Professional Documents

Culture Documents

6-15-0004 Rev 2 PDF

Uploaded by

thod3r0 ratings0% found this document useful (0 votes)

5 views6 pagesOriginal Title

6-15-0004 Rev 2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views6 pages6-15-0004 Rev 2 PDF

Uploaded by

thod3rCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

&

3

5

WaRUSE

aga a eqayite st

@ few ume fatacet

STANDARD SPECIFICATION FOR

EXPANDED

TUBE TO TUBESHEET JOINTS

16.07.88] REVISED AND REISSUED AS SPECIFICATION [Hew LHe ey (Toa

04.05.89] ISSUED AS STANDARD SPECIFICATION axa [P| ~ ase vem | as

OnE REVISION * ce Gc)

ENGINEERS INDIA LIMITED STANDARD SPECIFICATION FOR SPECIFICATION REV

y NEW DELHI ee 6-15-0004

TUBE TO TUBESHEET JOINTS Paice

S CONTENTS

z 10 SCOPE

5

Fs 2.0 APPLICABLE CODES

es 3.0 JOINT CONFIGURATION

HE

85 4.0 PROCEDURE TESTING

BS 5.0 CARE OF TUBE

: 60 ‘TUBE HOLES IN TUBESHEET

i 70 ASSEMBLY AND EXPANSION

5 8.0 TESTING

z

z 9.0 INSPECTION

@

5

2

if

A 1 NFOR| SPECIFICATION | REV

ENGINEERS INDIA LINMTED| ener cee es ecace

NEW DELHI eoneey 6-15-0004

TUBE TO TUBESHEET JOINTS pace acl =

1.0

2.0

q

z

3.0

4.0

}

8

3

3

5

i

i

i

:

z

i

wor forthe intended use, Ell 1647

41

E

of ENGINEERS INDIA LIMITED. They a

by @ written consent gi

42

424

3

The drawing, design and details given on thie format

SCOPE

This specification covers the minimum requirements of expanded tube-to-tubesheet joints for

shell & tube heat exchangers and air coolers. It is the fabricator’s responsibility to furnish

sound, leak free joints. For the purpose of this specification, the term “joints” shall be

construed to mean “tube-to-tube sheet joints”.

APPLICABLE CODES

‘The latest edition of the following Codes and Standards shall be complied with:-

a) ASME See. VIII Div. 1 (Code)

b) TEMA for tubular exchangers

©) API 661 for aircoolers.

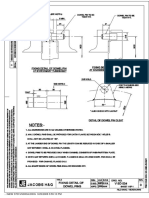

JOINT CONFIGURATION

Joint with two grooves as per 7-15-0006 shall be used unless specified otherwise.

PROCEDURE TESTING

Procedure testing is required to be carried out in any of the following cases:-

a) Authorised Inspector of Purchaser or EIL requires it to be carried out.

b) There are no previously established procedures for Fr values (Factor of Reliability) in

the last five years with the same combination of tube and tubesheet material, outside

diameter (OD) and thickness of tubes, tube hole groove detail and length of expansion

(excluding contact expansion),

©) Code or specification or the equipment drawing requires it to be carried out.

4) The length of expansion in the job is less than existing qualification length of expansion

of same materials, tube size, tube hole groove detail. However, if qualification exists

for length of expansion of 51 mm or more for the same combination of materials, size

of tubes, tube hole grooving details, and the length of expansion for the job is 51 mm

or more, the procedure testing need not be repeated. The length of expansion to be

considered excludes any contact expansion.

e) If previously established procedure of the fabricator is to be used, Authorised Inspector

has the option of asking for a demonstration of the procedure to satisfy himself of its

accuracy or to confirm the suitability of the expanding equipment or control unit. With

time, the equipment used for expansion may change its characteristics and Authorised

Inspector may like to check this by actual procedure tests

Procedure test shall demonstrate % thinning vs machine setting and shear load test as per the

requirements given below.

A sample tubesheet of same material and thickness as required for the job shall be drilled and/or

reamed to achieve the required surface finish as per clause 6.0 and grooved as per 7-15-0006.

Tube hole dimensions shall be as specified in clause 6.0 and as far as possible tube holes shall

be prepared to cover the complete range of tolerance allowed. Tubesheet thickness used for

procedural testing shall be as per item drawing or specification except that it need not exceed

Gg) ENGINEERS INDIA LIMITED

} NEW DELHI 6-15-0004

STANDARD SPECIFICATION FOR| SPECIFICATION REV

EXPANDED

TUBE TO TUBESHEET JOINTS

Page 3 of 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Dhi DCW Group Co.,Ltd.: Erection Drawing ListDocument3 pagesDhi DCW Group Co.,Ltd.: Erection Drawing Listthod3rNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Draw SprocketDocument15 pagesDraw Sprocketfernandop_77No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- (KG-M) (KG-M) : SurveillanceDocument1 page(KG-M) (KG-M) : Surveillancethod3rNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Kef 5 PDFDocument21 pagesKef 5 PDFthod3rNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vendor revisions must be clearly markedDocument1 pageVendor revisions must be clearly markedthod3rNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Lug Support 2 PDFDocument1 pageLug Support 2 PDFthod3rNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Maintenance Drawing List-12Document2 pagesMaintenance Drawing List-12thod3rNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Kef 7 PDFDocument11 pagesKef 7 PDFthod3rNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Dowel Pin PDFDocument1 pageDowel Pin PDFthod3rNo ratings yet

- GADocument35 pagesGAthod3rNo ratings yet

- GADocument35 pagesGAthod3rNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- (KG-M) (KG-M) : SurveillanceDocument1 page(KG-M) (KG-M) : Surveillancethod3rNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Is Stringent: If Any Part Is To Be Deleted, Retain The Part No. and Write 'Deleted' in Front of ItDocument1 pageIs Stringent: If Any Part Is To Be Deleted, Retain The Part No. and Write 'Deleted' in Front of Itthod3rNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Υδραυλικές αντλίες - κινητήρεςDocument14 pagesΥδραυλικές αντλίες - κινητήρεςthod3rNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Χάλυβες Υψηλής Αντοχής PDFDocument18 pagesΧάλυβες Υψηλής Αντοχής PDFthod3rNo ratings yet

- Σημειώσεις Ειδικά Θέματα Μεταφοράς Μάζας Και ΘερμότηταςDocument39 pagesΣημειώσεις Ειδικά Θέματα Μεταφοράς Μάζας Και Θερμότηταςthod3rNo ratings yet

- Υδραυλικές αντλίες - κινητήρεςDocument11 pagesΥδραυλικές αντλίες - κινητήρεςthod3rNo ratings yet

- ΜΕΛΕΤΗ ΕΓΚΑΤΑΣΤΑΣΗΣ ΦΥΣΙΚΟΥ ΑΕΡΙΟΥDocument253 pagesΜΕΛΕΤΗ ΕΓΚΑΤΑΣΤΑΣΗΣ ΦΥΣΙΚΟΥ ΑΕΡΙΟΥthod3r100% (1)

- ΑΣΜΟΠΑΡΑΓΩΓΟΙ ΑΣΜΟΣΡΟΒΙΛΟΙ θαη ΔΝΔΡΓΔΙΑΚΑ ΤΣΗΜΑΣΑDocument87 pagesΑΣΜΟΠΑΡΑΓΩΓΟΙ ΑΣΜΟΣΡΟΒΙΛΟΙ θαη ΔΝΔΡΓΔΙΑΚΑ ΤΣΗΜΑΣΑthod3rNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WEG Weg Technical Poster Ustechposter Brochure EnglishDocument1 pageWEG Weg Technical Poster Ustechposter Brochure Englishingvic1No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- ΣημειώσειςDocument101 pagesΣημειώσειςthod3rNo ratings yet

- Τεχνικοσ Κaνονισμοσ Κατανομησ - απαν - ν 25-04-07Document8 pagesΤεχνικοσ Κaνονισμοσ Κατανομησ - απαν - ν 25-04-07thod3rNo ratings yet

- ΒΙΟΜΗΧΑΝΙΚΑ ΣΥΣΤΗΜΑΤΑ ΕΛΕΓΧΟΥDocument139 pagesΒΙΟΜΗΧΑΝΙΚΑ ΣΥΣΤΗΜΑΤΑ ΕΛΕΓΧΟΥthod3rNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ανύψωση 112-2Document3 pagesανύψωση 112-2thod3rNo ratings yet

- Inside Diameter ID MM Inside Diameter Straight Face SF MM Straight Face Crown Radius CR 0 MM Crown Radius Knuckle Radius KR 0 MM Knuckle Radius Height IH 0 MM HeightDocument7 pagesInside Diameter ID MM Inside Diameter Straight Face SF MM Straight Face Crown Radius CR 0 MM Crown Radius Knuckle Radius KR 0 MM Knuckle Radius Height IH 0 MM Heightthod3rNo ratings yet

- Frame Size MotorsDocument1 pageFrame Size Motorsthod3rNo ratings yet

- ΠΡΑΞΗ ΔΙΟΙΚΗΤΙΚΟΥ ΠΡΟΣΔΙΟΡΙΣΜΟΥ ΦΟΡΟΥDocument1 pageΠΡΑΞΗ ΔΙΟΙΚΗΤΙΚΟΥ ΠΡΟΣΔΙΟΡΙΣΜΟΥ ΦΟΡΟΥthod3rNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Totee-Nomos 25-04-07Document18 pagesTotee-Nomos 25-04-07Kostas SotiriadisNo ratings yet

- Ανοξείδωτοι ΧάλυβεςDocument34 pagesΑνοξείδωτοι Χάλυβεςthod3rNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)