Professional Documents

Culture Documents

LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - Sheet

Uploaded by

Wang MbaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - Sheet

Uploaded by

Wang MbaoCopyright:

Available Formats

™ ™

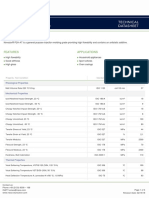

LNP THERMOCOMP COMPOUND WF0069

WF-1006 FR-S

DESCRIPTION

LNP THERMOCOMP WF0069 is a compound based on Polybutylene Terephthalate (PBT) resin containing 30% Glass Fiber. Added features of this material

include: Flame Retardant.

TYPICAL PROPERTY VALUES Revision 20201026

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

MECHANICAL

Flexural Strength, 1.3 mm/min, 50 mm span 165 MPa ASTM D790

Flexural Modulus, 1.3 mm/min, 50 mm span 9650 MPa ASTM D 790

Tensile Stress, brk, Type I, 5 mm/min 121 MPa ASTM D 638

Tensile Strain, brk, Type I, 5 mm/min 2.5 % ASTM D 638

IMPACT

Izod Impact, unnotched, 23°C 370 J/m ASTM D 4812

Izod Impact, notched, 23°C 64 J/m ASTM D 256

THERMAL

HDT, 1.82 MPa, 3.2mm, unannealed 204 °C ASTM D 648

PHYSICAL

Density 1.68 g/cm³ ASTM D 792

Mold Shrinkage, flow, 24 hrs 0.4 – 0.5 % ASTM D 955

Water Absorption, (23°C/24hrs) 0.06 % ASTM D570

FLAME CHARACTERISTICS

UL Yellow Card Link E121562-101358191 - -

UL Recognized, 94V-0 Flame Class Rating 0.73 mm UL 94

INJECTION MOLDING

Drying Temperature 110 – 120 °C

Drying Time 2–4 hrs

Maximum Moisture Content 0.02 %

Melt Temperature 245 – 260 °C

Nozzle Temperature 230 – 255 °C

Front - Zone 3 Temperature 240 – 260 °C

Middle - Zone 2 Temperature 235 – 250 °C

Rear - Zone 1 Temperature 230 – 240 °C

Hopper Temperature 40 – 60 °C

Mold Temperature 40 – 100 °C

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed

otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE

PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller

materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is

intended, or should be construed, to grant any license under any patent or other intellectual property right.

© 2020 Copyright by SABIC. All rights reserved

You might also like

- CYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - C1200HF - Asia - Technical - Data - SheetShrikantNo ratings yet

- LEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ FR Resin - 945 - Asia - Technical - Data - SheetSapphire PolycarbonatesNo ratings yet

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 pagesCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloNo ratings yet

- SABIC_Cycolac_MG47FDocument3 pagesSABIC_Cycolac_MG47FChu ChuNo ratings yet

- TDS - Lexan HF1140-111Document2 pagesTDS - Lexan HF1140-111It WittayaNo ratings yet

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraNo ratings yet

- CYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- TP Wanhua Clarnate A1227 vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 vs Lexan 243RMitja GorseNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- CovestroDocument2 pagesCovestroRonaldo CamargoNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Starflam PA66 25VDocument2 pagesStarflam PA66 25VjahabarsathickNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- hopelex pc-1100uDocument2 pageshopelex pc-1100uChu ChuNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Technical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticDocument1 pageTechnical Data Sheet for ALTECH ABS C 2017/500 GF17 PlasticarmandoNo ratings yet

- Christo Lube MCG 134 Tech DataDocument1 pageChristo Lube MCG 134 Tech Datarobertoalfaro492023No ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- RTP 2500 FR ADocument2 pagesRTP 2500 FR ASoopNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDocument3 pagesSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- GENESTAR™ GP2300S - KurarayDocument4 pagesGENESTAR™ GP2300S - KurarayRafael CastroNo ratings yet

- Grade: St900 DM311: Polypropylene CompoundDocument1 pageGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 pagesNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeNo ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Makrolon RW6267 X ISO enDocument3 pagesMakrolon RW6267 X ISO envahdatvahedyNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- TDS - Shengyuan - Pc-907ur - enDocument3 pagesTDS - Shengyuan - Pc-907ur - endinhdat1604No ratings yet

- Hojas TécnicasDocument2 pagesHojas TécnicasalejandrocharlescollNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- GD&T Reference ChartDocument1 pageGD&T Reference ChartWang MbaoNo ratings yet

- Super-X No.8008Document6 pagesSuper-X No.8008Wang MbaoNo ratings yet

- CCP Pogo Pin Connector 20210111Document33 pagesCCP Pogo Pin Connector 20210111Wang MbaoNo ratings yet

- E20196 Tuf Gaming X670e Plus Um WebDocument72 pagesE20196 Tuf Gaming X670e Plus Um WebWang MbaoNo ratings yet

- 121R-21051紅外線穿透資料 - 物性表Document5 pages121R-21051紅外線穿透資料 - 物性表Wang MbaoNo ratings yet

- ASTM C42. Standard Test Method For Obtaining and Test Drilled Cores and Sawed Beams of ConcreteDocument7 pagesASTM C42. Standard Test Method For Obtaining and Test Drilled Cores and Sawed Beams of ConcreteENGYA2007No ratings yet

- Concrete Industrial Floor Design - Engineers EdgeDocument1 pageConcrete Industrial Floor Design - Engineers EdgeNeil WilsnachNo ratings yet

- Cracking in Soil - Ceme T: R R R RDocument16 pagesCracking in Soil - Ceme T: R R R RCharme LangaNo ratings yet

- Norma ASTM C1609Document9 pagesNorma ASTM C1609Adrián Guevara100% (1)

- Improving Bending and Dynamic Mechanics Performance of 3D Printing Through Ultrasonic Strengthening PDFDocument4 pagesImproving Bending and Dynamic Mechanics Performance of 3D Printing Through Ultrasonic Strengthening PDF손종인No ratings yet

- 2006 Structural Seismic Design Manual 1Document220 pages2006 Structural Seismic Design Manual 1vttrlc93% (14)

- Trogamid CX - en 3-2012 PDFDocument28 pagesTrogamid CX - en 3-2012 PDFJosip DuvnjakNo ratings yet

- HW05Document4 pagesHW05Potatoes123No ratings yet

- CIB-W18 2006 Paper39-6-2 Steiger Arnold Fontana FinalSubmitDocument18 pagesCIB-W18 2006 Paper39-6-2 Steiger Arnold Fontana FinalSubmitAleksandraNo ratings yet

- MT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)Document25 pagesMT 03 - Mechanical Properties and Tests, A-Z Abbrev (Tinius Olsen - Kul 1)zingerNo ratings yet

- Flexural Behavior of Coconut Wood LaminatesDocument9 pagesFlexural Behavior of Coconut Wood Laminatesjun del rosarioNo ratings yet

- (2017) Review On Mechanical Properties of Banana FiberDocument5 pages(2017) Review On Mechanical Properties of Banana Fiberdeepen_banoriyaNo ratings yet

- Kerto Manual LVL Mechanical PropertiesDocument6 pagesKerto Manual LVL Mechanical PropertiesTiago GonçalvesNo ratings yet

- Obtaining and Testing Drilled Cores and Sawed Beams of ConcreteDocument7 pagesObtaining and Testing Drilled Cores and Sawed Beams of ConcreteAshraf TomizehNo ratings yet

- Bangladesh National Building Code 2012 Part6 Chapter 6Document111 pagesBangladesh National Building Code 2012 Part6 Chapter 6morphie_blackNo ratings yet

- Transparent ConcreteDocument15 pagesTransparent ConcreteUnknown PersonNo ratings yet

- z.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Document6 pagesz.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Sutarno -No ratings yet

- Three-Point Beam Bend Test AnalysisDocument7 pagesThree-Point Beam Bend Test Analysisrajesh100% (1)

- RCCDocument54 pagesRCCashok KumarNo ratings yet

- Experimental Study On Concrete Using Glass Powder and Granite PowderDocument5 pagesExperimental Study On Concrete Using Glass Powder and Granite PowderijaertNo ratings yet

- Astm D790-15Document12 pagesAstm D790-15Leonardo Boa Sorte100% (2)

- Concrete Strength Acceptance Criteria IRCDocument7 pagesConcrete Strength Acceptance Criteria IRCSurinderPalSinghGillNo ratings yet

- VW 50134 en 2015-09Document13 pagesVW 50134 en 2015-09xu zhangNo ratings yet

- Strength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksDocument10 pagesStrength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksSam ChongNo ratings yet

- Module 3Document40 pagesModule 3kookie maeNo ratings yet

- CS1-2010 Vol 2 Rev 00-101130 PDFDocument98 pagesCS1-2010 Vol 2 Rev 00-101130 PDFbaxterNo ratings yet

- Development of Solid, Foam Concrete Interlocking Blocks and Studies On Short Masonry SpecimensDocument11 pagesDevelopment of Solid, Foam Concrete Interlocking Blocks and Studies On Short Masonry SpecimensJONAR LEONESNo ratings yet

- SEAOC Seismic Design Manual Examples Vol 3 PDFDocument350 pagesSEAOC Seismic Design Manual Examples Vol 3 PDFmoamenmahmoud84100% (7)

- Astm c42Document7 pagesAstm c42Tavo Suarez CNo ratings yet

- Ain Shams University - Faculty of Engineering: Tension, Compression, Shear and Flexure Test Reports of Balsa WoodDocument8 pagesAin Shams University - Faculty of Engineering: Tension, Compression, Shear and Flexure Test Reports of Balsa WoodDolzMaGiCz100% (1)