Professional Documents

Culture Documents

Safety Audit Check List

Safety Audit Check List

Uploaded by

Santhosh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Audit Check List

Safety Audit Check List

Uploaded by

Santhosh KumarCopyright:

Available Formats

Division of Administration and Finance

Planning + Design + Construction

PO Box 210186

Cincinnati, Ohio 45221-0186

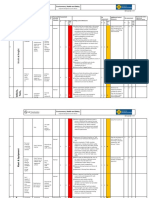

CONTRACTORS MONTHLY SAFETY AUDIT CHECKLIST

Project Number: Project Name:

Phase:

Date Completed:

Contractor:

Safety Representative:

Total Employees:

Total Contractor employees:

Total subcontractor employees:

1.0 Current Status of Contract (Check appropriate activities)

Site clearing & grubbing Overhead mechanical/electrical

Excavation Interior finishes

Foundations Demolition

Structural frame Remodeling

Exterior enclosure Close out

Other:

2.0 Office Procedures

Yes No N/A Description

1. Safety & health poster posted.

2. Emergency telephone numbers posted.

3. First aid kit & supplies on job.

4. Copy of OSHA safety standard in the office.

5. Toolbox meeting reports issued, forwarded to Project Superintendent & filed.

6. Safety notices issued, forwarded to appropriate personnel and filed.

7. Received visit from OSHA this month.

8. Emergency stretcher located on job – near hoist or elevator.

9. Any first aid injuries reported were forwarded to Site Management.

10. OSHA Form 200 posted.

Contractors Monthly Safety Audit Checklist Page 1 of 8 Rev 6/2002

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 2 of 8 Rev 6/2002

3.0 Site Security & Warning Signs

Yes No N/A Description

1. Site secured with fence and gates. Gates closed and locked.

Corrective action:

2. Warning signs posted for general public.

Corrective action:

3. Overhead protection installed where any overhead work is taking place.

Corrective action:

4. Any exterior storage of flammable liquids:

a) At least 20 feet from all buildings

b) No smoking signs posted (signs should read Danger- Flammable)

c) Containers properly labeled

d) Spill containment in place

Corrective action:

5. All excavation are appropriately laid out and secured.

Corrective action:

6. All mobile equipment is locked when not in use.

Corrective action:

7. Occupied areas of the project are barricaded and warning signs posted.

Corrective action:

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 3 of 8 Rev 6/2002

4.0 Safety Responsibilities

Yes No N/A Description

1. Perimeter guard rails are installed properly for protection of all employees.

Corrective action:

2. All floor openings protected by guardrails or are covered, secured and marked.

Corrective action:

3. Temporary ladders properly installed to all levels, and secured at the top and the bottom.

Corrective action:

4. Operating rules posted in operator’s station (or equivalent), and all equipment safety

inspected at the start of the day.

Corrective action:

5. Adequate overhead protection for individuals working near hoisting areas.

Corrective action:

6. All hoist entrances guarded by barricades and/or conventional fall protection.

Corrective action:

7. Employees are wearing hard hats and all required personal protection equipment.

Corrective action:

8. Fire protection and emergency evacuation procedures are established.

Corrective action:

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 4 of 8 Rev 6/2002

4.0 Safety Responsibilities (Continued)

Yes No N/A Description

9. Fire extinguishers installed throughout the project and have been adequately inspected.

Corrective action:

10. Weekly toolbox meetings are taking place with field employees of

contractors/subcontractors.

Corrective action:

11. Adequate toilet facilities are installed and are kept in a sanitary condition.

Corrective action:

12. Trash containers and regular disposal is provided.

Corrective action:

13. An adequate supply of portable water is available and clearly marked. Paper cups and

trash containers are also provided.

Corrective action:

14. Traffic control measures are used to protect crossing traffic and pedestrians.

Corrective action:

15. New employees processed through project orientation and have been instructed on

specific safety procedures.

Corrective action:

16. Excavations and trenches are sloped properly or braced.

Corrective action:

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 5 of 8 Rev 6/2002

4.0 Safety Responsibilities (Continued)

Yes No N/A Description

17. Perimeter guardrail systems installed at all floor edges and openings.

Corrective action:

18. Housekeeping is kept up to date.

Corrective action:

19. All flammable liquids are properly stored and handled.

Corrective action:

20. Gas cylinders are transported, used and/or stored properly.

Corrective action:

21. Temporary lighting is installed in areas where it is needed. Lighting is in good working

condition.

Corrective action:

22. Temporary electrical systems are on ground fault systems.

Corrective action:

22a. Extension cords include ground fault protection and are in good condition.

Corrective action:

23. All cranes and/or rigging equipment are inspected daily before use.

Corrective action:

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 6 of 8 Rev 6/2002

4.0 Safety Responsibilities (Continued)

Yes No N/A Description

24. Mobile cranes are checked for stability, and outriggers properly blocked on stable

ground.

Corrective action:

25. Counterweight swing areas are barricaded to prevent access to unaware workers.

Corrective action:

26. Crane operators are cautioned to stay an adequate distance from all overhead power

lines.

Corrective action:

27. All welders are instructed in safe welding and cutting practices. Fire protection measures

are taken and fire extinguishers are available.

Corrective action:

28. Scaffolds are adequately erected. Scaffolds are equipped with ladders and base plates.

Corrective action:

29. Scaffolds or platforms are tightly planed for full width.

Corrective action:

30. All scaffolds or platforms are provided with a guard rail (2 x 4) or equivalent 42" high,

midrail (2x4) or equivalent and a toe board 4" high.

Corrective action:

31. Hanging or suspended scaffolds are checked daily. Safety harnesses and lifelines are

used by employees.

Corrective action:

N/A = Not Applicable “NO” requires Corrective Action

Contractors Monthly Safety Audit Checklist Page 7 of 8 Rev 6/2002

4.0 Safety Responsibilities (Continued)

Yes No N/A Description

32. All damaged or excessively worn equipment is tagged out or removed from service.

Corrective action:

33. Additional safety requirements implemented for this project.

Corrective action:

5.0 Additional Comments,

N/A = Not Applicable “NO” requires Corrective Action

cc:

File 0031A

Contractors Monthly Safety Audit Checklist Page 8 of 8 Rev 6/2002

You might also like

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Jsa Excavation For Water Filling PitDocument5 pagesJsa Excavation For Water Filling PitDelta akathehuskyNo ratings yet

- Site Visitor Management PlanDocument8 pagesSite Visitor Management Planhanshul sisodiyaNo ratings yet

- SWMS Piling Works RKDocument22 pagesSWMS Piling Works RKrakeshkhanna78100% (3)

- Presentation Safety InductionDocument76 pagesPresentation Safety Inductionanisaan100% (4)

- JHA Lifting-Moving Heavy ObjectsDocument6 pagesJHA Lifting-Moving Heavy ObjectsMiguel AugustoNo ratings yet

- Scaffold Plan 1Document17 pagesScaffold Plan 1Joe Waller100% (1)

- Design Calculation of Pile Cap PDFDocument8 pagesDesign Calculation of Pile Cap PDFMarvin MessiNo ratings yet

- SWP Work at Height CBTDocument52 pagesSWP Work at Height CBTRasLDK100% (1)

- Working at HeightsDocument2 pagesWorking at HeightsSusana BarriscoNo ratings yet

- 5 2 Legal RegisterDocument2 pages5 2 Legal RegisterGagan VashishthaNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- 004 Hirac Confined SpaceDocument3 pages004 Hirac Confined Spaceeunice.pacerstradings100% (1)

- Safety Checklist TrainingDocument36 pagesSafety Checklist Trainingjiks_i4u100% (2)

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- Sakhalin Energy Investment Company Ltd. Safety Consequence Management StandardDocument13 pagesSakhalin Energy Investment Company Ltd. Safety Consequence Management StandardAnilNo ratings yet

- Scaffolding Safety: Erection of Mobile ScaffoldingDocument18 pagesScaffolding Safety: Erection of Mobile Scaffoldingmuzica muzNo ratings yet

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocument26 pagesQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- TFBRK We 0871 PDFDocument202 pagesTFBRK We 0871 PDFabd alkader100% (1)

- Scaffold Towers CatalogDocument22 pagesScaffold Towers Catalogdox4printNo ratings yet

- OHSAS180012007 Health Safety Management System ManualDocument36 pagesOHSAS180012007 Health Safety Management System ManualCandra Wae Lah100% (3)

- Monthly Site Safety Audit ReportDocument3 pagesMonthly Site Safety Audit Reporttajshah283100% (1)

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- JCA Full SetDocument68 pagesJCA Full SetaymenmoatazNo ratings yet

- SOP 10 - Safe Lifting Operations PDFDocument5 pagesSOP 10 - Safe Lifting Operations PDFMohammedJunaid100% (1)

- 9.7 Ladder Inspection ChecklistDocument1 page9.7 Ladder Inspection ChecklistArshad MahmoodNo ratings yet

- Department of Health.: Occupational Health & Safety PolicyDocument10 pagesDepartment of Health.: Occupational Health & Safety PolicyMuhammad SaeedNo ratings yet

- Mobilization of CabinDocument1 pageMobilization of CabinRashidi RahmanNo ratings yet

- Job Description Safety & HealthDocument1 pageJob Description Safety & HealthNiz IsmailNo ratings yet

- 1 WAH ChecklistDocument2 pages1 WAH Checklistvirendra kumar singhNo ratings yet

- 06 - Tata Power Mobile Crane Safety ProcedureDocument27 pages06 - Tata Power Mobile Crane Safety Procedurehse bsj100% (1)

- Monthly Safety PPE Report - SEP 2019Document1 pageMonthly Safety PPE Report - SEP 2019razambaNo ratings yet

- JSA Circular Saw OperationDocument1 pageJSA Circular Saw OperationNira100% (1)

- Overhead Powerlines SafetyDocument26 pagesOverhead Powerlines SafetyVinay AgrawalNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Construction QuestionsDocument132 pagesConstruction QuestionsAdeeb MalikNo ratings yet

- Day5 Delivery WAH Management Training.Document88 pagesDay5 Delivery WAH Management Training.MarthaNo ratings yet

- JSA - Replace Grinding Wheel From Bench GrinderDocument2 pagesJSA - Replace Grinding Wheel From Bench GrinderAshok Suresh100% (1)

- Workingatheights 110623224858 Phpapp02Document21 pagesWorkingatheights 110623224858 Phpapp02naveeduddin2001No ratings yet

- Sop LiftingDocument5 pagesSop LiftingShaiful AnnuarNo ratings yet

- Safety & Health ProgramDocument2 pagesSafety & Health ProgramD.k. PathakNo ratings yet

- Completed Example of A Risk Assessment - Example 1Document3 pagesCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- Dump Truck SafetyDocument1 pageDump Truck SafetyMusharaf ShahNo ratings yet

- Goomax Aluminium FormworkDocument38 pagesGoomax Aluminium FormworkDavy GoomaxNo ratings yet

- Play It SAFE: Working AT HeightDocument20 pagesPlay It SAFE: Working AT Heightandi permanaNo ratings yet

- Equipment & Vehicles List-16 08 2012.Document32 pagesEquipment & Vehicles List-16 08 2012.razambaNo ratings yet

- Equipment & Vehicles List-16 08 2012.Document32 pagesEquipment & Vehicles List-16 08 2012.razambaNo ratings yet

- Hazard Full SlideDocument31 pagesHazard Full SlideRenKangWongNo ratings yet

- BAAN User Manual PDFDocument262 pagesBAAN User Manual PDFrazambaNo ratings yet

- Fall Protection GRP 4Document9 pagesFall Protection GRP 4Ruben SibayanNo ratings yet

- Concrete Preparation GeneralDocument14 pagesConcrete Preparation GeneralTahar Berrachedi100% (1)

- 9 Safety Inspection Report (Daily and Weekly) 02-12-14Document3 pages9 Safety Inspection Report (Daily and Weekly) 02-12-14Saboor KabierNo ratings yet

- HIRAC Work at HeightDocument7 pagesHIRAC Work at HeightMitchRappNo ratings yet

- Cis10 Standard Industri PembinaanDocument47 pagesCis10 Standard Industri PembinaanWanie Maz100% (2)

- Window Cleaning Safety GuidelineDocument4 pagesWindow Cleaning Safety Guidelinejhunvalencia1203No ratings yet

- Personal Protective Equipment Policy RT POL 009Document2 pagesPersonal Protective Equipment Policy RT POL 009billpaparounisNo ratings yet

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Behavioral Based Safety TrainingDocument2 pagesBehavioral Based Safety Trainingchinnaraj100% (1)

- Daily So Report Safety ObservationDocument1 pageDaily So Report Safety Observationem_we19No ratings yet

- Health and Safety Inspection ChecklistDocument10 pagesHealth and Safety Inspection ChecklistlilaraharjoNo ratings yet

- E-Fact 14 - Hazards and Risks Associated With Manual Handling in The WorkplaceDocument10 pagesE-Fact 14 - Hazards and Risks Associated With Manual Handling in The WorkplaceDeby Damayanti SupardiNo ratings yet

- Sharing of Industry Best Practice - Straits ConstructionDocument79 pagesSharing of Industry Best Practice - Straits Construction88sanNo ratings yet

- Luffing Tower Crane Preshift InspectionDocument1 pageLuffing Tower Crane Preshift InspectionEdmond KeraNo ratings yet

- Violations & Penalties (Aug 6, 2017)Document6 pagesViolations & Penalties (Aug 6, 2017)yagnamoid_21No ratings yet

- Safety Audit CheckListDocument7 pagesSafety Audit CheckListJamil HossainNo ratings yet

- Site Survey WorkDocument24 pagesSite Survey WorkShehzad MeharNo ratings yet

- Seminar Certificate - 098140 - 17-08-2018Document1 pageSeminar Certificate - 098140 - 17-08-2018razambaNo ratings yet

- Electrical Item Code CatalogueDocument4 pagesElectrical Item Code CataloguerazambaNo ratings yet

- Consumable InventoryDocument57 pagesConsumable InventoryrazambaNo ratings yet

- Inventory STOREDocument156 pagesInventory STORErazamba0% (1)

- Subject: List of Coring Machines As of JULY, 2017Document4 pagesSubject: List of Coring Machines As of JULY, 2017razambaNo ratings yet

- Subject: Photocopier & Plotter Machines Inventory Report As of JULY, 2017Document6 pagesSubject: Photocopier & Plotter Machines Inventory Report As of JULY, 2017razambaNo ratings yet

- Aylik Diesel AlimDocument32 pagesAylik Diesel AlimrazambaNo ratings yet

- Slno Date Item Description Unit QTY ID# Name of Borrowing RemarkDocument2 pagesSlno Date Item Description Unit QTY ID# Name of Borrowing RemarkrazambaNo ratings yet

- To/For Sub-Contractor: Sub-Contractor: Nahdat Al-Emar Material Issued Information SheetDocument5 pagesTo/For Sub-Contractor: Sub-Contractor: Nahdat Al-Emar Material Issued Information SheetrazambaNo ratings yet

- Arac. Zim - ListDocument18 pagesArac. Zim - ListrazambaNo ratings yet

- Monthly Ppe Issuing Record: Kaar Project - MakkahDocument2 pagesMonthly Ppe Issuing Record: Kaar Project - MakkahrazambaNo ratings yet

- RAWABIDocument4 pagesRAWABIrazambaNo ratings yet

- Export FinanceDocument59 pagesExport FinancerazambaNo ratings yet

- Dozer&Greuder SpareDocument4 pagesDozer&Greuder SparerazambaNo ratings yet

- Incoming Battery: Date Item Code Description Size Model MFR Unit QTY Request byDocument5 pagesIncoming Battery: Date Item Code Description Size Model MFR Unit QTY Request byrazambaNo ratings yet

- Final Project of MallikDocument77 pagesFinal Project of MallikrazambaNo ratings yet

- Spiral Wound Gaskets Main TypesDocument2 pagesSpiral Wound Gaskets Main TypeskhurramNo ratings yet

- Free CAPM Exam Questions and Answers 2022Document4 pagesFree CAPM Exam Questions and Answers 2022Dhanilo Cardoso SantosNo ratings yet

- Datasheet 175SR20S66-0863Document1 pageDatasheet 175SR20S66-0863Frank RodriguezNo ratings yet

- TR 94 40.psDocument85 pagesTR 94 40.psIshtiaqUrRehmanNo ratings yet

- WDDocument200 pagesWDArsenNo ratings yet

- Heat Affected Zone: Page 1 of 5Document5 pagesHeat Affected Zone: Page 1 of 5sujkubvsNo ratings yet

- Data Sheet Sylomer SR 28 ENDocument4 pagesData Sheet Sylomer SR 28 ENlpczyfansNo ratings yet

- Rdbms and TypesDocument19 pagesRdbms and TypesParimala SampathNo ratings yet

- A Simplified Method For The Flexural Design of Stiffened Hybrid GirdersDocument2 pagesA Simplified Method For The Flexural Design of Stiffened Hybrid GirdersalbertoxinaNo ratings yet

- Project Proposal For The Establishment of An Agro-Industrial Laboratory in Faculty of EngineeringDocument8 pagesProject Proposal For The Establishment of An Agro-Industrial Laboratory in Faculty of Engineeringmehedibinmohammad mohammadNo ratings yet

- Electric Conductivity ApparatusDocument4 pagesElectric Conductivity Apparatusapi-3759646No ratings yet

- Bringing Root Locus To Class Rooms PDFDocument8 pagesBringing Root Locus To Class Rooms PDFDivy Kumar GuptaNo ratings yet

- SONUDocument23 pagesSONUOYSTERNo ratings yet

- Week 11 AssignmentDocument7 pagesWeek 11 AssignmentP.HoneyNo ratings yet

- 2 Introducing The SGC65000F PDFDocument16 pages2 Introducing The SGC65000F PDFpalash11No ratings yet

- A B C A B C: T&B Kitchen Bedroom 3Document1 pageA B C A B C: T&B Kitchen Bedroom 3Jay IsidroNo ratings yet

- 05-28P Parkside Block J Final ReportDocument12 pages05-28P Parkside Block J Final Reportnguyen ngoc linhNo ratings yet

- Manual Distribution Transformer PDFDocument16 pagesManual Distribution Transformer PDFSudhakara Rao YanamadalaNo ratings yet

- Conceptual Design of Plem Structure Labuhan DeliDocument4 pagesConceptual Design of Plem Structure Labuhan DeliFandy SipataNo ratings yet

- BHEL (Bharat Heavy Electricals Limited) Haridwar Block 2 Heavy FabricationDocument27 pagesBHEL (Bharat Heavy Electricals Limited) Haridwar Block 2 Heavy FabricationUdit Soni100% (1)

- CCEWQ 04 ReverseOsmosisWtrTrt PDFDocument6 pagesCCEWQ 04 ReverseOsmosisWtrTrt PDFVeldaa AmiraaNo ratings yet

- HPLC Manual: Sample PreparationDocument2 pagesHPLC Manual: Sample PreparationIman IltihamNo ratings yet

- Assignment Problems: Guoming TangDocument26 pagesAssignment Problems: Guoming TangManueli Kebbles MckubwaNo ratings yet

- Autocad 2D Tutorials: Technical College of Engineering Engineering Drawing and AutocadDocument15 pagesAutocad 2D Tutorials: Technical College of Engineering Engineering Drawing and AutocadNazar AhmedNo ratings yet

- CINH 01cgDocument3 pagesCINH 01cgWindy MartdianzahNo ratings yet

- Applications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDocument5 pagesApplications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDũng LêNo ratings yet

- Unit TestingDocument4 pagesUnit Testingapi-3709875No ratings yet