Professional Documents

Culture Documents

Weld Built Up Procedure

Weld Built Up Procedure

Uploaded by

Mohd Shafuaaz KassimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Built Up Procedure

Weld Built Up Procedure

Uploaded by

Mohd Shafuaaz KassimCopyright:

Available Formats

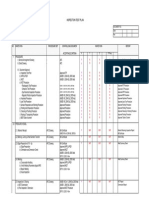

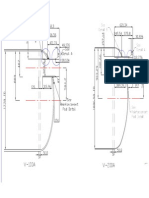

Weld Built-Up Procedure

1. Identify all the areas on the channel shell, floating head cover and pass partition plates

(PPP) for weld build up and repairs.

2. Removed all the affected lining and thoroughly clean up the surfaces by power brushing

(or wire brushing for areas non-accessed by power tool). All rusts and scales shall be

removed.

3. Those corroded areas with narrow groove/rough edges shall be ground out (opened up) in

order to allow a good & proper welding.

4. Carry out general preheating to drying up moisture (approximately 80°C~100°C).

5. Proceed with welding (Gasket area, shell & on the PPP).

6. Perform NDT after completion of welding (Dye Penetrat Test).

7. To carry out grinding to remove excess weld metal on the PPP. Ensure that the finishing

is straight & smooth and thicknesses at PPP edge are within required tolerance (to fit into

groove on tube sheet).

8. Perform machining on the gasket face.

9. Perform NDT after machining on the gasket face (Dye Penetrant Tets)

10. Carry out lining repair at the repaired areas on the internal shell/PPP.

11. Install channels & cover to equipment and perform pressure test. Check for leak

especially on the gasket areas.

You might also like

- Inspection Test PlanDocument3 pagesInspection Test PlanMohd Shafuaaz Kassim100% (2)

- Tank 7 Repair Procedure Rev1Document6 pagesTank 7 Repair Procedure Rev1Mohd Shafuaaz Kassim33% (3)

- Titanium Cladded Sheet Welding ProcedureDocument4 pagesTitanium Cladded Sheet Welding ProcedureNaveenNo ratings yet

- Weld Built Up ProcedureDocument4 pagesWeld Built Up ProcedureMohd Shafuaaz KassimNo ratings yet

- Flange Weld Build UpDocument3 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- Phils Heavy Engineering PVT LTD.: DATE: 06/04/2020 Sub: Methodology of Fabrication of ColumnDocument5 pagesPhils Heavy Engineering PVT LTD.: DATE: 06/04/2020 Sub: Methodology of Fabrication of ColumnSachin LadNo ratings yet

- API 510 PC 5mar05 Case Study 2 Thickness CalculationsDocument3 pagesAPI 510 PC 5mar05 Case Study 2 Thickness CalculationsSameh AminNo ratings yet

- Plug Process Repair Heat Exchangers PDFDocument6 pagesPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVANo ratings yet

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 pagesInvestigation and Repair of H (1) - E.R Flange LeakriysallNo ratings yet

- Tank Bottom Plate CorrosionDocument5 pagesTank Bottom Plate CorrosionShaalan AI-ZuhairiNo ratings yet

- PWTH RequirementDocument2 pagesPWTH Requirementveeru290683_20976731No ratings yet

- HTR900 Inspection, Maintenance, and TestingDocument27 pagesHTR900 Inspection, Maintenance, and TestingVicente Regulez FernandezNo ratings yet

- 9.Mb21 5f Externally Finned TubesDocument4 pages9.Mb21 5f Externally Finned Tubesyulianus_srNo ratings yet

- Condenser Cladding InfoDocument37 pagesCondenser Cladding Infoabhishe_reenaNo ratings yet

- CPI Steam Heated BoilerDocument4 pagesCPI Steam Heated BoilerGTpianomanNo ratings yet

- Flange Weld Build UpDocument2 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- 01 Saip 38Document14 pages01 Saip 38Arjun RawatNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Tank SettlementDocument6 pagesTank SettlementkorichiNo ratings yet

- Socket WeldDocument7 pagesSocket WeldahmedNo ratings yet

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- API 653 Round-2023Document6 pagesAPI 653 Round-2023Mohammed YoussefNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- Plant Inspections PDFDocument5 pagesPlant Inspections PDFMohamed100% (1)

- I Object: Repair Procedure For Tank BottomDocument6 pagesI Object: Repair Procedure For Tank BottomZouhair BenmabroukNo ratings yet

- CSWIP NotesDocument6 pagesCSWIP Notestulasirao.nammiNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- BGAS Grade1 Exam-1 To 5Document7 pagesBGAS Grade1 Exam-1 To 5Shamim AlamNo ratings yet

- Heater Erection Procedure PDFDocument7 pagesHeater Erection Procedure PDFhasan_676489616No ratings yet

- Hydrotest WaiverDocument4 pagesHydrotest Waiverbidyut100No ratings yet

- Interzone 954 Antifungus ReportDocument10 pagesInterzone 954 Antifungus Reportsteffy182100% (1)

- Drawing B BS 499 Part. 2Document10 pagesDrawing B BS 499 Part. 2محمد اظهرNo ratings yet

- Header Plug Seal Weld ProcedureDocument2 pagesHeader Plug Seal Weld ProcedureMohd Shafuaaz KassimNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Surface Preparation StandardsDocument3 pagesSurface Preparation StandardsSajeesh KrishnanNo ratings yet

- Case Study - Amine Regeneration ColumnDocument2 pagesCase Study - Amine Regeneration ColumnAshfaq Anwer100% (2)

- Heat Exchanger Tube Material SpecificationsDocument2 pagesHeat Exchanger Tube Material SpecificationssdrtfgNo ratings yet

- Piping FBE Spool MethodologyDocument28 pagesPiping FBE Spool MethodologyHariharan MNo ratings yet

- API 510 Petrosync Course PDFDocument301 pagesAPI 510 Petrosync Course PDFAkramKassis100% (1)

- Pipeline Welding InspectionDocument4 pagesPipeline Welding InspectionRizky TrianandaNo ratings yet

- P91 Heating CurveDocument1 pageP91 Heating CurveiplaruffNo ratings yet

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- P3TF49 - S3 BorescopeDocument12 pagesP3TF49 - S3 BorescopeRajesh KannanNo ratings yet

- Dewpoint: Coating & Painting InspectionDocument6 pagesDewpoint: Coating & Painting InspectionMeet Patel100% (1)

- Api653 Question N°06 ResponsesDocument3 pagesApi653 Question N°06 ResponseskorichiNo ratings yet

- Guide To Prepare WPQR According To Asme Section IxDocument5 pagesGuide To Prepare WPQR According To Asme Section IxHoque AnamulNo ratings yet

- Method Statement For Derrick Structure00Document3 pagesMethod Statement For Derrick Structure00khaled saeed100% (1)

- CLSCC LiteratureDocument62 pagesCLSCC LiteratureNakarin PotidokmaiNo ratings yet

- Critical Observations During A Shut Down Audit of A PF BoilerDocument9 pagesCritical Observations During A Shut Down Audit of A PF Boilerparthi20065768No ratings yet

- Welders Qualification, According To Asme Sec IxDocument47 pagesWelders Qualification, According To Asme Sec Ixravi00098No ratings yet

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىNo ratings yet

- How To Create Pid: Yohanneti RWH Process EngineerDocument22 pagesHow To Create Pid: Yohanneti RWH Process Engineeryohanneti rwhNo ratings yet

- An Overview of Pipeline Leak Detection TechnologiesDocument9 pagesAn Overview of Pipeline Leak Detection TechnologiesharmlesdragonNo ratings yet

- Stainless Steel 410Document2 pagesStainless Steel 410Suriyachai NiamsornNo ratings yet

- SAIC-D-2002 Rev 2Document5 pagesSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 4.2.1 Graphitization 4.2.1.1 Description of DamageDocument3 pages4.2.1 Graphitization 4.2.1.1 Description of DamageAjmi HmidaNo ratings yet

- Pig Launcher Fabrication Activity PlanDocument1 pagePig Launcher Fabrication Activity PlanbeqsNo ratings yet

- Repair Procedure F - 23202 NewDocument5 pagesRepair Procedure F - 23202 NewMohd Shafuaaz KassimNo ratings yet

- Repair WeldingDocument33 pagesRepair WeldingAkhilesh Kumar100% (1)

- Method of StatementDocument46 pagesMethod of StatementZack ThiemNo ratings yet

- Case Study - BoilerDocument17 pagesCase Study - BoilerMohd Shafuaaz KassimNo ratings yet

- Excluding Excluding Excluding Excluding ExcludingDocument1 pageExcluding Excluding Excluding Excluding ExcludingMohd Shafuaaz KassimNo ratings yet

- Section No. Section Title Page No.: Table of ContentDocument3 pagesSection No. Section Title Page No.: Table of ContentMohd Shafuaaz KassimNo ratings yet

- SLG-0001-1b Flange Designation Chart PDFDocument2 pagesSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimNo ratings yet

- Header Plug Seal Weld ProcedureDocument3 pagesHeader Plug Seal Weld ProcedureMohd Shafuaaz Kassim100% (1)

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Details of Pressure Vessel: (To Be Completed Where Possible)Document2 pagesDetails of Pressure Vessel: (To Be Completed Where Possible)Mohd Shafuaaz KassimNo ratings yet

- Generic Leak Test Procedure PDFDocument7 pagesGeneric Leak Test Procedure PDFMohd Shafuaaz Kassim100% (3)

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Document4 pagesInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimNo ratings yet

- Vessel DrawingDocument1 pageVessel DrawingMohd Shafuaaz KassimNo ratings yet

- Repair Procedure F - 23202 NewDocument5 pagesRepair Procedure F - 23202 NewMohd Shafuaaz KassimNo ratings yet

- Alfa Laval Brazed Heat ExchangersDocument20 pagesAlfa Laval Brazed Heat ExchangersCelso FernandesNo ratings yet

- CALCULATORDocument6 pagesCALCULATORSrikanth Sikha100% (1)

- Ea 0002Document1 pageEa 0002fereetNo ratings yet

- Safe Bearing Capacity Values of Different SoilsDocument2 pagesSafe Bearing Capacity Values of Different SoilsXiao TanNo ratings yet

- TARGET Electrical BOQDocument60 pagesTARGET Electrical BOQDILSHAD AHEMADNo ratings yet

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel Sheetpravincs_007No ratings yet

- 3-Days Training Course: September 26-28, 2011Document50 pages3-Days Training Course: September 26-28, 2011chibssa alemayehuNo ratings yet

- HexPly M77 EpoxyResin DataSheetDocument4 pagesHexPly M77 EpoxyResin DataSheetpablo.vila2000No ratings yet

- Alfanar Banan Wiring Accessories CatalogDocument6 pagesAlfanar Banan Wiring Accessories CatalogAmmar YasserNo ratings yet

- Building Estimate Manoj PalDocument8 pagesBuilding Estimate Manoj PalMriganka GhoshNo ratings yet

- 50 AEDG Small To Med Office TABLESDocument18 pages50 AEDG Small To Med Office TABLESJulio Fernandez AmodiaNo ratings yet

- Enclosure: Types of Enclosure Systems in High Rise BuildingDocument4 pagesEnclosure: Types of Enclosure Systems in High Rise BuildingSanju Muppala100% (1)

- Finite Element Structural Analysis Movable Crusher Supports: Dan Neff and Conrad Huss, USADocument6 pagesFinite Element Structural Analysis Movable Crusher Supports: Dan Neff and Conrad Huss, USAJakesNo ratings yet

- Insulators - DP: Distancer and Load-Bearing InsulatorsDocument1 pageInsulators - DP: Distancer and Load-Bearing InsulatorsAdel AdelNo ratings yet

- Industrial RevolutionDocument28 pagesIndustrial RevolutionMa. Lourdes Angerica P. AquinoNo ratings yet

- Geoflex Sheet Piles Design ManualDocument19 pagesGeoflex Sheet Piles Design ManualMairon MirandaNo ratings yet

- KeracolorffDocument4 pagesKeracolorffdiv_bamaniaNo ratings yet

- Electron Beam EvaporationDocument27 pagesElectron Beam EvaporationS shek DhavudNo ratings yet

- Inventor EVI EVO Service Manual 18 24000btuDocument101 pagesInventor EVI EVO Service Manual 18 24000btuAnjan ChatterjreNo ratings yet

- Expansive Soil StabiliazationDocument51 pagesExpansive Soil StabiliazationSyed Jibran Ishtiaq0% (1)

- Houston Specialty Meat & Seafood: Replacement Facility ForDocument90 pagesHouston Specialty Meat & Seafood: Replacement Facility ForsaitalNo ratings yet

- The Influence of Pipe Soil InteractionDocument16 pagesThe Influence of Pipe Soil InteractionjsNo ratings yet

- Technical Presentation On Engine ValvesDocument32 pagesTechnical Presentation On Engine ValvesRockey RahulNo ratings yet

- Working Cast and DieDocument47 pagesWorking Cast and DieFira Maminya Maurah0% (1)

- PSP Profile, TPU Piston Cap SealDocument3 pagesPSP Profile, TPU Piston Cap SealSamira 1986No ratings yet

- Pre-Board Exam For Building Utilities 2014 (No Answers)Document14 pagesPre-Board Exam For Building Utilities 2014 (No Answers)Thea Abelardo0% (1)

- A Lady Mae P. Brigoli Maricel Arizo Tyler Proposed 1-Storey Residential BuildingDocument1 pageA Lady Mae P. Brigoli Maricel Arizo Tyler Proposed 1-Storey Residential BuildingLady Mae BrigoliNo ratings yet

- Green Antz Eco Products Technical Information and Product PricelistDocument20 pagesGreen Antz Eco Products Technical Information and Product PricelistMartin SantosNo ratings yet

- 8-Common Wire Splices and JointsDocument24 pages8-Common Wire Splices and JointsApril Castro Abayo RilloNo ratings yet