Professional Documents

Culture Documents

Test Procedure of Surge Arrester

Test Procedure of Surge Arrester

Uploaded by

ykh92167Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Procedure of Surge Arrester

Test Procedure of Surge Arrester

Uploaded by

ykh92167Copyright:

Available Formats

Introduction:

To evaluate the insulation integrity of an arrester, measure the power loss

(watts-loss or dissipation factor) at a specified voltage and compare it with

previous measurements on the same or similar arrester. Measurements on a

surge arrester should always be performed at the same or recommended test

voltage since nonlinear elements may be built into an arrester. When using

this test set, all measurements should normally be made at 10 kV. Except for

the specific purpose of investigating surface leakage, the exposed insulation

surface of an arrester should be clean and dry to prevent leakage from

influencing the measurements.

Some types of arresters show substantial temperature dependence, while

others show very little dependence. Temperature correction curves for each

arrester design should be carefully established by measurement, and all

measurements should be temperature corrected to a base temperature,

Usually 20°C. The temperature measurement should be based on that at the

arrester surface. The air temperature should also be recorded. The surface of

the arrester should be at a temperature above the dew point to avoid moisture

condensation.

Test under IEC 60099 .

In substations, surge arrestors appears on two types

1. Single arrester unit

2. Multi-unit arrester stacks.

It is recommended that tests be made on individual arrester units rather than

on a complete multi-unit arrester stack. A single arrester unit can be tested by

the normal ungrounded specimen test (UST) in the shop; however, it can only

be tested by the grounded specimen test (GST) when mounted on a support

structure in the field.

1. Single arrester unit:

Surge arresters which contains single unit tested by Insulation

resistance test, Capacitance test by tan delta equipment and leakage

current monitor test.

Insulation resistance test:

Insulation resistance test must be carried out at the surge

arresters through Insulation resistance tester such as Megger. Insulation

resistance test must be carried out between the conductor of bushing

and ground of the bushing. By applying 5KV to the Surge arrester for

1minute, record the value of insulation resistance with atmospheric

temperature.

Capacitance and Dissipation power factor test:

Surge arrester with single unit must be subject to

capacitance and dissipation power factor test by applying 10 KV through

Tan delta equipment with the GST (Ground Specimen Test) mode. The

temperature must be noted at the time of testing and the values

measured must be compensated to 20°C.

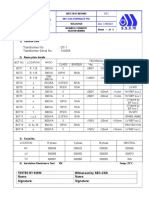

The below table show the connections on single unit.

The results must be match with factory reports for their integrity.

TEST LOW VOLTAGE CONFIGURATION TEST CONNECTIONS TO

NO SURGE ARRESTOR REMARKS

SYMBOL SURGE ARRESTOR

INSULATION

TESTED TEST MEASURE GROUND GAURD BLACK RED BLUE

MODE

SA GST RED 1 5

Leakage current monitor test:

For every phase of the surge arrester the leakage current monitor is

available. The monitors must be calibrated and tested by injecting milliamps

current by sverker. Record the calibrated values with standard values and its

error must be within the limits of respected manufacturer.

2. Multi-unit arrester stack:

Surge arresters which contains multi-unit tested by Insulation

resistance test, Capacitance and dissipation power factor test by tan

delta equipment and leakage current monitor test.

For the Insulation resistance and leakage monitor test the above mention

procedures in single unit can be followed. For the capacitance and dissipation

power factor the following procedures must be used.

Table below shows the recommended test procedure for testing installed

multi-unit arrester stacks. When testing in the field, disconnect the related

high-voltage bus from the arrester.

Surge Arrester Test Connections

TEST LOW VOLTAGE CONFIGURATION TEST CONNECTIONS TO

NO SURGE ARRESTOR REMARKS

SYMBOL SURGE ARRESTOR

INSULATION

TESTED TEST MEASURE GROUND GAURD BLACK RED BLUE

MODE

1. SA-A UST BLUE RED 2 3 1 TERMINAL 3

GROUND

2. SA-B UST RED BLUE 2 3 1 TERMINAL 1

GOUND

3. SA-C UST RED BLUE 4 3

4. SA-D GST RED 4 3 TERMINAL 3

GUARDED

Note: Apply 10KV for each injection

Typical Multi-Unit Arrester Stack

Record the values as per the requirements and standards with the

temperature at the time of testing. These recorded values of Dissipation power

factor must be corrected to 20°C.

You might also like

- High Pot Test ProcedureDocument5 pagesHigh Pot Test Procedurebookbum100% (1)

- Castor Business Plan - enDocument28 pagesCastor Business Plan - enVpsingh86% (7)

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Testing NotesDocument12 pagesTesting NotesJigar TakoliaNo ratings yet

- Methods of Earth Resistance TestingDocument6 pagesMethods of Earth Resistance Testingsubu100% (1)

- Various Routine Test of Power Transformer - (Part-3)Document8 pagesVarious Routine Test of Power Transformer - (Part-3)supermannonNo ratings yet

- Switchgear and Circuit Breaker - TestingDocument18 pagesSwitchgear and Circuit Breaker - TestingSyam KushainiNo ratings yet

- HV Cable CommissioningDocument2 pagesHV Cable CommissioningAtchut Rao100% (1)

- Collar Test For BushingDocument21 pagesCollar Test For Bushingfajar9nugraha-2100% (1)

- Technical Report On Current Transformer TestDocument4 pagesTechnical Report On Current Transformer TestEgbodor PeterNo ratings yet

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Classical Guitar Class Curriculum, Grades 6-12 Teacher ManualDocument38 pagesClassical Guitar Class Curriculum, Grades 6-12 Teacher Manualgstith9597No ratings yet

- Method Statement For Protection TestingDocument4 pagesMethod Statement For Protection TestingAfanda Rodgers100% (4)

- Testing of CTDocument17 pagesTesting of CTsasikumar100% (1)

- SOP For Testing TransformerDocument1 pageSOP For Testing TransformerPARAMSIVAMNo ratings yet

- 33 KV VLF Method - Statement For ATSDocument4 pages33 KV VLF Method - Statement For ATSTesting PLQNo ratings yet

- GT - 1 Bushing Current Transformer Ir Test ReportDocument5 pagesGT - 1 Bushing Current Transformer Ir Test ReportPrathap KumarNo ratings yet

- Megger-Application Guide For Power Factor Testing of Circuit BreakersDocument6 pagesMegger-Application Guide For Power Factor Testing of Circuit Breakerspemanr1914No ratings yet

- Relay Testing Procedure PDFDocument50 pagesRelay Testing Procedure PDFLawrence Alex100% (2)

- Surge Arrest Test ProceduresDocument11 pagesSurge Arrest Test Proceduresmarevey100% (3)

- Power Transformer Testing & Commissioning Procedure - Rev R0Document16 pagesPower Transformer Testing & Commissioning Procedure - Rev R0nanaNo ratings yet

- What Is VLFDocument9 pagesWhat Is VLFnysa6987No ratings yet

- Switch Gear SlideDocument54 pagesSwitch Gear SlidebutunsonaNo ratings yet

- Currnt Transformer Testing ProcedureDocument3 pagesCurrnt Transformer Testing ProcedurePrabagaran PrtNo ratings yet

- Commissioning Test Report For Circuit Breaker SiteDocument3 pagesCommissioning Test Report For Circuit Breaker SiteGuru Mishra100% (1)

- Bus Bar Protection ProcedureDocument3 pagesBus Bar Protection Procedurewaqas_a_shaikh4348100% (1)

- Test Procedure - CT & PTDocument6 pagesTest Procedure - CT & PTmayur dhande100% (2)

- Transformer Testing - Type Tests and Routine Tests of TransformerDocument10 pagesTransformer Testing - Type Tests and Routine Tests of TransformerKaleem UllahNo ratings yet

- Transformer Winding ResistanceDocument20 pagesTransformer Winding Resistancekajale.shrikantNo ratings yet

- Tests On Bushing Current Transformer InstalledDocument3 pagesTests On Bushing Current Transformer InstalledAnonymous utxGVB5VyNo ratings yet

- Current Transformer TestingDocument4 pagesCurrent Transformer TestingKarthick Rathinasamy100% (1)

- Testing of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsDocument14 pagesTesting of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsRANGASWAMY SNo ratings yet

- Tan Delta Test ProcedureDocument4 pagesTan Delta Test Procedurearshadsbd167% (3)

- Lecture # 3, Separate Source & Induce TestDocument26 pagesLecture # 3, Separate Source & Induce Testraza239No ratings yet

- 80MVAR Reactor Test ReportDocument28 pages80MVAR Reactor Test ReportSARAVANAN ANo ratings yet

- Elite Precommissioning Procedures and Formats For SS Bay EquipmentDocument92 pagesElite Precommissioning Procedures and Formats For SS Bay EquipmentSurya Mvs100% (1)

- Auxiliary Transformer Test ProcedureDocument3 pagesAuxiliary Transformer Test ProcedureArun Kumar100% (1)

- 220kv Cable Cross Bonding TestDocument7 pages220kv Cable Cross Bonding Testvivek2159No ratings yet

- Pharmacognosy - Lab-ManualDocument28 pagesPharmacognosy - Lab-ManualHarish KakraniNo ratings yet

- Voltage Ratio and Magnetizing Current Tests by Kareem oDocument18 pagesVoltage Ratio and Magnetizing Current Tests by Kareem oKAREEM OLAWALENo ratings yet

- Bushings for Power Transformers: A Handbook for Power EngineersFrom EverandBushings for Power Transformers: A Handbook for Power EngineersRating: 1 out of 5 stars1/5 (1)

- Transformer Testing - Type Test and Routine Test of TransformerDocument15 pagesTransformer Testing - Type Test and Routine Test of TransformerPrabhakar RamachandranNo ratings yet

- Transformer Testing: Type Test of TransformerDocument9 pagesTransformer Testing: Type Test of TransformerSanjeev DhariwalNo ratings yet

- Current Transformer Test ProcedureDocument2 pagesCurrent Transformer Test ProcedureEzeldeen AgoryNo ratings yet

- Capacitor Bank Testing SWPDocument8 pagesCapacitor Bank Testing SWPaniler100% (3)

- Studies in IbadhismDocument226 pagesStudies in IbadhismBADAR MOHAMMED100% (2)

- Quality Procedure - Testing ManualDocument43 pagesQuality Procedure - Testing Manualsheik hussain100% (1)

- Measurement of Insulation Resistance (IR) - Part 2 - EEP PDFDocument16 pagesMeasurement of Insulation Resistance (IR) - Part 2 - EEP PDFHeri SulaimanNo ratings yet

- Transformer Testing - Type Test and Routine Test of Transformer - ElectricalDocument15 pagesTransformer Testing - Type Test and Routine Test of Transformer - ElectricalvolkanNo ratings yet

- Testing of Power TransformerDocument55 pagesTesting of Power TransformerDiego Betancourt MejiaNo ratings yet

- Rmu Test ProcedureDocument5 pagesRmu Test Proceduresmi1989100% (2)

- Demand Forecasting QuestionsDocument30 pagesDemand Forecasting QuestionsgigipapasNo ratings yet

- CT TandeltaDocument2 pagesCT Tandeltakishansai100% (2)

- Power Transformer Testing ProcessDocument19 pagesPower Transformer Testing ProcessRajj PruthiviNo ratings yet

- Transformer Testing ProDocument17 pagesTransformer Testing ProAnonymous 2l8XJIVNo ratings yet

- SP0407 Commissioning Tests For HV UG CablesDocument13 pagesSP0407 Commissioning Tests For HV UG Cablesyavuz772100% (4)

- Transformer Demagnetizing ProcedureDocument5 pagesTransformer Demagnetizing ProcedureMerlyn Jordano Choqque Vilca100% (1)

- High Voltage TestingDocument41 pagesHigh Voltage Testingpvrk123No ratings yet

- Pre-Commissioning TestsProcedure For SEC Transmission Electrical InstallationDocument222 pagesPre-Commissioning TestsProcedure For SEC Transmission Electrical Installationsmi198986% (7)

- NXAIR Design Catalogue PDFDocument51 pagesNXAIR Design Catalogue PDFZalatiel Mecott ArandaNo ratings yet

- Mintel Global Consumer Trends 2030 April 2020 Shared by WorldLine TechnologyDocument48 pagesMintel Global Consumer Trends 2030 April 2020 Shared by WorldLine Technologylebaosip100% (1)

- Routine Test-Acceptance Criteria IEC (Power Transformer)Document2 pagesRoutine Test-Acceptance Criteria IEC (Power Transformer)Yingyong_s75% (4)

- Science-9 q1 w1 Mod1 Adm-1Document62 pagesScience-9 q1 w1 Mod1 Adm-1Carla GabrielNo ratings yet

- S09-3 Compressor CTN10-16 (1.00)Document34 pagesS09-3 Compressor CTN10-16 (1.00)Anonymous AW4pRV7r75% (4)

- Bus Bar Contact Resistance Measurement TestDocument4 pagesBus Bar Contact Resistance Measurement TestAnil100% (2)

- 4 Ammeter Test ReportDocument1 page4 Ammeter Test ReportJayaprakash M PNo ratings yet

- VIDAR-DC Test Vacuum Integrity MV Switchgear AN enDocument4 pagesVIDAR-DC Test Vacuum Integrity MV Switchgear AN ennassarkiNo ratings yet

- TRNSFRMR 194-230Document37 pagesTRNSFRMR 194-230SukumaraNo ratings yet

- Application Guide For Power Factor Testing of Surge (Lighting) ArrestersDocument2 pagesApplication Guide For Power Factor Testing of Surge (Lighting) ArrestersWilliam NuevoNo ratings yet

- Electrical Instruments: Insulation Resistance (IR) TesterDocument2 pagesElectrical Instruments: Insulation Resistance (IR) Testertmtt44No ratings yet

- A: The Circuit NamesDocument1 pageA: The Circuit Namessmi1989No ratings yet

- Accord PDFDocument13 pagesAccord PDFsmi1989No ratings yet

- Technical Pens and Its UsesDocument6 pagesTechnical Pens and Its UsesBridget Nicole BordeosNo ratings yet

- What Is ReactDocument40 pagesWhat Is Reacthabtamu fentewNo ratings yet

- Peritonitis NCPDocument3 pagesPeritonitis NCPANNA V. LARITANo ratings yet

- UNIT 5 Notes - OoadDocument33 pagesUNIT 5 Notes - OoadMALARMANNAN ANo ratings yet

- Lexicology Week 6 2023Document6 pagesLexicology Week 6 2023Gvanca GrdzelishviliNo ratings yet

- Tendor of EsiDocument7 pagesTendor of EsiRaj KumarNo ratings yet

- Wang1996 Design and Performance Prediction PDFDocument14 pagesWang1996 Design and Performance Prediction PDFalper yeterNo ratings yet

- A Dual-Linear Polarized Highly Isolated CrossedDocument4 pagesA Dual-Linear Polarized Highly Isolated CrossedPhạm GiangNo ratings yet

- Tivoli MessagesDocument851 pagesTivoli Messagesjackiexie3813No ratings yet

- Tale of Two SievesDocument13 pagesTale of Two SievesMark MarkesonNo ratings yet

- Webinar KNX Visualisation - Updates and Solutions July 2017 - BU EPBP GPG Building AutomationDocument37 pagesWebinar KNX Visualisation - Updates and Solutions July 2017 - BU EPBP GPG Building AutomationIorgoni LiviuNo ratings yet

- Climate Change and Emerging Food Safety Issues - A ReviewDocument14 pagesClimate Change and Emerging Food Safety Issues - A ReviewKerian FerreiraNo ratings yet

- Ac SequenceDocument4 pagesAc SequencejenolivaNo ratings yet

- A Charge of A Light BrigadeDocument26 pagesA Charge of A Light Brigadeniluka welagedaraNo ratings yet

- Worksheet ExerciseDocument2 pagesWorksheet Exerciseshaan shekharNo ratings yet

- Case StudyDocument73 pagesCase Studyvishanth rameshNo ratings yet

- Gas Filter SizingDocument148 pagesGas Filter SizingRAJIV_332693187No ratings yet

- Karim Noui - Loop Quantum Gravity: State of The ArtDocument15 pagesKarim Noui - Loop Quantum Gravity: State of The ArtLopmazNo ratings yet

- Lyrics BLOODY MARYDocument1 pageLyrics BLOODY MARYMuhd Baqir AzidzNo ratings yet

- Mod2 GMRC PDFDocument7 pagesMod2 GMRC PDFCyrill Mico De GuzmanNo ratings yet

- Career Essay Eng 1302Document4 pagesCareer Essay Eng 1302Madison MorenoNo ratings yet

- An Psalter C 00 BrowDocument264 pagesAn Psalter C 00 BrowHumphrey Ibifubara100% (1)