Professional Documents

Culture Documents

(ME 183) Heat Pump Trainer - Additional Parts and Functions

Uploaded by

Rogie M Bernabe0 ratings0% found this document useful (0 votes)

10 views1 pageUP

Original Title

[ME 183] Heat Pump Trainer - Additional Parts and Functions

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 page(ME 183) Heat Pump Trainer - Additional Parts and Functions

Uploaded by

Rogie M BernabeUP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

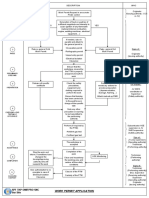

ME 183 WFXY

Sir Paul Rodgers

Lab HW 1

Heat Pump Trainer (Hampden H-RST-8)

Additional parts and functions

1. Liquid Receiver

It is between the condenser and liquid control device. It separates any leftover vapor in the receiver.

The outlet is near the bottom; thus, the only liquid flows out of the receiver. “This feature allows

the quantity of refrigerant to be less critical. The liquid receiver serves as a storage tank for liquid

refrigerant [1].”

2. Suction Accumulator

The compressor can be damaged by liquid refrigerant. Therefore, a suction accumulator is placed

just before the compressor to trap any liquid that may come from the evaporator.

3. High/Low Pressure Sensor

• The LOW SIDE light will come on if the compressor shuts off due to low pressure.

• The HIGH SIDE light will come on if the compressor shuts off due to high pressure.

4. Sight Glass and Filter/Drier

For the system to function properly, moisture should be kept to a minimum. The sight glass is a

handy tool to quickly check whether moisture has entered the system.

5. Valves

a. Reversing Valve

“ In recent years, usage of the ‘heat pump’ principle to enable an air conditioning unit to supply

both cooling and heating has become increasingly popular [1].” This basically reverses the flow,

thus reversing the function of the evaporator and condenser. The indoor coil will be used for

cooling, while the condenser will be used for heating.

b. Thermostatic Expansion Valves (TEV-1 and TEV-2)

“The most commonly used device for controlling the flow of liquid refrigerant into the

evaporator is the thermostatic expansion valve. An orifice in the valve meters the flow into the

evaporator, the rate of flow is modulated by a needle type plunger and seat, which varies the

orifice opening [1].”

c. Hand Expansion Valves (HV-1 and HV-2)

“The hand expansion valve is the least precise liquid control device equipped on the H-SRT-6. A

needle valve controls the rate of refrigerant flow into the evaporator and is adjusted manually.

The degree adjustment is dependent on system load, and capacity of the evaporator and the

type of refrigerant. [1]”

Works Cited

[1] M. J. Moran and H. N. Shapiro, Fundamentals of Engineering Thermodynamics, 5th ed.,

West Sussex: John Wiley & Sons Ltd, 2006.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Chen Noda Wahab Akaishi Sano Takase Fekete 64Document20 pagesChen Noda Wahab Akaishi Sano Takase Fekete 64Rogie M BernabeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Tie-33 Design Strength of Optical Glass and Zerodur UsDocument10 pagesTie-33 Design Strength of Optical Glass and Zerodur UsRogie M BernabeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- OF COM Merce U.S. Departm TNT: Fracture Mechanics Study of Skylab I - Ïindoi (SDocument48 pagesOF COM Merce U.S. Departm TNT: Fracture Mechanics Study of Skylab I - Ïindoi (SRogie M BernabeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Implementation Ofiso 10110 Optics Drawing Standards For The National Ignition FacilityDocument7 pagesImplementation Ofiso 10110 Optics Drawing Standards For The National Ignition FacilityRogie M BernabeNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- .Sïß85 'F +-KL Úrãtr R - : Let+:ttDocument9 pages.Sïß85 'F +-KL Úrãtr R - : Let+:ttRogie M BernabeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Product Design and Manufacturing - R.C. Gupta, A.K. Chitale (PHI, 2011) PDFDocument539 pagesProduct Design and Manufacturing - R.C. Gupta, A.K. Chitale (PHI, 2011) PDFRogie M BernabeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Product Design and Manufacturing - R.C. Gupta, A.K. Chitale (PHI, 2011) PDFDocument539 pagesProduct Design and Manufacturing - R.C. Gupta, A.K. Chitale (PHI, 2011) PDFRogie M BernabeNo ratings yet

- Design Strength of Optical GlassDocument12 pagesDesign Strength of Optical GlassRogie M BernabeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- LE 1 - Cheat SheetDocument1 pageLE 1 - Cheat SheetRogie M BernabeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Final List of Student With Deficiency 1-18-19Document7 pagesFinal List of Student With Deficiency 1-18-19Rogie M Bernabe0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Science Education Brochure 2017 PDFDocument9 pagesScience Education Brochure 2017 PDFRogie M BernabeNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ME 188 Power Plant Engineering: Guide For Design 1 (D1)Document1 pageME 188 Power Plant Engineering: Guide For Design 1 (D1)Rogie M BernabeNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- T Series TorqueDocument8 pagesT Series TorqueBrian OctavianusNo ratings yet

- InventionDocument3 pagesInventionSekolah Kebangsaan Lubuk SirehNo ratings yet

- Rec Erc 78 08Document22 pagesRec Erc 78 08Jerry PellerNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Why 50 OhmDocument2 pagesWhy 50 Ohmwrite2arshad_mNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Van Der WallsDocument24 pagesVan Der WallsAnonymous oVRvsdWzfBNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Document8 pagesDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainNo ratings yet

- Six SigmaDocument92 pagesSix SigmaJan Karina Lapeña PadlaNo ratings yet

- Encryption - LaravelDocument3 pagesEncryption - LaravelOissor RodriguezNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CableTies Technical Data PDFDocument1 pageCableTies Technical Data PDFmohammed moussNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- IAMI Revision Questions Motor and GeneralDocument8 pagesIAMI Revision Questions Motor and GeneralStewart LongNo ratings yet

- Cameron BoyingtonDocument7 pagesCameron BoyingtonCameron BoyingtonNo ratings yet

- Astm A 159 - 83 R01Document5 pagesAstm A 159 - 83 R01Er WidodoNo ratings yet

- Practice ZAcademy Excel NewiesModeDocument9 pagesPractice ZAcademy Excel NewiesModedadang hermawanNo ratings yet

- Cold ChainDocument15 pagesCold ChainLok KannNo ratings yet

- Motor Vehicle Traffic Fatalities & Fatality Rate: 1899 - 2003Document2 pagesMotor Vehicle Traffic Fatalities & Fatality Rate: 1899 - 2003Yoni ReinónNo ratings yet

- Columbia and Challenger: Organizational Failure at NASA: Article in PressDocument9 pagesColumbia and Challenger: Organizational Failure at NASA: Article in PressTuấn Kiệt NguyễnNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Nr-311104 Biological Control SystemsDocument4 pagesNr-311104 Biological Control SystemsSrinivasa Rao GNo ratings yet

- Tla ch03Document2 pagesTla ch03api-334420312No ratings yet

- PTW Logic DiagramDocument1 pagePTW Logic DiagramAdrianNo ratings yet

- 4 Bit Manchester AdderDocument14 pages4 Bit Manchester AdderHacking_Deface0% (2)

- 5528 PDFDocument33 pages5528 PDFPham The TuNo ratings yet

- Stadium ACL Test PlanDocument10 pagesStadium ACL Test Planonlycisco.tkNo ratings yet

- Labeling SOPDocument22 pagesLabeling SOPEduard Moncunill MontesNo ratings yet

- Lecture 03Document42 pagesLecture 03Laís Medeiros100% (1)

- 32 Bahrain Bridge 0914RBDocument3 pages32 Bahrain Bridge 0914RBAshutoshAparaj100% (1)

- 3102354-EN R015 VS Series Compatibility ListDocument20 pages3102354-EN R015 VS Series Compatibility ListFrancisco CanoNo ratings yet

- Desain Ruangan CT-ScanDocument3 pagesDesain Ruangan CT-ScannewmanonmarsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaDocument7 pagesThe Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaLegendaryNNo ratings yet

- As 4941-2001 Oil of Backhousia Citriodora Citral Type (Lemon Myrtle Oil)Document6 pagesAs 4941-2001 Oil of Backhousia Citriodora Citral Type (Lemon Myrtle Oil)SAI Global - APACNo ratings yet

- NovoQuad Brochure - ND-SV009 - 20220520Document3 pagesNovoQuad Brochure - ND-SV009 - 20220520Mohammad AkifNo ratings yet