yet

- Nozzle-1 Buque SEA DUTYDocument1 pageNozzle-1 Buque SEA DUTYhijodebudasNo ratings yet

- Sage Symphony MedicineDocument1 pageSage Symphony MedicinehijodebudasNo ratings yet

- Pneumatic Scaling Hammer Spare Parts-1Document1 pagePneumatic Scaling Hammer Spare Parts-1hijodebudasNo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- Agricultural Machinery in PakistanDocument19 pagesAgricultural Machinery in PakistanBadar NiaziNo ratings yet

- Fender TransformersDocument2 pagesFender TransformersVincenzo TabaccoNo ratings yet

- The Greek LettersDocument18 pagesThe Greek LettersSupreet GuptaNo ratings yet

- Explaining Zambian Poverty: A History of Economic Policy Since IndependenceDocument37 pagesExplaining Zambian Poverty: A History of Economic Policy Since IndependenceChola Mukanga100% (3)

- Rockwell Allen BradleyDocument73 pagesRockwell Allen BradleymaygomezNo ratings yet

- Planning & Cost Control Engineer (Primavera & MS Project) : Aouache FaridDocument3 pagesPlanning & Cost Control Engineer (Primavera & MS Project) : Aouache FaridFarid FaridNo ratings yet

- Obs Inf Worksheet 2013Document2 pagesObs Inf Worksheet 2013api-338002331No ratings yet

- Cooking Off The Clock by Elizabeth Falkner - Recipes and ExcerptDocument16 pagesCooking Off The Clock by Elizabeth Falkner - Recipes and ExcerptThe Recipe ClubNo ratings yet

- Nav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaDocument4 pagesNav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaRishabh KatiyarNo ratings yet

- LH514 - OkokDocument6 pagesLH514 - OkokVictor Yañez Sepulveda100% (1)

- The Art of Logical ThinkingDocument210 pagesThe Art of Logical ThinkingAndyAyam100% (1)

- Stratigraphy MCQs With AnswerDocument10 pagesStratigraphy MCQs With Answerkumar Harsh67% (3)

- MS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1Document21 pagesMS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1vusal huseynli100% (2)

- Boil-Off Gas CalculationsDocument14 pagesBoil-Off Gas CalculationsAlberto100% (1)

- BSN Curriculum 2012Document1 pageBSN Curriculum 2012Joana Bless PereyNo ratings yet

- GEHC Service Manual CARESCAPE Monitor B850 v1 2011Document172 pagesGEHC Service Manual CARESCAPE Monitor B850 v1 2011NguyễnCảnhBắcNo ratings yet

- Intro To BiochemDocument2 pagesIntro To BiochemPeachy PieNo ratings yet

- SW Chapter 21 KeyDocument9 pagesSW Chapter 21 KeykylevNo ratings yet

- Servo Controlled FBW With Power Boost Control, Operations & Maint. ManualDocument126 pagesServo Controlled FBW With Power Boost Control, Operations & Maint. ManualKota NatarajanNo ratings yet

- 8Document3 pages8Anirban Dasgupta100% (1)

- China Care Foundation - Fall 2010 NewsletterDocument8 pagesChina Care Foundation - Fall 2010 NewsletterChinaCareNo ratings yet

- ME 175A Midterm SolutionsDocument4 pagesME 175A Midterm SolutionsDavid ChonNo ratings yet

- 2019 BMS1021 Practice Questions Answers PDFDocument12 pages2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkNo ratings yet

- Introduction To Second Quantization: 1.1 Single-Particle Hilbert SpaceDocument6 pagesIntroduction To Second Quantization: 1.1 Single-Particle Hilbert Space김띵No ratings yet

- Air Cooler With Checking DoorDocument2 pagesAir Cooler With Checking DoorSuraj KumarNo ratings yet

- Chapter - 2 - Unit Hydrograph2Document33 pagesChapter - 2 - Unit Hydrograph2Abhilekh PaudelNo ratings yet

- Suez Canal ReportDocument5 pagesSuez Canal ReportAnonymous Pc6LwfCNo ratings yet

- List of Irc Publications Referred To in The Specifications: AppendicesDocument17 pagesList of Irc Publications Referred To in The Specifications: AppendicesPrasad BoniNo ratings yet

- QuestionsDocument6 pagesQuestionsRomeo martinezNo ratings yet

- 2011 33 MaintenanceDocument16 pages2011 33 MaintenanceKrishna Khandige100% (1)