Professional Documents

Culture Documents

Vol% Sicp/2124Al Composite at Temperatures Between 623 K and 748 K. The Plot Vs

Uploaded by

Syed Danishul HaqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vol% Sicp/2124Al Composite at Temperatures Between 623 K and 748 K. The Plot Vs

Uploaded by

Syed Danishul HaqueCopyright:

Available Formats

37

of load transfer during creep of unreinforced aluminum alloy (Park and

Mohamed, 1995).

On the basis of examination of creep data of several discontinuous SiC/Al

composites, based on the value of true stress exponent (n = 8), Gonzalez and

Sherby (1993) reported that the threshold stress exhibits two main characteristics.

Firstly, it depends linearly on temperature and becomes zero in the temperature

range between 733 K and 743 K. Secondly, the threshold stress is higher for

whisker reinforced composites than the particulate composites. Gonzalez and

Sherby (1993) concluded that the threshold stress in discontinuous SiC/Al

composites originates due to the presence of SiC particles or whiskers.

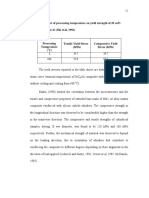

Cadek et al (1998) investigated the high temperature creep behavior of 20

vol% SiCp/2124Al composite at temperatures between 623 K and 748 K. The plot

of shear creep rate versus applied shear stress ( ln γ& m vs ln τ ) indicates the origin of

threshold stress with the value of apparent stress exponent, na = ( ln γ& m / ln τ )T,

which is observed to decrease with increasing applied stress. By considering

threshold stress into analysis, it is observed that the minimum creep rate of the

composite is controlled by the matrix lattice diffusion with a true stress exponent

close to 5. The threshold stress, as estimated by the extrapolation technique,

decreases linearly with increasing temperature and disappears at a temperature near

735 K. This finding is in good agreement with that of Gonzalez and Sherby (1993),

though these workers have introduced the structure invariant model with a stress

exponent of 8.

You might also like

- p26 PDFDocument1 pagep26 PDFSyed Danishul HaqueNo ratings yet

- 1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 ParticlesDocument6 pages1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 Particlesyaswanth1992No ratings yet

- Temperature Distributions and Variations in Concrete Box-Girder Bridges Experimental and Finite Elem1Document19 pagesTemperature Distributions and Variations in Concrete Box-Girder Bridges Experimental and Finite Elem1俊青薛No ratings yet

- Tensile, Creep, and ABI Tests On Sn5%Sb Solder PDFDocument8 pagesTensile, Creep, and ABI Tests On Sn5%Sb Solder PDFeid elsayedNo ratings yet

- Wettability of Carbon by Aluminum and Aluminum AlloysDocument13 pagesWettability of Carbon by Aluminum and Aluminum AlloysAlberto Rincon VargasNo ratings yet

- Development of Johnson Cook Model For Zirconium AlloyFinalDocument15 pagesDevelopment of Johnson Cook Model For Zirconium AlloyFinalsandeepNo ratings yet

- Ying 2017Document8 pagesYing 2017Teknik MesinBagus Setiyo AjiNo ratings yet

- International Journal of Plasticity: Akhtar S. Khan, Shaojuan YuDocument13 pagesInternational Journal of Plasticity: Akhtar S. Khan, Shaojuan YupurnashisNo ratings yet

- Vacuum: Le Xu, Liang Chen, Gaojin Chen, Maoqiu WangDocument10 pagesVacuum: Le Xu, Liang Chen, Gaojin Chen, Maoqiu WangChigoChigoNo ratings yet

- MM21M022 SHASHI 1975 (CHAPMAN and HALL LTD.) Temperature and Stress Dependences of Creep in Single Crystal of Lead Between 20K and 500KDocument6 pagesMM21M022 SHASHI 1975 (CHAPMAN and HALL LTD.) Temperature and Stress Dependences of Creep in Single Crystal of Lead Between 20K and 500KGangula Shreya Vardhan Reddy mm21m007No ratings yet

- Effect of Temperature On Mechanical Behavior of AZ31 Magnesium AlloyDocument5 pagesEffect of Temperature On Mechanical Behavior of AZ31 Magnesium Alloyazizieh5701No ratings yet

- Dislocation Mechanics1 PDFDocument9 pagesDislocation Mechanics1 PDFkakarlasantosh22No ratings yet

- 1 s2.0 0025541686902612 MainDocument13 pages1 s2.0 0025541686902612 MainVikram JainNo ratings yet

- Modelling of Heat Transfer Across Bolted Joints in Abaqus/CAEDocument11 pagesModelling of Heat Transfer Across Bolted Joints in Abaqus/CAEacar1No ratings yet

- The Creep Parameters of SAC305 Unleaded SoldersDocument10 pagesThe Creep Parameters of SAC305 Unleaded SoldersMartin BánfalviNo ratings yet

- ɤ-TiAl Alloy: Revisiting Tensile Creep Deformation Behaviour and Creep Life at 832 °CDocument11 pagesɤ-TiAl Alloy: Revisiting Tensile Creep Deformation Behaviour and Creep Life at 832 °CMainak SahaNo ratings yet

- Journal of Materials Processing TechnologyDocument6 pagesJournal of Materials Processing TechnologymonikeshNo ratings yet

- The Influence of Constraint On Fracture Toughness T0 Shift in Master Curve 2022Document23 pagesThe Influence of Constraint On Fracture Toughness T0 Shift in Master Curve 2022cehamos882No ratings yet

- Constitutive Modelling of AZ31B-O Magnesium Alloy For Cryogenic MachiningDocument6 pagesConstitutive Modelling of AZ31B-O Magnesium Alloy For Cryogenic MachiningSyamsul Bahry HarahapNo ratings yet

- Plastic Deformation of The Intermetallic: Compound MGZNDocument11 pagesPlastic Deformation of The Intermetallic: Compound MGZNFaris FadliNo ratings yet

- Temperature Dependence of The Microstructure and MDocument11 pagesTemperature Dependence of The Microstructure and MAlokNo ratings yet

- 58 4 NieDocument12 pages58 4 Nieestag.engNo ratings yet

- Long Lab ReportDocument2 pagesLong Lab ReportNicky FinchamNo ratings yet

- 1 s2.0 S092150932101296X MainDocument8 pages1 s2.0 S092150932101296X MainÁlvaro Nieto CastroNo ratings yet

- BA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsDocument9 pagesBA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsBhavana ValetiNo ratings yet

- Basic Creep Modelling of AluminiumDocument35 pagesBasic Creep Modelling of AluminiumSubash JainNo ratings yet

- Effect of Temperature On Fatigue Transition Life and Strength of Aluminum AlloyDocument6 pagesEffect of Temperature On Fatigue Transition Life and Strength of Aluminum AlloyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- JMPS 2004 Zhang DunnDocument26 pagesJMPS 2004 Zhang Dunnp1muellerNo ratings yet

- Tribology International: Heguo Zhu, Cuicui Jar, Jinzhu Song, Jun Zhao, Jianliang Li, Zonghan XieDocument9 pagesTribology International: Heguo Zhu, Cuicui Jar, Jinzhu Song, Jun Zhao, Jianliang Li, Zonghan XiehariNo ratings yet

- 14-Interface Characterization and Bonding Mechanisms of Cold Gas-Sprayed Al Coatings On Ceramic SubstratesDocument8 pages14-Interface Characterization and Bonding Mechanisms of Cold Gas-Sprayed Al Coatings On Ceramic Substratesshaoyun ZHOUNo ratings yet

- Structural Test and Analysis of RC Slab After Fire LoadingDocument14 pagesStructural Test and Analysis of RC Slab After Fire LoadingArtVano0No ratings yet

- Buckling Load of Laminated Composite Plate Under Different Boundary ConditionsDocument18 pagesBuckling Load of Laminated Composite Plate Under Different Boundary ConditionsDEEPAKNo ratings yet

- Experimental Study of The Relationship Between Temperature and Adhesive Forces For Low-Alloyed Steel, Stainless Steel and Titanium Using Atomic Force Microscopy in Ultra-High VacuumDocument4 pagesExperimental Study of The Relationship Between Temperature and Adhesive Forces For Low-Alloyed Steel, Stainless Steel and Titanium Using Atomic Force Microscopy in Ultra-High VacuumBert MiltonssonNo ratings yet

- Thermal ShockDocument6 pagesThermal ShockAndrea CalderaNo ratings yet

- CFD, A Design Tool For A New Hot Metal Desulfurization TechnologyDocument14 pagesCFD, A Design Tool For A New Hot Metal Desulfurization Technologyjagadish mahataNo ratings yet

- Numerical Simulation of The Temperaturbe Filed in fixed-TIG Welding PoolDocument5 pagesNumerical Simulation of The Temperaturbe Filed in fixed-TIG Welding PoolRaul MamaniNo ratings yet

- 5 1033 PDFDocument12 pages5 1033 PDFtahera aqeelNo ratings yet

- Welding Thermal Stress Diagrams As A MeansDocument19 pagesWelding Thermal Stress Diagrams As A MeansmarcosNo ratings yet

- 10 1016@j Jma 2020 03 001Document7 pages10 1016@j Jma 2020 03 001ggNo ratings yet

- Thermal Cycling Analysis of Flip-Chip Solder Joint ReliabilityDocument8 pagesThermal Cycling Analysis of Flip-Chip Solder Joint Reliability鲁长武No ratings yet

- Janssens BCC09 PaperDocument11 pagesJanssens BCC09 PaperVyto BabrauskasNo ratings yet

- Ductile CeramicsDocument61 pagesDuctile CeramicsFlorin AndreiNo ratings yet

- Effects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsDocument8 pagesEffects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsBHARANINo ratings yet

- Partition of Plastic Work Into Heat and Stored PDFDocument11 pagesPartition of Plastic Work Into Heat and Stored PDFAsad MaqsoodNo ratings yet

- A Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenDocument14 pagesA Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenkotakamalsNo ratings yet

- Casting-Mold Thermal Contact Heat Transfer During Solidification of Al-Cu-Si Alloy (LM21) Plates in Thick and Thin MoldsDocument6 pagesCasting-Mold Thermal Contact Heat Transfer During Solidification of Al-Cu-Si Alloy (LM21) Plates in Thick and Thin MoldsJinsoo KimNo ratings yet

- Bjerg PRB14Document9 pagesBjerg PRB14Shabeer ali pcNo ratings yet

- Journal Pre-Proofs: Results in PhysicsDocument7 pagesJournal Pre-Proofs: Results in PhysicsIsmatov TolibNo ratings yet

- Karakteristik Tembaga TemperaturDocument12 pagesKarakteristik Tembaga TemperaturdharmantoNo ratings yet

- Investigation On Zener-Hollomon Parameter of A Medium Carbon Low Alloy of 1Cr-1Mn-1.5Ni-1Si-0.1V Under Hot Compression TestDocument7 pagesInvestigation On Zener-Hollomon Parameter of A Medium Carbon Low Alloy of 1Cr-1Mn-1.5Ni-1Si-0.1V Under Hot Compression TestEidelsayedNo ratings yet

- Burak Yıldızlı Strength of WasteDocument18 pagesBurak Yıldızlı Strength of WasteAbbasNo ratings yet

- Ceramics 03 00033Document12 pagesCeramics 03 00033Kristanto WahyudiNo ratings yet

- Computational Simulation of Turbulent Natural Convection in A Volumetrically Heated Square CavityDocument8 pagesComputational Simulation of Turbulent Natural Convection in A Volumetrically Heated Square Cavitysattar aljabairNo ratings yet

- Extension of The Double-Ellipsoidal Heat Source Model Tonarrow-Groove and Keyhole Weld ConfigurationsDocument13 pagesExtension of The Double-Ellipsoidal Heat Source Model Tonarrow-Groove and Keyhole Weld Configurationsal-masriNo ratings yet

- Temperature Dependence of The Yield Strength of Aluminum Thin Films Multiscale Modeling ApproachDocument10 pagesTemperature Dependence of The Yield Strength of Aluminum Thin Films Multiscale Modeling Approachrizkboss8312No ratings yet

- A Study of Zenner - Holomon Parameter Variation With Pass Reduction in Steel RollingDocument11 pagesA Study of Zenner - Holomon Parameter Variation With Pass Reduction in Steel RollinginventionjournalsNo ratings yet

- 108 MMTA2009 DiscussionofNiyamaDocument3 pages108 MMTA2009 DiscussionofNiyamaShu LiNo ratings yet

- Thermal Expansion Coefficient of 3C-Sic: D. N. TalwarDocument4 pagesThermal Expansion Coefficient of 3C-Sic: D. N. TalwarParlin Febrianto SianiparNo ratings yet

- 2.2 YIELD Criteria 2.2.1 Mathematical FormulationDocument1 page2.2 YIELD Criteria 2.2.1 Mathematical FormulationSyed Danishul HaqueNo ratings yet

- p05 PDFDocument1 pagep05 PDFSyed Danishul HaqueNo ratings yet

- p09 PDFDocument1 pagep09 PDFSyed Danishul HaqueNo ratings yet

- p08 PDFDocument1 pagep08 PDFSyed Danishul HaqueNo ratings yet

- Chapter - 2 Review of Literature: 2.1 GeneralDocument1 pageChapter - 2 Review of Literature: 2.1 GeneralSyed Danishul HaqueNo ratings yet

- p03 PDFDocument1 pagep03 PDFSyed Danishul HaqueNo ratings yet

- p40 PDFDocument1 pagep40 PDFSyed Danishul HaqueNo ratings yet

- 2.2.3 Yield Criteria For Isotropic MaterialDocument1 page2.2.3 Yield Criteria For Isotropic MaterialSyed Danishul HaqueNo ratings yet

- 2.2.4 Yielding in Presence of Residual StressDocument1 page2.2.4 Yielding in Presence of Residual StressSyed Danishul HaqueNo ratings yet

- 2.5.1 Analysis of Elastic-Plastic Stresses in Rotating DiskDocument1 page2.5.1 Analysis of Elastic-Plastic Stresses in Rotating DiskSyed Danishul HaqueNo ratings yet

- p10 PDFDocument1 pagep10 PDFSyed Danishul HaqueNo ratings yet

- p02 PDFDocument1 pagep02 PDFSyed Danishul HaqueNo ratings yet

- p37 PDFDocument1 pagep37 PDFSyed Danishul HaqueNo ratings yet

- p32 PDFDocument1 pagep32 PDFSyed Danishul HaqueNo ratings yet

- p39 PDFDocument1 pagep39 PDFSyed Danishul HaqueNo ratings yet

- p41 PDFDocument1 pagep41 PDFSyed Danishul HaqueNo ratings yet

- p33 PDFDocument1 pagep33 PDFSyed Danishul HaqueNo ratings yet

- p35 PDFDocument1 pagep35 PDFSyed Danishul HaqueNo ratings yet

- 2.4 Functionally Graded MaterialsDocument1 page2.4 Functionally Graded MaterialsSyed Danishul HaqueNo ratings yet

- p29 PDFDocument1 pagep29 PDFSyed Danishul HaqueNo ratings yet

- p28 PDFDocument1 pagep28 PDFSyed Danishul HaqueNo ratings yet

- p34 PDFDocument1 pagep34 PDFSyed Danishul HaqueNo ratings yet

- p36 PDFDocument1 pagep36 PDFSyed Danishul HaqueNo ratings yet

- Et Al (1996) Investigated The Creep Behavior of 10 Vol% Sicp/Al-4%Document1 pageEt Al (1996) Investigated The Creep Behavior of 10 Vol% Sicp/Al-4%Syed Danishul HaqueNo ratings yet

- p27 PDFDocument1 pagep27 PDFSyed Danishul HaqueNo ratings yet

- p23 PDFDocument1 pagep23 PDFSyed Danishul HaqueNo ratings yet

- M Q A E M: 2.3.7 Estimation of Threshold StressDocument1 pageM Q A E M: 2.3.7 Estimation of Threshold StressSyed Danishul HaqueNo ratings yet

- 2.3.8 Characteristics and Origin of Threshold StressDocument1 page2.3.8 Characteristics and Origin of Threshold StressSyed Danishul HaqueNo ratings yet