Professional Documents

Culture Documents

Homebuilt 6 - F15 Refractor and Mount

Homebuilt 6 - F15 Refractor and Mount

Uploaded by

aa ssOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homebuilt 6 - F15 Refractor and Mount

Homebuilt 6 - F15 Refractor and Mount

Uploaded by

aa ssCopyright:

Available Formats

Let's Make ...

Featured Write an Instructable Login | Sign Up

Classes Contests Community Teachers Pier 9

advertisement

HOMEBUILT 6" F15 REFRACTOR AND MOUNT

By Astrochef in Technology > Science 82,236 243 40 Featured

Published Aug. 3, 2011 Download Favorite

By Astrochef About: I am a Chef of 15 years and an astronomer for the past 20. I build my own

stuff wherever possible. I have a lovely supportive wife and two beautiful girls. More

Follow About Astrochef »

Hello fellow Instruct-ables... What better way to celebrate space than to look at it through

a really big telescope? I have been an ATM for quite a while and this is my latest project, a

big refracting telescope on a big mount.

Add Tip V Ask Question | Comment Download

Step 1: Gathering Parts

The mount is made from mostly easy to nd scrap parts I found on line. I spent a lot of time

looking for scrap pieces that were close to sizes I needed until I found that the metal

merchants would cut pieces to size for pretty cheap. I used common power tools such as a

small drill press, router, circular saw and chop saw. Working with aluminum is a lot like

working with very hard woods, the cutting feels the same but slower.

The chassis is made of 1/2" sheet aluminum. The bearings are pillow block bearings. The

Main(RA) shaft is 2-5/8" diameter aluminum and the smaller(dec) shaft is 1-1/6" steel. The

large

Homebuilt worm

6" F15 gear

Refractor andwas purchased

Mount by Astrochef cheaply

Follow from an astronomy website. Download Favorite

Add Tip V Ask Question | Comment Download

Step 2: Routing Aluminum

This is a step that I thought about for a good long while. An equatorial mount has to have

some adjustment for the angle of altitude in order to track properly. The angle for your

location is your latitude, Where I am the mount needs to be set at 42deg. I decided to make

the angle adjustable about 5 deg either way. To make these small arcs I used a circle-cutter

attachment on my router and made quick 1/8" passes until I cut through each side of the

chassis.

Add Tip V Ask Question | Comment Download

Step 3: Basic Chassis Assembly

I trimmed the mounting tabs from the large pillow block bearings and ground down the

sides with an angle grinder. After some drilling and some tapping, I bolted the base chassis

up...

I added a brace and tapped a hole for an adjustment bolt. Turning this bolt allows the angle

to be adjusted then clamped down when it's right.

Add Tip V Ask Question | Comment Download

Step 4: The RA Shaft

My large pillow block bearings were sold to me as 3"ID however when they arrived they

were closer to 2-5/8"ID. I was able to nd 2-5/8" aluminum cylinder and had it pressed into

a 6" dia 1" thick disk. Pressing the shaft in is a very strong and stiff junction but is a job for

a metal shop with a press, My local machine shop charged me $20.

Add Tip V Ask Question | Comment Download

Step 5: The Dec Shaft

I had the 1-1/16" dia x 24" long dec shaft pressed into a 2-1/2" x 2" x10" Aluminum bar.

For the correct alignment of the tube, this unit has to be trued on a lathe. Another $20 to

the machine shop.

I felt like Thor when I carried this into the house.

Add Tip V Ask Question | Comment Download

Step 6: The Dec Shaft Assembly

The dec shaft rides in two 1-1/16"ID pillow block bearings mounted to a 1/2" aluminum

plate which is bolted to the RA shaft. I added a 4"wx14"l aluminum bar to mount the tube

rings.

Add Tip V Ask Question | Comment Download

Step 7: Mounting of the Large Drive Gear

In a big scope the accuracy of the tracking is directly tied to the size of the worm gear. Big

worm gear means smaller errors. A big worm gear also needs a smaller drive motor. This

gear is clamped between two circles of HDPE which is actually cutting board material. I

routed two 12" circles to act as clutch plates as well as a smaller 6" donut for the gear to

ride on. This assembly is clamped tight via two threaded shafts. This clutch arrangement

allows the tube to be moved anywhere while the motor turns for effortless pointing and

tracking.

Add Tip V Ask Question | Comment Download

Step 8: Worm Drive Assembly

The worm drive is built from pieces of aluminum bar cut from left over material. The worm

gear came from another smaller drive and happened to t. The shaft rides in oilite bushings.

Gear slack is taken up by a screw that presses the shaft from the side and prevents lateral

movement of the gear. Each piece of this unit took a couple of tries because to avoid

binding, some precision was involved. By precision I mean drilling holes over and over until

nally the shaft stopped binding!

The motor is a synchronous timing motor which runs at a set speed from household

voltage. These are used in older or simple telescope drives because it uses the frequency of

your house voltage to keep accurate speed. Adjustments of the speed can be accomplished

by the use of a square-wave frequency generator, a simple circuit that allows you to speed

up or slow down the motor for tracking.

Add Tip V Ask Question | Comment Download

Step 9: Tripod Hub

The tripod hub is made from two disks of aluminum bolted to three leg mount bars. The top

of the hub is machined at. The bolt hods the chassis to the hub.

Add Tip V Ask Question | Comment Download

Step 10: Oak Tripod Legs

The tripod legs are built up from oak ooring boards discarded as scrap by a neighbor. They

are as long as the shortest piece so abou 48"l.

Add Tip V Ask Question | Comment Download

Step 11: Mount Assembled

All the different assemblies together as a mount head.

Add Tip V Ask Question | Comment Download

Step 12: Finished Mount

After some ddling, re tting, stiffening sanding and painting, the nished mount....

Add Tip V Ask Question | Comment Download

Step 13: The Heart and Soul....

Ah, now it's time for the cool stuff... The Objective! This lens was made by Istar Optical, at

the time a relatively new manufacturer of telescope optics. The lens has shown itself to be

an excellent performer, especially for the price. Currently the objective in cell costs about

$515.

Add Tip V Ask Question | Comment Download

Step 14: The Tube...

The tube is a section of aluminum tube made by Hastings Irrigation. I had to special order

the size as shipping an 8' l tube costs as much as the tube itself...

The focuser is a Synta refractor focuser painted blue for looks.

The interior is baf ed via 7 knife-edge baf es spaced 12" apart. The baf e assembly was

built from plans I drew of the optical path. The baf es are kept out of the light path by

about 1/4" or so.

Add Tip V Ask Question | Comment Download

Step 15: Objective Cell Mounting

The objective needs to be mounted in a collimatable ring. This ring was routed from three

pieces of HDPE drilled and tapped for three push-pull screw arrangements.

Add Tip V Ask Question | Comment Download

Step 16: Sliding Dew Shield

Traveling with a 9'l tube is tough, traveling with an 8' tube is much easier, ts right in the

mini-van. To make things easier the dewshield slides over the objective to shield the lens

from stray light.

Add Tip V Ask Question | Comment Download

Step 17: How Does It Perform?

This refractor is an achromat which normally would not be suitable for photography. Due to

it's large focal ratio (f15) and long focal length(2276mm) this scope is a superb planetary

performer. This is a photo of Saturn taken with a Celestron Neximager, a webcam-based

imaging camera. This photo is a stack of 1000 frames in Registax. There is a white blob

which is a storm imaged on the surface of Saturn from 3 blocks outside of Chicago!

Add Tip V Ask Question | Comment Download

CFD in your browser CFD in your browser

Run uid mechanics analysis Run uid mechanics analysis

in minutes. Test it for free! in minutes. Test it for free!

advertisement advertisement

Grand Prize in the

View Contest

Celestron Space Challenge

Share

Did you make this project? Share it with us!

I Made It!

Recommendations

WiFi Controlled Camera High Velocity Vortex Cannon How to Build a PHOTO 3D CAM and CNC

Slider by NightHawkInLight in Science LIGHT BOX Class

by Toglefritz in Technology by diycreators in Photography 495 Enrolled

Add Tip

V

Ask Question

|

Post Comment

We have a be nice policy.

Add Images Post

Please be positive and constructive.

40 Comments

jwoodward8 5 years ago Reply

Does it work

X Astrochef (author) 6 years ago Reply

8 WOW! Thanks everyone who voted! I am proud to be a part of such an active building community.

Thank you Instructables and Celestron, I'll put the scope to good use!

Hopefully my wife will let me spend a little more time in the shop now!

Sean

Mechanic2011 6 years ago Reply

For building a telescope:

Do you know of anyone that has used a section of the heavy Green plastic sewer pipe which is

available in diameters starting at 10 or 12 inches for this?

I have found the white PVC pipe locally that is 8 inches approx. in diameter.

Anything 6 inches or less is available in the plumbing supply / home improvement stores .

The problem is that once you get to the green commercial PVC piping the gets buried underground a

ways , it also gets very heavy as the wall thickness is quite thick as it is schedule 30 or 40 so it won't

crush when buried in the ground.

The Blue PVC underground piping is for water mains and has an even thicker wall on it than the green

sewer piping as it needs to be schedule 80 and be able to take the municipal water pressure

continuously .

5 replies F

X georgeATM 6 years ago Reply

8 Beautiful scope! I am surprised you went with oak on the tripod legs. I Built an 8" f/15 refractor and

used all aluminum except for the alt-az box on top of the tripod.

6 replies F

jmacdonald6 6 years ago Reply

Very nice work indeed bro. Congratulations. But I found those instructions are so imprecise to the

inexperienced (myself) that I could as easily end up with a vertical lawn mower or letter opener for

giraffes. Not only that, this project could be impossible in many other countries: one bemoans e.g. in

the UK the lack of DIY venues -- of junkyards, 'local machine shop guy', spare materials, shops,

suppliers, space, of ANY PERSON within 1000 miles 'discarding' any hardwood in size and number

bigger than a single chopstick. Thus MY assessment: life is tough in the US now but appreciate that

you don't need to crop your own talents as in Europe. Keep on building and posting!

1 reply F

pcgate 6 years ago Reply

just plain ole wow. good job.

raul38 6 years ago Reply

Thanks for share your excellent works

| spark master 6 years ago Reply

Any scope builders on LI (nassau cty) that would like parts to build a small Galileo telescope? My

friend has 2 3 in parts and one complete (maybe he will parrt with it don't know). They are the standard

cherapo scopes so you could make 1 perhaps from the parts or take two and make really big

binoculars (yeah that ain't happening cause the parts to make them cost more then buying a pair).

let me know and perhpas it will be for you. 2 scopes and crappy needs reapirs tripods. free for

experimentals on LI.

Drop me a line through instructables and I will put you in touch. These will be free, but you gotta go

get'm

More Comments Post Comment

Categories About Us Resources Find Us

Technology Food Who We Are Residency Program

Workshop Play Why Publish? Community

Craft Outside Jobs Sitemap

Home Costumes Contact Help

© 2018 Autodesk, Inc. Terms of Service | Privacy Statement | Privacy settings | Legal Notices & Trademarks

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- TH220B TH330B PDFDocument66 pagesTH220B TH330B PDFOctavio Ramos100% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

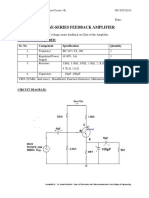

- Expt 1 Voltage Series Feedback ApmlifierDocument5 pagesExpt 1 Voltage Series Feedback Apmlifiersamarth100% (3)

- Background Debug Mode (BDM)Document33 pagesBackground Debug Mode (BDM)rosmaryNo ratings yet

- Use of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and ColumnsDocument34 pagesUse of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and Columnszakaria200811060No ratings yet

- Geberit New Sovent High Power 1474952245Document4 pagesGeberit New Sovent High Power 1474952245Hồ ThànhNo ratings yet

- CM13AS-L WDocument87 pagesCM13AS-L Wngocdhxd920% (1)

- High Pressure Drilling Riser SystemDocument2 pagesHigh Pressure Drilling Riser SystemSuci Nur HidayahNo ratings yet

- Fundamental Principles of Diaphragm MetersDocument4 pagesFundamental Principles of Diaphragm MetersMahdiNo ratings yet

- Waste Management ProcedureDocument3 pagesWaste Management ProcedureBoby ThomasNo ratings yet

- Emergency Stop Safety Module: FeaturesDocument12 pagesEmergency Stop Safety Module: FeaturesMarcos AldrovandiNo ratings yet

- Stock CatalogDocument42 pagesStock Catalogspleen60No ratings yet

- Soil Stabilization New German Technology PDFDocument53 pagesSoil Stabilization New German Technology PDFvdbshamsabad labNo ratings yet

- GEA Colby Rotary Continuous FillerDocument2 pagesGEA Colby Rotary Continuous Fillerchien_yu_leeNo ratings yet

- Project Report Food GrainDocument5 pagesProject Report Food GrainNeel KhandelwalNo ratings yet

- Executive Summary RivigoDocument1 pageExecutive Summary RivigoKeshav GuptaNo ratings yet

- Types of BricksDocument5 pagesTypes of BricksMian M Khurram100% (1)

- DC Power DistributionDocument24 pagesDC Power DistributionZay YarNo ratings yet

- Industrial Visit-Report NAME:-Mayank D. Kateshiya SEM:-6, Mechanicle Department en - No:-200540119507 (114) Company Name:-Rolex Rings LimitedDocument4 pagesIndustrial Visit-Report NAME:-Mayank D. Kateshiya SEM:-6, Mechanicle Department en - No:-200540119507 (114) Company Name:-Rolex Rings LimitedEarn MoneyNo ratings yet

- Fine Woodworking - Gluing and Clamping StrategiesDocument7 pagesFine Woodworking - Gluing and Clamping Strategiescajunhillbilly100% (1)

- Illustrated Parts List: RTLO-16713A November 2012Document56 pagesIllustrated Parts List: RTLO-16713A November 2012Hamilton MirandaNo ratings yet

- Bus Shelter Assembly 15' Revised-1 PDFDocument1 pageBus Shelter Assembly 15' Revised-1 PDFsamirbendre1No ratings yet

- Vacbi Questions Phase 3Document9 pagesVacbi Questions Phase 3Rambo OoNo ratings yet

- Pc-12 Amm TR 05-07 ManualDocument122 pagesPc-12 Amm TR 05-07 ManualAndré ResendeNo ratings yet

- 13inch Macbook Air Product Environmental ReportDocument3 pages13inch Macbook Air Product Environmental ReportChintan GondaliaNo ratings yet

- Comparison Chart Led Lights vs. Incandescent Light Bulbs vs. CflsDocument4 pagesComparison Chart Led Lights vs. Incandescent Light Bulbs vs. CflsK Vijay Bhaskar ReddyNo ratings yet

- Performance Evaluation of Evacuated Tube Collector Solar Water Heating System: A ReviewDocument4 pagesPerformance Evaluation of Evacuated Tube Collector Solar Water Heating System: A ReviewIJAMTESNo ratings yet

- Natural Gas: Pipe Sizing ChartDocument1 pageNatural Gas: Pipe Sizing Chartjacked19No ratings yet

- Astm A214 PDFDocument1 pageAstm A214 PDFgaminNo ratings yet

- Vibration EngineeringDocument30 pagesVibration Engineeringclient laspoñaNo ratings yet