Professional Documents

Culture Documents

Roop Polymers LTD (Unit Iii) : Laboratory Results On Slabs

Uploaded by

LALIT SHARMA0 ratings0% found this document useful (0 votes)

9 views1 pageer

Original Title

Gasket

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenter

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageRoop Polymers LTD (Unit Iii) : Laboratory Results On Slabs

Uploaded by

LALIT SHARMAer

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

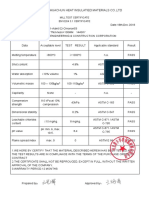

ROOP POLYMERS LTD (UNIT III)

PLOT No-30 SECTOR-3 Date:- 01.09.18

IMT, MANESAR GURGAON

Laboratory results on Slabs

Client/Customer: M/s SOGEFI SYSTEMS Part Name:- Part No.

Material:- FPM (ROOP POLYMERS LTD) GASKET EFIN7018512

Specification:- As per drawing

Characteristics Units Specifications Observations Test Method

Elastomer

Colour GREEN GREEN

Hardness Shore A 65±4 As per ASTM

Tensile Strength N/mm² (Min.) 9 As per ASTM

Elongation at Break % Min. 180 As per ASTM

Tear Strength kN/m (Min.) 13 As per ASTM

After Ageing 168 Hrs

AT 150°C Air

Change in Hardness Shore A +10 As per ASTM

Elongation at Break % Min. 150 As per ASTM

Change in Tensile strength % Max -30 As per ASTM

Compression set % (Min.)

for 70 Hrs at 150°C % (Max) 10 As per ASTM

Compression set % (Max.) (on seal)

for 5000 Hrs at 110°C % (Max) 80 on product

Fluid Ageing, 168 h at

40°C in ASTM RFC E85

Change Tensile max. % (Max.) -55 As per ASTM

Change in Elongation, % (Max.) -35 As per ASTM

Volume Swell, % 0 to 25 As per ASTM

Oil Resistence test in 504H at 150°C

in (15W40 Oil)

Change in Tensile strength % 0 to -45 As per ASTM

Change in Elongation % 0 to -60 As per ASTM

Volume Swell, % -5 to +5 As per ASTM

Oil Resistence test in 504H at 150°C

in (10W30 Oil)

Change Tensile range % 0 to -45 As per ASTM

Change Elongation, % 0 to -60 As per ASTM

Volume Swell, % -5 to +5 As per ASTM

Fluid Ageing, 48 h at E85 E15

RT in Gasoline+Ethanol (0~100%)

Change in volume % -5 to +10 As per ASTM

Change in Hardness Shore A ±8 As per ASTM

DSC Analysis (ISO 11359-2) °C -20 As per ASTM

Fuel permeability rate

determination

at 55°c for 72 hrs gms/m2.h 30 As per ASTM

Density gm/cm3 ±0.05 As per ASTM

Held in Ozonised air

at 40°cx168 hrs

Variation elongation at break % 150 (Min) As Discussed with As per ASTM

Variation Tensile strength % -30 (Max) Sogefi team This test As per ASTM

Volume variation % +10 (Max) not to be done As per ASTM

Cleanliness

Gravimatery (as per ISO 16232-10) Max 5 mg/1000cm² As Discussed with As per ASTM

Grenulometry (as per ISO 16232-10) --- No particle over 1000 m Sogefi team This test As per ASTM

No Metal particle not to be done As per ASTM

DV 35- change interior with following As per ASTM

chemical

Fix-head flange set downward

(gasket submerge with chemical)

AT Room Temp X1000 Hrs.

(i)Fuel C ----

(ii)Fuel C +M 15% ----

No cracks or no damage

(iii)Fuel C +LPO(3)% ---- or deformation in resin

part. No leak after test

(ii)Fuel C +E20% ---- with air

(iv)Engine Oil ----

DV 36- Apply following chemical to As per ASTM

surface.

AT 120°C X96 Hrs

(i)Engine coolant ----

(ii)Engine oil ----

(iii)Break fluid (DOT 3) ----

No cracks or No damage

or deformation in resin

(iv)Battery Liquid(distilled water) ----

part.

(v)Washer liquid ----

(vi)Calcium chloride saturated ----

aqueous solution

* At the time of material feasibility it is decided the DSC spec -15 °c (Max).

* As discussed with Sogeffi San Hardness will maintain in 61±4. APPROVED BY:-

You might also like

- Ifg 5500Document1 pageIfg 5500Amir100% (1)

- Inexhaust Gasket SpecificationsDocument1 pageInexhaust Gasket Specificationsmuhammad0umar-4No ratings yet

- Request Quote EPDMDocument4 pagesRequest Quote EPDMTumbin DilseNo ratings yet

- EPDM - Test by Romac Inc PDFDocument2 pagesEPDM - Test by Romac Inc PDFRajendra Kumar SharmaNo ratings yet

- Pultruded Rod GRT GenesisDocument1 pagePultruded Rod GRT GenesismiraclelovesgamesNo ratings yet

- Elastron TPE DatasheetDocument2 pagesElastron TPE DatasheetMateria by Purple AvenueNo ratings yet

- ERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDocument1 pageERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDarkedgeNo ratings yet

- C 4400Document2 pagesC 4400Efraín DaríoNo ratings yet

- Klinger C4401 PDFDocument2 pagesKlinger C4401 PDFArtur MkrtchyanNo ratings yet

- Fluorocarbon Rubber Laboratory Report ResultsDocument1 pageFluorocarbon Rubber Laboratory Report Resultsleidy0529No ratings yet

- Toparts Pte LTD: Laboratory ReportDocument1 pageToparts Pte LTD: Laboratory ReportkmulyadiNo ratings yet

- ArmaGel - HT - TDS - English - HotDocument4 pagesArmaGel - HT - TDS - English - HotLee Kok RoyNo ratings yet

- Viton Material - Dopont PDFDocument1 pageViton Material - Dopont PDFKamlesh DalavadiNo ratings yet

- Temasil BlueDocument1 pageTemasil BluealkjghNo ratings yet

- MS Black Nitrile Hi Tear 80 Shore Specs 6 22 18Document1 pageMS Black Nitrile Hi Tear 80 Shore Specs 6 22 18Juan UchuyaNo ratings yet

- Na NM gf300Document4 pagesNa NM gf300Bảo Trung LêNo ratings yet

- Study of Materials123Document12 pagesStudy of Materials123Jagan TnNo ratings yet

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 pagesBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanNo ratings yet

- Test Report ConformanceDocument2 pagesTest Report ConformancePriyadarshini KrishnaswamyNo ratings yet

- Performace Evaluation of Slag Aggregates As Construction MaterialDocument49 pagesPerformace Evaluation of Slag Aggregates As Construction MaterialMd Ashiqur RahmanNo ratings yet

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- 80 NBR 878Document2 pages80 NBR 878adhityaNo ratings yet

- Marco Material Datasheet N1000 PDFDocument2 pagesMarco Material Datasheet N1000 PDFAlaa SaadNo ratings yet

- Beryllium CopperDocument2 pagesBeryllium Coppershawntsung100% (1)

- Gasket Flanged Teadit Na1040Document1 pageGasket Flanged Teadit Na1040hijodebudasNo ratings yet

- Jayem JNA-33 gasket material technical data sheetDocument1 pageJayem JNA-33 gasket material technical data sheetjaskaran singhNo ratings yet

- Shall Be Supplied by An Approved Supplier in Accordance With ITM 581. PerformanceDocument15 pagesShall Be Supplied by An Approved Supplier in Accordance With ITM 581. PerformanceMog GomNo ratings yet

- Ge Mao Rubber Industrial Co., Ltd Laboratory Report SummaryDocument1 pageGe Mao Rubber Industrial Co., Ltd Laboratory Report Summaryleidy0529No ratings yet

- O-Ring Compound Data SheetDocument3 pagesO-Ring Compound Data SheetScarlet BlancoNo ratings yet

- Mykin Inc Rn00390 Nitrile Compound: General PropertiesDocument1 pageMykin Inc Rn00390 Nitrile Compound: General PropertiesmatteoNo ratings yet

- MTC Rockwool Board 80KDocument1 pageMTC Rockwool Board 80KAdrianNodaloNo ratings yet

- ArmaGelDT - TDS - EN-Dual TempDocument4 pagesArmaGelDT - TDS - EN-Dual TempLee Kok RoyNo ratings yet

- Ba SDocument2 pagesBa SFajar SodiqNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- Viton DS - Downloaded - 90 ShoreDocument1 pageViton DS - Downloaded - 90 ShoreazadeazNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

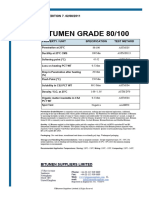

- Penetration Bitumen 80 100 SpecificationsDocument1 pagePenetration Bitumen 80 100 Specificationsnnadoziekenneth5No ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Request Quote for NBR O-Ring MaterialDocument2 pagesRequest Quote for NBR O-Ring MaterialChang MikeNo ratings yet

- Marco Material Datasheet V1000Document2 pagesMarco Material Datasheet V1000FinNo ratings yet

- Dymonic 100 Data SheetDocument2 pagesDymonic 100 Data SheetDavid LuongNo ratings yet

- Klingersil C 4300Document2 pagesKlingersil C 4300Feri KaruanaNo ratings yet

- Specifications Asfalto 50-80-2023Document1 pageSpecifications Asfalto 50-80-2023H JNo ratings yet

- Request Quote 70 Duro NBRDocument2 pagesRequest Quote 70 Duro NBRAlaa SaadNo ratings yet

- Datasheet V7500AA Viton 75 - Toparts - ApprovedDocument1 pageDatasheet V7500AA Viton 75 - Toparts - ApprovedBogdan CăpățînăNo ratings yet

- Certificate of Quality - Cq/020/21: SGS Oil, Gas and ChemicalsDocument1 pageCertificate of Quality - Cq/020/21: SGS Oil, Gas and ChemicalsLai_Wei_Wah_7018No ratings yet

- Transmissions To4 10w 30 and 50 en tcm14-189615Document1 pageTransmissions To4 10w 30 and 50 en tcm14-189615agung fals dwi cahyonoNo ratings yet

- Viton Compound Properties for High Temperature ResistanceDocument1 pageViton Compound Properties for High Temperature ResistanceiswantmachooNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Bitumen 60 70Document1 pageBitumen 60 70BariNo ratings yet

- PDF Sab PMBDocument2 pagesPDF Sab PMBGhanshyam Kumar PandeyNo ratings yet

- 3.4 Bituminous Materials: 3.4.1 DescriptionDocument5 pages3.4 Bituminous Materials: 3.4.1 DescriptionSujon AhmmedNo ratings yet

- HY509 PTFE Material for Oxygen Gas CompressionDocument1 pageHY509 PTFE Material for Oxygen Gas CompressionТатьяна ВасильеваNo ratings yet

- 1.8 Thong So Ky Thuat Bao On AeroflexDocument1 page1.8 Thong So Ky Thuat Bao On AeroflexDatNo ratings yet

- ITEM 594.14010011 - Molded Rubber Fender Panel SystemDocument7 pagesITEM 594.14010011 - Molded Rubber Fender Panel Systemphd.meethaqNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Two Coupled PendulumsDocument10 pagesTwo Coupled PendulumsBilal HaiderNo ratings yet

- AHP 1st UnitDocument33 pagesAHP 1st UnitSith AnanthanNo ratings yet

- Transport PhenomenaDocument8 pagesTransport PhenomenawaqaskhanNo ratings yet

- Tutorial 3 - Answers May14Document3 pagesTutorial 3 - Answers May14Raymond Kakala100% (6)

- R 410a Si PDFDocument20 pagesR 410a Si PDFMarin Munteanu0% (1)

- 2014 BookDocument92 pages2014 Bookbrian delgado de lucioNo ratings yet

- 10 1021@acsreagents 4191Document2 pages10 1021@acsreagents 4191Hans TorresNo ratings yet

- Physics 1.11 - PressureDocument29 pagesPhysics 1.11 - PressureAJAYI PETERNo ratings yet

- Velasc0 E-PortfolioDocument8 pagesVelasc0 E-PortfolioAngelyn Nicole MagsanoNo ratings yet

- Article1430240348 - Isehunwa Et AlDocument7 pagesArticle1430240348 - Isehunwa Et AlAbhishek DubeyNo ratings yet

- VMC AitsDocument25 pagesVMC AitsPrateek Madaan100% (1)

- CKB 20104 Reaction Engineering UniKL MICET Experiment 1a: The Batch Saponification of Ethyl Acetate Full Lab ReportDocument11 pagesCKB 20104 Reaction Engineering UniKL MICET Experiment 1a: The Batch Saponification of Ethyl Acetate Full Lab ReportSiti Hajar Mohamed82% (11)

- Worksheet Oxidation ReductionDocument7 pagesWorksheet Oxidation ReductionRudi BerlianNo ratings yet

- Problem Set 6 SolutionDocument3 pagesProblem Set 6 SolutionSourajit RoyNo ratings yet

- 0002 - 709 Gas Testing Using Portable Gas MonitorsDocument12 pages0002 - 709 Gas Testing Using Portable Gas MonitorsSrinivas Maddenapelli100% (2)

- 721547000Document2 pages721547000Kuldeep MalNo ratings yet

- TM10 450Document119 pagesTM10 450Christophe BrissonnetNo ratings yet

- Safety Data Sheet for LGFP 2 Lubricating GreaseDocument6 pagesSafety Data Sheet for LGFP 2 Lubricating GreaseZumrotus Saadah AbazNo ratings yet

- Stiffness and Weight: Density and Elastic Modulus Jayant JainDocument20 pagesStiffness and Weight: Density and Elastic Modulus Jayant JainTarun GuptaNo ratings yet

- Environment, Health and Safety Stipulations in Production OperationsDocument35 pagesEnvironment, Health and Safety Stipulations in Production OperationsWilfred ThomasNo ratings yet

- Geografia Bilingüe 1º EsoDocument121 pagesGeografia Bilingüe 1º Esoanamanuel652886No ratings yet

- Here are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideDocument67 pagesHere are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideCacey Daiwey CalixtoNo ratings yet

- COD Test Determines Organic PollutantsDocument13 pagesCOD Test Determines Organic PollutantsOshin Sharel Britto50% (2)

- BulletinofMTA2014 ENGDocument10 pagesBulletinofMTA2014 ENGVed PrakashNo ratings yet

- Tecnologia de Separacion Liquido Gas - Separsol PlusDocument4 pagesTecnologia de Separacion Liquido Gas - Separsol PlusLuis Alejandro Mariño - RamguzNo ratings yet

- AP Chemistry - Specific Heat of A Metal LabDocument2 pagesAP Chemistry - Specific Heat of A Metal LabJonathan Chen0% (1)

- Construction and Application of Heat SensorDocument42 pagesConstruction and Application of Heat Sensorokereke ebuka87% (23)

- Assignment PipelineDocument8 pagesAssignment PipelineDiego SerrateNo ratings yet

- Toxicokinetic PDFDocument29 pagesToxicokinetic PDFKirush MitaNo ratings yet

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet