Professional Documents

Culture Documents

Pfi - Es 3 2000 PDF

Pfi - Es 3 2000 PDF

Uploaded by

Денис ПекшуевOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pfi - Es 3 2000 PDF

Pfi - Es 3 2000 PDF

Uploaded by

Денис ПекшуевCopyright:

Available Formats

~

STD.PFI ES-3-ENGL 2000 7 L b 4 5 4 4 00005LL bT8 D

PFI Standard ES-3

(Reaffimied September 2000)

FABRICATING TOLERANCES

Prepared by

Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no

agreement to adhere to any PFI Standard and their

use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedirnted io Teclinicnl Adiwnceinenis nnd Stondnrdizntion in

rlie Pipe Fnbricniioii lridiisii.).

Since i913

USA CANADA

PMB 323 655. 32"" ove. sirite 201

61 I P e n n s j h m i a Averiire SE Lnrkine. Qirebec

Woshinglon. DC 20003 H8T3G6

WEB SITE

org

/zttp://iMi?ii.pfi-insfi/i~te.

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

PFI Standard ES-3

(Reaffirmed September 2000)

FABRICATING TOLERANCES

METRIC CONVERSIONS

The conversion of quantities between systems of units involves a determination of the number of

significant digits to be retained. All conversions depend upon the intended precision of the original

quantity and are rounded to the appropriate accuracy.

Pipe sizes together with applicable wall thickness are not shown with metric equivalents.

The SI (metric) values where included with the customary U.S. values in this Standard are the

rounded equivalents of the U.S. values and are for reference only.

Metric units were derived utilizing the following conversion factor:

Conversion Factor

inches to 25.4

millimeter

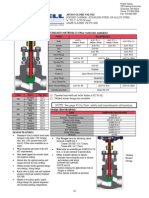

1. Scope excess of those specified in paragraphs 2.2

and 2.3 may occur.

1.1 This standard covers general pipe shop

fabricating tolerances for prefabricated 3. Angularity and Rotation Tolerances

piping assemblies.

3.1 Angularity tolerance across the face of

2. Linear Tolerances flanges, weld end preparation and on

rotation of flanges are as stated on Fig. 1.

2.1 The tolerances on linear dimensions

(intermediate or overall) apply to the face to 4. Closer Tolerances

face, face to end, and end to end

measurements of fabricated straight pipe and 4.1 When closer tolerances than those given in

headers; center'to end or center to face of paragraphs 2.2, 2.3 and 2.4 are absolutely

nozzles or other attachments; or center to necessary, they shall be subject to agreement

face of bends; as illustrated on Fig. 1. These between the Purchaser and Fabricator.

tolerances are not accumulative.

2.2 Linear tolerances on "A" are k 1/8" (3.0

mm) for sizes 10" and under, k 3/16" (5.0

mm) for sizes 12" through 24" and I 1/4"

(6.0 mm) for sizes over 24" through 36".

2.3 Linear tolerances on "A" for sizes over 36"

are subject to tolerances o f f 1/4" (6.0 mm),

increasing by plus or minus 1/16" (2.0 mm)

for each 12" in diameter over 36".

2.4 Due to the cumulative effects of tolerances

on fittings or flanges, when joined without

intervening pipe segments, deviations in

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

~ ~

S T D - P F I ES-1-ENGL 2000 7 1 b 4 5 4 4 0000513 470

4

"A" b

FOR BENDINGTOLERANCE, MINIMUM

RADIUS AND MINIMUM TANGENT SEE

PFI STANDARD ES-24

TOLERANCES ON DIMENSIONSWHICH Do

NOT INCLUDE PIPE SEGMENTS ARE TO

BE BASED ON ANSI SPECIFICATIONS FOR

FITTINGS OR FLANGES INVOLVED

(SEE PARAGRAPH 2.4)

ROTATION OF FLANGES

FROM THE INDICATED

POSITION MEASUREDAS

SHOWN, 1/16' (2.0 mrn) MAX

(3.0mm)

IL ALIGNMENT OF FACINGS OR

SECTION X-X

ENDS SHALL NOT DEVIATE

FROM THE INDICATED

POSITION MEASUREDACROSS

ANY DIAMETER MORE THAN

3/64" PER FOOT (1.0 mm PER

25.0 cm) OR 1/32" (1.O mm)

WHICHEVER IS GREATER

APPLICATION OF PIPE FABRICATION TOLERANCES

3

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

= 7Lb4544

~

S T D - P F I ES-3-ENGL 2000 OOOCI5L'i 307

CHARTER MEMBERS

ACCORD PIPE FABRICATORS, INC. Jamaica, New York

AIR CONDITIONING COMPANY, INC. Glendale, California

FLO-RITE, INC. Riviera Beach, Florida

GEM INDUSTRIAL, INC. Wal bridge, Ohio

HPI CONSTRUCTION CO., INC. Huntington, West Virginia

HUXTABLE & ASSOCIATES, INC. Lawrence, Kansas

IDEAL WELDERS, LTD. Delta, British Columbia (Canada)

INDUSTRIAL POWER SYSTEMS, INC. Toledo, Ohio

IVOR J. LEE, INC. Masury, Ohio

JOHN E. GREEN COMPANY Highland Park, Michigan

J. F. AHERN CO. Fond du Lac, Wisconsin

J. H. KELLY LLC Longview, Washington

J. S. MC KINNEY, INC. Freeport, Texas

KINETIC SYSTEMS, INC. Santa Clara, California

M & M WELDING AND FABRICATORS, INC. Gaithersburg, Maryland

MC ABEE CONSTRUCTION, INC. Tuscaloosa, Alabama

MC CARL'S, INC. Beaver Falls, Pennsylvania

MECHANICAL INCORPORATED Freeport, Illinois

MID STATES PIPE FABRICATING, INC. EI Dorado, Arkansas

MURPHY COMPANY St. Louis, Missouri

NARDE1 FABRICATORS, LTD. Calgary, Alberta (Canada)

NEWMECH COMPANIES, INC. St. Paul, Minnesota

PHILLIPS, GETSCHOW COMPANY Oconto Falls, Wisconsin

PIPING SYSTEMS, INC. New London, Wisconsin

S. A. COMUNALE COMPANY, INC. Barberton, Ohio

S&D I OSTERFELD MECHANICAL CONTRACTORS Dayton, Ohio

SCOTT CO. OF CALIFORNIA San Leandro, California

SPECIALTY PIPING CORPORATION Davisville, West Virginia

TEAM INDUSTRIES, INC. Kaukauna, Wisconsin

W. J. O'NEIL COMPANY Livon ia, Michigan

A current index of the latest revised ES Standards, Technical Bulletins and Safety Training Guideline is available from

the Pipe Fabrication Institute.

PFI Safety Training Guideline, Standards and Technical Bulletins are published to serve proven needs of the pipe

fabricating industry at the design level and in actual shop operations. Hence, such needs are continually considered and

reviewed by the Engineering Committee of the Pipe Fabrication Institute to provide recommended procedures, which

have been demonstrated by collective experiences to fiilfill requirements in a manner for Code compliance. However,

as the PFI Standards are for minimum requirements the designer or fabricator always has the option of specifying

supplementary conditions in the form of requirements beyond the scope of the PFI publications.

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

You might also like

- Pfi Es 3Document2 pagesPfi Es 3EstefaníaNo ratings yet

- ASTM A672 Welded Pipe Standard PDFDocument7 pagesASTM A672 Welded Pipe Standard PDFumeshNo ratings yet

- PFI ES-03 Fabricating TolerancesDocument4 pagesPFI ES-03 Fabricating TolerancesAL DOMANo ratings yet

- LRFD Composite Beam DesignDocument261 pagesLRFD Composite Beam DesignJuan Carlos FloresNo ratings yet

- Regenerative Braking System ProjectDocument61 pagesRegenerative Braking System ProjectHello world100% (4)

- TAYLOR FORGE - Catalog 722 PDFDocument79 pagesTAYLOR FORGE - Catalog 722 PDFMiguel Martinez Guerrero0% (1)

- Asme B16.21 - 2016Document29 pagesAsme B16.21 - 2016AMITNo ratings yet

- Standards ListDocument14 pagesStandards Listsunnyjack100% (1)

- b16 47Document65 pagesb16 47Gustavo FamaNo ratings yet

- Contributions of Early River Valley CivilizationDocument4 pagesContributions of Early River Valley Civilizationapi-327713634No ratings yet

- PFI-ES-07 (2000) NozzMinlengthspacing PDFDocument4 pagesPFI-ES-07 (2000) NozzMinlengthspacing PDFRamesh Kumar Ramisetti100% (2)

- PFI ES-7 Min Spacing For WeldingDocument6 pagesPFI ES-7 Min Spacing For WeldingNguyen Anh TungNo ratings yet

- PFI ES-2-2000 Method of Dimension Ing Piping AssembliesDocument4 pagesPFI ES-2-2000 Method of Dimension Ing Piping Assembliessekharsappa2100% (3)

- Asme B16.21 (2005) PDFDocument22 pagesAsme B16.21 (2005) PDFLevi Porter100% (1)

- Astm A350Document8 pagesAstm A350nse mcx100% (1)

- Pip Vespmi01-2019Document11 pagesPip Vespmi01-2019d-fbuser-93320248100% (2)

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsNo ratings yet

- BS 7354Document63 pagesBS 7354Abu Monsur Ali67% (3)

- Astm A671 2020Document7 pagesAstm A671 2020امينNo ratings yet

- ES-03 - PFI - Fabricationg TolerancesDocument5 pagesES-03 - PFI - Fabricationg TolerancesGiám đốc Tín MinhNo ratings yet

- ASME PCC-2-2015 Repair of PressureDocument1 pageASME PCC-2-2015 Repair of PressureJohn17% (6)

- Specification For Carbon Steel Forgings, For Piping ApplicationsDocument8 pagesSpecification For Carbon Steel Forgings, For Piping Applicationsedisson_barrera100% (1)

- Systems Hydraulics - Massey FergussonDocument15 pagesSystems Hydraulics - Massey FergussonJPJFNo ratings yet

- PFI ES 27 (2000) VisualExaminationDocument4 pagesPFI ES 27 (2000) VisualExaminationWilson AnteNo ratings yet

- Pfi Es-5 2002Document2 pagesPfi Es-5 2002bayu212100% (1)

- Case 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Document1 pageCase 2864 9Cr - 1Mo-V Material Section I: Table 1 Table 2Alevj Db100% (1)

- Eia StandardDocument12 pagesEia Standardthechoz1No ratings yet

- Din 30670 2012 PDFDocument37 pagesDin 30670 2012 PDFOMAR FREITESNo ratings yet

- Asme B16.24 PDFDocument25 pagesAsme B16.24 PDFRuben Dario Mamani ArellanoNo ratings yet

- 000-GC-P-009 R.3 Piping Installation PDFDocument35 pages000-GC-P-009 R.3 Piping Installation PDFJessica Torres100% (1)

- Pipe FabricationDocument42 pagesPipe FabricationJanani M Janani67% (6)

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocument6 pagesASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNo ratings yet

- Asme B16.11 2005Document30 pagesAsme B16.11 2005Starla Hill100% (4)

- ASME B 16.21 Non Metallic Gaskets For FlangesDocument28 pagesASME B 16.21 Non Metallic Gaskets For FlangesAlejandro VegaNo ratings yet

- Litany by Billy CollinsDocument10 pagesLitany by Billy Collinslucas100% (1)

- Partitive ProportionsDocument4 pagesPartitive ProportionsJudith Fernandez-Olay67% (3)

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingalberto rodriguezNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Pfi-Es-16 (2001)Document7 pagesPfi-Es-16 (2001)jothishNo ratings yet

- CSEC Mathematics June 1998 P2Document12 pagesCSEC Mathematics June 1998 P2zarzsultan12100% (1)

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDocument33 pagesASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesNo ratings yet

- Astm A733 Niples PDFDocument4 pagesAstm A733 Niples PDFyesNo ratings yet

- Asme B36.10 2004Document26 pagesAsme B36.10 2004rogersampaiocosta60% (5)

- Bsi BS 5572Document84 pagesBsi BS 5572Oli Hoenes100% (3)

- (0209) 031801Document12 pages(0209) 031801Sixto Gerardo Oña AnaguanoNo ratings yet

- ASME VIII 2023 ChangesDocument4 pagesASME VIII 2023 ChangesQuekch100% (1)

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 pagesClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićNo ratings yet

- PFI-ES-05 (Cleaning 2006) PDFDocument2 pagesPFI-ES-05 (Cleaning 2006) PDFRamesh Kumar RamisettiNo ratings yet

- Flexible PipeDocument7 pagesFlexible Pipenaren57No ratings yet

- Stub Ends Ansi b16.9Document1 pageStub Ends Ansi b16.9hisaj4uNo ratings yet

- Api 602Document4 pagesApi 602kreyson77750% (2)

- Asme B16.11Document27 pagesAsme B16.11hanan147100% (1)

- PROJECT STANDARDS and SPECIFICATIONS Piping Frabrication and Commissioning Rev01Document10 pagesPROJECT STANDARDS and SPECIFICATIONS Piping Frabrication and Commissioning Rev01GabrielPantilicaNo ratings yet

- PFI ES-3 Fabricating TolerancesDocument2 pagesPFI ES-3 Fabricating TolerancesaplicacionesNo ratings yet

- Asme B 16.34 InterpretacionDocument21 pagesAsme B 16.34 InterpretacionJuan Manuel Montoya G.No ratings yet

- Summative Exam Diss 2nd Quarter 333333Document3 pagesSummative Exam Diss 2nd Quarter 333333Christine Castro100% (5)

- BS 2633-1987 PDFDocument58 pagesBS 2633-1987 PDFAndres Afanador MuñozNo ratings yet

- MSS SP 95Document16 pagesMSS SP 95JUAN DAVID GOMEZ PATIÑONo ratings yet

- TAGAKAOLODocument3 pagesTAGAKAOLOJho-marie Vidal100% (2)

- Pfi-Es-22 (1999)Document4 pagesPfi-Es-22 (1999)jothish100% (5)

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangel kishoreNo ratings yet

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- Hydrualic Tube Expansion Vs Metallic Tube ExpansionDocument3 pagesHydrualic Tube Expansion Vs Metallic Tube ExpansionNath BoyapatiNo ratings yet

- The Difference Between ASTM A105 Flange and ASTM A105N FlangeDocument1 pageThe Difference Between ASTM A105 Flange and ASTM A105N FlangeMARIO HUAMANNo ratings yet

- Asme B31.3 2012Document2 pagesAsme B31.3 2012mortezaheidarianNo ratings yet

- Es2 PDFDocument4 pagesEs2 PDFmasimaha1379No ratings yet

- Pfi Es-3 (2000)Document4 pagesPfi Es-3 (2000)Esteban Calderón NavarroNo ratings yet

- Is 784 2001Document39 pagesIs 784 2001Parul MathurNo ratings yet

- Tech. Spec - Tubular PoleDocument8 pagesTech. Spec - Tubular PoleVarun SharmaNo ratings yet

- 45.1.04 AOAC Official Method 970.64 Carotenes and Xanthophylls in Dried Plant Materials and Mixed FeedsDocument2 pages45.1.04 AOAC Official Method 970.64 Carotenes and Xanthophylls in Dried Plant Materials and Mixed Feedsphan lyNo ratings yet

- Health and Economic Costs of Physical InactivityDocument5 pagesHealth and Economic Costs of Physical InactivityLeclerc Maturana Philippe AndreNo ratings yet

- IRC-114-2013 Use of Silica Fume in Rigid PavementDocument14 pagesIRC-114-2013 Use of Silica Fume in Rigid PavementZakee MohamedNo ratings yet

- Assessment of Explosive Strength-Endurance in Volleyball Players Through Vertical Jumping TestDocument4 pagesAssessment of Explosive Strength-Endurance in Volleyball Players Through Vertical Jumping TestDr. Krishna N. SharmaNo ratings yet

- Biology Samp WDocument41 pagesBiology Samp WMark DeaconNo ratings yet

- On The Necessity of Sadness & Other Poems: Mikael de Lara CoDocument6 pagesOn The Necessity of Sadness & Other Poems: Mikael de Lara CoLara AntonioNo ratings yet

- Seminar Report On MemristorDocument31 pagesSeminar Report On Memristorjasil1414No ratings yet

- Limit State Definitions of The Connection Design Calculations SDS2 V7331Document110 pagesLimit State Definitions of The Connection Design Calculations SDS2 V7331fzhouNo ratings yet

- The The: Evolution of Warren, or Triangular, TrussDocument1 pageThe The: Evolution of Warren, or Triangular, TrussMr. DreamNo ratings yet

- Books For GeographyDocument3 pagesBooks For Geographyapi-371002940% (5)

- SCADADocument12 pagesSCADAStephen Rey CaldeaNo ratings yet

- Isyarat VisualDocument7 pagesIsyarat VisualGede SegaraNo ratings yet

- Haftarah Tzav: Yirmeyahu (Jeremiah) : Chapter 7:21-34Document3 pagesHaftarah Tzav: Yirmeyahu (Jeremiah) : Chapter 7:21-34David StalljannNo ratings yet

- Electric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistDocument2 pagesElectric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistsebastianNo ratings yet

- Krasta Manual English PDFDocument243 pagesKrasta Manual English PDFvitezixNo ratings yet

- Internet of Things in The Context of Industry 4.0: An OverviewDocument16 pagesInternet of Things in The Context of Industry 4.0: An OverviewNur Dini LeeNo ratings yet

- Epb265 PDFDocument17 pagesEpb265 PDFMark WoodsNo ratings yet

- DP126LA: Doosan Infracore Generator EngineDocument4 pagesDP126LA: Doosan Infracore Generator EnginehirararaNo ratings yet

- Tender No 02 CTC Tea Machinery Kipchabo Tea Factory 2017Document37 pagesTender No 02 CTC Tea Machinery Kipchabo Tea Factory 2017frank kipkoechNo ratings yet

- ADC Guide Part1Document5 pagesADC Guide Part1thangaraj_ic100% (1)

- L03B-Dimensional Modeling IIDocument36 pagesL03B-Dimensional Modeling IIFrans SitohangNo ratings yet