Professional Documents

Culture Documents

Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping Systems

Uploaded by

Nattaphong Sudthichat0 ratings0% found this document useful (0 votes)

47 views1 pageContent1

Original Title

1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentContent1

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pagePiping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping Systems

Uploaded by

Nattaphong SudthichatContent1

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems

1.1 General Application 1.Scope 1.3 Fitness-For-Service (FFS) and Risk-

Based Inspection (RBI)

1.1.1 Coverage 1.2 Specific Applications

API 570 covers inspection, rating, repair, and alteration procedures The term non-metallics has a broad definition but in this

for metallic and fiberglass-reinforced plastic (FRP)

Code refers to the fiber reinforced plastic groups

piping systems and their associated pressure relieving devices that

encompassed by the generic acronyms FRP (fiberglass-

This inspection Code recognizes Fitness-For-

have been placed in service.This inspection Code

applies to all hydrocarbon and chemical process piping covered in reinforced plastic) and GRP (glass-reinforced plastic). The Service concepts for evaluating in-service

1.2.1 that have been placed in service unless extruded, generally homogenous non-metallics, such as high damage of pressure

specifically designated as optional per 1.2.2. This publication does and low-density polyethylene are not specifically containing piping components. API 579-1/ASME

not cover inspection of specialty equipment covered by this Code. Refer to API 574 and MTI 129 for

including instrumentation, exchanger tubes and control valves. guidance on degradation and inspection issues associated

FFS-1, Fitness-For-Service provides detailed

However, this piping Code could be used by owner/

with FRP piping. FFS assessment

users in other industries and other services at their discretion.

Process piping systems that have been retired from service and procedures for specific types of damage that are

abandoned in place are no longer covered by this “in referenced in this Code. This inspection Code

service inspection” Code. However abandoned in place piping may

still need some amount of inspection and/or risk

also recognizes RBI

mitigation to assure that it does not become a process safety hazard 1.2.1 Included Fluid Services concepts for determining inspection intervals or

because of continuing deterioration. Process due dates and strategies. API 580 provides the

piping systems that are temporarily out of service but have been a) raw, intermediate, and finished petroleum and basic minimum and

mothballed (preserved for potential future use) are

still covered by this Code. chemical products; recommended elements for developing,

b) catalyst lines; implementing, and maintaining a risk-based

1.1.2 Intent c) hydrogen, natural gas, fuel gas, and flare inspection (RBI) program for

systems; fixed equipment, including piping. API 581

The intent of this Code is to specify the in-service inspection and

condition-monitoring program as well as repair d) sour water and hazardous waste streams; provides a set of methodologies for assessing

guidance that is needed to determine and maintain the on-going e) hazardous fluid services; risk (both POF and COF)

integrity of piping systems. That program should

provide reasonably accurate and timely assessments to determine if f) cryogenic fluids such as: liquid N2, H2, O2, and and for developing inspection plans.

any changes in the condition of piping could air;

possibly compromise continued safe operation. It is also the intent of

this Code that owner/users shall respond to any

g) high-pressure gases greater than 150 psig

inspection results that require corrective actions to assure the such as: gaseous He, H2, O2, and N2.

continued integrity of piping consistent with appropriate

risk analysis. API 570 is intended for use by organizations that

maintain or have access to an authorized inspection

1.2.2 Optional Piping Systems

agency, a repair organization, and technically qualified piping and Fluid Services

engineers, inspectors, and examiners, all as defined in

Section 3.

The fluid services and classes of piping systems

1.1.3 Limitations listed below are optional with regard to the

requirements of API 570:

API 570 shall not be used as a substitute for the a) hazardous fluid services below designated

original construction requirements governing a threshold limits, as defined by jurisdictional

piping system before regulations;

it is placed in-service; nor shall it be used in b) water (including fire protection systems),

conflict with any prevailing regulatory steam, steam-condensate, boiler feed water,

requirements. If the requirements of and Category D fluid

this Code are more stringent than the regulatory services as defined in ASME B31.3;

requirements, then the requirements of this c) other classes of piping that are exempted

Code shall govern. from the applicable process piping code.

You might also like

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- 2.API Scope, Organization Structure & Repairs, Alterations, and Rerating of Piping SystemsDocument15 pages2.API Scope, Organization Structure & Repairs, Alterations, and Rerating of Piping SystemsAMAL VISHNUNo ratings yet

- Pnsddc6a PDFDocument11 pagesPnsddc6a PDFNguyễn QuyếtNo ratings yet

- Section 1 - Introduction: FFS FFSDocument8 pagesSection 1 - Introduction: FFS FFSmiguelmarchanmNo ratings yet

- Toaz - Info-Asme-B313-Ed2018-Pr - D1fa24e813ec7039e614e07a6fd080 32Document1 pageToaz - Info-Asme-B313-Ed2018-Pr - D1fa24e813ec7039e614e07a6fd080 32qwer39201466No ratings yet

- 570 2016 1 PDFDocument43 pages570 2016 1 PDFeduardo gonzalez100% (1)

- Section 1 - Introduction: DRAFT - API Recommended Practice For Fitness-For-ServiceDocument4 pagesSection 1 - Introduction: DRAFT - API Recommended Practice For Fitness-For-ServiceAmerico MolinaNo ratings yet

- Specification For Pipe BendsDocument20 pagesSpecification For Pipe BendsnavasNo ratings yet

- PNSC0021Document12 pagesPNSC0021romerobernaNo ratings yet

- Presentation API 570 - 510-653Document83 pagesPresentation API 570 - 510-653Hesham ismail Seddik100% (1)

- IMCA-D-018 R2 SummaryDocument3 pagesIMCA-D-018 R2 SummaryMuaz Haziq MusaNo ratings yet

- ASME B31.3 - 2002, First ResumeDocument34 pagesASME B31.3 - 2002, First ResumedanieldayettddNo ratings yet

- Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping SystemsDocument1 pagePiping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping SystemsMUHAMMAD SHARIFNo ratings yet

- PIP PLE00012 Piping Exam and Leak Test B31.8 PipelinesDocument8 pagesPIP PLE00012 Piping Exam and Leak Test B31.8 PipelinesCristian RA0% (2)

- Design, Installation and Maintenance of Fixed Automatic Sprinkler Fire Extinguishing Systems - Code of PracticeDocument92 pagesDesign, Installation and Maintenance of Fixed Automatic Sprinkler Fire Extinguishing Systems - Code of PracticeInyamul Hasan100% (1)

- Asme B31.1 Power PipingDocument21 pagesAsme B31.1 Power PipingIj Ooo100% (1)

- Session 2 Overview of IntegrityDocument19 pagesSession 2 Overview of IntegritysahandstmNo ratings yet

- PIP PCCLI001 Level Measurement Design CriteriaDocument10 pagesPIP PCCLI001 Level Measurement Design CriteriaM RNo ratings yet

- 1.2.2 Optional Piping Systems and Fluid Services: 2 Normative ReferencesDocument1 page1.2.2 Optional Piping Systems and Fluid Services: 2 Normative ReferencesRana Ishtiaq FarooqNo ratings yet

- Lifetime Extension of Flexible Pipe Systems: Extend OperationDocument24 pagesLifetime Extension of Flexible Pipe Systems: Extend OperationAaron ChristopherNo ratings yet

- General Piping InspectionDocument13 pagesGeneral Piping InspectionKingston Rivington100% (1)

- Assuring The Safety of Ammonia Plant Vessels and Piping Using API RP 579Document11 pagesAssuring The Safety of Ammonia Plant Vessels and Piping Using API RP 579varatharajan g rNo ratings yet

- General Piping - Process and Utility Field Pressure TestingDocument20 pagesGeneral Piping - Process and Utility Field Pressure TestingJanuar GhifaryNo ratings yet

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- PIP PLSC0021 Pressure Testing of ASME B31.8 Metallic PipingDocument15 pagesPIP PLSC0021 Pressure Testing of ASME B31.8 Metallic Pipingivanov5559100% (1)

- Saep 306Document13 pagesSaep 306Narvis RinconNo ratings yet

- API Safe Operation of Vessels & Piping As Per CodeDocument12 pagesAPI Safe Operation of Vessels & Piping As Per CodeMohammad YusoffNo ratings yet

- Saep 306Document15 pagesSaep 306Salvatore MasalaNo ratings yet

- Standard Review Plan: NUREG-0800Document14 pagesStandard Review Plan: NUREG-0800Abhinav OjhaNo ratings yet

- Api 570 NotesDocument3 pagesApi 570 NotesErdi Erdogan100% (1)

- Internal Corrosion Direct Assessment For Multiphase Flow Pipelines103922-MSDocument9 pagesInternal Corrosion Direct Assessment For Multiphase Flow Pipelines103922-MSGucNo ratings yet

- API Training ClassDocument57 pagesAPI Training ClassSakthi Pk100% (3)

- BS 5572Document10 pagesBS 5572Andrew MutuaNo ratings yet

- 26-2-2018 Closed and Open Book Exam: 1-Included Fluid ServicesDocument22 pages26-2-2018 Closed and Open Book Exam: 1-Included Fluid ServicesAshish Patel100% (5)

- Asme PCC-2 - 2022 HighlightedDocument112 pagesAsme PCC-2 - 2022 HighlightedAhmed Shakir67% (3)

- Gis-Te P6.3 2021Document16 pagesGis-Te P6.3 2021Ashraf Ismail HassenNo ratings yet

- F2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsDocument7 pagesF2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsMohamedNo ratings yet

- (Water Treatment & Cleaning System)Document5 pages(Water Treatment & Cleaning System)Mohamed MansourNo ratings yet

- Provided by IHS Under License With ASME No Reproduction or Networking Permitted Without License From IHS Not For Resale, 01/18/2009 17:48:28 MSTDocument2 pagesProvided by IHS Under License With ASME No Reproduction or Networking Permitted Without License From IHS Not For Resale, 01/18/2009 17:48:28 MSTIbonk MuhamadNo ratings yet

- Nace Standards and Specifications Related Oil Natural Gas InfrastructureDocument5 pagesNace Standards and Specifications Related Oil Natural Gas InfrastructurePharmacist ShimaaNo ratings yet

- Standard Review Plan: NUREG-0800 U.S. Nuclear Regulatory CommissionDocument17 pagesStandard Review Plan: NUREG-0800 U.S. Nuclear Regulatory CommissionNathan BlockNo ratings yet

- Ccad-Aed-Sp - G-223229 - 0 - Limestone Contactor Treatment SystemDocument17 pagesCcad-Aed-Sp - G-223229 - 0 - Limestone Contactor Treatment SystemArun UdayabhanuNo ratings yet

- Saep 306Document15 pagesSaep 306nadeem shaikh100% (1)

- Thrust Block DesignDocument12 pagesThrust Block DesignTarun PanwarNo ratings yet

- Inspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesDocument9 pagesInspection of Fixed Steel Offshore Structures During Fabrication and Installation - GuidelinesShanmugam SailappanNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- API Training ClassDocument57 pagesAPI Training Classuniquepp100% (8)

- Csa b149 1 2020 Impact AssessmentDocument4 pagesCsa b149 1 2020 Impact Assessmentjasonjason27091984No ratings yet

- 2 - ScopeDocument6 pages2 - Scopewaqas pirachaNo ratings yet

- RFI Oil & Gas NACE StandardsDocument3 pagesRFI Oil & Gas NACE StandardsABDELKADER BENABDALLAHNo ratings yet

- Coating Specification PAM EC 50 SP 001 1ADocument43 pagesCoating Specification PAM EC 50 SP 001 1ADavid Ricardo Diaz0% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNo ratings yet

- Specification For Leak Test PipeDocument10 pagesSpecification For Leak Test PipeEsteban Rios PitaNo ratings yet

- 1 - 570 (1000+ Q&a)Document113 pages1 - 570 (1000+ Q&a)Mohammed Kadhim100% (2)

- SAES-Z-003 Pipelines Leak Detection SystemsDocument13 pagesSAES-Z-003 Pipelines Leak Detection SystemsZubair RaoofNo ratings yet

- Abs Type Approval1 - TeamDocument5 pagesAbs Type Approval1 - TeamRogério FreitasNo ratings yet

- Gas Detection As A Risk Mitigation TechniqueDocument8 pagesGas Detection As A Risk Mitigation TechniqueFede Martinez100% (1)

- Understanding ISA S20 API 554 API 555 ISDocument5 pagesUnderstanding ISA S20 API 554 API 555 ISCeline Dian SitorusNo ratings yet

- All 207 20 r1 Audit Guide - All ProgramsDocument32 pagesAll 207 20 r1 Audit Guide - All ProgramsPablo OchoaNo ratings yet

- Annexure-1 Technical Specification For PipelinesDocument316 pagesAnnexure-1 Technical Specification For PipelinesUtkarsh ModhiaNo ratings yet

- API 571 QuestionsDocument2 pagesAPI 571 Questionsraghava1975No ratings yet

- ASNT Level III Study Guid Liquid Penetrant Testing MethodDocument87 pagesASNT Level III Study Guid Liquid Penetrant Testing MethodNattaphong SudthichatNo ratings yet

- API 570 PC 3sep05 Daily Exam 1A ClosedDocument6 pagesAPI 570 PC 3sep05 Daily Exam 1A ClosedNattaphong SudthichatNo ratings yet

- 2 Normative References: Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping SystemsDocument1 page2 Normative References: Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping SystemsNattaphong SudthichatNo ratings yet

- List รายชื่อหนังสือDocument1 pageList รายชื่อหนังสือNattaphong SudthichatNo ratings yet

- Feb 2017 - 570 - Publications EffectivitySheet Final 20170609Document1 pageFeb 2017 - 570 - Publications EffectivitySheet Final 20170609Nsidibe Michael EtimNo ratings yet

- API 653 Practice Exam Q A 2012 PDFDocument32 pagesAPI 653 Practice Exam Q A 2012 PDFAntony Bruno GenewinNo ratings yet

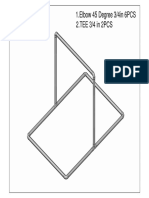

- 1.elbow 45 Degree 3/4in 6PCS 2.TEE 3/4 in 2PCSDocument1 page1.elbow 45 Degree 3/4in 6PCS 2.TEE 3/4 in 2PCSNattaphong SudthichatNo ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- API653Document20 pagesAPI653Nattaphong SudthichatNo ratings yet

- ADocument3 pagesANattaphong SudthichatNo ratings yet

- NDT Trining Lv3. ThailandDocument1 pageNDT Trining Lv3. ThailandNattaphong SudthichatNo ratings yet

- 10Document10 pages10Nattaphong SudthichatNo ratings yet

- Pre Test QuestionsDocument2 pagesPre Test QuestionsAndresNicolasBouvierNo ratings yet

- ADocument3 pagesANattaphong SudthichatNo ratings yet

- API 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017Document1 pageAPI 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017mohamedeldeeb88No ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- Oishi DeliveryDocument2 pagesOishi DeliveryNattaphong SudthichatNo ratings yet

- Api 653Document1 pageApi 653BashMohandesssNo ratings yet

- 2015 C1 Hydroweld Training Booklet PDFDocument6 pages2015 C1 Hydroweld Training Booklet PDFNattaphong SudthichatNo ratings yet

- This Tutorial Provides A Series of Screens That Orient You To The Computer Testing EnvironmentDocument14 pagesThis Tutorial Provides A Series of Screens That Orient You To The Computer Testing EnvironmentSEGO4EVERNo ratings yet

- Natural Fiber-Reinforced Polymer Composites: January 2007Document17 pagesNatural Fiber-Reinforced Polymer Composites: January 2007parkourNo ratings yet

- B 757 General Familiarisation in MaintenanceDocument167 pagesB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishNo ratings yet

- GRP Brochure AmiantitDocument6 pagesGRP Brochure Amiantitbhathiya8No ratings yet

- Investigation of Mechanical Properties of Natural FibersDocument10 pagesInvestigation of Mechanical Properties of Natural FibersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Piping and Equipment InsulationDocument4 pagesPiping and Equipment InsulationttshareefNo ratings yet

- Plastic Strips As Additives To CHBDocument18 pagesPlastic Strips As Additives To CHBNiña Criselle PasiaNo ratings yet

- Design, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareDocument6 pagesDesign, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareNitin shepurNo ratings yet

- BoltDocument4 pagesBoltShilpa DhanureNo ratings yet

- 2.study On Flexural Behaviour of Glulam Beams Reinforced by Near SurfaceMounted (NSM) CFRP LaminatesDocument9 pages2.study On Flexural Behaviour of Glulam Beams Reinforced by Near SurfaceMounted (NSM) CFRP LaminatesCălin MartonNo ratings yet

- Robit Top Hammer Product Catalogue 11 2021 LowresDocument120 pagesRobit Top Hammer Product Catalogue 11 2021 Lowressindy leeNo ratings yet

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- Plywood Boat PlansDocument3 pagesPlywood Boat Plansjacquesmayol100% (2)

- XXVV GGFDDocument2 pagesXXVV GGFDAmet koko TaroNo ratings yet

- Weaving Technical?: Do It Itema!Document54 pagesWeaving Technical?: Do It Itema!stareq100% (1)

- FCPP Fiberglass Coated ConcreteDocument20 pagesFCPP Fiberglass Coated ConcretemahdiNo ratings yet

- GRP Transformer Housing TR17Document1 pageGRP Transformer Housing TR17Mickey72BNo ratings yet

- Architect's Cost EstimateDocument27 pagesArchitect's Cost EstimateNoel Malinao Cablinda0% (1)

- Uniclass 2015 April 2020 UpdateDocument48 pagesUniclass 2015 April 2020 Updateabdullah sahibNo ratings yet

- Cgna16684enc 001 PDFDocument272 pagesCgna16684enc 001 PDFsunil jhaNo ratings yet

- Nota Bahan Teknologi Pembuatan - CompositeDocument45 pagesNota Bahan Teknologi Pembuatan - CompositeshantishaNo ratings yet

- Wavistrong Installation ManualDocument63 pagesWavistrong Installation ManualRenganathan Prabunath0% (1)

- Tender Specification - Sea WaterDocument12 pagesTender Specification - Sea WaterSuhas NatuNo ratings yet

- I-PF-21 Bonding Procedure SpecificationDocument10 pagesI-PF-21 Bonding Procedure SpecificationCamilo SierraNo ratings yet

- CLLK07 & 08 Technical Parameters BrochureDocument2 pagesCLLK07 & 08 Technical Parameters BrochureAlmario Sagun0% (1)

- Company ProfileDocument11 pagesCompany ProfileVishnu DuttaNo ratings yet

- Marley PRG 11B L PDFDocument64 pagesMarley PRG 11B L PDFIlkuNo ratings yet

- Fiber Reinforced Composites Mallick Solution Manual PDFDocument6 pagesFiber Reinforced Composites Mallick Solution Manual PDFGECJ0% (5)

- RESIN - TRANSFER - MOLDING - FINAL - REPORT With RefDocument37 pagesRESIN - TRANSFER - MOLDING - FINAL - REPORT With RefI DKNo ratings yet

- BS en 15422 - 2008Document10 pagesBS en 15422 - 2008Ceicilia WahyuningrumNo ratings yet