Professional Documents

Culture Documents

RC Corbel Design ACI318 05 PDF

RC Corbel Design ACI318 05 PDF

Uploaded by

JayChristian QuimsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RC Corbel Design ACI318 05 PDF

RC Corbel Design ACI318 05 PDF

Uploaded by

JayChristian QuimsonCopyright:

Available Formats

Project Job Ref.

SAFORY

00000 Section Sheet no./rev.

1

Calc. by Date Chk'd by Date App'd by Date

D 4/29/2011

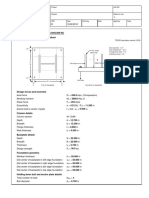

Vu Steel angle

Main

tension a

bars Nuc

min d / 2

Sh

2

3 d Sh

Sh d h

Horizontal

bars

Framing

bars

RC SINGLE CORBEL DESIGN TO ACI 318-05

Corbel geometry

;Width of corbel; b = 20.000 in

;Total thickness of corbel; h = 35.000 in

;Depth to main reinforcement; d = 28.000 in

Material properties

;Yield strength of reinforcement; fy = 60000 psi

;Compressive strength of concrete; f’c = 4000 psi

Type of concrete; Normal weight

Unit weight of concrete; = 1.00

Corbel construction; Monolithic

Coefficient of friction; = 1.4 = 1.40

Design load data

;Factored vertical load ; Vu = 2.000 kips

;Distance of vertical load from face of column; a = 5.000 in

;Horizontal force acting on corbel; Nuc = 2.000 kips

;Strength reduction factor; = 0.750

Vertical load capacity check

Nominal vertical load; Vn = Vu / = 2.667 kips

Nominal vertical load capacity; Vn_cap = min(0.2 f’c b d, 800 psi b d) = 448.000 kips

PASS - Nominal vertical load is less than the nominal vertical load capacity

Find shear friction reinforcement

Minimum horizontal force acting on corbel; Nuc_min = 0.2 Vu = 0.400 kips

Horizontal force acting on corbel; Nuc_act = max(Nuc, Nuc_min) = 2.000 kips

For balanced condition; j = 0.85

Area for shear friction reinforcement; Avf = Vn / (fy ) = 0.032 in2

Af = [(Vu a) + (Nuc_act (h –d))] / ( fy j d) = 0.022 in2

Nominal area required; An = Nuc_act / ( fy) = 0.044 in2

Project Job Ref.

SAFORY

00000 Section Sheet no./rev.

2

Calc. by Date Chk'd by Date App'd by Date

D 4/29/2011

Main tension reinforcement check

Minimum area of tension reinforcement; Asc_min = 0.04 f’c b d / fy = 1.493 in2

Area of tension reinforcement required; Asc = max([(2 Avf) / 3] + An, Af + An) = 0.067 in2

Asc_req = max(Asc, Asc_min) = 1.493 in2

Main tension reinforcement; 5 No.5 bars

Diameter of tension bars; Dtension = 0.625 in

Number of tension bars; Ntension = 5

Area of tension reinforcement provided; Asc_prov = Ntension Dtension2 / 4 = 1.534 in2

PASS - Tension reinforcement is adequate

Horizontal reinforcement check

Minimum area of horizontal reinforcement; Ah_min = 0.5 * (Asc_req – An) = 0.724 in2

Area of horizontal reinforcement required; Ah = max(Avf / 3, Af / 2) = 0.011 in2

Ah_req = max(Ah, Ah_min) = 0.724 in2

Horizontal reinforcement; 5 No.4 bars

Diameter of horizontal bars; Dhorizontal = 0.500 in

Number of horizontal bars; Nhorizontal = 5

Area of horizontal reinforcement provided; Ah_prov = 2 Nhorizontal Dhorizontal2 / 4 = 1.963 in2

PASS - Horizontal reinforcement is adequate

Maximum spacing of horizontal bars; Sh_max = 2 d / (3 Nhorizontal) = 3.733 in

Actual spacing of horizontal bars; Sh = 2.000 in

PASS - Horizontal bar spacing is adequate

Design Summary

Single corbel 20.0'' wide by 35.0'' deep with 4000 psi concrete and 60000 psi steel

Provide main tension reinforcement as 5 No. 5 bars

Provide horizontal reinforcement as 5 No. 4 link bars at maximum 2.000'' centres

You might also like

- Comment To Demurrer To The EvidenceDocument4 pagesComment To Demurrer To The EvidenceRalph Valdez100% (1)

- Themes - Overview - iOS Human Interface GuidelinesDocument3 pagesThemes - Overview - iOS Human Interface Guidelineskhaled alahmadNo ratings yet

- Girder-Slab System Design Guide v2.0 PDFDocument20 pagesGirder-Slab System Design Guide v2.0 PDFManoj GehlodNo ratings yet

- Angeles Pht413Document3 pagesAngeles Pht413Eduard AngelesNo ratings yet

- Layher Allround Industri Stillas 2015 - Engelsk - Utskrift.2Document68 pagesLayher Allround Industri Stillas 2015 - Engelsk - Utskrift.2cosmin todoran100% (1)

- RC Corbel Design (ACI318)Document2 pagesRC Corbel Design (ACI318)Emad KhanNo ratings yet

- Cobble Design - Sample NewDocument2 pagesCobble Design - Sample NewBekele AmanNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Spreadsheets To BS 8110: Made by DateDocument1 pageSpreadsheets To BS 8110: Made by Datemefaisal75No ratings yet

- ACI 318M-11 Slab Punching StressDocument9 pagesACI 318M-11 Slab Punching StressIsprotec IngenieriaNo ratings yet

- Corbel Design Based On 2018 IBC / ACI 318-14: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesCorbel Design Based On 2018 IBC / ACI 318-14: Project: Client: Design By: Job No.: Date: Review bycurlyjockey100% (1)

- Inverted-T Capacity Calculation@Phase1v2Document11 pagesInverted-T Capacity Calculation@Phase1v2satyaNo ratings yet

- ACI - 350.3-06 - Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev00 - 29-Sep-2013Document17 pagesACI - 350.3-06 - Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev00 - 29-Sep-2013Fredy ConejoNo ratings yet

- CORBEL Design V1 by UpalDocument3 pagesCORBEL Design V1 by Upalashraf04_ceNo ratings yet

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- Group 7 - Block B (Up To 28 Floors) Building & Structural ElementDocument3 pagesGroup 7 - Block B (Up To 28 Floors) Building & Structural ElementChung ChanNo ratings yet

- Purlin DESIGNDocument10 pagesPurlin DESIGNMohamed NkNo ratings yet

- Add An Extra DL and Revise - 0.15 PSFDocument1 pageAdd An Extra DL and Revise - 0.15 PSFsharif uddinNo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- Detailing and Placing Reinforcing BarsDocument6 pagesDetailing and Placing Reinforcing Barsتوان امتياس سامسدينNo ratings yet

- Chapter 3 Stairs and StaircasesDocument25 pagesChapter 3 Stairs and StaircasesRamiro TiconaNo ratings yet

- Chapter 8 Design of Short ColumnsDocument64 pagesChapter 8 Design of Short ColumnsiiMa sticNo ratings yet

- J Bolt Precast Anchor Design ExampleDocument4 pagesJ Bolt Precast Anchor Design ExampleruayoNo ratings yet

- Composite Floor Deck DesignDocument4 pagesComposite Floor Deck DesignsaipodinNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriNo ratings yet

- Shear Reinforcement of ColumnDocument1 pageShear Reinforcement of ColumnAkhtar BahramNo ratings yet

- Corbel Design ACI 318 PDFDocument2 pagesCorbel Design ACI 318 PDFShamim Ahsan ZuberyNo ratings yet

- 2 Interpretation SBT Full ColourDocument36 pages2 Interpretation SBT Full ColourNaveen SharmaNo ratings yet

- N F N A: Input Data & Design SummaryDocument9 pagesN F N A: Input Data & Design SummaryOswaldo SuárezNo ratings yet

- Numerical Analysis of Piled Raft Foundation in Sandy and Clayey SoilsDocument4 pagesNumerical Analysis of Piled Raft Foundation in Sandy and Clayey Soilspperic13No ratings yet

- Tek 14-01BDocument8 pagesTek 14-01BkevinalmerNo ratings yet

- Formula BookDocument52 pagesFormula Bookmatshona100% (2)

- Pad Foundation Design To Bs 81101997Document23 pagesPad Foundation Design To Bs 81101997Anonymous 66uWhphVNo ratings yet

- Guidelines For The Design of Sediment ContainmentDocument10 pagesGuidelines For The Design of Sediment ContainmentBudi NadatamaNo ratings yet

- 10m Unipole - Sungai AbongDocument26 pages10m Unipole - Sungai Abongatokku50% (2)

- Analysis and Design of FlatDocument10 pagesAnalysis and Design of FlatHari RNo ratings yet

- Foundation Example 9.7Document14 pagesFoundation Example 9.7Deana WhiteNo ratings yet

- Structure Engineer CertificateDocument1 pageStructure Engineer CertificateSantosh100% (2)

- Pile Group AnalysisDocument4 pagesPile Group AnalysisrahimNo ratings yet

- Cell / Model Name Description DateDocument19 pagesCell / Model Name Description DateHemanthNo ratings yet

- Design of Flat PlateDocument32 pagesDesign of Flat PlateumairNo ratings yet

- Early Thermal Cracking CalculationsDocument1 pageEarly Thermal Cracking Calculationsmassive85No ratings yet

- Design of Flat Slabs For PunchingDocument8 pagesDesign of Flat Slabs For PunchingAli Alskeif100% (1)

- Pile Cap DesignDocument7 pagesPile Cap Designmd. alaul azmirNo ratings yet

- 6.7 - Story DriftDocument2 pages6.7 - Story DriftFranklyn P. GenoveNo ratings yet

- Corbel Design: Dolomite Batu Caves 21st April 2003 Chow It Corbel To Support The Ramp Driveway Karthe / InezDocument1 pageCorbel Design: Dolomite Batu Caves 21st April 2003 Chow It Corbel To Support The Ramp Driveway Karthe / InezEdrick LimNo ratings yet

- AZ024 Lecture 7 Steel ConnectionDocument14 pagesAZ024 Lecture 7 Steel ConnectionTong Kin Lun100% (15)

- Design of Anchored Sheet Pile WallDocument5 pagesDesign of Anchored Sheet Pile WallbomsilagaNo ratings yet

- Esr 3814Document49 pagesEsr 3814Fahim IslamNo ratings yet

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriNo ratings yet

- Ordinary Shear WallDocument1 pageOrdinary Shear WallArwen CerenoNo ratings yet

- Steel DeckDocument38 pagesSteel Deckrabih87100% (1)

- Combined Systems SEAOC Blue BookDocument3 pagesCombined Systems SEAOC Blue BookHirad GrivaniNo ratings yet

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawNo ratings yet

- Girder Slab PDFDocument16 pagesGirder Slab PDFArbi811No ratings yet

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- CorbelDocument2 pagesCorbelaahtagoNo ratings yet

- RC One Way Slab Design (ACI318)Document2 pagesRC One Way Slab Design (ACI318)Bunkun15100% (1)

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- 10 No. 16 MM Diameter Longitudinal Bars: Project Job RefDocument4 pages10 No. 16 MM Diameter Longitudinal Bars: Project Job RefErwin MaguideNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- Cell Respiration FermentationDocument5 pagesCell Respiration FermentationRozuwan ZakariaNo ratings yet

- 1 s2.0 S0167732217315696 MainDocument10 pages1 s2.0 S0167732217315696 MainMayaGhazaNo ratings yet

- The Agikuyu Concept of God and Understanding of The Triune GodDocument8 pagesThe Agikuyu Concept of God and Understanding of The Triune GodDominic M NjugunaNo ratings yet

- Bell's Palsy - Symptoms and Causes - Mayo ClinicDocument6 pagesBell's Palsy - Symptoms and Causes - Mayo ClinicRoxan PacsayNo ratings yet

- Specifications YCL 15 To 50 Ton ChillersDocument4 pagesSpecifications YCL 15 To 50 Ton ChillersEdgar MoyaoNo ratings yet

- Full Thickness Skin Grafts in Periocular Reconstructions: Long-Term OutcomesDocument4 pagesFull Thickness Skin Grafts in Periocular Reconstructions: Long-Term OutcomesdrelvNo ratings yet

- Newshound MagazineDocument24 pagesNewshound MagazineLovely BeconiaNo ratings yet

- Septone Brake Dust Cleaner SDSDocument15 pagesSeptone Brake Dust Cleaner SDSMarkSomniumNo ratings yet

- Apricot Kernel Shell MSDSDocument3 pagesApricot Kernel Shell MSDSdesi AdelinaNo ratings yet

- Philosophy NotesDocument6 pagesPhilosophy NotesRishi Raj MukherjeeNo ratings yet

- OceanofPDF - Com Learning To Love Myself - Alex AubreyDocument143 pagesOceanofPDF - Com Learning To Love Myself - Alex AubreyJeshvanthNo ratings yet

- Intersection A Curve and A LineDocument16 pagesIntersection A Curve and A LineIr HeriawanNo ratings yet

- The Cell's Life Cycle: Anatomy and Physiology Laboratory ManualDocument6 pagesThe Cell's Life Cycle: Anatomy and Physiology Laboratory ManualJan Edward Abarientos MandaniNo ratings yet

- C871Document5 pagesC871dinhtung2210No ratings yet

- Altai C2s Catalog Eng 170224Document2 pagesAltai C2s Catalog Eng 170224glocallNo ratings yet

- Bioorganic & Medicinal Chemistry 13 (2005) 3219-3227Document9 pagesBioorganic & Medicinal Chemistry 13 (2005) 3219-3227prashantNo ratings yet

- Revival Candle Meaning - Google SearchDocument1 pageRevival Candle Meaning - Google SearchAlanaNo ratings yet

- Properties of Pure SubstanceDocument26 pagesProperties of Pure SubstanceMahadi HasanNo ratings yet

- February 01, 2016 at 0731AMDocument5 pagesFebruary 01, 2016 at 0731AMJournal Star police documentsNo ratings yet

- Rdsopeskac0206-2019 Sheet 1 To 48 25-04-2019Document48 pagesRdsopeskac0206-2019 Sheet 1 To 48 25-04-2019Arshad AlamNo ratings yet

- Standard Insurance Co., Inc. vs. CuaresmaDocument14 pagesStandard Insurance Co., Inc. vs. CuaresmaTJ Dasalla GallardoNo ratings yet

- Final BrochureDocument24 pagesFinal BrochureSania LokhoNo ratings yet

- Qualitative Tests For Carbohydrates: 1) Molisch TestDocument20 pagesQualitative Tests For Carbohydrates: 1) Molisch TestFRANCEEN LEANNA KATIGBAKNo ratings yet

- Notes On Molecular Orbital CalculationDocument170 pagesNotes On Molecular Orbital CalculationFreeWill100% (1)

- Dense Phase Pneumatic Conveying SystemDocument1 pageDense Phase Pneumatic Conveying SystemH3mantNo ratings yet