Professional Documents

Culture Documents

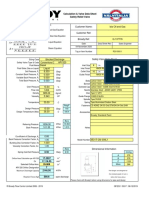

EJMA Calculations for t=.03, w=1.095, q=1 inch

Uploaded by

Julian Morantes0 ratings0% found this document useful (0 votes)

36 views3 pagesThis document contains calculations for the EJMA (Expanded Joint Metal Association) parameters of a bellows design with an inside diameter of 38 inches, a mean diameter of 39.125 inches, and a wall thickness of 0.03 inches. It calculates values for the meridional membrane and bending stresses due to both internal pressure and axial deflection, as well as the theoretical axial spring rate and total spring rate of the bellows design.

Original Description:

EJMA Bellows Calculator

Original Title

EJMA Bellows Calculator

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains calculations for the EJMA (Expanded Joint Metal Association) parameters of a bellows design with an inside diameter of 38 inches, a mean diameter of 39.125 inches, and a wall thickness of 0.03 inches. It calculates values for the meridional membrane and bending stresses due to both internal pressure and axial deflection, as well as the theoretical axial spring rate and total spring rate of the bellows design.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views3 pagesEJMA Calculations for t=.03, w=1.095, q=1 inch

Uploaded by

Julian MorantesThis document contains calculations for the EJMA (Expanded Joint Metal Association) parameters of a bellows design with an inside diameter of 38 inches, a mean diameter of 39.125 inches, and a wall thickness of 0.03 inches. It calculates values for the meridional membrane and bending stresses due to both internal pressure and axial deflection, as well as the theoretical axial spring rate and total spring rate of the bellows design.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

EJMA Calculations for t=.03 , w=1.095, q= 1.

0 inches

Db 38 in Inside diameter

Dm= Db+w+nt 39.125 in Mean diameter

tp=t(Db/Dm)^-2 0.0295655 in

tp^2 0.0008741

Cp 0.68 from curves, Figure 4.16 EJMA

n 1 material plies of thickness "t"

t 0.03 in

w 1.095 in

w^3 1.3129324

q 1 in

P 14.5 psi

S3=Pw/2ntp Meridional Membrane due to pressure

Eq. 4-30

S3 268.56 psi

P/2 7.25

(w/tp)^2 1371.6916

S4=P/2n(w/tp)^2Cp Meridional Bending due to pressure

Eq.4-31

S4 6762.44 psi

Eb 29000000 psi Elastic modulus

e=X/N 0.0525 in Per convolution

X 0.315 in

N 6 Number of convolutions

Cf 1.65 from curve, Figure 4.17 EJMA

S5=Eb(tp)^2(e))/2(w)^3*Cf Meridional membrane due to deflection

Eq. 4-32

S5 307.17 psi

S6=5(Eb)(tp)e/3(w^2)Cd Meridional Bending due to deflection

Eq.4-33

S6 38386.29 psi

Cd 1.63 from curve, Figure 4-18

Spring Rate

fiu=1.7 ((DmEb(tp^3)n)/(w^3)Cf)) Bellows Theoretical Axial Spring Rate

Eq.4-37

tp^3 2.584E-05

DmEb 1.13E+09

DmEb*(tp^ 29323.11

w^3Cf 2.166338

fiu 23010.847 lbs/in Note: Per convolution

Ktotal 3835.14 lbs/in For N=6 (total convolutions)

in series

23010.85 11505.42 5752.7117 3835.1411

23010.85

23010.85 11505.42

23010.85

23010.85 11505.42

23010.85

Required Parameters for all Curve Constants

1.82rm/(Dmtp)^-2 0.423

rm 0.25 in

2rm/w 0.457

Fatigue Life Calculations

Sf = 0.7 (S3 +S4) + (S5 +S6) See Figure 4-20

Sf= 43615.153 psi

You might also like

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 pagesMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanNo ratings yet

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002No ratings yet

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocument9 pagesPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNo ratings yet

- Bruce MoenDocument4 pagesBruce MoenGeorge Stefanakos100% (5)

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSNo ratings yet

- Proposal to Enhance Science InstructionDocument4 pagesProposal to Enhance Science InstructionAzzel ArietaNo ratings yet

- EJMA Bellows CalculatorDocument3 pagesEJMA Bellows CalculatorRyan FisherNo ratings yet

- Pathways Rw1 2e U7 TestDocument9 pagesPathways Rw1 2e U7 TestGrace Ann AbanteNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDocument5 pagesCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- OPTIMIZED DESIGN OF U-SHAPED METAL BELLOWSDocument5 pagesOPTIMIZED DESIGN OF U-SHAPED METAL BELLOWSdaymonNo ratings yet

- Design Conditions: Design of Base PlateDocument6 pagesDesign Conditions: Design of Base PlateSaravanan SilambanNo ratings yet

- Titanium Bellows Design CalculationsDocument8 pagesTitanium Bellows Design CalculationsNamıkNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Air Blowers Data SheetDocument9 pagesAir Blowers Data Sheetgharsallah mounaNo ratings yet

- Snamprogetti fluid list piping classDocument3 pagesSnamprogetti fluid list piping classadesloopNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- Consumer Perception of Digital Payment Modes in IndiaDocument14 pagesConsumer Perception of Digital Payment Modes in Indiakarthick50% (2)

- Easyheat s27 - 02 SarcoDocument8 pagesEasyheat s27 - 02 SarcoMarcelo ResckNo ratings yet

- Geraldez Vs Ca 230 Scra 329Document12 pagesGeraldez Vs Ca 230 Scra 329Cyrus Pural EboñaNo ratings yet

- Screw Conveyor and Feeder Calculation FiDocument90 pagesScrew Conveyor and Feeder Calculation FiTheodoros AtheridisNo ratings yet

- Engg Databook ch9Document38 pagesEngg Databook ch9drjonesg19585102No ratings yet

- Evosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceDocument12 pagesEvosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceMunir AhmedNo ratings yet

- Heat Exchangers Explained: KSI/... Series OverviewDocument4 pagesHeat Exchangers Explained: KSI/... Series OverviewJohn F Diaz HNo ratings yet

- Clampco CatalogueDocument39 pagesClampco CatalogueMisaghNo ratings yet

- Differentiated Lesson PlanningDocument2 pagesDifferentiated Lesson Planningapi-398854125No ratings yet

- UITM Faculty of Business Entrepreneurship Rubric Social Media PortfolioDocument9 pagesUITM Faculty of Business Entrepreneurship Rubric Social Media PortfolioShamsyul AriffinNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- DIN-En-1822 Mez Klasifikace enDocument1 pageDIN-En-1822 Mez Klasifikace enGabrielNo ratings yet

- Background To Design Rules - Issue of EN13445 EN1591 Part PDFDocument19 pagesBackground To Design Rules - Issue of EN13445 EN1591 Part PDFBenoit LabreNo ratings yet

- 7-Ideal and Real GasDocument12 pages7-Ideal and Real GasLeoThomasNo ratings yet

- WPS GMAW FCAW D1.1 2015 Form PDFDocument1 pageWPS GMAW FCAW D1.1 2015 Form PDFHoque AnamulNo ratings yet

- ME ProductCatalogDocument20 pagesME ProductCatalogLim Chee SiangNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Pressure-Temp Chart for Materials 4 Spec-GradeDocument5 pagesPressure-Temp Chart for Materials 4 Spec-GradeWilson Ramirez ZuniniNo ratings yet

- Thermodynamic RelationsDocument28 pagesThermodynamic RelationsAmrita DinilNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDocument2 pagesScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisNo ratings yet

- Fluid Bed DryerDocument16 pagesFluid Bed DryerDiego ANo ratings yet

- Everything You Need to Know About Jockey PumpsDocument4 pagesEverything You Need to Know About Jockey PumpsChemical.AliNo ratings yet

- Cyclic Service - Intergraph CADWorx & AnalysisDocument2 pagesCyclic Service - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- Data Sheet: Description Unit Design DataDocument2 pagesData Sheet: Description Unit Design DataEDUARDONo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Finglowv2Document16 pagesFinglowv2RobinReyndersNo ratings yet

- Discharge Nozzle Load Analysis for Fire Water Pump P-05ADocument22 pagesDischarge Nozzle Load Analysis for Fire Water Pump P-05ASeptian FirdausNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Steam ConsumptionDocument4 pagesSteam ConsumptionhuahmedNo ratings yet

- Question 1: Bezier Quadratic Curve Successive Linear Interpolation EquationDocument4 pagesQuestion 1: Bezier Quadratic Curve Successive Linear Interpolation Equationaushad3mNo ratings yet

- Multi Hole DesignDocument10 pagesMulti Hole DesignAlberto CorticelliNo ratings yet

- Derivation of Pressure Loss To Leak Rate Formula From The Ideal Gas LawDocument3 pagesDerivation of Pressure Loss To Leak Rate Formula From The Ideal Gas Lawsatheez3251No ratings yet

- Anson industry manufactures heavy equipmentDocument12 pagesAnson industry manufactures heavy equipmentJuan P RuizNo ratings yet

- Pbe - 200810-Conveying Line Elbows Provide Maintenance-Free OperationDocument4 pagesPbe - 200810-Conveying Line Elbows Provide Maintenance-Free Operation설동하No ratings yet

- Technical Evaluation HAM BAKERDocument1 pageTechnical Evaluation HAM BAKEReko123No ratings yet

- Horizontal Vessel Volume Calculator - Preliminary Sizing SheetDocument1 pageHorizontal Vessel Volume Calculator - Preliminary Sizing SheetJ.SIVIRANo ratings yet

- FOAMGLAS Cellular Glass InsulationDocument18 pagesFOAMGLAS Cellular Glass InsulationermizeNo ratings yet

- WRC Bulletin 537 - Rectangular Attachment (Excel)Document21 pagesWRC Bulletin 537 - Rectangular Attachment (Excel)Rey FiedacanNo ratings yet

- BS 5500 Appendix K and DDocument14 pagesBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNo ratings yet

- EJMA Bellows CalculatorDocument3 pagesEJMA Bellows CalculatorSaad Ur RehmanNo ratings yet

- UTH homework template for English exercisesDocument8 pagesUTH homework template for English exercisesCinthya Peña de MezaNo ratings yet

- Dictation TechniquesDocument12 pagesDictation TechniquesMuhamad IbrohimNo ratings yet

- Reported SpeechDocument2 pagesReported SpeechlacasabaNo ratings yet

- Joyce2016 PDFDocument13 pagesJoyce2016 PDFAffan ArrizqiNo ratings yet

- First Communion Liturgy: Bread Broken and SharedDocument11 pagesFirst Communion Liturgy: Bread Broken and SharedRomayne Brillantes100% (1)

- Engineers Guide To Microchip 2018Document36 pagesEngineers Guide To Microchip 2018mulleraf100% (1)

- Section 5 - Triangles - Part 1 Answer KeyDocument48 pagesSection 5 - Triangles - Part 1 Answer KeyErryn Lowe100% (2)

- TNPSC Vas: NEW SyllabusDocument12 pagesTNPSC Vas: NEW Syllabuskarthivisu2009No ratings yet

- Surveying 2 Practical 3Document15 pagesSurveying 2 Practical 3Huzefa AliNo ratings yet

- Diesel Pump of The Desmi GroupDocument10 pagesDiesel Pump of The Desmi Groupngocdhxd92No ratings yet

- Australian Securities and Investments Commission V KingDocument47 pagesAustralian Securities and Investments Commission V KingCourtni HolderNo ratings yet

- Israel Film FundDocument1 pageIsrael Film FundgodardsfanNo ratings yet

- 7) Set 3 Bi PT3 (Answer) PDFDocument4 pages7) Set 3 Bi PT3 (Answer) PDFTing ShiangNo ratings yet

- Common Expressions in Business 2Document2 pagesCommon Expressions in Business 2abdeljelil manelNo ratings yet

- In The Matter of The Adoption of Elizabeth MiraDocument2 pagesIn The Matter of The Adoption of Elizabeth MiradelayinggratificationNo ratings yet

- Diagrama RSAG7.820.7977Document14 pagesDiagrama RSAG7.820.7977Manuel Medina100% (4)

- Forms of WillsDocument24 pagesForms of WillsJasNo ratings yet

- Types of Companies Classified by Incorporation, Membership, Liability and ControlDocument11 pagesTypes of Companies Classified by Incorporation, Membership, Liability and ControlPrasad BulbuleNo ratings yet

- Sec 4 RA 6713 & Sec 3 RA 3019 OutlineDocument4 pagesSec 4 RA 6713 & Sec 3 RA 3019 OutlineAivan Charles TorresNo ratings yet

- SMEspdfDocument13 pagesSMEspdflilpumpdidnothingwrong dNo ratings yet

- Not Qualified (Spoken Word Poem) by JonJorgensonDocument3 pagesNot Qualified (Spoken Word Poem) by JonJorgensonKent Bryan Anderson100% (1)

- School RulesDocument2 pagesSchool RulesAI HUEYNo ratings yet