0% found this document useful (0 votes)

695 views4 pagesBOQ for 380kV D/C OHTL Project

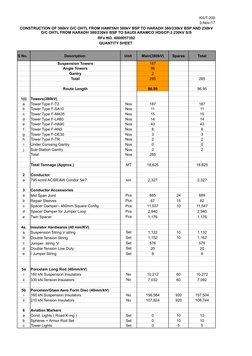

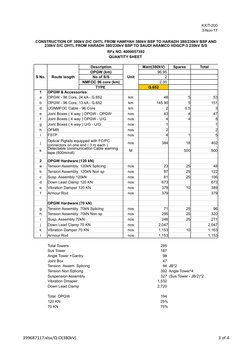

The document is a quantity sheet for the construction of a 380kV overhead transmission line from Hawiyah to Haradh and a 230kV line from Haradh to a Saudi Aramco facility. It lists the materials needed including 285 towers, over 18,000 metric tons of tower materials, over 96km of conductor, insulators, hardware, aviation markers, spares, maintenance equipment, and 96.95km of fiber optic ground wire (OPGW) and associated accessories. The quantity sheet provides the estimated amounts of each item needed for the main transmission lines and additional spares.

Uploaded by

Shashi RanjanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

695 views4 pagesBOQ for 380kV D/C OHTL Project

The document is a quantity sheet for the construction of a 380kV overhead transmission line from Hawiyah to Haradh and a 230kV line from Haradh to a Saudi Aramco facility. It lists the materials needed including 285 towers, over 18,000 metric tons of tower materials, over 96km of conductor, insulators, hardware, aviation markers, spares, maintenance equipment, and 96.95km of fiber optic ground wire (OPGW) and associated accessories. The quantity sheet provides the estimated amounts of each item needed for the main transmission lines and additional spares.

Uploaded by

Shashi RanjanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Suspension Towers

- Spares

- Conductors and OPGW

- Total Towers and Distribution