Professional Documents

Culture Documents

p05 PDF

Uploaded by

Syed Danishul HaqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p05 PDF

Uploaded by

Syed Danishul HaqueCopyright:

Available Formats

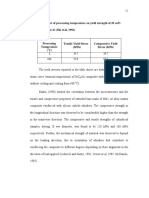

17

As the yield criterion does not depend on the path of loading, it does not tell

anything about deformation. To develop a yield function, the components of the

multiaxial stress state are combined into a single quantity known as the effective

stress (σ e ) . The effective stress is then compared with the yield stress in some

appropriate form to check the inset of yielding.

The state of stress can be determined by specifying the principal stress and

orientation of principal axes. The three principal stresses and three angles

constitute the six dimensional spaces. Thus, the yield function can be written as,

f = f (σ 1 , σ 2 , σ 3 , α 1 , α 2 , α 3 )

where σ 1 , σ 2 , σ 3 are the principal stresses and α 1 , α 2 , α 3 are the orientations of

principal axes.

The yield criterion must be consistent with a number of experimental

observations, the chief of which is that pure hydrostatic pressure should not cause

yielding in a continuous solid (Dieter, 1988).

2.2.2 Geometrical representation

There exist three principal stresses and their orientation for a given state of

stress at a point. Hence one can represent the state of stress as a point in three

dimensional vector space whose bases are the principal stresses for isotropic

materials, where the orientation of the axes is not important. For isotropic materials

f (σ 1 , σ 2 , σ 3 ) = 0 represents a surface in the principal stress space. If a material is

acted upon by deviatoric stress, then the yield surface can be represented as,

f (σ 1 , σ 2 , σ 3 ) = 0 (2.1)

Subject to the condition that,

You might also like

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- Stress, Strain, and Constitutive RelationsDocument23 pagesStress, Strain, and Constitutive RelationsMekro Permana PinemNo ratings yet

- Yield Criteria in 3D PlasticityDocument21 pagesYield Criteria in 3D Plasticity한종훈100% (1)

- Chapter 9Document72 pagesChapter 9Elmar CuellarNo ratings yet

- 17.lecture 27 Finite Element Derivation PDFDocument17 pages17.lecture 27 Finite Element Derivation PDFKarina NaudéNo ratings yet

- Complex Stress AnalysisDocument12 pagesComplex Stress AnalysishaymanotNo ratings yet

- 1 - Load and Stress AnalysisDocument27 pages1 - Load and Stress AnalysisAyesha KhanNo ratings yet

- Tables of Normalized Associated Legendre Polynomials: Mathematical Tables SeriesFrom EverandTables of Normalized Associated Legendre Polynomials: Mathematical Tables SeriesNo ratings yet

- Salençon, J. and Pecker EC8 Foundation Bearing CapacityDocument20 pagesSalençon, J. and Pecker EC8 Foundation Bearing CapacityYang LuNo ratings yet

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- Lecture 13 Yield CriterionDocument10 pagesLecture 13 Yield CriterionManoj MallickNo ratings yet

- A Method of Analysis of The Stability of Embankments Assuming Parallel Inter - Slice ForcesDocument16 pagesA Method of Analysis of The Stability of Embankments Assuming Parallel Inter - Slice ForcesCostinel Cristescu100% (2)

- Stress and StrainDocument17 pagesStress and StrainakshatbhargavaNo ratings yet

- Fea-Finite Element Analysis: Chapter-1 Stress TensorDocument106 pagesFea-Finite Element Analysis: Chapter-1 Stress Tensorkamsubh66No ratings yet

- Primer 1 On The Simplest Inelastic Model: Non-Hardening Von Mises (J2) PlasticityDocument9 pagesPrimer 1 On The Simplest Inelastic Model: Non-Hardening Von Mises (J2) PlasticityNguyễn Hữu HàoNo ratings yet

- 1974 - Matsuoka NakaiDocument12 pages1974 - Matsuoka NakaiMohdHilmyNaimNo ratings yet

- DeformacionEsfuerzoInglésDocument11 pagesDeformacionEsfuerzoInglésPepePepeNo ratings yet

- Mechanics of Materials BasicsDocument65 pagesMechanics of Materials BasicsengrasheedNo ratings yet

- Essay U4Document5 pagesEssay U4marianacarmonargzNo ratings yet

- STRESS-STRAIN ANALYSISDocument20 pagesSTRESS-STRAIN ANALYSISSboniso KhethukuthulaNo ratings yet

- Stresses: 2.1 General TheoryDocument25 pagesStresses: 2.1 General TheoryLocoo Goku YoshiiNo ratings yet

- 4.1 Principal Stresses and Principal Stress AxesDocument21 pages4.1 Principal Stresses and Principal Stress Axes4114018No ratings yet

- Critical Plane Anisotropy Adapted For General 3-D Stress ConditionsDocument5 pagesCritical Plane Anisotropy Adapted For General 3-D Stress ConditionsMarcelo AguilarNo ratings yet

- Understanding stresses in 3D solidsDocument21 pagesUnderstanding stresses in 3D solidsBendis AmmNo ratings yet

- Unit 5 Principal Stresses and Strains: StructureDocument32 pagesUnit 5 Principal Stresses and Strains: StructureRiddhima MukherjeeNo ratings yet

- Chapter2 PDFDocument18 pagesChapter2 PDFamirthraj74No ratings yet

- Plane Stress and Strain Analysis in Solid MechanicsDocument8 pagesPlane Stress and Strain Analysis in Solid MechanicskingstonNo ratings yet

- 02 Kaselowch2Document22 pages02 Kaselowch2JCMMPROJECTNo ratings yet

- Plane Stress and Plane Strain: 4.2.1 Displacement FunctionsDocument25 pagesPlane Stress and Plane Strain: 4.2.1 Displacement FunctionswearplayNo ratings yet

- Closed-Form Solutions for Stress AnalysisDocument14 pagesClosed-Form Solutions for Stress AnalysisADITYANo ratings yet

- 101 PDFDocument21 pages101 PDFThaung Myint OoNo ratings yet

- 3 StressDocument11 pages3 StressGbenga AdewumiNo ratings yet

- in This Module Text in "Italic" Indicates Advanced Concepts. 2., Are Used For Shear' in Books and LiteratureDocument35 pagesin This Module Text in "Italic" Indicates Advanced Concepts. 2., Are Used For Shear' in Books and LiteratureKanti SolankiNo ratings yet

- Stress PresentationDocument26 pagesStress PresentationDhakshina KNo ratings yet

- Plastic Yield LodeDocument9 pagesPlastic Yield LodesengozkNo ratings yet

- Lode Dependences Pressure-Sensitive Materials For Isotropic ElastoplasticDocument9 pagesLode Dependences Pressure-Sensitive Materials For Isotropic Elastoplasticaasc1981No ratings yet

- Calculation of Stress Intensity Factors and Crack Opening Displacements For Cracks Subjected To Complex Stress FieldsDocument7 pagesCalculation of Stress Intensity Factors and Crack Opening Displacements For Cracks Subjected To Complex Stress FieldsAkash AkuNo ratings yet

- Chapter OneDocument27 pagesChapter OnehaymanotNo ratings yet

- Force-Balance and Mohr's Equations: Structural GeologyDocument8 pagesForce-Balance and Mohr's Equations: Structural GeologyPatchole Alwan TiarasiNo ratings yet

- Dam TauDocument44 pagesDam TauHarsh Kumar NarulaNo ratings yet

- Principal stresses and maximum shearDocument13 pagesPrincipal stresses and maximum shearSathish SelvaNo ratings yet

- Initial Curvature Reduces Strength of Inelastic ColumnsDocument18 pagesInitial Curvature Reduces Strength of Inelastic ColumnsrjtcostaNo ratings yet

- 503 QuiDocument10 pages503 QuiMona AwadNo ratings yet

- Principle Stresses & StrainsDocument35 pagesPrinciple Stresses & StrainskalpanaadhiNo ratings yet

- 08 Plasticity 03 YieldCriteriaDocument22 pages08 Plasticity 03 YieldCriteriaFrancisco EscobarNo ratings yet

- Chapter 9Document52 pagesChapter 9Navian NadeemNo ratings yet

- Lecture 03Document32 pagesLecture 03businessw025No ratings yet

- Ball Bearing Mechanics: Ni/SaDocument107 pagesBall Bearing Mechanics: Ni/SathisisjineshNo ratings yet

- 3 D LectureDocument36 pages3 D LectureAisha AbuzgaiaNo ratings yet

- Stress DistributionDocument44 pagesStress DistributionebalicNo ratings yet

- Tangent Stiffness Method For Biaxial Bending 1971 (72-1)Document28 pagesTangent Stiffness Method For Biaxial Bending 1971 (72-1)filipeNo ratings yet

- Chap 1. Stress-Strain AnalysisDocument36 pagesChap 1. Stress-Strain Analysisteknikpembakaran2013No ratings yet

- 08 Plasticity 06 Strain HardeningDocument15 pages08 Plasticity 06 Strain Hardeningmicael_89No ratings yet

- Stress and Strain TransformationDocument14 pagesStress and Strain TransformationGabriel SoaresNo ratings yet

- p03 PDFDocument1 pagep03 PDFSyed Danishul HaqueNo ratings yet

- p09 PDFDocument1 pagep09 PDFSyed Danishul HaqueNo ratings yet

- 2.2.4 Yielding in Presence of Residual StressDocument1 page2.2.4 Yielding in Presence of Residual StressSyed Danishul HaqueNo ratings yet

- p08 PDFDocument1 pagep08 PDFSyed Danishul HaqueNo ratings yet

- p05 PDFDocument1 pagep05 PDFSyed Danishul HaqueNo ratings yet

- 2.2 YIELD Criteria 2.2.1 Mathematical FormulationDocument1 page2.2 YIELD Criteria 2.2.1 Mathematical FormulationSyed Danishul HaqueNo ratings yet

- Chapter - 2 Review of Literature: 2.1 GeneralDocument1 pageChapter - 2 Review of Literature: 2.1 GeneralSyed Danishul HaqueNo ratings yet

- p10 PDFDocument1 pagep10 PDFSyed Danishul HaqueNo ratings yet

- p41 PDFDocument1 pagep41 PDFSyed Danishul HaqueNo ratings yet

- p37 PDFDocument1 pagep37 PDFSyed Danishul HaqueNo ratings yet

- p39 PDFDocument1 pagep39 PDFSyed Danishul HaqueNo ratings yet

- p40 PDFDocument1 pagep40 PDFSyed Danishul HaqueNo ratings yet

- 2.2.3 Yield Criteria For Isotropic MaterialDocument1 page2.2.3 Yield Criteria For Isotropic MaterialSyed Danishul HaqueNo ratings yet

- p02 PDFDocument1 pagep02 PDFSyed Danishul HaqueNo ratings yet

- p33 PDFDocument1 pagep33 PDFSyed Danishul HaqueNo ratings yet

- 2.4 Functionally Graded MaterialsDocument1 page2.4 Functionally Graded MaterialsSyed Danishul HaqueNo ratings yet

- 2.5.1 Analysis of Elastic-Plastic Stresses in Rotating DiskDocument1 page2.5.1 Analysis of Elastic-Plastic Stresses in Rotating DiskSyed Danishul HaqueNo ratings yet

- p35 PDFDocument1 pagep35 PDFSyed Danishul HaqueNo ratings yet

- p32 PDFDocument1 pagep32 PDFSyed Danishul HaqueNo ratings yet

- p36 PDFDocument1 pagep36 PDFSyed Danishul HaqueNo ratings yet

- p34 PDFDocument1 pagep34 PDFSyed Danishul HaqueNo ratings yet

- p28 PDFDocument1 pagep28 PDFSyed Danishul HaqueNo ratings yet

- p29 PDFDocument1 pagep29 PDFSyed Danishul HaqueNo ratings yet

- Vol% Sicp/2124Al Composite at Temperatures Between 623 K and 748 K. The Plot VsDocument1 pageVol% Sicp/2124Al Composite at Temperatures Between 623 K and 748 K. The Plot VsSyed Danishul HaqueNo ratings yet

- p26 PDFDocument1 pagep26 PDFSyed Danishul HaqueNo ratings yet

- Et Al (1996) Investigated The Creep Behavior of 10 Vol% Sicp/Al-4%Document1 pageEt Al (1996) Investigated The Creep Behavior of 10 Vol% Sicp/Al-4%Syed Danishul HaqueNo ratings yet

- p27 PDFDocument1 pagep27 PDFSyed Danishul HaqueNo ratings yet

- p23 PDFDocument1 pagep23 PDFSyed Danishul HaqueNo ratings yet

- M Q A E M: 2.3.7 Estimation of Threshold StressDocument1 pageM Q A E M: 2.3.7 Estimation of Threshold StressSyed Danishul HaqueNo ratings yet

- 2.3.8 Characteristics and Origin of Threshold StressDocument1 page2.3.8 Characteristics and Origin of Threshold StressSyed Danishul HaqueNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Taking Back Eden: Eight Environmental Cases that Changed the WorldFrom EverandTaking Back Eden: Eight Environmental Cases that Changed the WorldRating: 4 out of 5 stars4/5 (2)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)