Professional Documents

Culture Documents

JSCAST Optional Modules

JSCAST Optional Modules

Uploaded by

tranvando19860 ratings0% found this document useful (0 votes)

63 views2 pages12345!

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document12345!

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views2 pagesJSCAST Optional Modules

JSCAST Optional Modules

Uploaded by

tranvando198612345!

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

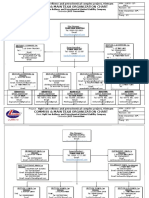

SSCAST oviionainossies

Quantitatively predicts macro- and micro-shrinkage in both the

riser and casting with consideration of solidification contraction,

‘mass feeding and liquid level drop in liquid and mushy regions.

ie

Simulates cyclic casting processes in permanent mold casting.

Essential for the cooling system design of dies.

Considers the effect of backpressure on mold filling for both

permanent and sand mold casting processes. Predicts gas

defects caused by poor designs of gas-evacuation and gating

systems.

Provides interface with commercial software, NASTRAN,

allowing users to export temperature data from JSCAST

solidification simulation to NASTRAN for thermal stress, strain,

deformation and cracking of both casting and mold

V|VALANS

Simulates mold filling during gravity tilt casting by defining the

tilt angle as the function of time.

One of our original developments intended to increase the

accuracy of geometry approximation. Improves the mesh

quality of thin-walls and curved surfaces of the castings, and

consequently, the simulation accuracy.

Considers the unique solidification phenomena of ductile cast

iron. The maximum principal stress during solidification is used

as the prediction criteria for porosity defects.

Provides interface with commercial software, JMatPro,

allowing users to predict thermo-physical and mechanical

properties of casting alloys just by simply inputting their

compositions.

AC LEm i Bag

JSCAST Optional Modules

Predicts porosities caused by gas entrainments during mold

filing. Applicable to various casting alloys.

—E

‘Simulates mold filling in HPDC with consideration of the shot-

sleeve, including [Pouring of the shot sleeve], [Holding before

shot], and [Plunger moving]

a~-~7

Allows users to specify the generation conditions of sand and

slag particles, and trace particle movement in the melt with

consideration of buoyancy and predict particle final positions

and adhesions to the mold,

“Particle status

Adhesion mechanism

‘Adhson stagnation ete

‘Generation condition

Prose, ley fil ate

“1: Functions previous included inthe basic module up to Ver.

v|VALANS

Predicts casting stress, strain and deformation based on output

data of solidification simulation.

Simulates mold filling with consideration of melt surface

tension and wettability between melt and mold. Improves the

simulation accuracy of free surface morphology and position,

and misruns, especialy for thin-walled castings.

‘Simulates how the foam pattern is replaced by liquid metal during

‘mold filling. Considers the effects of vacuum suction and

permeability of sand mold and coating. Helps users to decrease

low-related defects and optimize casting designs.

|

www.valans.com.tr

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LLM RQ WQ 0007Document1 pageLLM RQ WQ 0007tranvando1986No ratings yet

- LLM RQ NDT 0436Document2 pagesLLM RQ NDT 0436tranvando1986No ratings yet

- eta/VPG Training Manual: A LS/DYNA Based Full Vehicle Simulation Solution PackageDocument54 pageseta/VPG Training Manual: A LS/DYNA Based Full Vehicle Simulation Solution Packagetranvando1986No ratings yet

- LLM RQ NDT 0002Document1 pageLLM RQ NDT 0002tranvando1986No ratings yet

- All SoftwareDocument1 pageAll Softwaretranvando1986No ratings yet

- ONECNCDocument10 pagesONECNCtranvando1986No ratings yet

- 22 October, 2012: Killed Carbon SteelDocument1 page22 October, 2012: Killed Carbon Steeltranvando1986No ratings yet

- Applicationform Kwangjin VietnamDocument6 pagesApplicationform Kwangjin Vietnamtranvando1986No ratings yet

- 100% RT Line: RT Shooting Result (By JGCS)Document9 pages100% RT Line: RT Shooting Result (By JGCS)tranvando1986No ratings yet

- Practical Intelligence For Die Casting: Piq2 SRLDocument16 pagesPractical Intelligence For Die Casting: Piq2 SRLtranvando1986No ratings yet

- NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)Document9 pagesNSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986No ratings yet

- 2018.01.01 NSRP 3RD RT (Film Interpretation Meeting by NSRP and JGCS)Document4 pages2018.01.01 NSRP 3RD RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986No ratings yet

- 2018.01.04 NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)Document2 pages2018.01.04 NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986No ratings yet

- Welder List of JVTT - LilamaDocument15 pagesWelder List of JVTT - Lilamatranvando1986No ratings yet

- LLM18 MAIN & COMMISS Site Organization ChartDocument2 pagesLLM18 MAIN & COMMISS Site Organization Charttranvando1986No ratings yet

- QC Data Received Status For TP Preparation - LILAMA - 20180109Document2 pagesQC Data Received Status For TP Preparation - LILAMA - 20180109tranvando1986No ratings yet

- NSRP LLM WPQTDocument3 pagesNSRP LLM WPQTtranvando1986No ratings yet

- Department Department Code Administrative A Contract T Construction C Quality Control Q Safety S Material MDocument1 pageDepartment Department Code Administrative A Contract T Construction C Quality Control Q Safety S Material Mtranvando1986No ratings yet

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocument3 pagesIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986No ratings yet

- 100% RT Line: RT Shooting Result (By JGCS)Document8 pages100% RT Line: RT Shooting Result (By JGCS)tranvando1986No ratings yet

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocument3 pagesIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986No ratings yet

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocument3 pagesIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986No ratings yet

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Document4 pagesHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986No ratings yet

- Post Weld Heat Treatment Report: °C °c/hrDocument6 pagesPost Weld Heat Treatment Report: °C °c/hrtranvando1986No ratings yet

- Dayly Report For Piping: Report No: DL-P-001 Date: 12-NOV-2011Document18 pagesDayly Report For Piping: Report No: DL-P-001 Date: 12-NOV-2011tranvando1986No ratings yet

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Document4 pagesHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986No ratings yet

- Post Weld Heat Treatment Report: °C °c/hrDocument6 pagesPost Weld Heat Treatment Report: °C °c/hrtranvando1986No ratings yet