Professional Documents

Culture Documents

Hopelex Af 3100

Uploaded by

FarizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hopelex Af 3100

Uploaded by

FarizCopyright:

Available Formats

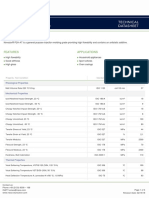

AF-3100 PC/ABS/GF alloy resin

General information

Description

10% glass-fiber reinforced PC/ABS, easy mold release

Non-brominated, non-chlorinated flame retardant

Optimum combination of high modulus and impact strength

Applications

Electric housing, etc.

Typical properties1

Test method Typical value Unit

Physical

Melt Flow Index, 300°C, 1.2 kg ASTM D1238 - g/10 min

Specific Gravity ASTM D792 1.2

Mold Shrinkage ASTM D955 0.3~0.4 %

Mechanical

Tensile Strength, yield, 50 mm/min ASTM D638 900 kgf/cm2

Tensile Elongation, break, 50 mm/min ASTM D638 >6 %

Flexural Strength, yield, 10 mm/min ASTM D790 1,100 kgf/cm2

Flexural Modulus, 10 mm/min ASTM D790 40,000 kgf/cm2

IZOD Impact Strength, notched, 23°C, 1/8” ASTM D256 10 kgf∙cm/cm

notched, 23°C, 1/4” ASTM D256 - kgf∙cm/cm

notched, -30°C, 1/8” ASTM D256 - kgf∙cm/cm

Thermal

Heat Distortion Temp. 4.6 kgf/cm2 ASTM D648 - °C

18.6 kgf/cm2 ASTM D648 115 °C

Vicat Softening Temp. Rate B/50 ASTM D1525 - °C

Flammability

UL94 V-0 UL94 1.5 mm

UL94 V-0 UL94 3.0 mm

Notes ISO 9001, 14001, TS 16949

1 Typical properties : these are not to be construed as specifications.

www.lottechem.com

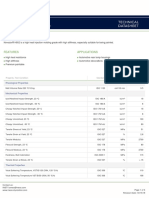

AF-3100 PC/ABS/GF alloy resin

Processing guides1

Typical value Unit

Drying condition

Drying temperature 90 ~ 100 °C

Drying time 4 hr

Maximum moisture content 0.02 %

Injection molding

Melt temperature 280 ~ 300 °C

Nozzle temperature 270 ~ 290 °C

Rear zone 280 ~ 300 °C

Barrel Middle zone 270 ~ 290 °C

Front zone 260 ~ 280 °C

Hopper temperature 60 ~ 80 °C

Mold temperature 60 ~ 80 °C

Mold Nozzle Rear Middle Front Hopper

zone zone zone

Recycling

Sprues and runners can be reground with virgin resin within the ratio of 20%. Care must be taken to ensure that the regrind is free from

impurities and regrind should not be used in applications where impact performance and/or agency compliance are required.

Notes ISO 9001, 14001, TS 16949

1Processing guides : Typical processing parameters are noted. Actual processing conditions will depend on machine size,

mold design, material residence time, shot size, etc.

www.lottechem.com

You might also like

- Caterpillar 3126Document0 pagesCaterpillar 3126manuel12515100% (22)

- Montana State Electrical Code BookletDocument35 pagesMontana State Electrical Code BookletMetis2011No ratings yet

- Inverter Sumitomo Af3100Document20 pagesInverter Sumitomo Af3100FarizNo ratings yet

- Report Business Plan Iron OreDocument37 pagesReport Business Plan Iron Orearun1974100% (1)

- hopelex pc-1100uDocument2 pageshopelex pc-1100uChu ChuNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetDocument1 pageLNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetWang MbaoNo ratings yet

- SABIC_Cycolac_MG47FDocument3 pagesSABIC_Cycolac_MG47FChu ChuNo ratings yet

- PG-GL Data SheetDocument1 pagePG-GL Data Sheetazeem bilalNo ratings yet

- SAN - KUMHO - 350-HW - TDS FDocument4 pagesSAN - KUMHO - 350-HW - TDS FakshayNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Atriot: Technical Data SheetDocument1 pageAtriot: Technical Data Sheetazeem bilalNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- KOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical ValueDocument2 pagesKOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical Valuehugo santiago chavez godoyNo ratings yet

- Supreme SH 03 High Impact Polystyrene Technical DatasheetDocument2 pagesSupreme SH 03 High Impact Polystyrene Technical DatasheetVignesh CmvrNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- PG 23Document1 pagePG 23azeem bilalNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- TP Wanhua Clarnate A1227 vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 vs Lexan 243RMitja GorseNo ratings yet

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- ABS HI121H Injection Molding Grade PropertiesDocument2 pagesABS HI121H Injection Molding Grade PropertiesPhuoc Thinh TruongNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Zytel® 45HSB NC010-gbDocument14 pagesZytel® 45HSB NC010-gbJuan Fernando CampuzanoNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- Makrolon RW6267 X ISO enDocument3 pagesMakrolon RW6267 X ISO envahdatvahedyNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- ABS Technical Data SheetDocument1 pageABS Technical Data SheetarmandoNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- 20% Glass Fiber Reinforced PC/PBT Product Data SheetDocument1 page20% Glass Fiber Reinforced PC/PBT Product Data SheetsrinivasaNo ratings yet

- Braskem CP 741 Blow Molding PolypropyleneDocument2 pagesBraskem CP 741 Blow Molding PolypropyleneRonaldo CamargoNo ratings yet

- Econamid FL 6B30Document2 pagesEconamid FL 6B30Jagadeesh WaranNo ratings yet

- SikaGrout-215 2011-11 - 1Document2 pagesSikaGrout-215 2011-11 - 1Fajar SodiqNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Productcatalog Eastman Com Tds ProdDatasheet Aspx Product 71097791 PN Turbo Oil 2197 Ga 2 203238289 1466225733 1606728244 1342979021 1606728244Document2 pagesProductcatalog Eastman Com Tds ProdDatasheet Aspx Product 71097791 PN Turbo Oil 2197 Ga 2 203238289 1466225733 1606728244 1342979021 1606728244KostiantynNo ratings yet

- PP11280 SpecificationDocument2 pagesPP11280 Specificationudummy552No ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Radel® R-5900 - SolvayDocument3 pagesRadel® R-5900 - SolvayTRUONGNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- polarlite-UK 4mmDocument4 pagespolarlite-UK 4mmoportunidade.engenharia.slzNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Grade: St900 DM311: Polypropylene CompoundDocument1 pageGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyNo ratings yet

- Eastma Turbo Oil 2197 TDSDocument2 pagesEastma Turbo Oil 2197 TDSstoreairkgNo ratings yet

- White NBR PDFDocument1 pageWhite NBR PDFNik Danial Aiman Nik HassanNo ratings yet

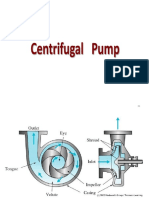

- Introduction To Pumps, Compressors, Fans & BlowersDocument68 pagesIntroduction To Pumps, Compressors, Fans & BlowersSagarSatyaNo ratings yet

- Daftar Nama Peserta Kopdar Dan Seminar Imc Asathi - Engineering Building SystemDocument2 pagesDaftar Nama Peserta Kopdar Dan Seminar Imc Asathi - Engineering Building SystemFarizNo ratings yet

- Centrifugal Pump Impeller Design and PerformanceDocument105 pagesCentrifugal Pump Impeller Design and PerformanceMohamed Moataz100% (1)

- CONCENTRATION AND DILUTION CALCULATIONSDocument32 pagesCONCENTRATION AND DILUTION CALCULATIONSRaja Mohan Gopalakrishnan100% (2)

- Shape Memory AlloysDocument11 pagesShape Memory AlloysAnonymous oOBXlaNo ratings yet

- Metalcraft Metrib 750: PurposeDocument2 pagesMetalcraft Metrib 750: PurposeAshleyHammondNo ratings yet

- Approximate Mix design calculation for concrete gradesDocument30 pagesApproximate Mix design calculation for concrete gradesMohamed Amine ZemouriNo ratings yet

- Mil PRF 87937DDocument23 pagesMil PRF 87937DmurphygtNo ratings yet

- BCA Publication "Making Good & Finishing"Document14 pagesBCA Publication "Making Good & Finishing"MisterphylNo ratings yet

- MODEL A ALARM VALVE TECHNICAL DATADocument9 pagesMODEL A ALARM VALVE TECHNICAL DATAjabbanNo ratings yet

- Compound Vapor Refrigeration System ExamplesDocument65 pagesCompound Vapor Refrigeration System Examplesm_alodat6144100% (1)

- Osmosis: Osmosis Is The Spontaneous Net Movement of SolventDocument3 pagesOsmosis: Osmosis Is The Spontaneous Net Movement of SolventCHIEF VISHAAL 45No ratings yet

- Building Utilities Reviewer ComprehensiveDocument3 pagesBuilding Utilities Reviewer ComprehensiveReynald HarrisNo ratings yet

- PRECIOS SCI PriceBook Full May10 VikingDocument294 pagesPRECIOS SCI PriceBook Full May10 VikingsueNo ratings yet

- Seminar ReportDocument34 pagesSeminar ReportShreyas GowdaNo ratings yet

- Shimano Disc ManualDocument0 pagesShimano Disc ManualnubirunNo ratings yet

- CONTROL TECHNICIAN TUBING INSTALLATIONDocument19 pagesCONTROL TECHNICIAN TUBING INSTALLATIONsomucdm6023No ratings yet

- MORTALEX ZSz0Document1 pageMORTALEX ZSz0Muhammad TayyabNo ratings yet

- Justifications for Using Robots in ManufacturingDocument12 pagesJustifications for Using Robots in ManufacturingAnil Sah100% (1)

- Operating & Maintenance for Medical Gas ManifoldDocument40 pagesOperating & Maintenance for Medical Gas ManifoldDebajyoti BarmanNo ratings yet

- Performance Analysis of Separating and Throttling Calorimeter To DetermineDocument5 pagesPerformance Analysis of Separating and Throttling Calorimeter To DetermineDaniel LauNo ratings yet

- MISON 8C Shielding GasDocument2 pagesMISON 8C Shielding Gascamelod555No ratings yet

- Cable Impedance Calculations Open Electrical PDFDocument4 pagesCable Impedance Calculations Open Electrical PDFblaagicaNo ratings yet

- MTC MasterFlow 718Document1 pageMTC MasterFlow 718Vikram DhabaleNo ratings yet

- API 579-1/ASME FFS-1 2007 Fitness-For-Service: ForewordDocument4 pagesAPI 579-1/ASME FFS-1 2007 Fitness-For-Service: ForewordMarlon VillarrealNo ratings yet

- Cliq Cliqsmart 111 Technical Data SheetDocument1 pageCliq Cliqsmart 111 Technical Data SheetSuravi BhaskarNo ratings yet

- Shinano Catalog 2014-2015Document30 pagesShinano Catalog 2014-2015edy105No ratings yet

- 高強度鋁合金擠型材之研究Document119 pages高強度鋁合金擠型材之研究Chin-Min YangNo ratings yet

- Crawl Space Plastic Visqueen ProjectsDocument1 pageCrawl Space Plastic Visqueen ProjectsRahimNo ratings yet

- Prolec Trafos Dimension Sbtr-1208-1Document2 pagesProlec Trafos Dimension Sbtr-1208-1rober2222No ratings yet